Gas cutting equipment

So, in Russia, since the times of the USSR, the P1-01 cutter was considered the most common. It is manual with an injection nozzle, which gives a high pressure jet, which cuts metal “like a hot knife of oil.”.

More powerful models are P2-01 and P3-01P. Their main difference is the size of the nozzle, the operating pressure of oxygen in the system, and the operating pressure of the heating mixture supply..

There are also stand-alone tables – these are gas equipment for cutting metal in automatic mode, which is produced without the participation of an operator..

The control of such a table is numerical-programmed. That is, a person simply sets the cutting parameters..

Such oxygen cutting equipment is used exclusively on sheet metal, where either straight cutting or arc cutting is performed..

It is worth noting that there are a huge number of models of these tables, but almost all of them are analogues of the AN-01, which was developed by Shepelev back in the USSR.!

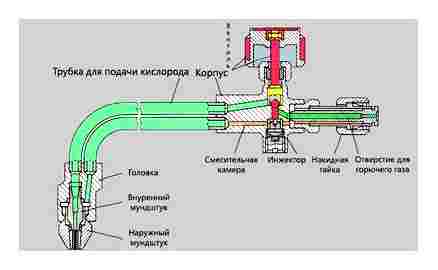

Oxygen cutter schematic

These, for example, are “Change”, “Orbit”, “Secator”, “Quicky-E”. All of them have an operating temperature in the range of 1000-3200 degrees Celsius. Works with both acetylene and propane heaters.

The Quicky models also use mixed-acetylene-propane heating. In this case, only a split nozzle is used. That is, acetylene is supplied to one of them, propane is supplied to the second..

By the way, it is worth noting that in such cutting, the heating mixture lends itself from the center (that is, from the oxygen jet).

Also, the so-called stationary torches for gas cutting of metal are also noted..

They differ from the mobile one, it is not difficult to guess, in that they are built into a special niche-machine, which can be moved by the operator of the device..

These cutters are more convenient to work with, but are very expensive. But their cutting power is more than enough to cut a thick layer of high-strength metal!

This became possible due to the fact that in such cutters an additional blower is used, with the help of which both the heater and the oxygen stream are supplied under even greater pressure..

An additional compressor is powered by electricity, moreover – three-phase (380 volts). Because of this, it cannot be mobile! This cutter is used exclusively in professional enterprises..

Portable cutter – Gugark

Gugark is the most popular representative of such cutters..

By the way, a gas torch for cutting metal also comes in two types – the so-called straight and bent:

- The first is the one you are all used to seeing. Represents the letter G and works with the help of the operator direction.

- Well, the second, direct, is a nozzle-type burner, which is used on cutting tables.

It is also worth noting that straight nozzles use twin tips to ensure that the nozzle angle is not disturbed one-to-one when moving..

By the way, keep in mind that each of the cutters has its own coefficient of work and power with each metal..

For example, when using the standard P1-01, to cut copper, a coefficient of 0.5 acetylene is sufficient, but for aluminum, as much as 0.7 is required.

Most of all, of course, will go to tungsten – as much as 1.4! In this case, the heating will be in the region of 3800 degrees Celsius (use only specialized tips)!

Gas cutting technology

The modern technology of gas cutting of metal is somewhat different from the one described above. For example, to work with “light metals” temperatures of 1000 degrees Celsius and above can simply destroy the metal you are working with (melt and vaporize).

In these cases, the cutting itself is performed with simultaneous heating. Torch tip is pyramid shaped with 3 nozzles.

A heating mixture is supplied through two side ones, and a thin nozzle is mounted in the center for supplying oxygen under high pressure.

Oxy-fuel cutting technology

In modern cutters, oxygen is supplied under a pressure of 12 atmospheres! Simply put – even the skin can be damaged under a stream of air (meaning an unlit stream).

The flux that is formed during such cutting is either thrown out by the heating flame to the sides, or is burned directly through the entire metal (if through cutting is performed).

Don’t forget that gas cutting metal has a big advantage over electric cutting. What?

No “torn” seam is created. And if you additionally use overlays (stencils, as professional welders call them), then the cutting seam turns out to be very neat!

But keep in mind that cutting metal with oxygen does not involve using metals that melt below 600 degrees Celsius. In this case, a simple removal of the top layer of metal will be performed, rather than cutting it..

