The oil level rises on the CHAMPION MOTOB block

The main working unit of the motor unit is the engine. It is driven only by turning the key, if the unoic tractor Neva does not start, then several reasons are possible.

There is no spark

In this case, it is necessary to check its performance. Pull the candle out of the motor and insert into a special bandwater, and place the case on the cylinder. Next, turn on the engine. If there is no spark, then you can replace the candle if it does not appear, you should check the starting mechanism and ignition work. Most often, the start button fails, it can be replaced with a new.

A special key is intended for extracting a candle. It is necessary to be careful, because during operation the candle heats up, so we pull out the candle to the start or after the engine motor cooles cooled. Install a new one, and then check the clearance. It must be, but not big. The recommended lumen width is 0.5-0.6 mm.

Gasoline does not reach the engine

The second reason that the engine is not started is the problem in the supply of fuel mixture. In this case, you should go through the full gasoline delivery scheme. From fuel tank to carburetor.

- Initially, check if there is fuel in the gas tank. It should not only be, but 2-3 cm to be higher than the bottom, since the gas tank in the Neva motorblock is designed in such a way that fuel fuel goes just at this height.

- If there is fuel, then you should check the operation of the tap on the fence of gasoline. To do this, remove it from the hose and look, if the gasoline is poured, then everything is fine if you can not clean the tap itself or replace it with a new one.

- Next, check the hose that connects the crane and carburetor. Remove it and try to blow it. If the air passes freely, then it functions well. If not, then clean it or replace it.

- And the last in this chain is the carburetor. Disassemble it and thoroughly rinse all the details 95 with gasoline. Thanks to him, he was washed off and slags. After completing the work, thoroughly blow the compressor all the joints and places of the connection, to minimize the remnants of gasoline, which evaporates under air pressure. After that, collect all the details back.

Here are a few more problems that may arise with the Neva motor block:

The unoic tractor turns off during operation. Here the main reason is a small amount of fuel, since if it has started, it means in good condition. Since we examined the gas tank device earlier, the fuel for reliable operation should be approximately 5 cm above the bottom.

The same.based tractor is not started the first time. Check the performance of candles, and if necessary, replace with new. Also use a primer to add gasoline to the carburetor.

Playing the walk.behind tractor

After the same.based tractor was purchased, it is necessary to run into it. This process must be carried out qualitatively. Since it is he who underlies the correct and durable use of equipment.

The running.in the walk.behind tractor is, in fact, its operation is not at full capacity. Here you need to choose the correct load on the one.axle tractor.

It is recommended to carry out half a maximum power on the uno.ears Tractor of Neva with Subaru engines. For example, if the plow in working condition should fall into the ground by 30 cm, then during operation it must be immersed, only 15 cm.

The termination period is prescribed for each individual model. It is measured in motorcycles and usually from 5 to 20 hours.

For a more sparing regime, it can be done completely without hanging equipment.

Important! Before starting the run, pour oil into the crankcase. The start of operation with an empty crankcase is not allowed. The selection of an oil brand should be made in accordance with the instruction manual. Usually used motor oil 10W.

The same.based tractor smokes at idle

Most often the reason is in the air filter that he clogged and became dirty. In this case, you can remove it and see if the smoke will go further. If it has stopped, then the reason is detected.

If you smoke anyway, check the oil level. Perhaps it is poured too much and it is “thrown”.

Revolutions adjustment

A working spring is responsible for the number of revolutions. The opening and closing of the throttle depends on how it is stretched. One end is attached to the working lever, it goes from the handle to the spring. And, when the position of the handle on the Neva motoblock changes, its position will also change. To adjust the number of revolutions, you should adjust its tension.

Adjustment of valves

In working condition, the gap on the inlet valves should be 0.15 mm, and the exhaust. 0.2 mm. In this case, the probe should be freely located under the valves. If this is in reality, then everything is fine. If not, then they should be adjusted.

- For this, the following actions must be carried out:

- Warm the engine and then give time to cool

- Dismantle the casing

- Remove the valve cover to gain access to flywheels

- Unscrew the locknuts

- Adjust their position with a key so that a thin blade can freely pass under them.

- Gather everything in the reverse order.

What kind of oil to fill

A large number of different oils are found on sale, which can be poured into a gearbox and motor. The main classification is as follows:

- Summer varieties are characterized by increased viscosity, intended for use in the summer. The high ambient temperature becomes the reason for the increase in viscosity, due to which the load decreases.

- Winter varieties are used in the winter, have low viscosity. The negative ambient temperature becomes the reason why the viscosity of the oil increases. Manufacturers take into account this moment and make the substance less viscous.

- All.season options are considered the most popular. They can be used in any operating conditions of the cultivator, suitable for four.stroke engines and other options.

In the manufacture of substances, various foundations can be used. On this basis, they distinguish:

- Mineral. This option is much cheaper, but it does not cope with the load provided.

- Synthetic. A similar substance is produced when using modern technologies. Therefore, it provides the required level of protection of the motor from wear and overheating.

- Semi.synthetic. The product from this category is cheaper and, at the same time, is considered universal, t.to. Added to various devices.

