Cultivator KPS-4: technical characteristics and device

Continuous cultivation should be used for the complete destruction of various weeds and loosening of the soil without additional wrapping in preparation for sowing and care of fallows. The loosening procedure promotes the retention and accumulation of moisture and a variety of nutrients. Cultivators used for continuous soil cultivation are divided into the following types: steam, garden, forest and anti-erosion. This article will consider one of the many types of cultivators and describe in detail its structure and principle of operation.

Diagram and device of the cultivator KPS-4

Below we provide a diagram of the KPS-4 cultivator

The steam high-speed cultivator KPS-4 is used for multilayer loosening of the soil before the start of sowing work and the destruction of various types of weeds, while harrowing occurs at a speed of up to 12 km / h. This model is available in two versions, trailed and mounted, additionally there is a device for attaching additional harrows. The working bodies of the cultivator are universal lancet paws, they have a working width of 27 cm or 33 cm, the second element is loosening shares based on a rigid stand, the working width is from 35 to 65 mm, the last element is spring loosening shares with a working width of 5 cm.

The tines of the paws are mounted on special beetles, which are hinged to the cultivator frame. Universal lancet paws are located in two rows of a checkerboard pattern. 27 cm wide paws are attached in the front row of the bed, and in the secondary row 33 cm wide paws on a long bed.

If it is necessary to till the soil up to 25 cm deep, it is necessary to use loosening paws, and for loosening the soil up to 16 cm deep and “combing out” root-sprouting weeds. spring loosening paws. On short beads, one loosening paw is fixed, and on long ones with the help of double 1 holders, two paws each.

With the T-150 and T-150K tractors, two or three cultivators with the SP-11 hitch or the central section of the SP-16 hitch are aggregated, and with the K-701. four with the SP-16 hitch. Cultivators in row units are connected to each other by hinges, which creates a stable course and good copying of the relief in the vertical-transverse plane.

When preparing the unit for operation, the tractor’s hitch mechanism is set to the uppermost position, and the towing bracket is set to the rear yoke forks. A harness is put on it.

To work with three or four cultivators, it is necessary to unfold the side wings of the SP-16 special hitch and mark the joints on the cultivator bar. The nominal distance between the two points of the cultivator’s trailer is 4 m. The cultivators must be positioned so that their trailers are located on the same mowing line, and the distance between the ends of the front beams of their frames is 80 100 mm. The bars of the cultivator frames are connected to each other by hinges.

Cultivator trailers are connected to the hitch, remote hydraulic cylinders are installed on the cultivators and connected to the tractor hydraulic system.

Technical characteristics of the cultivator

Below is a table with the technical characteristics of KPS-4 cultivators of various modifications

Preparing the KPS-4 cultivator for work

Appointment. The KPS-4 cultivator is designed for continuous processing of vapors, pre-sowing loosening and pruning of weeds with simultaneous harrowing.

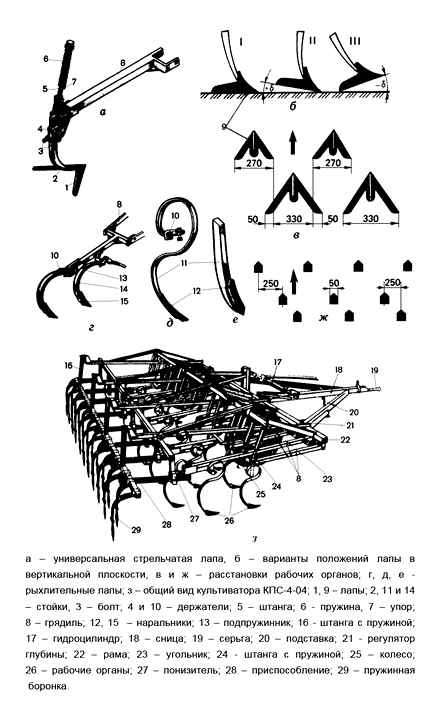

Cultivator working bodies. universal duckfoot and loosening shares The universal duckfoot share (Fig. 1, a) is attached to a rigid rack 2. The angle of inclination of the blade to the horizontal plane is 23 30 °, the angle between the blades (angle of the paw opening) is 60 65 °, width capture 270 and 330 mm. The versatile tines loosen the soil well and cut the weeds. They are used to cultivate the soil to a depth of 12 cm.