In such cases, it is recommended to use the so-called mobile heaters – ordinary cans with compressed gas and a nozzle at the end of the tube..

Standard oxyfuel cutting technology uses a pilot controlled torch. The gas supply is regulated by means of two valves (in some models – one common).

The handle of the cutter itself has two tubes, which are just built into the handle. The first handle supplies fuel for the heater, the second (usually the central one) supplies oxygen. That is, as many as 3 tubes are supplied to the main nozzle!

Through two, propane is supplied, through the third, oxygen. Older cutter models used two tips that worked in a similar way.

What is the gas consumption when cutting metal? It depends on the temperature to which the metal itself is heated during operation.

In a standard R1-01 cutter, an average of 10 cubic meters of oxygen and 0.7 cubic meters of acetylene are consumed in one hour of operation (when using propane, 1 cubic meter of fuel).

But in the P2-01 cutter the consumption is much higher – 21 m3 of oxygen and 1.2 – of acetylene! The heater consumption depends on the heating temperature and the plane that is cut.

The “older” cutters also use the so-called nozzle direction, which also partially affects the flow rate (the closer to the oxygen stream, the larger the jet has to be supplied).

Gas (oxygen) metal cutting

So [flame cutting] is the most popular right now. Why?

Because it is extremely simple to perform, you do not need to use any phase inverters (as in an electric cutter), you do not have to comply with the mandatory room standards (presence of a central grounding cable).

And almost all torches are mobile, that is, they can be transported by regular transport.

When cutting, a gas torch uses two gases – directly oxygen, with the help of which the metal separation process is carried out, as well as a heater, which is most often propane or acetylene..

The heater heats the surface to be cut to a temperature of 1000-1200 degrees, after which a stream of oxygen is supplied. On contact with a heated surface, the jet ignites.

Photo of gas cutting

It turns out – a burning jet that easily cuts the metal. At the same time, the most important thing is to observe a continuous supply of oxygen..

If there is an interruption, the flame can simply go out, after which the surface will have to be heated again..

Standard oxygen cutting of metal is performed using the R1-01P torch. It is best suited for working with hardened steel, including cast iron!

This torch is not used as a welding machine.

But it is suitable for precise cutting of the pipe – for this, a special articulated pad RF7 is used, which is made of steel, but covered with a layer of tungsten.

By the way, lately [gas welding] and metal cutting is carried out by combining acetylene and propane. But such equipment is used exclusively for working with high-strength metals (for example, steel for copulating knives).

The equipment that supports this gas is not cheap! So we won’t talk about him especially …

Services popular on the market

If you need to cut metal, then the easiest way is to hire a craftsman or specialist who will provide you with the necessary services. After all, not every house in the garage has a cutter with two oxygen cylinders and a heater..

Moreover, it is very dangerous to work with such equipment without experience! If you do not know how, then it is better not to take up this business – entrust the work to professionals!

Well, on average, the price of gas cutting of metal consists of the following indicators: the metal that will need to be worked with, the cutter used, the thickness of the metal, the quality and type of cut.

For example, conventional sheet cutting is the cheapest. Pipe cutting – it is much more expensive, since additional linings are used during such work!

But cutting in depth is an expensive pleasure, since it uses expensive equipment..

Moreover, if such work is performed “on the road”, it will be very expensive. Cars that can transport cutting stations need to be additionally refitted.

Oxygen cutting of metal –

Well, gas cutting of sheet metal can be performed even with an ordinary gas soldering iron. If you are using aluminum or copper, then it should be enough for this job..

In some cases, you can use gas welding. But instead of carbon dioxide, propane, acetylene or butylene is supplied (not every gas welding supports the use of such gas, be careful)!

The most expensive sheet metal cutting is the one that is performed along the prepared cutting contour. In this case, a CNC machine is used, the services of which are not paid cheaply!

By the way, if you need to do not cutting, but cutting, then in some cases it will be much easier and cheaper to use a knife for cutting metal, and not a gas cutter. In more detail about this, you can find out directly from the master, whom you would like to entrust the performance of the work..

Now many enterprises offer on-site gas cutting of metal.

Here it is, assessed by the following parameters:

- the metal with which you will need to work;

- the complexity of the work;

- used cutter.