How To Repair Brush Cutter Repair In Hindi | Manual Repair | How to Repair at Home grass cutter

Manufacturers produce options for two.stroke and four.stroke engines. A motor.cultivator with the first type of motor costs much cheaper, maintenance provides for the addition of a lubricant to fuel.

Transmission

Periodic maintenance of the motor block allows you to extend the life and improve the characteristics of the equipment. The gearbox is considered one of the most important elements, the purpose of which is to increase the transmitted effort. The oil in the gearbox is poured in order to reduce the degree of wear between the two rubbing elements. When choosing transmission oil, it is taken into account:

Each manufacturer of the walk.behind tractor indicates the most suitable brands according to GOST. Various gearboxes can be installed with the Honda engine, the features of which are the choice of oil.

For diesel walk.behind tractor

On Honda and other cultivators, diesel engines are installed. The advantages of such a node are as follows:

Diesel mechanisms are characterized by a complex design, so special attention is paid to the choice of proper oil. The classification is carried out as follows:

- CA. an option designed for use in conditions of low and medium mechanical stresses. A substance can work with low.hearted diesel fuel. The inclusion of additional elements in the composition allows the composition to exclude the likelihood of corrosion, as well as a halter. Not suitable for use under severe operating conditions.

- CB is a substance suitable for use at low and medium.sized voltages when pouring high.sulfur diesel fuel. Unlike the previous type, the option under consideration provides higher corrosion protection.

- CC. such oil in motor blocks must be poured with medium and high mechanical loads. Additives reduce the likelihood of deposits when exposed to high temperature.

- CD. this type of oil is used to maintain an engine that does not have a supercharger on which a turbine is installed. The special composition protects the metal surface from the effects of corrosion.

It is recommended to give preference exclusively synthetic oils, t.to. They are able to provide high surface protection. Minerals are much cheaper.

For a gasoline cultivator

Gasoline engines are widely used, t.to. They have high efficiency when applying. Unlike diesel devices, gasoline vibrates less during operation, with a start in the winter period there are no problems. In this case, the following oil is poured:

- SA. a similar option can be used at low mechanical stresses, when additives are not required.

- SB. a substance suitable for use in the middle range of mechanical voltage. A special composition provides a weak degree of oxidability, stable lubricating properties.

- SC. the lubricants of this group are suitable for servicing motors that are not equipped with a PCV system. This option eliminates the likelihood of the formation of various deposits at high temperature.

- SD. a product of this category is used for engines equipped with a PCV system. Compared to the previous option, it more effectively copes with the task of protecting the surface from the formation of deposits.

- SE. used to maintain engines that were released after 1972. A special composition protects the device from wear and corrosion.

- SF. the substance is used to maintain motors that were released after 1980. New production technologies made it possible to increase the performance of the substance.

- SG. such oils began to produce for engines released after 1988. In basic qualities, the product is similar to the one that belongs to the category of SF, but, at the same time, is characterized by additional properties.

- SH. a version of the lubricant, which has been put on sale since 1992. This category includes universal lubricants.

The most common is the gasoline cultivator, t.to. it is easier to maintain and operate.

Is it possible to fill in car oil

Most often, car oil is most often found on sale. It is available for an internal combustion engine of cars, but is used in various fields. In some cases, car oil is poured into the engine engine engine. When considering such an opportunity, it is worth considering:

how to eliminate gasoline overflow on a walk.behind tractor.

It should be noted that one.axle tractor is poorly started with a missing oil volume. See only this parameter before starting a carburetor and diesel unoic tractor. On some models, a low level is set to protect. The sensor covers the start, and the unit stalls.

It should be kept in your head that some type of motor asks for gasoline of a certain brand. For a two.stroke engine, fuel is prepared separately. The fuel mixture consists of gasoline and oil. The number of ingredients is maintained in a serious ratio.

Buy gasoline for walk.in at gas stations. The service life of the machines directly depends on the property of the fuel. No need to start a single tractor on bad gasoline.

Starting a diesel motor block after buying you will like a difficult. What exists, that air enters the fuel supply system. If long.term scrolling (starter) does not manage to start, then air plugs should be released. For this purpose, they open the diesel tap tap and promote what remains to make our client a connection during the fuel channels. The final pt of purges is nozzles.

So that the gasoline engine starts, you need to fulfill a number of requirements. We list them all in order:

The implementation of the listed criterion guarantees the launch of any engine.

Difficulties in the start indicate a malfunction of the nodes and devices. The repair van is depending on the correctness of the diagnosis. If flaws are detected, they are repairing diesel motoblock. Service and small repair are carried out by its employees. A set of keys, locksmith tools and experienced hands will come in handy.

The whole truth about the malfunction of the Lifan engine and similar Chinese engines

In the step of preparing the fuel consistency, subsequent incidents are likely:

- The air filter does not pass the air;

- the hole of the tank cover is clogged;

- The fuel supply tract clogged;

- The carburetor broke.

After a series of unsuccessful launches, it is useful to unscrew the candle. The working part can pour fuel. We dry the detail. Then we pump the cylinder through the hole. We twist the candle and let it down again.

