What is chain lubrication on an electric saw for?

Electric saw oil is used as a chain lubricant to reduce frictional forces and reduce heat build-up. As a result, a fast and trouble-free operation of the cutting blade is achieved. Sometimes it happens that at some stages of cutting it is necessary to exert additional efforts to obtain the required cut, and this directly indicates an insufficient amount of lubricant or its not very good quality. In this case, it is recommended to immediately check the oil level in the reservoir or simply lubricate the chain to complete the current work.

Most new models of the electric chain saw have a built-in automatic oil supply system to the surface of the cutting element, and manual lubrication is only necessary for outdated equipment.

General recommendations for choosing a lubricant for an electric saw

When choosing an oil for lubricating an electric saw, each of the users asks the question, which of the options is more profitable and acceptable. a special oil for chain mechanisms or an ordinary machine oil? If you listen to the experts, then, of course, the first option is preferable, since the oil for lubricating chains was specially developed taking into account the technical characteristics of the electric saw.

Technical characteristics mean a certain temperature regime and friction of the working parts of the lubrication mechanism.

Although conventional engine oil is cheaper than special oil, it must be taken into account that it serves completely different purposes and will not be able to guarantee moderate wear of working parts. So you can win a little in price now, but then you will have to overpay for the repair of prematurely worn mechanisms.

Many experts recommend using a brand of special oil with the letter N to lubricate the electric saw. It is slightly more expensive, but guarantees a long and trouble-free operation of the chain. Its main advantages include:

- excellent biodegradability;

- increased adhesive capabilities;

- presence in the composition of special additives that protect against premature wear.

By following these guidelines, you can significantly increase the life of your electric saw chain. However, the final choice of lubricant is always up to the user.

What kind of oil should be poured into an electric saw

For most electric saw owners, it is not a big secret that the oil used to lubricate the chainsaw is one of the main consumables. However, at the same time, not everyone pays due attention to the quality of the lubricant. And it is completely in vain, since the term of its further operation will depend on how well this product will lubricate the working surface of the chain. Therefore, before pouring oil into the saw, you need to pay attention to its technical characteristics.

How the chain lubrication system works

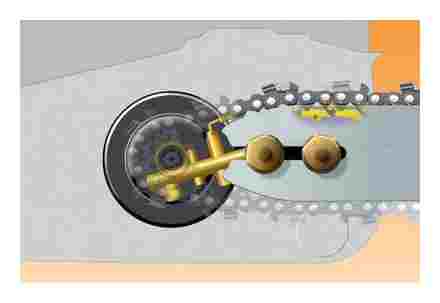

As already mentioned, the pump is the main link in the lubrication system. It works as follows. When the engine speed rises, the gear, which is located on the main shaft, starts the pump operation by means of transmission. At this moment, the pressure in the oil supply system rises, and it begins to move in the direction of the tire. This movement ends where the saw crankcase touches the tire, in the very place where the longitudinal groove is located, to which the oil channel itself is directed when installing the tire. This groove is required to supply lubricant to the tire at any tension level of the chain mechanism, i.e. regardless of the position of the tire when the electric saw is running, the groove will ensure the supply of lubricant to it. The next link in the feed is the chain itself. Its links have their own separate groove or hole through which the material is distributed along the length of the chain.

Automatic chain lubrication system

In the case of an increase in engine speed, the lubricant pumping speed also increases. Therefore, it is recommended to pour oil into the saw only when the engine is off.

Many modern models of electric saws, for example, Makita, have built-in pumps with additional skip adjustment, with which you can adjust the amount of lubricant supplied. In older saw modifications, this feature is usually absent. There, the oil supply is carried out in a constant and unchanging mode, or, as in the very first models, the user has to lubricate the chain manually. Those who own outdated copies need to know how to properly lubricate the chain mechanism by hand. It’s not difficult at all:

- take any old container and fill it with oil;

- the chain mechanism is gently immersed in this container.

These actions should be carried out periodically as the lubricant on the chain is consumed.

Main components of the lubrication system

Usually, oil enters the chain lubrication system of an electric saw from a special tank, where it is periodically poured. From there, it is pushed out by a powerful oil pump, doing this at regular intervals sufficient to consume the previous injection. The main task of the oil mechanism is to prevent the occurrence of such situations when the lubrication on the chain becomes insufficient, and as a result of this, severe overheating of the cutting part may occur due to sharply increased friction forces. As a result, the chain can become dull and fail. Therefore, the oil must be constantly monitored. Typically, a saw’s lubrication system consists of the following components:

- oil tank for chain lubrication;

- special oil filter;

- oil line, which is a small rubber hose that serves to supply oil from the tank;

- an oil pump that pumps the lubricant from the tank to the cutting mechanism;

- special gear, with the help of which the force is transferred to the pump from the electric saw motor.