By the way, it is recommended to buy gas cylinders yourself! Many companies sell it at too high a cost (about 1000 rubles for a cylinder of acetylene, although its market value).

It also takes into account how long the work will take. On average, an hour of work of the master is paid at about 300 rubles. Here you can calculate in advance how much metal cutting services will cost you!

And finally, we should talk about those cases when poor-quality work is performed. Very often, many people use instead of acetylene – its cheap analogue is propane or propylene. Or they use cheaper cutters than they themselves announced.

For example, instead of P2-01, P1-01 or the like is used. This, by the way, is the most common problem! You can distinguish these two cutters from each other by visual inspection..

The P1-01 model has a double nozzle with a gold mount (golden color), while the P2-01 model has a steel mount (it has a black or copper tint).

By the way, the P1-01 cutter is not so expensive, so you can even get it! Average per piece. Well, of course, you will need to purchase two cylinders – with oxygen and a heater, and a transport cart.

On average, the whole set will cost you 3000 rubles, not more. It will be enough for 3 hours of metal cutting. More than enough for home needs.

And when working with a gas torch, be sure to follow the safety rules! And this is the use of a protective mask, overalls and gloves. Gloves are a must!

Oxygen pressure when cutting metal

The cutter functions normally if the oxygen pressure when cutting metal is 3-12 atmospheres (depending on the thickness of the workpiece and the diameter of the nozzle). The higher the pressure for a specific size, the more oxygen hits the metal surface, it oxidizes better (but up to a certain limit). If the pressure for a particular work piece and equipment is higher than normal, oxygen flows through the cut uselessly..

The second negative point is an increase in the width of the cut and an overexpenditure of oxygen. The material is wasted. Therefore, the pressure is calculated separately for each nozzle and workpiece. The level is controlled by the readings of the pressure gauge, but they are inaccurate, since the pressure decreases as it passes through the hose and mouthpieces.

When cutting metal, the oxygen reducer is adjusted using a screw. To increase the pressure, turn it clockwise, to lower it – vice versa..

Important! You also need to know what is the pressure on the combustible gas reducers when cutting metal. They are classified according to the maximum pressure (when cutting 15-30 atmospheres).

The pressure is set before starting work, the role of the reducer is to maintain the level.

Gas cutting of metal – instructions for metal processing

Gas cutting is the most popular because it does not require compliance with the norms for the room and is easy to do. The seam is not torn and neat if stencils are used. All torches are compact and mobile and easy to transport. Many gases can be used. This method allows you to work with thick workpieces and perform complex operations. No power supply required, the mode can be manual or automatic.

- Technology features

- Metal cutting instruction

- Oxygen pressure when cutting metal

- Metal cutting allowances

- Safety precautions for gas cutting of metal

Metal cutting instruction

It is important to correctly connect and prepare the torch. Tubes with closures at the ends are connected to the cylinders. Next, the gas supply is checked (if it is oxygen-propane metal cutting) – the valve closes, the valve on the cylinder opens. Then, observing the pressure gauge, the valve is slowly opened. The pressure should be 0.35-0.55 atmospheres. Then you need to blow through the hose – open the valve. Gas starts to come out with a characteristic sound. If the pressure gauge shows a stable pressure, the valve closes.

The next step is to check the oxygen supply and adjust the pressure. First, the valve on the cylinder opens, then the regulator (flow pressure 1.7-2.7 atmospheres). The oxygen valves on the torch are opened to purge the hose. There are two of them: for feeding into the nozzle and forming a mixture. First you need to open the first, then the second (for 3-5 seconds).

Attention! Before igniting the valve, make sure that there are no leaks in the connections, children are not playing or animals are walking around.

Acetylene torch basics

The gas supply valve is opened first to release oxygen, which remains in the mixer after checking. The valve must be turned until you can hear the gas coming out. The lighter in front of the torch should be in contact with the mouthpiece. After pressing the lever, sparks ignite the gas.

Open the oxygen valve immediately. Its sufficient volume is indicated by a change in the color of the flame to blue. More oxygen needs to be supplied for the torch to grow in size. The pressure of gas and oxygen when cutting metal completely depends on the thickness of the workpiece.

Important! If the flame is unstable and sniffles, there is too much oxygen. The volume must be reduced so that the flame is in the form of a cone.