If the candle is dry, it means that fuel does not enter the burning chamber. We will perform a number of actions in turn to restore the accounting system:

- drain old gasoline;

- wash the tank;

- Clean the filter of dirt;

- blow the fuel supply hose;

- blow the jackets of the carburetor;

- Twine the tank with non.worthless gasoline;

- Open a tap;

- Clean the respiratory canal in the lid.

The engine will not start with defects in the ignition system. Why is this happening? Sources of failure are usually magneto, high.voltage wire, cap and spark plug. External inspection inspect the cleanliness of parts that allows accounting (software) of the ignition. Mud and moisture are a prerequisite for the breakdown of the highest voltage to the body. The lack of spark is with a bad contact of the cap with the central electrode of the candle.

A weak spark shows a bad spark plug. You need to check the gap and condition of the electrodes. The gap is inspected by the probe. It usually is 0.8 mm. If necessary, grief is removed from iron parts and isolator. Changing a candle is recommended.

The condition of the parts of the piston group affects the readiness of the motor by and large. They work in languid criteria. Under load, the rubbing surfaces heat up. Cylinder, piston and rings regulate the fundamental indicator. compression. Low compression degree in the cylinder will indicate parts.

My list of actions for launch:

Disconnecting the oil level sensor.

This sensor is a float in a crankcase with butter. If it stands uneven, then the ignition circuit opens. In winter, he often froze to the wall of the crankcase and until it falls into place, it will be impossible to start the engine.

Remove the sensor wire on the front of the crankcase.

P.S. Before turning off the sensor, be sure to check the presence of oil in the crankcase.

Removing an air filter.

This happens when there is not enough oxygen in the combustion chamber for starting. After the last work, the paper filter gained wet air, cooled down, condensation appeared on paper, which froze and did not let fresh air into the combustion chamber.

Remove the filter casing, then the filter itself, try to start.

Oily precipitate from gasoline in carburetor.

One of the reasons is a frozen sediment in a carburetor. To solve the problem with it, you will need a balon with ether (sold in any car shop, a useful thing, it will come in handy in the farm).

Remove the filter casing, then the filter itself, in the hole under it 2-3 spray ether and start the engine.

After all these operations, the engine is treacherously silent?

We unscrew the candle, leave the cap dressed on a candle, bring it to the engine body, look at the presence of a spark (for this, slowly pull the engine starter cable).

Нет искры? Меняйте свечу или чистите эту. Готово.

These tips are the basis of the operation of the gasoline engine, but they do not cover all reasons. If the replacement of the candle does not give a spark, then it is time to change the magneto, it did not help and this? Look at the work of the flywheel and so on.

Why not start a single tractor?

The repair of the walk.behind tractor will be successful if you competently perform diagnostics of motor vehicles.

The reasons for the breakdown breakdown are very different:

- The hole in the gas tank was clogged;

- Fuel supply channels were clogged with garbage;

- Air filter overlaps the hit of the clogged air;

- Carburetor breakdown.

Gasoline and diesel unoic tractor must be carefully prepared for seasonal work. It is important to make sure that all structural elements are in their places and are reliably fixed.

Subaru installed engines or motors of other brands may not start after prolonged downtime, especially in the winter period. Incorrect conditions for the storage of technology negatively affect.

The following malfunctions may occur:

- Contacts in the wiring were oxidized;

- Water got into the oil or fuel;

- The integrity of the insulation of the wires was violated;

- Garbage accumulated in the carburetor’s jackets.

Before you start a single tractor, you need to view all the connections in the nodes of the device, check the integrity and connection of gas cables, reverse and adhesion. If clamps or twisted cables are detected, this must be corrected to start the unit.

It is necessary to control the amount of oil in the crankcase. The lack of lubrication can adversely affect the piston group. Diesel or gasoline unoic tractor may not start if the oils are not enough. Low level protection is established on individual models, if it is not, you need to constantly control the volume of the lubricant fluid.

It is important to consider the quality of the filling gasoline. The same.based tractor needs to be filled with a brand recommended by the manufacturer, then the unit will work without interruptions. Two.stroke engines are operated on separately prepared fuel: gasoline and oil. It is important to maintain a strict ratio of substances.

Specifications

Technical characteristics of the motor unit cascade MB-6 are as follows:

- Engine type-1-cylinder, 4-stroke carburetor with air cooling.

- Power. 6 l.With.

- Working volume. 317.4 cm³.

- Cylinder diameter. 76 mm.

- The volume of oil in the motor. 0.9 liters.

- Kolench shaft rotation frequency-2750-3250 1ob/min.

- Type of chassis. wheeled according to the 2×2 scheme.

- Clutch. cuneiform transmission.

- The size of the belt per one.axle tractor cascade:

- front-line belt-A-1180.IV GOST 1284.1-89;

- reversing belt-A-1400 IV GOST 1284.1-89.

- Reducer-2-speed.

- Reducer oil seals:

- 941/20 GOST 4060-78-7 pcs.;

- 942/30 GOST 4060-78-2 pcs.;

- 306k GOST 8338-75-2 pcs.;

- 942/15 GOST 4060-78.

- Number of programs:

- front door. 2;

- reverse. 2.

