Types of attachments for metal cutting drills: their cost

If there is a need to cut metal, and the angle grinder or hacksaw is not available, you can use an electric drill with a special attachment for this purpose. Such devices allow you to separate a piece of sheet steel, and some models allow you to work with a metal profile as well.

These devices have not only a lot of advantages, but also limitations, the main of which is the thickness of the material with which you can work.

In manufacturing and construction, you need to regularly cut metal sheets, cut holes in them, cutouts of different shapes.

Many types of tools and equipment can cope with such tasks:

-

. It is also an angle grinder. Using special trimming wheels, can cut sheet metal, rebar. Often used for just this purpose. But there are disadvantages. Burrs remain on long cuts, it is not suitable for corrugated board, because it damages the polymer coating, you must constantly buy cutting discs, which quickly wear out.

- Guillotine. Performs metal cutting of a fairly wide range of thicknesses. Has a high productivity. Used mainly only in enterprises because of the high cost of equipment.

- Circular saw. It is possible to cut metal at different angles and with high precision. It is not possible to perform complex cuts, after working with it a lot of waste is left.

- Jigsaw. Allows you to cut the material at different angles. Suitable for cutting sheet metal.

- Electric sheet metal shears. There are different types. For sheet steel. designed for simple metal cutting only. Cutting shears. in addition to straight and shaped cutting, performs a variety of holes. Slit shears. excellently cope with shape cutting, most accurately and precisely perform their task. The disadvantage of such tools is quite high cost. Suitable for those who are professionally engaged in construction and repair. For one-time work and small amounts of work, the purchase of electric shears is inexpedient.

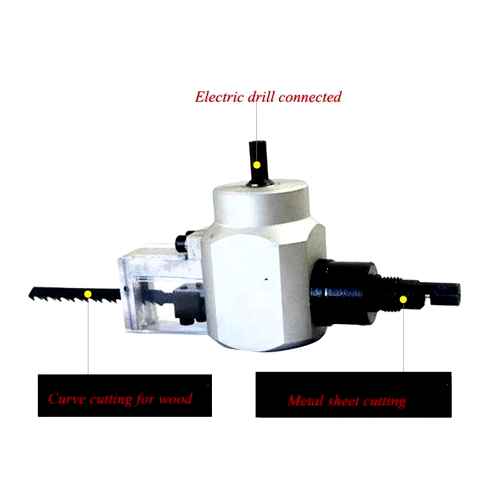

- Drill bits for metal cutting. There are two types. “cricket” and “steel beaver”. By the principle of action is similar to a punching electric shears, but several times cheaper in cost.

There are undeniable advantages of using a drill to cut metal products. Every craftsman has this tool. both the professional builder and the cottager.

Drill. universal equipment thanks to ability to change nozzles. They can be for drilling holes, grinding, milling, sharpening, etc. д.

How to choose and use an electric screwdriver attachments for cutting metal?

An electric screwdriver can be converted by a special accessory into a tool for cutting metal products. It’s quite convenient, high quality and economical. This method is quite an effective alternative to special metal-cutting tools. But in order to achieve really good results with an electric screwdriver with such a bit, you need to choose the right bit.

Новая электрическая отвертка Xiaomi Mijia Electric Screwdriver 3 6 В

Advantages and disadvantages of the scissor bit for cutting metal and metal tiles

The use of a special device for handheld power tools for the purpose of cutting metal has a number of advantages, in comparison with other methods of processing:

- Achieve the right cut by repetitive reciprocating motion of the eccentric piston.

- No need for frequent consumable replacement.

- Improved productivity.

- Versatility, because only by changing the nozzle, it is possible to carry out all the necessary manipulations with the material.

- Easy operation and maintenance.

- The nozzle can be used with pneumatic and electric devices.

- Achieving any shape of cut.

- Affordable price.

Metal accessories have only two disadvantages. The first is the need for skill and practice to get a smooth cut and increase the efficiency of use. The second disadvantage. the ability to work only with two hands, which is inconvenient for some types of work.

To note! The instructions for use of metal tile establishes a ban on its processing with an angle grinder, so the purchase of the nozzle will be the only option to keep the warranty.

Drill attachment for metal cutting: characteristics of the attachment

There are many different tools for cutting metal, such as an angle grinder, metal scissors and a hacksaw. In addition, few people know that metal can be cut even with a drill, but this requires a special attachment. The metal-cutting bit on a drill makes it as easy to use as the tools listed above.

Drill. a tool that is available in the arsenal of every craftsman. However, for metal cutting it is used quite rarely. But the attachments, whose variations are increasing in number, allow the tool to be used for this purpose as well.