Using the technology of gas cutting of metal, the flame was brought to the material by the tip, heating the surface. After the appearance of the molten metal, oxygen begins to flow, igniting it. The jet increases until the material is fully cut through. At the same time, the mouthpiece moves along the mowing line of the cut. Sparks and slag are jetted away.

The optimal cutting speed is determined by sparks – they should fly away at an angle of 85-90 °. If the angle is less, the speed must be reduced. If the workpiece is thick, it must be positioned at an angle so that the slags flow down. It is not recommended to stop without completing the process. At the end of the work, oxygen is first shut off, then gas.

Metal cutting allowances

Allowance for cutting metal with gas – a layer that is lost during processing according to the drawing. The norms for steel billets are defined in the Minimum allowances of GOST 12169-82:

- 3-5 mm with a thickness of up to 60 cm;

- 5-10 mm with a thickness of 100 cm;

- 10-25 mm for extra thick.

Important! The amount of allowances for cutting metal depends on the width of the furrow, errors of the equipment used, the chemical composition of the material, deviations due to deformations, technological inaccuracies made by workers.

Technology features

The choice of cutting gas depends on the properties of the metal workpiece. In addition to technical oxygen, acetylene, coke oven and petroleum gas, methane, propane, butane and mixtures thereof can be used..

Oxygen is used when cutting metal with gas if the material has certain characteristics:

- high thermal conductivity;

- a melting point above the ignition temperature in oxygen;

- the melting temperature of refractory oxides is lower than the melting temperature of the metal;

- the formation of liquid slags during the cutting process;

- generating a large amount of heat.

To cut a metal workpiece, it must first be heated. Then the material is burned, the combustion products are removed with a gas jet.

Cutting can be:

- superficial – the formation of slots and channels;

- spear – the formation of holes or openings;

- dividing – in the form of a through cut.

Different burners are selected for different jobs. There are several types that are designed to perform different jobs..

Any burner consists of:

- handles;

- valve;

- valve (not in all models);

- tip (extension tube);

- mouthpiece (nozzles).

Mixing of gas with air can take place in the tip or mouthpiece. On valve models, the gas is mixed with oxygen in the head for increased safety. The use of models without a valve allows the use of gas at different pressures. Gas torches for cutting thick metal come with multiple mouthpieces.

The technology consists of four steps:

- heating the workpiece;

- introducing a gas mixture into the processing area;

- ignition of the material;

- combustion process.

The jet must be uniform so that the flame does not go out. During combustion, oxides are formed, which are removed by a gas jet.

Safety precautions for gas cutting of metal

Safety precautions for gas cutting of metal determined that it is better to work in the air or in a room with an ideal ventilation system, earthen or concrete floor. The floor covering within a radius of 5 meters must be cleaned of objects that are flammable: shavings, rags, paper, leaves and plants. The workpiece is best placed on a metal table of a comfortable height. There should be no flammable stains on the floor or table.

Before starting work, you must make sure that you have at hand:

- protective equipment (leather gloves, goggles, sturdy shoes);

- fire-resistant clothing (synthetics, torn edges, loose fit are not allowed);

- tools (special pencil, square, ruler);

- special lighter (matches do not fit).

The greatest harm to the worker is caused if the mixture explodes due to improper handling of cylinders or a burner. The most dangerous are the explosions of cylinders filled with oxygen. Burns can result if the burner is handled incorrectly. Visible and infrared rays, sparks, slag splashes adversely affect the eyes. If you do not wear protective glasses, there is a possibility of losing your eyesight for a while..

how to cut with a torch. oxygen acetylene welding cutting torch

Nuances

The main task of the performer is to maintain the speed correctly:

- normal mode – sparks fly at right angles relative to the surface of the workpiece;

- low speed – flying away from the performer and an angle of less than 85 degrees.

After the end of the process, the oxygen supply is first shut off, and the propane is turned off last..

[stextbox N. Ishkulov, education: vocational school, specialty: fifth-grade welder, work experience: since 2005: “For the first time cutting with oxygen equipment, it should be remembered that after a sudden stop it is necessary to start a new cut from a different point, and not where the process ended “.