In the chisel-shaped shanks of the loosening paws (Fig. 1, d, e, f) there are two cutting edges with an opening angle of 60 70 °. The anklets are fixed on spring or rigid struts. Double-sided shaft fittings turn 180 ° after one end is worn out.

Plowshares with spring struts (Fig. 1, d and e) with a working width of 20 50 mm are used for loosening the soil to a depth of 16 cm, combing out root weeds, and cultivating high moisture soil. During operation, they vibrate and self-clean from plant residues hanging on the stands. Paws with arcuate stands (Fig. 1, d) are used on all soils, except for those clogged with stones. Paws with S-shaped stands (Fig. 1, e) are used on stony soils. Paws with a rigid stand (Fig. 1, e) and a working width of 35 65 mm are used for soil cultivation to a depth of 25 cm in gardens, vineyards and under cotton.

The general device of the cultivator (Fig. 1, h): welded frame 22, cot 18, support wheels 25 with a screw mechanism 21 for adjusting the depth of travel of the working bodies, 8 with feet 26, device 28 for mounting harrows 29 and hydraulic cylinder 17.

Racks of paws are attached to beads 8, pivotally attached to the frame beam. Pointed paws are staggered in two rows (Fig. 1, c).

Подготовка культиватора КПС. 4 к работе

For processing weakly clogged fields in the front row on short beads, paws are fixed with a working width of 270 mm, and in the back row on long beads. paws with a working width of 330 mm. The ends of the cutting edges of the hind paws on each side should overlap the edges of the front paws by 40 50 mm to ensure complete cutting of weed roots.

When processing heavily weedy fields on short and long ridges, the paws are installed with a grip of 330 mm. The blades of the paws must be sharp at least 1 mm. Dull blades are re-sharpened to ensure complete weed cutting.

Loosening paws are placed in three transverse rows (Fig. 1, g). On short beads, they are fixed with one paw, and on long ones with the help of double holders, two each. The distance between adjacent grooves is 167 mm. The depth of processing is changed by the screws of the regulator 21, moving (in height) the support wheels relative to the frame.

The rack of the duckfoot paw is attached to the beams 8 (Fig. 1, a) with bolts and a holder 4. Rotating the bolt 3, the rack inserted into the holder is moved and thus the angle of inclination of the paw is changed. On light soils with shallow processing, the racks are installed so that the cutting edges of the paws are adjacent to the surface of a flat area (Fig. 1, b, I). On heavy soils and shallow cultivation, the toes of the paws should be tilted forward by 2… 3 °. A paw, strongly inclined forward (Fig. 1, b, II), will unload the soil, inclined backward (Fig. 1, b, III). it is difficult to deepen.

Preparing the cultivator for work. The arrangement of the working bodies, their adjustment and installation, respectively, of a given processing depth is carried out on a flat surface. The cultivator is transferred to the working position and bars are placed under its wheels, the thickness of which is 2 4 cm less than the required processing depth (taking into account the immersion of the wheels). By rotating the screw of the regulator 21 (Fig. 1, h), the frame with the feet is lowered until they touch the surface of the platform. In this case, the frame should be horizontal, and the heads of the push rods 24 should rest on the square 23. If the heads protrude above the square or the paws do not touch the support platform, loosen the bolts 3 (Fig. 1, a) and the legs of the paws are moved in the holder 4 down or up On clogged areas and on hard soils where there is no full penetration, the compression of the springs 6 is increased by repositioning the stop 7. After the adjustment is completed, the compression force of the springs on all rods should be the same. The compression of the springs on the rods of the paws, moving after the tractor wheels, increases the.