- Capture width with the cultivator KMB 1.002.000. 930 mm.

- Processing depth-100-200 mm.

- Operation temperature5 35 ° C.

- Dimensional dimensions. 1500x600x1150 mm.

- Car weight. 103 kg.

The Unoic tractor cascade MB-61 has the following design features:

- MB61-102, 104 units are equipped with Vanguard 7.5 HP engines 0035A1 from Briggsstratton (USA) designed to work in extreme and difficult conditions. Such a motor has a working volume of 205 cm³.

- MB61-122, 124 units are equipped with Intek I/C 6.5 HP (Briggsstratton) total purposes with high performance, reliability and endurance.

- MB61-142, 144 have Intek Pro 6.5 HP engines with a dual Dura-Bore cylinder for long-term operation and a float carburetor for consistent light launch.

- MB61-152 and 154 with Vanguard 7.5 HP engines 0127E1.

Features of the cascade MB61 favorably distinguish it from agricultural equipment Cascade MB6. Motomashins are effective, reliable and efficiently collected, but the cost of units with American and Japanese engines is much more expensive. Therefore, motoblocks with domestic engines are more popular among farmers.

Problems with a carburetor

The carburetor of the walk.behind tractor can be contaminated, in many cases it may be adjusted incorrectly. If this happens, then such a node is removed and cleaned, its adjustment is performed, which should be provided for by the rules:

- Another problem may arise, which is expressed in the fact that the air into the carburetor is incomplete. This can turn out due to clogging of the air filter, ultimately the fuel mixture comes out of the reinforced. During use, you must do a periodic cleaning of a special filter to eliminate the occurrence of such problems. However, if the use of equipment is performed under very dusty conditions, then more common cleaning may be needed.

- You should think in what condition your air filter. Depending on the material at the base, it is necessary to save the part of the dirt in one of the effective ways. If the carburetor of the device began to receive air in small quantities, then it may be necessary to clean the paper filter, which is done with a slight tapping or blowing.

- In the presence of a foam filter, you can rinse it, and then completely dry it. The mesh filter is cleaned by a vacuum cleaner. Such details have its own period of use, as soon as it is developed, the node will need to be changed.

So you learned how to carry out repair of the Cascade motornote.

The reasons why the unoic tractor and ways to eliminate them are not started

The reasons why motor equipment does not start when starting, there are several. Consider them below.

Damage to the carburetor (in walkways with a gasoline engine)

Когда в мотокультиваторе появляются странные изменения, и его работа становится не стабильной, в первую очередь проверяют карбюратор. In this important node, the fuel mixture (TVS) and dosing it for supply to the internal combustion engine (ICE) are formed in this important node. And if the jackets are clogged, the obstruction of the fuel system occurs, as a result of which the carburetor loses the ability to ensure the launch of the motor. To eliminate the malfunction, repairs of the fuel supply are carried out: the carburetor is partially disassembled, the pump is washed and the nozzles are blown through the fitting fitting.

Failure of ignition devices

Sometimes the reason that the uniform tractor does not start is lies in the malfunction of the spark plugs (the spark), which play an important role in the start of the carburetor ICE, or the glow of incandescent, ensuring the launch of the diesel engine. If the devices of the fuse become moist, which happens due to throwing their TVS, a spark begins to disappear on them. In the absence of sparking, there is no ignition of the fuel mixture, which means that the engine does not start.

You can solve such a problem in different ways:

Failure of incandescent devices

Motorized technique is not started due to the fact that damage to the glow of incandescent occurs. In the diesel engine, fuel ignition comes from contact with red.hot air, which warms up in the cylinder by compressing the piston. This happens without problems when the diesel has already warmed up and the working temperature in it is maintained by the heated walls of the cylinder. But in cold weather, and especially in winter, heating the engine is carried out using incandescent devices and, if they fail, it will not succeed in starting a single.axle tractor.

If, when examining the carburetor engine or diesel, there were no defective candles, but the problems remained, and even accompanied by claps in the silencer, the performance of all the devices responsible for fuel ignition should be checked. Diagnostics is best done in the service center, where professionals will find the cause of the damage and competently carry out repairs.

Low lubrication

Motics is not started with insufficient lubricant fluid levels in the motor. Some models are equipped with special control sensors, which, in case of lack of lubrication, prevent the engine. Particular attention should be paid to those options for cars that do not have such sensors. Sooner or later, the level of lubricant mixture will reach a critical value and, if it does not make it up to the norm, this will soon lead to wear of the parts and, as a result, to the overhaul of the engine.

Preparation of the walk.behind tractor for launch

Problems with the start of the motor can arise not only the motoblock and the cultivator who were in use, but also new, just bought in the store. Therefore, before the first time to start a single.axle tractor, whether it is a cascade, a mole, a bison, a centaur, a hoper, a tarn, an eye, a salute, it is necessary to read the guide for its operation, then carefully examine all the connections and, of course, check the oil level in ICE.