How much gas is consumed

Gas consumption when cutting metal with a propane-oxygen cutter depends on the thickness of the structure and the configuration of the cut. For clarity, we present the table below:

| Workpiece size (thickness), mm | Time per hole, sec | Cut size (width), mm | Consumption, per m 3 cut | |

| propane | oxygen | |||

| 4.0 | 5-8 | 2.5 | 0.035 | 0.289 |

| 10.0 | 8-13 | 3.0 | 0.041 | 0.415 |

| 20.0 | 13-18 | 4.0 | 0.051 | 0.623 |

| 40.0 | 22-28 | 4.5 | 0.071 | 1,037 |

| 60.0 | 25-30 | 5.0 | 0.087 | 1,461 |

Gas consumption is significantly reduced when surfacing or brazing is performed.

Beginning of work

How to cut metal with a gas cutter – after completing the preparation, the performer slightly opens the propane valve, ignites the gas stream, while the nozzle of the product rests on the metal surface. Now you need to adjust the flame strength, alternately adding propane and oxygen. After setting the optimal jet force of the burning mixture, the product is located at right angles to the surface of the part, the nozzle is located no closer than 5 mm.

If the cut starts in the middle of the sheet, then the starting point is set at the beginning of the cut. The surface heats up to a temperature of at least 1000 0 C, it looks like it gets wet, then the oxygen supply increases to form a powerful narrowly directed jet.

Propane to oxygen ratio

To properly cut metals with an oxy-propane cutter, you need to adjust the flow of gases to the nozzle. Such adjustment is carried out according to the recommendations of reference books, where tables and diagrams are available; in the absence of the necessary literature, one must check the technology specified in the product documents. In the absence of regulatory documents, the ratio of one part of propane to ten parts of oxygen is used..

Preparatory work

How to set up a torch for cutting metal – first of all, you need to make sure that the product is in good condition, ready for work, then the following procedure is performed:

- The hoses from the cylinders are connected to the cutter by pre-blowing the product to remove foreign inclusions from the inside.

- Oxygen is connected to the right hand thread and propane to the left hand thread.

- Set the propane supply level to 0.5, and oxygen supply to 5.0 atmospheres.

- We check connections for leaks, as well as the operation of reducers and pressure gauges.

If gas leaks are found, then the nuts are tightened or the gaskets are changed..

The diagram shows the correct connection of the cylinders to the cutter.

Safety engineering

The equipment is classified as explosive, so the work site must be equipped with the following accessories:

- fire extinguisher;

- sand box;

- fire stand with appropriate tools.

Each performer must have a set of protective clothing.

It is not allowed to wear under the protection of clothing made of easily flammable material, for example, from synthetics, and the edges of the sleeves should tightly fit the body so that sparks do not get inside..

Terms of use

They are similar to safety precautions for welding, but have specific additions:

- It is not recommended to neglect protective equipment, since this leads to injuries in the form of skin burns or damage to the cornea of the eyes by flying sparks, therefore glasses and gloves with long sockets to the elbow are required.

- The performer’s clothes and footwear are made of non-combustible material..

- Gas cylinders are located at least five meters from the cutting site.

- The torch flame is directed only in the opposite direction from the hoses.

- Cutting is carried out in rooms equipped with strong ventilation or in open areas.

If the equipment is idle for a long time, it is necessary to carry out preventive work before using the torch for its intended purpose..

Danger of kickback

If the jet burns incorrectly, cotton occurs and the flame is drawn into the inside of the product, which leads to an explosion, since the fire spreads through the hoses and reaches the containers with gases. To prevent a hazardous situation, the torch is equipped with a non-return valve to isolate the flame and prevent it from spreading..

Oxygen and propane consumption for metal cutting

Metal cutting technologies

Today, the industry uses three typical technologies for thermal separation of metal blanks:

- Oxygen cutting.

- Plasma cutting.

- Laser cutting.

The first technology, oxyfuel cutting, is used to separate carbon and low alloy steel workpieces. In addition, the oxygen cutter can trim the edges of the already cut workpieces, prepare the interface of the joint before welding and “clean up” the surface of the cast part. The consumption of working gases, in this case, is determined by the consumption of both fuel (combustible gas) and oxidizer (oxygen).

The second technology – plasma cutting – is used for the separation of all types of steels (from structural to high-alloyed), non-ferrous metals and their alloys. There are no unavailable materials for a plasma cutter – it cuts even the most refractory metals.

