trimmer for grass what gap on the coil

The most vulnerable element of the carburetor engine is the spark plug. This also allows us to judge the possible causes of the failure of individual nodes of the gasoline engine. The following procedure is recommended.

The gap should be adjusted when installing a new electric module on a magnetic engine. The optimal distance between the flywheel and the ignition coil for most chainsaws is 0.2-0.4 mm.

With such a small gap, an accessible measuring device cannot be used for direct measurement. In practice, Husqvarna saws are used, cut out of thin and flexible sheet material of the desired thickness. When it is installed, it is clamped in the space between the flywheel and the reel, and then removed.

To avoid ignition adjustment, use the tool carefully, avoiding blows. In particular, this applies to chainsaws with electronic chips in the ignition system, since they are very sensitive to mechanical damage

Settling of the ignition on the trimmer. How to set a ignition on a benzoca

On gasoline trimmers, both two.stroke internal combustion engines (ICE) and four.stroke. But the ignition system there is no different from each other, so the repair and configuration of this complex of accounting programs for ignition of fuel will be identical to different types of internal combustion engine.

The ignition system of a two-stroke ICE consists of 2 parts: flywheel and coils (magneto). The figure below shows how they look.

There is a impeller on the flywheel, which works like a fan for cooling a motor. There are also permanent magnets on one side of the flywheel, the figure is shown by the arrow.

When the flywheel rotates in the coil, an electric current is produced, which serves for a spark on the spark plug. The spark appears at the moment when the magnets are directly under the magneto.

From time to time when the engine does not start, the ignition adjustment will be necessary. Naturally, first you need to check the serviceability of a candle and a high.voltage cable with a cap.

It is necessary to adjust the ignition on a two.stroke engine to ensure timely ignition of fuel in the combustion chamber of the motor. Below is a scheme, you can understand the principle of operation of the internal combustion engine.

The spark in the candle should appear at the time of compression of the fuel piston, when it does not reach the top of the upper dead point (VMT) more than the best. When the piston passes through the VMT, the fuel mixture is ignited, under the influence of which the piston goes down under the action of the energy of the explosion.

If for at least any reasons (to a greater extent this is due to the shift of the flywheel to the shaft relative to its starting position), the fire of fuel occurs earlier than the piston passes, then it will come back, and the crankshaft scrolls in the opposite direction. Such a movement can damage the starter knot, cut off the launch cord, etc.D. Then there is an early ignition of fuel.

Also, you will like a later ignition on the trimmer more for you: the piston after compressing the fuel, which did not ignite, goes down, and in this case there is a spark. Then the engine will either not be launched or significantly lose power and will be poorly gaining momentum.

But such tasks with early or late ignition on two.stroke ICE are quite found from time to time, because the flywheel with magnets is already established in the correct position, which is completely synchronized with the movement of the piston. In addition, the flywheel is fixed on the shaft using a key and nut. Therefore, the wrong installation of the part is excluded.

For the most part, the ignition adjustment is to set the correct gap between the magneto and the flywheel.

Magneto is the main detail in the ignition system of the motor and is a coil with primary and secondary windings located around the core. Often, due to the malfunction of the magneto, the spark on the spark plug disappears, and the fuel ignition does not occur. To check the coil, it will be necessary to use the tester, and fulfill the following acts.

- On the tester, going into the resistance measurement mode, you need to set 200 Ohms. In this way, the primary winding will be checked.

- Connect one tester electrode to the “mass” of the coil, and the 2nd-to the contact emerging from the magneto. Normally, the resistance will be from 0.4 to 2.7 Ohm.

- To check the secondary winding, it will be necessary to install the device switch by 20 kOhm. Further, one probe of the device is inserted into the cap of the candle, and the 2nd-is connected to the “mass”. Normally, the properties of resistance should be in the range from 4-6 kOhm and above (depending on the model).

When a circuit is broken, the device will show infinity, and when close. 0 (zero).

The first way

You can check the work capacity of the magneto using a tester. To do this, you need to perform such a sequence of actions.

- True tester: use the resistance measurement function and set 200 Ohms to remove measurements of the primary winding.

- The 1st electrode of the measuring device is put on the “mass” of the magneto, and the 2nd-to the output contact. If the primary winding is working, the characteristics should be from 0.4 to 2 Ohms.

- Install the tester switch by 20 kOhm to diagnose the secondary winding. Then bring the 1st probe into the cap of candles, and the 2nd-to the “mass”. If everything is in order, the characteristics will diversify from 4 to 6 kOhm, depending on the model of the trimmer for the grass, whether it is Patriot 547, Husquarna 128 R or a technique of another brand. If the chain is cut off, the infinity value appears on the tester display. And if there is a short circuit, zero will be displayed on the screen.

Why do I need ignition control

In some cases, when the engine does not start, ignition control will require. Of course, you must first check the condition of the spark plug and a high.voltage cable with a lid.