To study the instructions compiled by the manufacturer, it is necessary to find out what kind of working cycle the engine has: four.stroke (like Forte, centaur, Lifan, bison) or two.stroke. This is important to know, since for models with a two.stroke engine (like a mole cultivator) you need a special combustible mixture, consisting of a certain proportion of gasoline and oil. Due to the discrepancy between the fuel, the technique will stall, and the candles of the fuse and the fuel pipeline can also suffer, which is fraught with the refusal of the gasoline pump-and this is a direct path to expensive repairs in one hundred. You can determine if the fuel is suitable for motor vehicles by smoke. With poor quality of gasoline, it will have white color, as is the case with a strong slope of the machine. If you have poor gasoline, replace it to prevent breakdown.

Fuel quality is also important for a diesel walk.behind. It does not start in winter or start, but soon stalls if the summer diesel fuel is flooded into its engine. At reduced temperatures, it begins to thicken and clog the fuel stove. In such cases, the risk of breakdown increases. In cold weather, select the corresponding fuel.

Starting of motor vehicles both in summer and in winter should be carried out in a certain sequence. For example, to start the MROT brand motor.cultivator, the following procedure is carried out:

- open benzovran;

- put the lever lever in the “chock” position (launch);

- turn off the ignition and scroll through the motor several times with a manual starter starter;

- Run the engine again and the lever is transferred to the Run position (work).

Often there are situations when the power unit easily starts, but after a few seconds it stalls. In this case, it is necessary to check the patency of the sump, perhaps the reason is that the crane is clogged. then it is cleaned with gasoline.

Starting motorcycle engineering with a diesel engine (such as a bison, cascade, centaur, nonsense) will be somewhat more difficult than mole. The diesel engine is starting with the “fuel” of the fuel line, that is, from the release of its accumulations. For this:

- open the fuel supply crane;

- unwind the compounds of the fuel.ascending channel until the fuel appears;

- twist the joints and blow the nozzles.

If, after the actions carried out, the engine does not function properly, and the technique is very smoked with white smoke, the reason is in the old lubricant. It should be completely replaced. Diesel is not started due to insufficient volume of oil fluid, so do not forget to control this parameter.

The launch of a motor cultivator after winter or long.term downtime also has its own nuances. In order to bring the car to working condition, the following manipulations are done:

Well, of course, before launching motor equipment, whether it is a centaur, cascade, Neva, Patriot or bison, check all the compounds, including transmission nodes, clutch, starting mechanisms and, if necessary, adjust them.

Start of gasoline and diesel units

The same.based tractor is a multifunctional tool. It is indispensable for conducting a personal economy. Awaken equipment allows you to treat land, mowing of grass, snow removal, cargo transportation, landing and harvesting.

Equipment is equipped with gasoline or diesel engines. The launch of a diesel engine and gasoline unit has differences. Therefore, to analyze the reasons for which the unoic tractor does not start, it follows for each specific type of engine.

Before you start a single tractor, they are preparing equipment. We must make sure of all the details, make sure of the reliability of fastening the mechanisms.

Mechanisms often refuse to work after winter. A long break causes a malfunction of the motor block systems. Storage in the cold and cheese room leads to the following breakdowns:

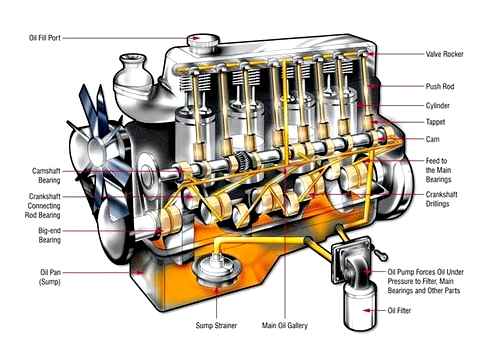

Lubrication System

Before starting the new walk.behind tractor, all connections, clutch, reverse and gas cable are checked. The course of the cables should be smooth, without effort. You can not run the unit if there are clamps and twisting of the thread threads.

During the first launch, the level of oil in the crankcase must be checked. Lack of lubrication will damage the piston group. The crankshaft rotates up to 1400 rpm per minute at idle. A couple of seconds are enough to form a score on the surface of the cylinder.

Old oil can cause a refusal to operate the engine. At the same time, the uniform tractor smokes white exhaust gases. Full of oil replacement suggests itself.

It should be borne in mind that the uniform tractor is poorly started with insufficient oil volume. Follow this parameter before starting a carburetor and diesel unoic tractor. On some models, a low.level protection is set. The sensor blocks the start, and the unit stalls.

It should be remembered that each type of engine requires gasoline of a certain brand. For a two.stroke motor, fuel is prepared separately. The fuel mixture consists of gasoline and oil. The number of ingredients is maintained in strict ratio.

Buy gasoline for walk.in at gas stations. The life of the machines directly depends on the quality of fuel. Do not start a single tractor on poor gasoline.

Repair of nodes and mechanisms

The launch of a diesel motor unit after buying may be difficult. The fact is that air enters the fuel supply system. If it will not succeed in prolonged scrolling (starter), then air plugs should be released. To do this, open the diesel tap tap and unwind all the connections along the fuel channels. The ending point is nozzles.

In order for the internal combustion engine to start, it is necessary to fulfill a number of requirements. We list them in order:

The fulfillment of the listed conditions guarantees the launch of any motor.