Moreover, the quality of the cutting seam, in this case, is significantly higher than that of the competing technology. When determining the volumes of working gases, in this case, oxygen consumption is important – when cutting metal with plasma, it is the oxidizer that is responsible for the combustion of the material. And the plasma itself is used as a catalyst for the process of thermal oxidation of the metal..

The third technology – laser cutting – is used to separate thin-sheet workpieces. Accordingly, the volumes of consumed gases, in this case, will be significantly less than that of oxygen and plasma cutting, which are designed to work with large, thick-walled workpieces..

Pipe cutting oxygen consumption table

| Pipe (outer diameter × wall thickness), mm | Oxygen consumption, m 3 |

| Ø 14 × 2.0 | 0.00348 |

| Ø 16 × 3.5 | 0.00564 |

| Ø 20 × 2.5 | 0.00566 |

| Ø 32 × 3.0 | 0.0102 |

| Ø 45 × 3.0 | 0.0143 |

| Ø 57 × 6.0 | 0.0344 |

| Ø 76 × 8.0 | 0.0377 |

| Ø 89 × 6.0 | 0.0473 |

| Ø 108 × 6.0 | 0.0574 |

| Ø 114 × 6.0 | 0.0605 |

| Ø 133 × 6.0 | 0.0705 |

| Ø 159 × 8.0 | 0.119 |

| Ø 219 × 12.0 | 0.213 |

| Ø 426 × 10.0 | 0.351 |

| Ø 530 × 10.0 | 0.436 |

Determination of the rate of gas consumption

To accurately determine the volumes of consumed gases, it is necessary to determine the basis of the formula – the rate that determines the gas consumption per linear meter of the cut metal, denoted in the formula by the letter “H”.

According to general recommendations, the normalized flow rate is equal to the quotient of the permissible flow rate of the separating apparatus (p) (oxygen, plasma or laser cutter) and the metal cutting speed (V).

That is, the formula by which the normalized oxygen consumption for cutting metal (H) is calculated, as well as any other gas participating in the thermal separation process, is as follows:

The desired result is substituted into the first formula and a specific value of the consumed volume is obtained.

Standards for calculating combustible gases and oxidizer

The consumption rates of propane and oxygen or acetylene and oxygen or only the oxidizer are calculated as follows:

- Fuel or oxidizer consumption rate per linear meter of cut (H) multiplied by the length of the cutting seam (L).

- After that, the product of the same flow rate (H) by the loss factor (k) associated with blowing and adjusting the torch is added to the resulting sum..

As a result, the oxygen consumption during welding (or the consumption of combustible gas) is calculated using the formula:

Moreover, the coefficient k is taken equal to 1.1 (for small-scale production or piece cutting, when it is required to turn on and off the cutter frequently) or 1.05 (for large-scale production, when the cutter operates almost without interruptions).

Oxygen and propane consumption for metal cutting

The cost of the metal cutting process determines the consumption of oxygen and propane, summed up with the cutter’s wages. Moreover, the consumption of oxidizer and fuel depends on the technology of thermal separation of metals..

Therefore, we will begin our article with a description of cutting methods and then consider the oxygen consumption when cutting pipes..

Determination of the value of the permissible flow rate and cutting speed

The operands p (allowable flow) and V (cutting speed) used in the second formula depend on many factors.

In particular, the value of the permissible flow rate is determined by the passport data of the welding machine. In fact, p is equal to the maximum throughput of the torch nozzle in operation..

But the cutting speed – V – is determined based on the depth of the seam, the width of the cutting jet of the oxidizer or plasma, the type of material to be separated and a whole series of indirect parameters.

As a result, the value of the permissible flow rate is extracted from the “cutter” passport, and the cutting speed is found in reference books that contain special tables or diagrams linking all the input data..

And according to the reference data, the permissible oxygen consumption is 0.6-25 cubic meters per hour. And the maximum cutting speed is 5-420 m / h. Moreover, laser cutting is characterized by a minimum consumption (0.6 m3 / h) and a maximum speed (420 m / h): after all, such a cutter will separate only a 20 mm workpiece.

But the plasma cutter “burns” up to 25 m3 / hour of oxygen and 1.2 m3 / hour of acetylene. At the same time, he separates even 30-centimeter workpieces, making a cut at a speed of 5 meters per hour.

In a word, in such calculations everything is relative: the higher the speed, the shallower the depth, and the higher the flow rate, the lower the speed..

