How to sharpen

Chainsaw chain sharpening is not an easy process. There are three options that are used today:

- using a file;

- Angle Grinder;

- special sharpening machine.

Similar methods are used when sharpening knives, scissors and other cutting tools, so nothing extraordinary has been invented here. However, there are also special tools for sharpening the PowerSharp system. They allow you to quickly sharpen saws at home, on which there is a special mark indicating the design features.

Description of the sharpening process with files

The first thing to start with straightening the saw chain on the saw is placing the tool on a flat surface or table. In forest conditions, a large diameter chock is well suited for this. Next, you need to inspect the saw chain for any defects, it can be cracks, completely broken off teeth. After inspection, you need to set the brake in working condition, thereby blocking its movement on the tire.

The chain must be taut when sharpening with a file.

It is advisable to put a stand under the tire, as it you can use a log, a piece of a branch of a suitable diameter, or the manufacturers of sharpening tools have special clamps to hold the bar in the process of sharpening the chain.

The chain is sharpened by moving the file from the inside of the tooth to the outside. In this case, the file should be located parallel to the special mark on the chain. This mark is applied by the chain manufacturer to indicate the standard sharpening angle.

The sharpened tooth should be located approximately in the middle of the tire, this is necessary for the convenience of work, during the sharpening process, you need to move the chain along the tire, not forgetting to set the brake to the working position each time.

Work on sharpening the chain on a chainsaw must be carried out using gloves made of coarse material, otherwise it is quite easy to injure yourself, because the working surface of the teeth is very sharp.

Ideally, manufacturers advise to make the same number of file movements for each tooth, but in practice this is not always possible. teeth have different degrees of damage to the working edge.

To facilitate sharpening the saw chain with a file, special holders with corner markings can be used. The markings are made not only for the standard cross-cut, but also for the longitudinal.

Tool holders are also handy if you don’t have sufficient sharpening experience. Experienced sharpeners do not use holders for sharpening, but can only use special devices that support the file.

Another device designed for sharpening is a manual saw chain straightener. It uses a regular file as a sharpening tool, which can be replaced independently. The machine is mounted directly on the tire, it also has the ability to adjust the angle of sharpening of the tooth and a special stop that holds the sharpened tooth.

Manual sharpening machine, perfect for beginners. Along with electric models of sharpening machines, manual has its undeniable plus in the form of a low price. Depending on the manufacturer of the hand-held machine, their appearance may differ, but the principle of operation is the same for all.

The depth of cut is adjusted with a flat file, so that there is a difference between the upper cutting edge of the tooth and the height stop.

As you can see from the figure, the depth gauge is grinded in such a way as to bring the gap indicator to the factory value. Below is a table showing the main values of the angles, as well as the clearances for the most common types of chains.

As a rule, the size of the gap is adjusted using a special die. It is installed on the chain during sharpening, after which the depth gauge is grinded.

File

Using a set of files is the most common way you can do it at home. But it is not as simple as it might seem at first glance. For sharpening, you need two types of files: round and flat. Each of them has its own purpose.

With the help of a round tool, it is necessary to sharpen the working edge of the saw tooth, because its configuration is rounded. For household chainsaws, a file with a diameter of 4-5 mm is used, because the saw teeth are small. Professional saws sharpen with files with a diameter of 5.2-5.5 mm.

The cut depth gauge is sharpened with a flat file. If this edge is not adjusted, the chain will not cut into the wood to the required depth, which will reduce the cutting speed. And this will directly affect both the excessive consumption of fuel and the overheating of the saw engine.

PowerSharp System

It should be noted that this device cannot sharpen all types of chains. They have their own PowerSharp-branded chains and bars. The bar fits easily into any saw, and it has one difference from the standard. an additional hole in the front.

The sharpening system has a plastic block in which the sharpening stone is installed. That is, a bus is inserted into the block, on which the chain is previously put on. It is fixed there with a pin, which is pushed through just an additional hole in the tire. The block is closed with a lid. In the front part of the block there is a button that acts as a lever. It must be bent, thereby pressing the abrasive stone to the teeth of the chain.

After that, the saw must be resting on the ground with the key and turned on at maximum speed. A couple of seconds and the saw is sharpened.