Drill bits and accessories

The drill has many advantages over other tools discussed above. In particular, it is ease of use, accessibility, versatility. Battery powered models are available. Can be used when mains power is not available.

Editor of the category “construction” on the portal Stroyday.ru. Plumbing and drainage specialist.

Attachments are devices that are designed as a punch. Metal core pierces the sheet through reciprocating motion inside the die. The method is particularly suitable for materials coated with protective coatings: Due to the point impact, the top layer is rarely damaged.

The upper cutting part of the nozzle moves up and down, thus cutting the metal and pushing its particles into the slot

The maximum thickness of sheet metal that can be cut with this tool depends on the type of metal.

Table 1. Type of metal and average sheet thickness for cutting.

| Aluminum | 2 |

| Brass | 1,5 |

| Galvanized sheet metal | 1,5 |

| Copper sheet | 1,5 |

| Iron | 1,5 |

| Stainless steel | 0,8 |

Reference. The more powerful models can cut thicker sheets.

Nozzles are used for electric and pneumatic tools.

Drill bits for metal cutting: types, features, applications

The need to cut products made of metal arises in many situations related to construction and repair work. To perform this technological operation different types of special equipment are used, but if it is not at hand, the nozzle on the drill for metal cutting can help. Using such nozzles and handheld electric drill, you can perform effective cutting of small thickness products made of various metals.

Shaped cutting metal tile punching nozzle for a drill

Review: Drill bit cutter bits for metal Enkor “Cricket. They say you need a third hand when working. You need to use your brain, it will work, and both.

But circumstances were such that I had to take.The roof was. Metal tile. Few people know that it is categorically impossible to cut it with an angle grinder.A hot spark burns the protective layer and violates the integrity of the material, which leads to a lot of trouble later.As I said before, the roof is not my thing, and therefore buy electric scissors for metal, throwing away 15. 20 thousand I really did not want.I did a search on the Internet, I accidentally saw in the answer nozzles. Looked through the information, punched the possibility of buying in Bataisk. The Enkor store gave out.I went to the store and bought it. It’s only 1300.

The principle is quite simple. Hexagonal part is inserted into the head of the drill and tightly clamped.

Other parts (punches) can be used to cut the metal.Since there are two devices on the head for cutting, with the direction of the opposite side, you can work in different directions, which greatly simplifies the work.

You can cut metal both straight and radially.The same way you can cut holes. It is enough to drill with a 12 mm bit, it is enough and forward, the punch is enough.Decking generally no problems cut, with metal, however, you need a little skill.

There is another disadvantage, but it is inevitable in principle, when working, with these types of tools.This is a crescent-shaped die cut, which gathers quite a lot of work.It can be swept away by a moklovitsev, or removed, with a magnet.And now about the “third” hand. When cutting metal tile length of 4 meters or more, you can not “sweat” at all. The weight doesn’t allow the sheet to wiggle.If it’s smaller, it’s not a problem either. All the same. I personally used to put a board underneath to make it easier to cut, and not really “bothering” to press the metal with my knee.The third hand was just not needed.In any case, yes, if you are professionally involved in works related to metal cutting, of course, it is better to buy specialized tools, and it is silly to deny that.But in a case like mine, (and they happen and not infrequently) can get along with the above option and it will be optimal.

Drill attachment for metal cutting. cutters

Any man who likes to do everything with his own hands has a drill in his kit. It is this simple device can cope with cutting metal tiles, if you buy a accessory to it: a nozzle on the drill for metal cutting.

In essence, this is a splint or punch, which, thanks to the matrix, pierces the metal with many repetitive motions. By means of this in the treated metal is formed by the band of the shape you need. The impact on the metal is point, maximum preserved for the integrity of the protective layers of metal. The width of the slot is 3.1 mm.

Such a nozzle is also called a punching or die-cutting shears for metal. Of course, it does not work like a scissor, contrary to electric scissors with two blades, but it works according to the piercing principle.

Nozzle scissors on the drill is presented in the market several models from different manufacturers:

With the help of the nozzle you can work metals with the following parameters:

that is, the softer the substrate, the thicker it can be, so that it can be cut with a drill with such a nozzle. In principle, all models of this attachment work about the same parameters with respect to the thickness of metal, perhaps with some exceptions. The edge formed by the nozzle is not crumpled, but accurate and sharp. You only need to choose the correct speed on the drive of the drill itself.

It is very convenient to cut rounded and any shaped cuts, using such a mechanism, thanks to the punching punch. With the same method you will cut ventilating accessories for the roof.

To work with the nozzle on the drill for cutting metal tiles need a little bit of skill, but you quickly master it. The nozzle is attached to the chuck of the drill, which starts it in the work. Similarly, the cutting of electromechanical scissors work.