Often, when welding, it is necessary to make not only the connection of metal parts, but also their cutting. Gas cutting of metal is carried out using combustible gases such as acetylene. Oxygen, methane, propane, butane and various mixtures of these gases can also be used. Sometimes flame cutting of metal is carried out with the help of flammable liquids, namely gasoline and kerosene..

Let us dwell in more detail on gas cutting of metal, on materials and equipment used during work. We also note the features of oxygen cutting of metal.

Gas cutting of metal

Gas torch for cutting metal.

There are several types of burners that are designed for different jobs. This time we will be interested in torches designed specifically for cutting metals..

Among these, acetylene and propane burners can be distinguished, as well as special universal ones. These torches allow both welding of metal products and their cutting.

Note that the peculiarities of propane burners include the fact that they can be equipped with several mouthpieces. Acetylene burners are often used when working in protective gases.

Universal burners are designed to handle any gas. In addition, their versatility lies in the fact that they can be used for almost all types of welding work. The functionality of such burners increases and due to the ability to use a variety of nozzles with them.

Gases for cutting metals and their features.

First of all, you should consider the features of gases that are used to cut various metals..

We have already said that gas cutting of metal is carried out using certain types of gases. So, the most widespread is acetylene, which allows you to achieve high quality flame during work. The peculiarity of this gas is that it can burn even in conditions where there is no oxygen or any other oxidizing agent..

Note that acetylene, both dissolved in acetone and in gaseous form, can be used for cutting metals. It is safest to use dissolved gas. In addition, in this state, it is able to ensure the stability of the entire cutting process..

Due to the scarcity of acetylene recently, welders often use its substitutes, which, nevertheless, are inferior to this gas in terms of thermal conductivity. Substitutes for acetylene are called kerosene and gasoline, as well as their mixtures. In addition, other gases are used, which are usually divided into two types: compressible and liquefied..

The first type includes methane, oil, city, coke and natural gases. The second is propane, butane, and mixtures.

Also, when gas cutting, pure oxygen is used (not less than 99.5 percent). Note that the use of oxygen in the work requires caution and attention from the welder. Oils and fats are especially dangerous, and even a small amount can lead to an explosion. Therefore, the equipment used during metal cutting must be degreased. They also make sure that there are no grease or oil stains on the welder’s workplace and clothing.

Features of oxygen cutting of metals.

Immediately, we note that with the help of oxygen, you can cut metals that meet certain requirements. Namely:

- The temperature at which the cut metal melts must be higher than the temperature of its ignition in oxygen. These include, for example, low carbon steels.

- When cutting metal, refractory oxides should not form, that is, the melting point of these oxides should be lower than that of metal. This feature, for example, is distinguished by aluminum, high-chromium steels, etc..

- Metals should not have very high thermal conductivity.

- When cutting metal, liquid slags should form.

- A large amount of heat must be generated during the combustion of metal during oxyfuel cutting.

Metal cutting is carried out only after preheating with a flame. Note that heating is also carried out during cutting..

Actually, the process of cutting metal itself is the combustion of the material with a jet of oxygen. The same jet removes combustion products from the cut. Note that the amount of oxygen during work must be carefully monitored. Since its overabundance can lead to cooling of the metal, and a deficiency will cause incomplete combustion of the metal.

During the cutting process, it is also important to ensure that the oxygen jet causes continuous oxidation along the entire length of the cut. Hence the rule: the speed of movement of the torch should be equal to the speed with which the metal is oxidized (throughout the entire thickness).

Cutting metal with gas, be it acetylene or oxygen, requires strict adherence to safety measures from the welder.

Gas cutting technology

The essence of the oxygen cutting process is as follows. The heater heats the metal to an average temperature of 1100 degrees C. Then a stream of oxygen is supplied to the working area. The stream, in contact with a heated metal, ignites.

The burning jet easily cuts the metal sheet, provided there is a constant and stable gas supply.

For metal, the combustion temperature should be lower than the melting temperature. Otherwise, melted but not burnt masses are difficult to remove from the working area..

Thus, the cutting operation is performed by burning the material in the gas jet. The main module of the flame cutting tool is the torch. It provides accurate dosage of mixing gases or vapors of liquid fuel with oxygen masses into a gas-air mixture.