Difficulties in the start indicate a malfunction of the nodes and mechanisms. The success of the repair depends on the correctness of the diagnosis. If defects are detected, they are repairing diesel motoblock. Service and minor repairs can be done on your own. You will need a set of keys, locksmith tools and skillful hands.

At the stage of preparing the fuel mixture, the following incidents are possible:

- The air filter does not pass the air;

- the hole of the tank cover is clogged;

- The fuel supply tract clogged;

- The carburetor broke.

After a series of unsuccessful launches, it is useful to unscrew the candle. The working part can pour fuel. We dry the detail. Next, pump the cylinder through the hole. We twist the candle and let it down again.

If the candle is dry, it means that fuel does not enter the burning chamber. We perform sequentially a number of actions to restore the feed system:

- Drain the old gasoline;

- Rinse the tank;

- Clean the filter of dirt;

- blow the fuel supply hose;

- blow the jackets of the carburetor;

- refill the tank with clean gasoline;

- Open a tap;

- Clean the respiratory canal in the lid.

Gasoline in the crankcase of the engine of the walk.behind tractor cause

As you know, specialists and experienced motorists recommend checking the oil level at least once a week. It should be noted that there are good reasons for this. Regular examinations also allow not only to timely detect a decrease in the oil level in the engine, but also to evaluate the shape and condition of the oil.

In this article, we will consider the situation when it turned out that the engine oil smells of gasoline, gasoline in engine oil is clearly visible, the causes of this phenomenon and ways to solve this problem.

How gasoline enters the engine oil and what can be the consequences

So, the very topic of the article answers the question whether gasoline can get into the engine oil. Indeed, fuel can be in oil, even in engines with a fully functional cylinder-piston group.

We are moving on. This problem is quite serious and can lead to malfunctions, a significant reduction in engine service life, as well as to a complete refusal of power plant. Let’s see why this is happening.

To begin with, gasoline in oil significantly worsens the protective properties of oil, dilutes the oil. If you do not go into details, the more gas gets into the crankcase, the more serious the consequences.

Below are some of the main functions that can to varying degrees indicate the occurrence of the problem under consideration:

The black circuit in the center of the spot indicates the presence of functional additives in oil. It should also be noted that this method is also useful for general quality testing, oil condition and the presence of water and other impurities.

If any of the above signs was noticed (noise during work, detonation, overspending, fat, fuel smell, falling when calibrating on the sheet differs from the usual one), then it is necessary to prepare that gasoline can be in oil.

As already mentioned, the influence of further movement on such a mixture can be different. The main thing is that gasoline is a rather aggressive product in relation to lubricants, since it contains a large number of chemical additives.

Motor oil also contains a whole package of additives, while these additives are not intended for direct contact with fuel. In other words, there is an irreversible change in the physical and chemical properties of motor oil. For this reason, an increase in oil level through gasoline poses a serious threat to the engine.

As for gasoline in grease, there is a certain danger that often fuel gradually dilutes oil, that is, it falls into a small amount. This means that the driver does not notice the problem for a long time, continuing to work with the device as usual. This significantly increases engine wear. Now let’s move on to how gasoline goes to the oil.

Where gasoline enters oil: elimination of malfunctions

To understand why gasoline is in engine oil, you need to refer to the design features of various internal combustion engines.

Malfunctions in the engine engine, try to determine on our own

Spring has passed, arable work passed and you noticed that your metal horse was slightly clouded at the end of the plow. And ahead of the hilling, if there is equipment, or even a digging potato and much more. Let’s see if you should raise a panic or do it yourself.

Partly about the repairs of the walk.behind tractor and the cultivator, it was said in the article “The most common breakdowns in the walk.behind tractor and cultivator and how to eliminate them yourself”.

Typically, the engine on motor blocks is four.stroke, with air cooling, so I describe this option.

It has a fuel supply system in which a working mixture is prepared. The system consists of a fuel tank, fuel hose, carburetor and working hose.

There is a lubricant system, a crankshaft promotion system (starter). By the way, there are models that have starters working from the battery, that is, electric starters, there are models that have both an electric and manual starter.

The cooling system works using the impeller that drives the air to the engine. Ignition system. well, it gives a constant spark on the candle. There works a flywheel with a shoe that transform the force developed in Magneto into an electric one, which is supplied to the candle with providing a skirmish slip, which ignites that very working mixture.

Parsing of the breakdowns of a walk.behind tractor

We divide all breakdowns of the walk.behind tractor into two main parts: these are problems with the engine and problems with the rest of the nodes. The most common problems arise with the engine. And if you decide to start repairs yourself, take out your equipment with the scheme of your equipment. If not, try to find and download on the Internet.

In this article I will talk about the engine, the main malfunctions, the rest of the malfunctions in another boot.

Two types of malfunctions happen to the engine: the engine does not start at all and the engine does not work well, with interruptions, does not have enough power or stalls spontaneously.

Диагностируем первую проблему.