Preparing the KPS-4 cultivator for work

Appointment. The KPS-4 cultivator is designed for continuous processing of vapors, pre-sowing loosening and pruning of weeds with simultaneous harrowing.

Cultivator working bodies. universal duckfoot and loosening shares The universal duckfoot share (Fig. 1, a) is attached to a rigid rack 2. The angle of inclination of the blade to the horizontal plane is 23 30 °, the angle between the blades (angle of the paw opening) is 60 65 °, width capture 270 and 330 mm. The versatile tines loosen the soil well and cut the weeds. They are used to cultivate the soil to a depth of 12 cm.

In the chisel-shaped shanks of the loosening paws (Fig. 1, d, e, f) there are two cutting edges with an opening angle of 60 70 °. The anklets are fixed on spring or rigid struts. Double-sided shaft fittings turn 180 ° after one end is worn out.

Plowshares with spring struts (Fig. 1, d and e) with a working width of 20 50 mm are used for loosening the soil to a depth of 16 cm, combing out root weeds, and cultivating high moisture soil. During operation, they vibrate and self-clean from plant residues hanging on the stands. Paws with arcuate stands (Fig. 1, d) are used on all soils, except for those clogged with stones. Paws with S-shaped stands (Fig. 1, e) are used on stony soils. Paws with a rigid stand (Fig. 1, e) and a working width of 35 65 mm are used for soil cultivation to a depth of 25 cm in gardens, vineyards and under cotton.

The general device of the cultivator (Fig. 1, h): welded frame 22, cot 18, support wheels 25 with a screw mechanism 21 for adjusting the depth of travel of the working bodies, 8 with paws 26, a device 28 for mounting harrows 29 and a hydraulic cylinder 17.

Культиватор КПС.4,5 м в работе /Cultivator of KPS. 4 with spring harrows in-process

Racks of paws are attached to beads 8, pivotally attached to the frame beam. Pointed paws are staggered in two rows (Fig. 1, c).

For the processing of weakly clogged fields in the front row, on short beads, paws with a working width of 270 mm are fixed, and in the back row, on long beads, paws with a working width of 330 mm are fixed. The ends of the cutting edges of the hind paws on each side should overlap the edges of the front paws by 40 50 mm to ensure complete cutting of weed roots.

When processing heavily weedy fields on short and long ridges, the paws are installed with a grip of 330 mm. The blades of the paws must be sharp. Dull blades are re-sharpened for complete weed trimming.

Loosening paws are placed in three transverse rows (Fig. 1, g). On short beads, they are fixed with one paw, and on long ones with the help of double holders. two each. The distance between adjacent grooves is 167 mm. The depth of processing is changed by the screws of the regulator 21, moving (in height) the support wheels relative to the frame.

The rack of the duckfoot paw is attached to the beams 8 (Fig. 1, a) with bolts and a holder 4. Rotating the bolt 3, the rack inserted into the holder is moved and thus the angle of inclination of the paw is changed. On light soils with shallow processing, the racks are installed so that the cutting edges of the paws are adjacent to the surface of a flat area (Fig. 1, b, I). On heavy soils and shallow cultivation, the toes of the paws should be tilted forward by 2… 3 °. A paw, strongly inclined forward (Fig. 1, b, II), will unload the soil, inclined backward (Fig. 1, b, III). it is difficult to deepen.

Preparing the cultivator for work. The arrangement of the working bodies, their adjustment and installation, respectively, of a given processing depth is carried out on a flat surface. The cultivator is transferred to the working position and bars are placed under its wheels, the thickness of which is 2 4 cm less than the required processing depth (taking into account the immersion of the wheels). By rotating the screw of the regulator 21 (Fig. 1, h), the frame with the feet is lowered until they touch the surface of the platform. In this case, the frame should be horizontal, and the heads of the push rods 24 should rest on the square 23. If the heads protrude above the square or the paws do not touch the support platform, loosen the bolts 3 (Fig. 1, a) and the legs of the paws are moved in the holder 4 down or up On clogged areas and on hard soils, the compression of the springs 6 is increased by repositioning the stop 7. At the end of the adjustment, the compression force of the springs on all rods should be the same. The compression of the springs on the rods of the paws, moving after the tractor wheels, increases the.