The tire could also be added to this list, since it has special holes for oil supply.

How To Fix A ChainSaw If It Won’t Oil The Bar And Chain – Video

Consequences of insufficient or excess lubrication on the chain

Certain parameters must be respected for each mechanism whose operating mode is associated with lubrication based on machine oil. This applies primarily to the amount of oil required for its normal operation. Such problems can arise if there is not enough oil:

- overheating of the circuit;

- premature bluntness of cutting teeth;

- seized or broken chain;

- additional time spent on cutting;

- increased wear of the sprocket;

- tire failure.

For an electric chain saw, it is recommended to fill the oil tank in the following proportion: one full oil fill to a full gas tank, i.e. 1: 1. In some models, for example, Bosh, the lubrication system works in a fully automatic mode and if there is too much or too little oil on the chain, the saw itself begins to regulate its supply. However, if a malfunction occurs, and the oil starts literally pouring from the chain mechanism, then its excess can lead to the following undesirable consequences:

- increased oil consumption;

- excessive contamination of the tool body;

- wide spray of oil from the chain.

As you can see, an overabundance of lubricant does not lead to critical consequences, but its overexpenditure will certainly hit your. Considering that the cost of high-quality lubricating oil is quite high, it is better to use it sparingly.

Overview of brands from various manufacturers

There are many attractive offers on the market today from a wide variety of specialty oil manufacturers that can operate at high temperatures while still providing excellent gear lubrication performance. The most popular ones are presented in the following list.

- Forest Plus has high adhesion characteristics and can be used at ambient temperatures down to.15 ° C. Under certain conditions, the shelf life of the oil is 3 years. Sold in 1-liter and 5-liter packs.. 5 l. 1140 rubles.

- Bio Plus products are plant-based. It decomposes quickly when released into the soil. The oil can be used at temperatures down to.15 ° C. Packaging. 1 and 5 liter containers.

- Synth Plus is made on a synthetic base. Withstands increased loads and can be used at particularly low temperatures down to. 25 ° C. Packaging. 1 and 4 liter containers.. 4l. 2970 rubles.

- CHAMPION adhesive oil is formulated to withstand a wide temperature range. It is sold in 3 and 10 liter containers, which is very convenient for use in forestry.. 10 l. 2200 rubles.

- The HUSQVARNA Vegoil product is one of the most economical solutions for the lubrication mechanism of an electric saw. According to the manufacturer, the consumption of this material is 40% less than others.

Using special oil to lubricate the chain mechanism of the electric saw will ensure its smooth operation for a long time. This will allow work to be carried out quickly, efficiently and with a high level of safety, which ultimately will lead to significant savings in repairs and maintenance of the entire tool.

A little about the lubrication of the chainsaw chain by working off

Waste oil is oil that has already served its life in an engine or gearbox. It is often used to save money, including when servicing your chainsaw.

It should be borne in mind that mining can lead to rapid wear of the structure.

This can be attributed to the following points:

- Often, the breakdown is associated with a large amount of metal chips in the composition. It gets there at the time of operation of the engine and gearbox, then accumulates in the pallet.

- Metal swarf becomes abrasive when it hits the tire. Due to this, the process of surface wear is significantly accelerated. The sprocket with the bearing is worn out.

- Working off has a negative effect on the connection points of the moving elements of the chain. Due to strong wear, the likelihood of its breakage increases at the time of operation.

Danger of using counterfeit oil

Cheap lubricants are inferior in their properties to proprietary developments. At the same time, manufacturers of expensive versions indicate that the saw should be used with the lowest load. In addition, you should consider:

- Counterfeiters accelerate material wear. At the same time, in case of severe wear, the structure cannot be handed over for repair under warranty, since non-recommended oil was poured during operation.

- Rapid wear can cause the engine or tire to fail quickly. The fuel-fueled engine is a combination of various moving elements. In order to reduce their wear, a certain amount of a special lubricant is added to the structure, which also provides the required cooling. During operation, due to heating and slow wear of the metal, the properties of the oil change significantly. That is why from time to time it is necessary to carry out a complete replacement.

Choosing engine oil

Saw chain oil is not always used as a universal option. Often, the filling is also carried out for the engine, from which the tire receives rotation. When choosing it, the following points are taken into account:

- It is necessary to give preference only to the versions recommended by the manufacturer of the saw.