Also, the cutter provides ignition of the resulting mixture, and a separate supply of oxygen to the workplace..

Gas cutting refers to the thermal methods of metal processing. Its advantages are that you can work with material of any thickness, and with high productivity. The daily output of a welder can be measured in tons.

Experts note the advantages of this technology in that gas-plasma cutting is completely autonomous and does not depend on the presence / absence of power sources. Since the welder often has to work in the field or does not have the ability to connect to a power source at a specific object.

Oxy-fuel hand cutting is available for a wide range of materials, excluding brass, stainless steel, copper and aluminum.

Gas consumption when cutting metal

Gas consumption to cutting volumes depends primarily on the selected method of carrying out the operation. For example, air arc efficient metal cutting involves more gas use than oxygen flux metal cutting. Also, the consumption depends on the following parameters:

- the experience of the welder, the beginner will spend more volume per meter than the master;

- integrity and technological parameters of the equipment used;

- the grade of the metal with which to work, and its thickness;

- width and depth of the cut.

Below is a table if propane is used for cutting metal:

Types of metal cutting with gas

For example, if it is possible to connect to the network, then you can use oxygen-electric arc cutting, or when working with low-carbon steels, it is better to use a gas-air mixture with propane. The following methods are most in demand in practice:

- Propane cutting. Cutting metal with propane and oxygen is one of the most popular ways to work, but it has some limitations. The operation is feasible for titanium alloys, low carbon and low alloy steels. If the carbon or alloying component in the material exceeds 1%, it is necessary to look for other methods of oxygen efficient metal cutting. This method involves the use of other gases: methane, acetylene, propane and some others..

- Air arc cutting. Oxygen arc cutting is a very effective method. The metal is melted with an electric arc, and the air jet removes the residues. Oxygen-electric arc cutting involves the flow of gas directly along the electrode. The disadvantage of this method is shallow cuts. But their width when performing work with oxygen-electric arc welding can be any.

-

Oxygen-flux cutting. A feature of oxygen-flux metal cutting is the supply of an additional component to the working area. It is a flux in powder form. This component makes the material more pliable during oxy-flux metal cutting. The method is used to cut materials that form carbide oxides. Using the method of oxygen-flux metal cutting allows to create an additional thermal effect.

Thus, the cutting jet performs the operation efficiently. Oxygen flux metal cutting is applicable for cast iron, alloy steels, aluminum, copper and copper alloys, slagged metals and reinforced concrete.

Advantages and disadvantages of technology

- the ability to cut sheets and products of considerable thickness;

- the cut can be performed of any degree of complexity;

- the possibility of surface treatment of the material;

- the optimal ratio of the cost of work and its quality;

- fast enough and versatile.

Among the disadvantages, it should be noted:

if a specialist has little work experience, he should not undertake precise operations, since skills and knowledge are needed to complete;

- the method is not safe, since an explosion of the gas-air mixture is possible;

- a significant area is exposed to thermal effects;

- low cutting accuracy.

Deformation of the material when cutting with gas

Since cutting metal with gas involves thermal action on the material, deformation is a natural consequence of the operation. Uneven heating and cooling can measure the shape of the workpiece. But there are several ways to eliminate this defect:

- using tempering or roasting;

- straightening of sheet steel on rollers, after which the material becomes more stable;

- to avoid warping, you can fix the product before the operation;

- perform the operation at the maximum permissible speed and other.

Gas cutting technology

In this article you will learn about the features of gas cutting of metal, the advantages and disadvantages of this method, the principle of operation of the equipment and its types..

Today, flame cutting is the most popular method due to the absence of strict requirements for the place of work and the ease of performing operations. In this article, you will learn about the features of the technology, the advantages and disadvantages of this method, the principle of operation of the equipment and its types..

Gas cutting of metal is a technology that is widely used today, since it implies ease of performing the operation, does not require additional energy sources and sophisticated equipment.

This is the method used by specialists in repair, construction and agricultural work. Almost all devices designed for cutting metal with gas are mobile, easy to transport and use elsewhere.

Throttle kickback

There are also risks of significant damage to the health of the welder and other people in the vicinity. An effective solution to these dangers would be to install a valve.

You can look at some more features of cutting metal with gas at

If you have information on this topic, interesting facts or tips for using this technology, we invite you to share them in the comments block.