Adjustment of the KPS-4 cultivator

Construction and adjustment of cultivators for continuous soil cultivation

Purpose of work: to get acquainted with the device and the principle of operation of the cultivators KPS-4, KSHU-12, KSHP-8, ChKU-4, KSM-5.

Using the methodological instructions and equipment of the laboratory installation, to study the device and principle of operation of cultivators for continuous processing.

Learn the basic adjustments of cultivators for continuous tillage.

Examine the preparation of cultivators for work.

Examine possible malfunctions of KPS-4 cultivators.

Draw up a progress report.

Cultivator KPS-4, keys 6×10; 10×12; 14×17; 17×19; ruler.

According to their purpose, cultivators are divided into not three groups: for continuous tillage and inter-row tillage and for special purposes. Steam cultivators are used to destroy weeds and loosen the soil in preparation for sowing, as well as in the care of the fallows.

Row cultivators are used to process row crops. With their help, in addition to the destruction of weeds by pruning, combing out and sprinkling with earth, they feed the plants and loosen the row spacing.

Special cultivators are garden, forest and anti-erosion cultivators. During work, cultivators must destroy 98–99% of weeds and loosen the soil without bringing wet layers to the surface.

The device and principle of operation of cultivators for continuous cultivation

Cultivator device KPS-4

Purpose and technical characteristics

The KPS-4 cultivator is designed for continuous processing of vapors, pre-sowing loosening and pruning of weeds with simultaneous harrowing at a speed of up to 12 km s 2.50. 3.34

It is aggregated with tractors MTZ-80/82; T-40S

The cultivator is equipped with a device for mounting four medium tine harrows or one spring.

The cultivator consists of a welded frame 4, a suture assembled from three beams I, II and 12, support pneumatic wheels 3 with screw mechanisms for adjusting the position of the wheels in height 2, beams 5, 9 with paws b, devices for mounting harrows 8 with a leash 7 and hydraulic cylinder 10 for transferring organs to working and transport position.

The frame is welded rectangular. Attached to it are walkways, running wheels and side bars of the snail.

Pneumatic running wheels are mounted on the half-axles of the brackets, the outer ends of which are connected to the side beams of the bottom by screw mechanisms for adjusting the depth of travel of the working bodies.

Hydraulic cylinder 10, mounted on bracket 16 and pivotally connected to the central bar of the bottom, serves to transfer the trailed cultivator to the transport position.

Walking 5 on the cultivator are installed in two designs: short and long. On the short beads, one lancet share is mounted, and on the long ones, with the help of double holders, two loosening arms are fixed. The paw rack 7 is attached to the beam with a bolt 6, a holder 8 and a bar 9. The paw rack is held in a predetermined position by an adjusting bolt 12. The cultivator is equipped with lancet universal paws with a working width of 270 and 330 m, 8 and 16 pieces, respectively. On heavily clogged fields on long ridges, paws b with a working width of 270 mm are installed.

The harrow hitch is a structure assembled from four rods with rods, leads and four guy wires. Tooth harrows are attached to the device by means of hooks and loops of leashes 30. Braces 28 are used to fasten the braces or chains 29 to the ends of the rods. Stretch marks; or the chains are locked to the harrow links. When transporting over a longer distance, the harrow links must be laid on the beams of the cultivator frame, without disconnecting them from the leashes, and each link must be securely fastened to the frame.

The mounted cultivator KPS-4-03 has an auto-hitch lock instead of a snapper, which is mounted on the frame using brackets and bolts.

Varieties of cultivators

Cultivators KSHU-6 and KSHU-12 refer to sectional wide-cut machines. By design, they are similar to the KPS-4 cultivator.