File sharpening

For work, you need two files: round and straight. The first one is chosen along the oval in the link body. There are no diameters larger than 6 mm on household chainsaws. Usually this size does not exceed 5.5 mm. You cannot use a larger file. It will change the geometry of the cutter.

How to Sharpen a Chainsaw | Ask This Old House

There are two main technologies for manual sharpening. The simplest method is when the file is visually controlled. The craftsman observes the angles of the factory processing as much as possible and carefully, under full visual control, processes the vertical edge.

The tool partially touches the horizontal edge. Then, with a flat file, it is brought to the desired state and slightly pass along the limiter.

The second method is more accurate and productive, sharpening chains for chainsaws with your own hands with a file is done using a special holder for a round product. With such a device, sharpening a chain for a chainsaw with your own hands is easier.

It is configured so that both faces can be machined in one pass. The file moves vertically and horizontally along the cutting edge. The device significantly reduces the sharpening time, makes it better. The depth gauge can be removed with a straight file. Despite the technological difference for both methods, the general rules are:

- the chain must be fixed in a vice;

- the angle of the file relative to the tire is observed (about 30 °)

- done 2-3 movements from oneself with the same effort.

You can make a device for sharpening chainsaws with your own hands for a maximum of an hour. The photo shows an image of the factory device. Making the same at home is not difficult for an ordinary home craftsman.

Sharpening with a round file

How to quickly sharpen a chainsaw chain

Electric grinding machines

The most accurate and efficient way to repair a chain is to use specialized equipment. This is a machine for sharpening chainsaws with your own hands.

It costs a lot, but it completely eliminates the human factor, errors in manual sharpening. It is advisable to purchase it when the amount of work to be done is significant. However, there are budget models that are available to many owners of country houses, summer cottages.

It is necessary to set the angle of the chain and the abrasive wheel and the pitch of the links. Manufacturers offer several types of chain locking mechanisms. Refer to the user manual for specific model recommendations. Move the device to the edge slowly.

It is recommended not to make the passage for more than 2 seconds. If it is not possible to do the processing at once, the abrasive wheel is withdrawn and after a short period of time the tooth is again sharpened. Thus, it is possible to avoid overheating of the metal, while maintaining its performance. The product passport indicates which saw blade you need to use for the machine.

Signs of a dull chain and the consequences of further operation

The difficulty of working with a dull chainsaw should not be confused with the difficulty of sawing hardwood or heavily dry logs. In all these cases, the speed of the operation decreases, but a blunt tool has a certain behavior. signs by which one can judge the need for sharpening:

- the chainsaw does not immediately bite into the trunk of the tree, as if grinding, moving from the point of contact;

- during cutting of soft breeds, the tool sluggishly enters the thickness of the wood, you have to press on the tire;

- shavings from large with characteristic elongated particles turn into small thyrsa, which very rarely crumbles;

- the chain heats up quickly, there is an unpleasant smell of burning oil for lubricating the guide bar.

In addition to these alarms, always after hitting a chain on metal nails, wire or burying a chainsaw in the ground, you can be one hundred percent sure of the need for subsequent sharpening of cutting edges.

What can happen to the tool in the future if you ignore the problem? The most harmless thing is that it will be impossible to work with a chainsaw, in the end it will get bored and will force you to service the unit. But adherents of the saying “You don’t need to have power” can come to the following conclusion:

- an extra load on the body, because, frankly, you have to put pressure on the tool so that it saws;

- overconsumption of fuel up to 30%, which is explained by the need to go through a longer cycle of revolutions to achieve the same result;

- accelerated wear of the tire and other parts of the chainsaw.

In addition to all these negative consequences of a blunt saw, there is a high probability of the chain jamming in the trunk and injury to the operator performing the work.

Sharpening with a file

The first thing you need in order to sharpen the chain, or tweak it a little, are special files.

Electric grinding machines

For straightening a large number of chains, as a rule, in service centers or in manufacturing plants, electric sharpening machines are used. Depending on the manufacturer, the design of the machines may differ, but they have the same principle of operation.

File

For sharpening and straightening saw chains, two types of files are used. The first is a round file with a diameter corresponding to the diameter of the rounding of the working edge of the saw tooth.