- Mineral lubricants are more popular, as they are more effective in application.

- Products from well-known manufacturers are characterized by higher performance characteristics.

- It is necessary to take into account the recommended temperature regime. Some versions cannot be operated at too low temperatures, as this leads to an increase in viscosity. Too high viscosity causes structural damage when operating at high speeds.

Various brands of chainsaw oils

If the lubricant is not added to the engine in a timely manner, then it can wear out quickly or completely fail.

What parts of a chainsaw need oil?

A modern chainsaw is represented by a complex mechanism, which consists of a large number of different elements. The following elements need lubrication:

- The chain is the element on which the blades for sawing wood are attached. It consists of a large number of individual elements, movably interconnected. When the device is in use, the surface may become very hot. In this case, the metal due to high humidity can rust, due to which the operational life is significantly reduced.

- The engine is the part of the chainsaw, due to which rotation is transmitted to the tire. Modern engines also require a lubricant that can significantly extend their service life. Different lubricating products are used to lubricate the chain and the motor, which should be considered.

Filling the chainsaw with oil

The operating instructions also indicate which parts of the chainsaw need lubrication.

Chainsaw chain oil

Chainsaws are most widely used in everyday life and industry. Features of their design determine that in order to ensure a long service life, it is necessary to periodically lubricate the chain and many other elements. Lack of lubricant can negatively affect the performance of the tool, reduce its efficiency and duration of operation.

When to use special chain oil?

Manufacturers recommend the use of a special chain oil whenever the chainsaw is used. This recommendation is related to the points below:

- The oil pump may be damaged. This is due to the special properties of the lubricant.

- The use of waste or other oils for other purposes reduces the ability of the tool to high revs.

- If the tire is heavily worn, do not put a new chain on it. This is due to increased surface wear. It is recommended to purchase at least four chains with frequent work.

- It is strictly forbidden to work without the oil being poured into the tank. At the time of refueling the chainsaw with fuel, the tire must be lubricated.

When using a special oil for lubricating the chain, you need to pay attention to its quality, since the composition should not contain various impurities or debris. Otherwise, the oil pump can quickly fail.

Chainsaw chain lubrication

Almost all manufacturers of chainsaws and accessories are engaged in the production of lubricants. Chainsaw chain oil protects metal from rapid wear and corrosion. In addition, the chain oil stays on the surface for a long time even with prolonged operation of the device.

How a chain oil system should work?

To ensure the reliable operation of the chainsaw, a special oil chain lubrication system is installed. An example is the following information:

- Fuel tanks are selected in terms of volume, taking into account that a little oil should remain at full fuel consumption. In addition, it is important to properly tune the carburetor so that fuel is not used up quickly.

- With a slow decrease in oil at the time of using the saw, the lubrication efficiency decreases several times, the conductivity of the channels also decreases. Over time, a malfunction may appear, which will be quite difficult to fix.

- It is recommended to check the condition of the oil pump from time to time. If necessary, you can adjust the performance using a special screw.

- You can check the correct operation of the pump yourself. For this, the tire is brought to the illuminated surface. If oil splashes appear on it, then the structure is working correctly. Grease consumption is adjustable depending on the specific situation.

Saw chain lubrication system

cheap chainsaw chain oil

A sign that an insufficient amount of lubricant gets into the cutting zone can be called strong heating and the appearance of smoke, an unpleasant odor at the time of cutting wood. With strong heating, the metal expands, due to which the circuit is pinched in the groove.

The effectiveness of the degree of lubrication decreases when the tire hits the ground. That is why, if the saw is used carelessly, it wears out quickly. When in contact with the ground, the chain oil collects various substances on itself, due to which the heating of the metal is accelerated.

What parts of a chainsaw need oil?

A modern chainsaw is represented by a complex mechanism, which consists of a large number of different elements. The following elements need lubrication:

- The chain is the element on which the blades for sawing wood are attached. It consists of a large number of individual elements, movably interconnected. When the device is in use, the surface may become very hot. In this case, the metal due to high humidity can rust, due to which the operational life is significantly reduced.

- The engine is the part of the chainsaw, due to which rotation is transmitted to the tire. Modern engines also require a lubricant that can significantly extend their service life. Different lubricating products are used to lubricate the chain and the motor, which should be considered.

Filling the chainsaw with oil

The operating instructions also indicate which parts of the chainsaw need lubrication.

Choosing engine oil

Saw chain oil is not always used as a universal option. Often, the filling is also carried out for the engine, from which the tire receives rotation. When choosing it, the following points are taken into account:

- It is necessary to give preference only to the versions recommended by the manufacturer of the saw.