The ignition control on a two.stroke engine is necessary to ensure timely fuel ignition in the engine combustion chamber. Below is a scheme from which you can understand the principle of operation of the internal combustion engine.

The spark in the spark plug should appear when the fuel is compressed by the piston, when it reaches the upper dead point (VMT) slightly. Когда поршень проходит ВМТ, топливная смесь воспламеняется, в результате чего поршень падает под действием энергии взрыва.

Therefore, if for any reason (mainly due to the shift of the flywheel to the shaft relative to its starting position), the fuel is ignited before the piston passes, it departs, and the crankshaft rotates in the opposite direction. This movement can damage the starter node, cut the starter cord, etc. D. In this case, this occurs early ignition of fuel.

It can also be later ignition on the trimmer: the piston after compression of the fuel, which has not caught fire, goes out, and at that moment a spark appears. In this case, the engine will either not start or significantly lose power and will not gain momentum.

But such problems with early or late ignition on two.stroke internal combustion engines are quite rare, since the flywheel with magnets is already established in the correct position, which is perfectly synchronized with the movement of the piston. In addition, the flywheel is attached to the shaft using dowels and nuts. Therefore, the wrong installation of the part is excluded.

In fact, ignition control is to establish the correct clearance between the magnet and the flywheel.

The magnet is the main part of the engine ignition system and is a coil with the primary and secondary windings located around the core often due to a faulty magnet on the sparkling candle disappears, and the fuel does not heat up. To check the coil, you need to use the tester and perform the following actions.

- On the tester, switching to the resistance measurement mode, you need to set 200 Ohms. This will check the primary winding.

- Connect one tester electrode to the “grounding” of the coil, and the other. to contact leaving Magneto. Usually the resistance should be from 0.4 to 2 Ohms.

- To check the secondary winding, you need to install the device switch by 20 pcs. Next, one device of the device is inserted into the cap of the candle, and the second is connected to the “Earth”. Typically, resistance should be within 4-6 pieces and higher (depending on the model).

When the circuit is opened, the device will show infinity, and with a closed. 0 (zero).

If you do not have a tester, then you can use the following method with great caution so that the electrode does not touch the cylinder, otherwise the coil will burn.

When you need adjustment

It is necessary to adjust the ignition system so that the fuel is ignited at the right time in the combustion chamber.

Important! Когда поршень сжимает горючее и практически достигает мертвой точки сверху, в свече возникает искра. Further, when it passes the maximum upper point, the fuel is lit up, as a result of the explosion, energy forms and directs the piston down

If the flywheel is shifted to the shaft relative to its original position, the fuel is ignited faster than the piston overcomes the upper dead point. As a result of this, the piston moves back, and the crankshaft rotates in the opposite direction. You can determine the early fire of the fuel by a broken launch cord, a broken starter node or other breakdowns.

Sometimes ignition is late. The piston compresses the irreparable fuel, and then goes down, and only then the spark forms. As a result, the engine either does not work or its power is reduced, and the speed is gaining much slower.

Typically, a flywheel with magnets is installed in an ideal position, as if coordinated with the operation of the piston, and in order to avoid displacement, it is carefully fixed. This allows us to say that an incorrect installation of a part is impossible. But if the shift of the flywheel is a confirmed fact, then it is a failure or accident. Thus, the installation of the moment of the ignition is not required, since problems with early or late ignition of fuel happen very rarely.

Important! It is very simple to regulate the ignition system. There is no need to calculate the ignition angle angle

The maximum that you need to do is to properly set the gap between the flywheel and the reel.

Typical malfunctions

Before starting the ignition of the trimmer for the grass, you need to cut off other probable causes of breakdown and make sure that the problem is really in this node. For this, it is necessary to carry out a number of actions in the following sequence:

- inspect the ignition coil body for damage and defects;

- make sure that there are no pollution on all nodes and elements conducting current;

- check the integrity and isolation of the wiring, contacts, the strength of the fastening, the presence of rust at the joints;

- inspect the candle cap, as it regularly breaks away from the high.voltage wire, and they try to restore it manually, and any unreliable connection lowers the power of the electric arc of the candle;

- check the candle, since the quality of modern gasoline very quickly disables this part, but there is another possible problem. the candle is wet;

- make sure the circuit switch is working.

By excluding all possible malfunctions, you can proceed to adjust the ignition of the coil.

The second method

If you use the tester, there is no other way to check

At the same time, it is important not to touch the cylinder electrode, otherwise the coil will be damaged

- It is necessary to remove the cap from the spark plug. You should not unscrew the candle, as this will save compression.

- Then you need to choose a nail with a remote hat and tightly insert it into the cap.

- Further, the cap with a nail should be reliably tied to the cylinder by the dielectric. In this case, the electrode should be at a distance of 5.5-7 mm from the cylinder body, but do not touch the mass.