For sharpening saw chains of household tools, round files with a diameter of 4, 4.8 mm are used, due to the fact that they have a small tooth. For professional models, more powerful chains with a larger tooth are used, and accordingly files with a diameter of 5.2, 5.5 mm are needed.

In order to sharpen correctly, it is not enough to sharpen only the cutting edges of the tooth; it is also necessary to adjust the cutting depth limiter. If this is not done, the chain will not cut into the material being cut to the required depth, which will noticeably reduce the speed of work and, just like in a situation with a blunt chain, can lead to overheating of the saw motor due to insufficient load on the motor. This work is done with a flat file.

Description of the sharpening process with files

The first thing to start with straightening the saw chain on the saw is placing the tool on a flat surface or table. In forest conditions, a large diameter chock is well suited for this. Next, you need to inspect the saw chain for any defects, it can be cracks, completely broken off teeth. After inspection, you need to set the brake in working condition, thereby blocking its movement on the tire.

The chain must be taut when sharpening with a file.

It is advisable to put a stand under the tire, as it you can use a log, a piece of a branch of a suitable diameter, or the manufacturers of sharpening tools have special clamps to hold the bar in the process of sharpening the chain.

The chain is sharpened by moving the file from the inside of the tooth to the outside. In this case, the file should be located parallel to the special mark on the chain. This mark is applied by the chain manufacturer to indicate the standard sharpening angle.

The sharpened tooth should be located approximately in the middle of the tire, this is necessary for the convenience of work, during the sharpening process, you need to move the chain along the tire, not forgetting to set the brake to the working position each time.

Work on sharpening the chain on a chainsaw must be carried out using gloves made of coarse material, otherwise it is quite easy to injure yourself, because the working surface of the teeth is very sharp.

Ideally, manufacturers advise to make the same number of file movements for each tooth, but in practice this is not always possible. teeth have different degrees of damage to the working edge.

To facilitate sharpening the saw chain with a file, special holders with corner markings can be used. The markings are made not only for the standard cross-cut, but also for the longitudinal.

Tool holders are also handy if you don’t have sufficient sharpening experience. Experienced sharpeners do not use holders for sharpening, but can only use special devices that support the file.

Another device designed for sharpening is a manual saw chain straightener. It uses a regular file as a sharpening tool, which can be replaced independently. The machine is mounted directly on the tire, it also has the ability to adjust the angle of sharpening of the tooth and a special stop that holds the sharpened tooth.

Manual sharpening machine, perfect for beginners. Along with electric models of sharpening machines, manual has its undeniable plus in the form of a low price. Depending on the manufacturer of the hand-held machine, their appearance may differ, but the principle of operation is the same for all.

The depth of cut is adjusted with a flat file, so that there is a difference between the upper cutting edge of the tooth and the height stop.

As you can see from the figure, the depth gauge is grinded in such a way as to bring the gap indicator to the factory value. Below is a table showing the main values of the angles, as well as the clearances for the most common types of chains.

As a rule, the size of the gap is adjusted using a special die. It is installed on the chain during sharpening, after which the depth gauge is grinded.

How to sharpen a chain on a chainsaw with your own hands

A person who has a chainsaw in his household should know how to sharpen a chainsaw chain with his own hands. There are several ways:

- Sharpening with a file (the most common method of sharpening, as it allows you to sharpen the tool directly at the cutting site.)

- Sharpening using a special machine (this method is used in service centers, but can also be used on a personal farm)

- Sharpen using an angle grinder. To sharpen in this way, certain skills are required. Uncommon method, because it is quite difficult to sharpen with an angle grinder correctly.

In this video, you can familiarize yourself with the sharpening process, the most popular methods and tools used for this.

How to sharpen a chainsaw chain with your own hands

Everyone knows that the saw chain, which is used in chainsaws, needs to be sharpened periodically, but not everyone knows how to do it correctly. Determining that the saw requires sharpening the chain is very simple, for this you need to inspect the sawdust, and if they consist of fine dust, then the tool needs to be sharpened. If sharpening is impossible, it is worth replacing it with a new one.

The use of a chain that is not sharpened can lead to overheating of the engine and the formation of scoring on the cylinder.

We will analyze the main ways with which you can, without problems, sharpen the chain on a chainsaw.