- Mineral lubricants are more popular, as they are more effective in application.

- Products from well-known manufacturers are characterized by higher performance characteristics.

- It is necessary to take into account the recommended temperature regime. Some versions cannot be operated at too low temperatures, as this leads to an increase in viscosity. Too high viscosity causes structural damage when operating at high speeds.

Various brands of chainsaw oils

If the lubricant is not added to the engine in a timely manner, then it can wear out quickly or completely fail.

How to replace the original expensive oil and is it worth

In situations where it is not possible to use original ones, they can be replaced with oil for car engines. Cheap automobile oils such as autol or diesel lubrication options, due to low adhesion properties, are unsuitable for long-term use.

Some owners, despite the recommendations, still use analogs, preferring to change the tire and chain more often, but here everyone decides for himself. Such oil cannot have any negative effects on the lubrication system, which means that the only difference is in the quality of the tire protection against chain friction.

Chainsaw sprocket lubricant

To increase the service life and reduce friction on the drive sprocket, the manufacturer equips this mechanism with a needle bearing, which must be lubricated periodically. Stihl multipurpose grease can be used for lubrication.

If you do not want to overpay, it is better to use an inexpensive, but no less high-quality option, Litol or Litol 24 grease. Due to its viscosity, Litol will easily replace the original.

It is possible to lubricate the sprocket of the chainsaw tire with the same lubricants as the leading one, using a special filler for this. This allows the lubricant to be pressed in through the technological holes in the tire to the sprocket bearing.

Adjustment of oil density to external temperature factors

The performance of the grease decreases during its operation at the time the ambient temperature drops to 20 degrees Celsius and below. Also, at low temperatures, the pump, which is responsible for the oil supply, does not work correctly. The solution to this problem is often mixing the thickened composition with kerosene. Such an additive provides the required density of the substance, but it is still recommended to reduce the load applied.

If the ambient temperature is too low, the lubrication efficiency of the main elements must be monitored. This recommendation can also be attributed to the fact that the liquid in the wood begins to freeze, increasing the hardness and reducing the degree of workability. Too high load causes rapid wear.

An increase in viscosity makes the engine more difficult to operate. That is why many manufacturers indicate in what conditions a chainsaw can be used.

Oil does not flow to the chain, what are the reasons

It is not always during operation that you can immediately see that no oil is supplied to the chainsaw chain. Signs of lack of lubrication:

- the level in the tank does not drop;

- cutting is difficult, accompanied by the smell of burnt wood;

- oil droplets do not fly off the tip of the chainsaw tire.

Having found a malfunction of the oil system, you need to establish its cause. There are few of them. clogging, broken hose or malfunction of the oil pump.

Most often, the oil supply channel is clogged with dirt and sawdust. Air blowing or fine wire cleaning is sufficient to correct the fault. The oil reservoir has its own internal filter. When using normal oil, clogging is unlikely, and when filling, it is quite possible. Have to clean up.

The oil hose may be damaged or completely cut off. You can temporarily seal the damaged area, but it will be safer to replace it with a new one.

And the most serious problem is the breakdown of the oil pump. The reasons may be different. the teeth of the worm gear are worn out, the plunger has jammed, and others. Removing the pump and replacing a damaged part yourself will not be easy. It is safer and easier to contact the service center.

How a chain oil system should work?

To ensure the reliable operation of the chainsaw, a special oil chain lubrication system is installed. An example is the following information:

- Fuel tanks are selected in terms of volume, taking into account that a little oil should remain at full fuel consumption. In addition, it is important to properly tune the carburetor so that fuel is not used up quickly.

- With a slow decrease in oil at the time of using the saw, the lubrication efficiency decreases several times, the conductivity of the channels also decreases. Over time, a malfunction may appear, which will be quite difficult to fix.

- It is recommended to check the condition of the oil pump from time to time. If necessary, you can adjust the performance using a special screw.

- You can check the correct operation of the pump yourself. For this, the tire is brought to the illuminated surface. If oil splashes appear on it, then the structure is working correctly. Grease consumption is adjustable depending on the specific situation.

Saw chain lubrication system

A sign that an insufficient amount of lubricant gets into the cutting zone can be called strong heating and the appearance of smoke, an unpleasant odor at the time of cutting wood. With strong heating, the metal expands, due to which the circuit is pinched in the groove.

The effectiveness of the degree of lubrication decreases when the tire hits the ground. That is why, if the saw is used carelessly, it wears out quickly. When in contact with the ground, the chain oil collects various substances on itself, due to which the heating of the metal is accelerated.