The KSHU-12 cultivator consists of a central 13, two middle II and 14 and two extreme 10 and 15 sections, hingedly connected to each other. In the working position, the sections are located in one plane. The central section rests on paired wheels 12, and the outer sections. on wheels 5. To transport the cultivator over long distances, the extreme and middle sections are rotated relative to the central one by hydraulic cylinders I to 4 and positioned vertically. On the sections, universal paws 8 with a capture width of 330 mm or loosening paws on elastic suspensions, a spring harrow 9 or a bar roller are installed in three rows. The depth of travel of all paws is changed by rotating the adjuster screw 6, individual paws. by rearranging the stand in the holders. Coverage of the cultivator KSHU-12. 12 m, KSHU-6. 6 m.

Cultivators KSHP-8 and KPZ. 9.7 are used for pre-sowing soil cultivation with loosening to a depth of 6 12 cm and leveling the surface, as well as for processing vapors. Sectional folding machines are equipped with 22 loosening arms on S-shaped racks arranged in four rows, a leveling bar 16, 23 bar rollers or 9 oak harrows. On wet and heavy soils, tine harrows are used, on light soils. rollers.

The KShP-8 cultivator is aggregated with the MTZ-80 and T-150K tractors. Its capture width is 8 m, operating speed 7 12 km / h. Width of capture of the bullpen. 9.7. 9.7 m, capacity 8.7 gach, capacity 2.8 gach, working speed up to 6 km / h.

Adjustment of the KPS-4 cultivator

In the process of preparing for work, they check the health of the cultivator, arrange its working bodies and install them at a given depth of travel, prepare the tractor and connect it to the cultivator.

Date added: 2019-07-15; views: 988; We will help in writing your work!

Basic cultivator adjustments

One of the characteristic features of this kind of equipment is the possibility of its adjustment, which can be useful when sowing various crops. The main parameter that can be adjusted is the working depth. It directly depends on the support wheels. when they rise, it increases, and when they descend, it decreases.

You can also adjust the required parameters by preloading the spring on the bar. When it is compressed, the depth increases significantly. The paws must overlap the edges of the front working bodies by 7 cm, otherwise the product will not be able to effectively cut weeds.

The principle of operation of the cultivator “KPS-4

After driving into the treated area, the operator lowers the cultivator paws to the working position with the help of the hydraulic system. Since the tines are positioned at a certain crumbling angle, as well as under the influence of the massive weight and speed of the machine, they enter the soil to the required depth. At the same time, the blades of the paws cut and crumble the stems and roots of weeds.

The soil from the upper soil layer rises up the paws and, falling from them, crumbles into small lumps, which are evenly distributed over the surface of the field, leveling it. To enhance this effect of breaking the soil into small clods and leveling the surface, the KPS-4 cultivator is equipped with tooth harrows.

“KPS-4” of the “Gomselmash” plant, with tooth harrows.

Several trailed cultivators can be combined by means of couplings into large wide-cut units for working with tractors of 3-5 drawbar classes. And the mounted version of the KPS-4 cultivator was developed specifically for the processing of particularly heavy and stony soils. This modification is equipped with reinforced feet with spring safety locks.

Cultivator for continuous tillage KPS-4 N (MTZ-80, MTZ-82). from the manufacturer

Master of uniform tillage and preparation for sowing

The “KPS-4” cultivator is a trailed agricultural unit that performs work on continuous surface cultivation of soils of various types and compositions; for the preparation of soil for sowing cereals and other cultivated plants. This is one of the most common models of this type of tillage implements. “KPS-4” (decoding: High-speed Steam Cultivator, with a capture width of 4 meters) is designed to work as a trailed unit for tractors 1.4 of the traction class: “MTZ-80/82 Belarus” and the like. It is also produced not only as a trailed, but also in a mounted version.