- How to sharpen a chain on a chainsaw with your own hands

- Sharpening with a file

- File

- Description of the sharpening process with files

- Electric grinding machines

- How to sharpen with an angle grinder (angle grinder)

How to sharpen with an angle grinder (angle grinder)

The method of sharpening the saw chain using an angle grinder, the least common due to its insecurity. In order to straighten the chain teeth using an angle grinder as a sharpening tool, it is necessary to install it in a vice and clamp it securely. Then the tool is switched on and the sharpened edge of the tooth is placed on the rotating surface of the disc. A tooth sharpened in this way can differ significantly from that sharpened with a file, because in the process of dressing using an angle grinder, it is rather difficult to control the sharpening angle.

How to sharpen your chain the right way on a STIHL Chainsaw

A big disadvantage can be considered the possibility of a notch with an angle grinder with an angle grinder of the eyelet for attaching the connecting link of the chain, which in the future will lead to a rupture during work. If, in the process of carrying out work using a chainsaw, the need arose for sharpening, it is better to use a special tool than to come up with various tricks that can result not only in financial losses, but cause serious injuries during their implementation.

Sharpening the chain is not as difficult as it seems at first glance. Any person, after studying the process of straightening chains, is able to sharpen the cutting set of his tool on his own. Even if the first time you manage to do it not very well, you should not despair, because with every next try, the result will be better and better.

Correct sharpening of a chain for a chainsaw with your own hands. methods, necessary tools, secrets and nuances

Any instrument needs timely care. A chainsaw is one of the types of equipment that you need to pay special attention to. The device poses a certain danger, but if the chain is dull, then the risks increase significantly.

Sharpening is often necessary during intensive work. Therefore, it makes sense to learn how to restore its performance, since sharpening a chain for a chainsaw with your own hands is not a difficult operation, but having mastered it, labor productivity will increase, as well as work safety.

Electric grinding machines

The most accurate and efficient way to repair a chain is to use specialized equipment. This is a machine for sharpening chainsaws with your own hands.

It costs a lot, but it completely eliminates the human factor, errors in manual sharpening. It is advisable to purchase it when the amount of work to be done is significant. However, there are budget models that are available to many owners of country houses, summer cottages.

It is necessary to set the angle of the chain and the abrasive wheel and the pitch of the links. Manufacturers offer several types of chain locking mechanisms. Refer to the user manual for specific model recommendations. Move the device to the edge slowly.

It is recommended not to make the passage for more than 2 seconds. If it is not possible to do the processing at once, the abrasive wheel is withdrawn and after a short period of time the tooth is again sharpened. Thus, it is possible to avoid overheating of the metal, while maintaining its performance. The product passport indicates which saw blade you need to use for the machine.

Chainsaw sharpening angles and tooth configuration

- Base. the lower part of the tooth, which has holes for connection with the rest of the chain elements and during operation hides in the guide channel of the bar. It is this part that is lubricated.

- A special stop is a design element of the tooth that allows the cutter to remove only a certain thickness of wood chips in one pass. Thanks to him, the chain does not get stuck in the fibers, and the chainsaw does not wedge.

- The so-called tooth scapula is a cutter consisting of vertical and horizontal working surfaces that form cutting edges.

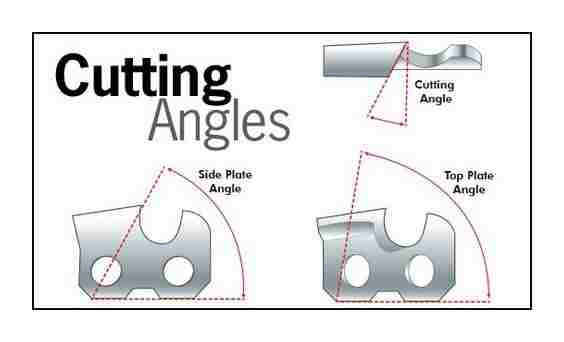

Tooth blades, or cutting edges, must be sharpened at a specific angle or it will be difficult to achieve optimal sawing characteristics of the chain. The upper blade (horizontal) has the function of plunging the tooth into the wood and forming a groove. Side or end blade (vertical) helps to trim fibers from the side.