If the engine operates on gasoline, and there are more, we check the following positions:

Check the air damper. when we start the cold engine, the damper is closed;

Check the flow of gasoline in the carburetor. You can disconnect the fuel hose and check for free gasoline. If the stream is small or it is not at all, then the blockage is either a fuel filter or a tank cover air valve. In principle, by cleaning or changing the filter and valve, repair work can be completed.

If everything is in order, we check the ignition system, which begins with a candle check. Disconnect the wiring with the cylinder and twist it from the cylinder cover. If it is dry upon examination, then gasoline is not supplied. We previously found that he enters the carburetor without problems. Then the problem in the carburetor. It can be either a clogged jail or a filter or something else was polluted. To do this, remove the carburetor, disassemble. This is a difficult job, it is necessary to have a carburetor scheme.

If the candle is wet, then the fuel comes, but perhaps there is an excess of fuel, then it will not be started. To eliminate this problem, we block the supply of gasoline and dry the cylinder. Then, when the candle is removed, pump the engine with a hand starter.

Perhaps the problem is in the candle that was oxidized, then with the help of gasoline and thin sandpaper. we clean it with zero. We also pay attention to the size of the gap between the electrodes. According to the instructions, the gap should be within 0.8 mm, if not like that, we adjust. After all, we check the candle, pressing the metallic part to the cylinder cover and make a false engine launch as it were. If the candle is working, the spark will be normal for ignition. If we are weak or not at all, we change the candle. If there is no spark here, check the ignition coil, it is electronic. If it is not working, we change.

There may be a reason in the discharge of the battery, a burned fuse, a faulty starter. Just check everything in turn. The starter can either be repaired or change.

The engine works but bad

The air filter was clogged, there is little air, a mixture of gasoline with air is a predominance towards gasoline. Since the one.axic tractor works in conditions very far from sterile, clean the air filter more often. If this is a paper filter, clean it just tapping a solid object and blow it with a vacuum cleaner. It is blowing out, do not pull the air.

The filter made of foam rubber is washed with any liquid for dishes or car washing and dried. Mesh is blown with a vacuum cleaner.

There is a reason in gasoline of poor quality or some mixture that friends advised. Use the one recommended by the manufacturer.

Perhaps the reason is in the candle and in the gap between the electrodes, then we adjust according to the user’s instructions.

Check the muffler, perhaps it is scored by soot from exhaust gases. We disassemble the muffler, clean, rinse with gasoline. If the muffler in your structure is unlimited, we wash and dry with a hair dryer, you can also for hair. It is important, be sure to rinse with detergent at the end, water and gasoline after washing, dispose. This dozen and soot contain harmful substances, dry cleaning with particles inhalation is very harmful.

Close the hole when removing the silencer as a gag with a clean rag.

Perhaps incorrect work of the walk.behind tractor is associated with an incorrectly adjusted carburetor. If the instructions have a item about this, we adjust its adjustment. Cylinders and pistons can be worn out, you may need to replace the piston rings. When connecting to the opening from the candle, the compressometer and the turning of the starter shaft, check the compression. Ideally, it should be at least 8 atmospheres (we look again in the passport for the same tractor). If the engine has a decompressor, then the indication of the compressometer will be inaccurate. When indicating 5 atmospheres, it will be possible to say that it worked a decompression valve.

Diesel engine

In repair and diagnosis, it is more complicated than gasoline. And the point is not a special complexity of the engine or some conditions, but the fact that gasoline devices are much more common and we are used to them. I propose to see the table in the instructions that are equipped with almost all instructions for the operation of diesel motoblocks, which list the main causes of malfunctions and ways to solve them.

Preparation of the walk.behind tractor for launch

Difficulties with the launch of the engine can appear not only for a motor block and a cultivator who were used, but also from new ones that have just been purchased in a shopping center. For this reason, before starting a mini-tractor for the first time, you should read the instructions for it, then carefully examine all the connections and, of course, control the oil level in the internal combustion engine.

To study the annotation compiled by the manufacturer, it should be found in order to find out what operating circulation the engine is: four.stroke or two.stroke. This is importantly understood, since for modifications with a two.stroke engine (like a mole cultivator) a special combustible mixture is needed, consisting of a mixture of fuel and oil in a special proportion.

Due to the discrepancy between the fuel, the special equipment will make noise, and the candles of the fuse and the fuel pipeline can also suffer, which is fraught with the refusal of the gasoline pump, and this is already a direct way to expensive repairs in one hundred. Install whether fuel is suitable for motorcycles

, You can by smoke that appears. With poor fuel quality, it will have a white tone, as it happens with a strong tilt of the car.

The quality of fuel is also important for a diesel walk.behind tract. It does not start in the winter. or starts up, but soon freezes. if the summer diesel fuel is flooded in its motor, since at low temperatures it begins to thicken and clog the fuel stove.

Starting of motor vehicles both in the summer season and in winter should be carried out in the established order. For example, to launch the Mole brand motor.cultivator, this procedure for operations is carried out:

- open benzovran;

- Install the suction engine in a “chock” state (start);

- turn off the ignition and twist the engine several times with a hand starter starter;

- start the engine again and move the engine to the Run state (work).