Technical characteristics of KPS-4

The main reason for the popularity of this device seems to be not only the affordable cost of the product, but also the excellent performance characteristics that allow you to easily process large areas of land. Among the most significant among them, it is advisable to include:

- dimensions (LxWxH). 4.98×4.09×0.95m;

- working speed. 9-12 km / h;

- transport speed. 15 km / h;

- unit capacity. 4.8 ha / h;

- processing width. 4m;

- weight. 690kg;

- number of working bodies. 16.

The ground clearance of the product, which is 30 cm, allows you to easily overcome small obstacles in the process of moving to the work site, which greatly simplifies the use of the device. Repair of the device is simple, does not involve significant financial costs.

Description, photo

It should be noted that, provided that the device is operated with additional equipment, it can be used for inter-row cultivation of fields after the necessary adjustments of the KPS 4 cultivator have been made. This is extremely useful in cases where it is necessary to remove weeds and prepare the soil without harming already existing plants.

The product is capable of processing land 5-12 cm deep, which guarantees high efficiency of manipulation. In the process of work, it loosens the top layer of the earth to the state of small clods, quickly destroys the roots and shoots of weeds, and also contributes to the general leveling of the field surface.

The use of this kind of equipment allows you to achieve the following advantages:

- reduce the amount of weeds;

- improve the permeability of soil to air and water;

- create optimal conditions for plant germination.

The unit significantly increases the germination of crops and, accordingly, the volume, quality of the crop, which made it incredibly popular.

In terms of its efficiency, it significantly surpasses manual methods of processing, does not require high-power models of tractor equipment for use.

Reviews of the owners of “KPS-4” and the cost of cultivators of this brand

Cultivators “KPS-4” are produced and sold today by a number of enterprises for the production of agricultural machinery in the vastness of the former Soviet Union. For example, LLC “AgroSpetsTechnika” (city of Ufa); LLC “M-Agro” (city of Belgorod); LLC “LesAgroMash” (Kirov city). for the new KPS-4 cultivator start at 114,000 rubles. As for used equipment of this brand, in most regions you can pick up a used cultivator “KPS-4” at a price of 25,000 rubles and more, depending on the year of manufacture and technical condition.

Compliance of “KPS-4” with agrotechnical requirements

Presowing soil cultivation is carried out to the depth of seeding. If the work is carried out on a cultivated field, not littered, with a sufficient degree of cultivation, this depth is quite enough. It is undesirable to exceed the depth of soil cultivation. Since the working bodies of the cultivator should not throw the lower, wet layer of soil onto the surface of the earth.

But in those cases when it is necessary to cultivate highly compacted land, clogged with the remnants of foreign vegetation, the depth of soil cultivation increases. rippers with spring tines are used. In full compliance with agrotechnical requirements, the “KPS-4” cultivator provides an even cultivation of the surface layer of the soil, with an uneven cultivation depth not exceeding one centimeter. After work, the upper layers of the soil acquire a fine-lumpy structure, all weeds and their roots in the cultivator‘s area of operation are completely cut and crushed.

After cultivation, the bottom of the furrows of the field turns out to be even, with the height of the ridges of the loosened layer not exceeding 3-4 centimeters. Therefore, cultivation is often carried out with simultaneous harrowing.

The actual parameters of the quality of pre-sowing cultivation can be determined, first of all, by a normal visual inspection. After a tractor with a “KPS-4” cultivator has passed the field, the soil surface should become uniform, especially in places where there were fall ridges and split furrows.

It is also important to take into account the timeliness of the land cultivation carried out, which is assessed by comparing the actual period of work with the period established in the agrotechnical plan (adjusted for current weather conditions). Other indicators of the quality of pre-sowing cultivation are also the depth of cultivation, ridging, completeness of cutting weeds, the absence of blemishes.

The working depth is determined in 10-15 places along the diagonal of the plot, along the entire width of the cultivator, by measuring the cultivation depth with a ruler with divisions. The ruler is inserted into the treated layer up to the sole. The ridge index can be measured with a profiler, also in 10-15 places along the diagonal of the area processed by the cultivator.