The most important thing when sharpening a chainsaw is to achieve the correct angle of the upper blade, which should be within 60-50 degrees. The angle of the end blade is maintained within 85-60 degrees. It is also worth adhering to the angle in the plan (sharpening angle), namely, what is clearly visible when you look at the chain link from above. it departs from the side edge along the front mowing line and should be 10-15 degrees.

The productivity of the operations of sawing wood in the transverse direction increases if the angle of sharpening of the chainsaw chain is increased to the maximum possible and vice versa. Chains designed for longitudinal cutting of a tree trunk should be sharpened at an angle of approximately 10 degrees.

Under no circumstances should the depth gauge be touched again: improper grinding can lead to vibration during tool operation. Its debugging is done according to a special template.

3 ways to sharpen your chainsaw chain with your own hands

Learn how to properly sharpen your chainsaw chain at home using a file, angle grinder and machine. A detailed video of the do-it-yourself sharpening process. We will show you how to work correctly with tools and devices.

It is very convenient to work with a chainsaw. Despite the fact that the unit weighs 5-7 kilograms, or even more, cutting a tree trunk into logs, you simply wonder how quickly this happens, and there is practically no fatigue. But then the moment comes when it is harder and harder for the tool blade to enter the wood. There is only one diagnosis. the saw is dull, so it is required to sharpen the chainsaw chain.

Whoever comes across this for the first time is a little upset, because it is not clear: to do it yourself or to give the instrument to the specialists in the workshop. And what is the general sharpening method? But in fact, there is nothing wrong with that, and if you have knowledge, you can easily sharpen chainsaw chains with your own hands. The correct strategy for solving the issue in this case directly depends on the load of the unit.

If the chainsaw is used from time to time, several times a year, then it may not make sense to buy a special sharpening machine or accessories, it is easier to solve the problem by using the services of a service center. But if a chainsaw is a means of earning or there is a desire to master the sharpening process yourself, then you should definitely purchase a sharpener or a machine tool and manually carry out this simple manipulation with the chain. Let’s see below what the correct sharpening of the chainsaw chain is based on.

File

For sharpening and straightening saw chains, two types of files are used. The first is a round file with a diameter corresponding to the diameter of the rounding of the working edge of the saw tooth.

For sharpening saw chains of household tools, round files with a diameter of 4, 4.8 mm are used, due to the fact that they have a small tooth. For professional models, more powerful chains with a larger tooth are used, and accordingly files with a diameter of 5.2, 5.5 mm are needed.

In order to sharpen correctly, it is not enough to sharpen only the cutting edges of the tooth; it is also necessary to adjust the cutting depth limiter. If this is not done, the chain will not cut into the material being cut to the required depth, which will noticeably reduce the speed of work and, just like in a situation with a blunt chain, can lead to overheating of the saw motor due to insufficient load on the motor. This work is done with a flat file.

Sharpening angle grinder

Professionals consider this work to be primitive. There is a risk of tire damage, and not only.

Process (seemingly easy, but really difficult)

- The chain also stays on the bus;

- We attach a metal cutting disc with a thickness of 1.5-2 mm to an angle grinder. It is advisable to take not a new one, that is, with a worn edge;

- We put an obstacle in front of the chain and the tire (the chip will come off);

- We carry out sharpening at the desired angle;

- Upon completion of work, the chain must be properly tightened.

With a professional approach and a “full hand”, the number of sharpenings in this case can be more than 7.

“For a beginner, it is better not to“ experiment ”with a saw, a chain, etc. with your body parts! “

Advantages of the method: Fast, cheap and does not take up energy;

Disadvantages: Requires special skills, a steady hand and the ability to comply with safety techniques.

Topics. some expert advice:

- Before starting work. run in the chain. To do this, run the chain at a low speed for ≈ 1 minute. During this period, the lubricant will fall on every necessary part, and the chain and the sprocket will warm up and “rub” together. If necessary, adjust the tension (after the chain has cooled down);

“Announcement in the newspaper: I am changing the chainsaw for a prosthesis”.

I hope the information was moderately useful. If yes, then subscribe to the blog for updates and share the article with your friends. All the best to you. Good luck!

Quote of wisdom: It’s not about the word, but the tone in which the word is pronounced (Belinsky).