, when the power apparatus easily starts, but after a couple of seconds it freezes. In this case, the patency of the sump should be controlled. If the reason is that the tap is littered, then it is cleaned with gasoline.

Start motor vehicles with a diesel engine

It will be somewhat more difficult. The diesel engine is starting with the “fuel” of the fuel path, that is, from the elimination of its accumulations. For this:

- open the fuel feed crane;

- unwind joints of the outlet channel before the occurrence of fuel;

- twist the joints and blow all the nozzles.

If after the operations the motor does not act properly, and the special equipment begins to smoke, then the reason is in the old lubricant, and it must be completely changed. The unit is not started and due to the missing volume of oil fluid, so do not forget to control this parameter.

or prolonged downtime also has its own nuances. In order to bring the unit to the working position, the following manipulations are done:

- open benzovran;

- conduct a check if food is enabled;

- check the availability of lubrication;

- give gas up to about half.

Before acting, the motorcycle equipment is checked, including transmission sections, clutch, launch mechanisms, and for need to be adjusted.

Start of gasoline and diesel unit

Equipment is equipped with gasoline or diesel engines. Starting a diesel engine

and the gasoline apparatus has differences. For this reason, analyze the factors because of which the unit is not started, follows for each specific type of motor.

, The training of special equipment is carried out. It is necessary to make sure of the presence of absolutely all elements, make sure of the strength of the mounting of the mechanisms.

Mechanisms often refuse to work after winter. A long break becomes a prerequisite for the occurrence of problems in the systems of the walk.behind tractor. Preservation in a cool and wet room leads to the following faults:

Abstract absolutely all compounds, clutch, reverse and gas cable. You can not turn on the device if there are clamps and twisting of the thread threads.

During the first launch, the level of oil in the crankcase is certainly checked. Lack of lubrication will spoil the piston group. The crankshaft spin up to 1,400 turns per minute at idle. Enough a couple of seconds for creating a bunker on the plane of the cylinder.

Old oil can be the cause of a non.working engine. At the same time, the one.axine tractor smokes white gas gases. Absolute oil change suggests itself.

It should be taken into account that a mini-tractor is poorly started with a missing oil volume. Follow this parameter before

, how to start a carburetor and diesel uno.based tractor. In certain modifications, defense is determined by low level. The device blocks the launch and the unit freezes.

Do not forget that any type of motor requires gasoline of a particular brand. For a two.stroke engine, fuel is prepared separately. The fuel mixture consists of fuel and oil. The number of ingredients is maintained in strict balance.

Why not start a cultivator?

The main reason due to which the equipment is not started is the presence of old oil in the crankcase. White smoke emanating from the exhaust system will talk about this. To solve this problem, you will need to completely drain the old oil and clean the carburetor. After that, you need to fill in a new lubricant.

Often the cultivator does not start due to lack of oil in the crankcase. Before launch, the farmer is obliged to check the amount of the composition inside the tank using the probe. Sometimes cultivators are equipped with special protection, which automatically works with a lack of oil. In these cases, a special sensor gives the command to block the launch, which is why the motor is instantly stalling.

When using the technique, you need to remember that each model cultivator works on gasoline of one specific brand. To refuel a 2-stroke ICE, for it you need to prepare in advance the fuel mixture. In this case, the proportions indicated in the operating manual for the equipment should be adhered to.

To extend the terms of the application of the cultivator, only clean fuel should be used to refuel it. The working resource of the piston group of the engine and the carburetor of the equipment depends on the presence of harmful impurities in it.

DIY cultivator repair

Very often farmers fail to start a cultivator due to air entering its fuel system. If after several attempts the technique has not started, then you need to steal the remaining air from the structure.

To get rid of air excess, it is necessary to open the fuel supply crane, as well as promote all bolted fuel mounts. After that, you need to blow the nozzles. To do this, you can use a spaced span.

If even after that the cultivator does not start, then you need to inspect other details of the technique.

Particular attention is paid to such nodes:

- Air filter-due to strong clogs, it may not let air into the carburetor;

- The tank cover. if a cork has formed on it, then the defect will need to be carefully removed;

- Fuel supply channel. due to the regular use of the cultivator, the hoses are very clogged. In this case, the channel must be removed and blowing it with compressed air;

- carburetor. this part of the equipment is constantly working with fuel. Due to the poor-quality fuel, a carburetor forms on the walls of the carburetor, which must be regularly removed;

- The exhaust system. on the inner walls of the pipe, the black carpet gradually accumulates, interfering with the normal work of the cultivator;

- The cylinder-piston group-the walls of this part of the engine should be perfectly smooth. If the slightest defects appeared on them, this will lead to a major breakdown. In this case, you will need to completely change the piston group of the cultivator motor.

Often the cultivator cannot be made due to the malfunction of the spark plug. To inspect the part, it must be unscrewed using the key. If a carpet formed on its surface, then the farmer added too much oil to the fuel mixture. To fix the problem, you need to clean the candle and screw it again. If even after that the cultivator does not start, then the candle will need to be replaced with a new part.

The owners of the cultivators SUNGARDEN, Texas and Neva are faced with all the above causes. They have almost the same design, so repairs for each cultivator will be carried out in a similar order.