- Then the starter needs to simulate the start of the motor with the ignition button. In this case, it is required to carefully monitor whether the spark will appear, and try to determine its color.

Important! A strong spark of white or with a blue shade indicates in favor of the serviceability of magneto. If it is weak, as well as orange or yellow, magneto is damaged

There is one important point that needs to be taken into account when diagnostics: uninhabited magneto in any state can form a powerful spark. However, if it is faulty, then, heated, stops creating a current, and the trimmer does not start for the grass. Later, cooing, the coil again returns to the working level, the unoic tractor turns on and for some time works at idle or under load, until the magneto temperature rises again. In this case, the part needs to be changed for a new.

On a note! In a number of situations, the problem with heating does not occur due to the fault of the coil, but due to the spark plug. This means that the test must be subjected to both parts.

Settling of the ignition on the trimmer

On gasoline trimmers, both two.stroke internal combustion engines (ICE) and four.stroke. But the ignition system in them is no different from each other, so the repair and adjustment of this fuel ignition system will be the same for different types of internal combustion engine.

How the ignition system operates on the trimmer

The ignition system of a two-stroke ICE consists of 2 elements: flywheel and coils (magneto). The figure below shows how they look.

There is a impeller on the flywheel, which works like a engine cooling fan. There are also permanent magnets on one side of the flywheel, the figure is shown by the arrow.

When the flywheel rotates in the coil, an electric current is produced, which serves for a spark on the spark plug. The spark appears at the moment when the magnets are directly under the magneto.

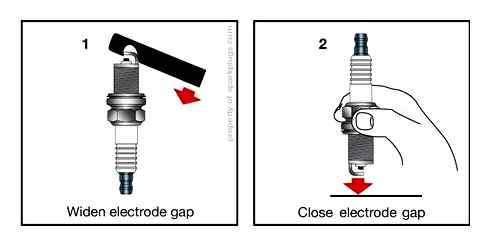

What is spark plug gap? [TECH BIT TUESDAY]

Why is the ignition adjustment

In some cases, when the engine does not start, the ignition adjustment will be required. Of course, first you need to check the serviceability of a candle and a high.voltage cable with a cap.

It is necessary to adjust the ignition on a two.stroke engine in order to ensure timely ignition of fuel in the engine combustion chamber. Below is a scheme from which you can understand the principle of operation of the internal combustion engine.

The spark in the candle should appear at the time of compression of the fuel with a piston, when it does not reach the upper dead point (VMT) at least a little. Когда поршень проходит ВМТ, происходит возгорание топливной смеси, в результате чего поршень под действием энергии взрыва уходит вниз.

Therefore, if for some reason (mainly this is due to the shift of the flywheel to the shaft relative to its original position), the fuel fire occurs earlier than the piston passes, then it returns back, and the crankshaft scrolls in the opposite direction. Such a movement can damage the starter knot, cut off the launch cord, etc.D. In this case, an early ignition of fuel occurs.

There may also be a later ignition on the trimmer: the piston after compression of the fuel, which does not ignite, goes down, and at that moment a spark appears. In this case, the engine will either not start or significantly lose power and will be poorly gaining momentum.

But such problems with early or late ignition on two.stroke ICE are quite rare, since the flywheel with magnets is already established in the correct position, which is perfectly synchronized with the movement of the piston. In addition, the flywheel is fixed on the shaft using a key and nut. Therefore, the wrong installation of the part is excluded.

Basically, the ignition adjustment is to set the correct clearance between Magneto and the flywheel.

How to check the serviceability of magneto

Magneto is the main detail in the engine ignition system and is a coil with primary and secondary windings located around the core. Often, due to the malfunction of Magneto, the spark on the spark plug disappears, and the fuel ignition does not occur. To check the coil, you will need to use the tester, and perform the following actions.

- On the tester, going into the resistance measurement mode, you need to set 200 Ohms. In this way, the primary winding will be checked.

- Connect one tester electrode to the “mass” of the coil, and the second. to the contact emerging from the magneto. Normally, resistance should be from 0.4 to 2 ohms.

- To check the secondary winding, you need to install the device switch for 20 kOhm. Further, one probe of the device is inserted into the cap of the candle, and the second is connected to the “mass”. Normally, resistance indicators should be in the range from 4-6 kOhm and above (depending on the model).

When a circuit is broken, the device will show infinity, and when close. 0 (zero).

If you do not have a tester, then you can use the following way, showing more accuracy so that the electrode does not touch the cylinder, otherwise the coil will burn out.

- Remove the cap from the candle. You do not need to twist the candle to save compression.

- You need to insert a nail without a hat into the cap. The nail should be of such a diameter to hold well in the cap.

- Tie the cap with a nail to the cylinder using the dielectric, so that the gap between the electrode and the cylinder body is in the range from 5.5 to 7 mm (but in no case touch the “mass”).

- Using the starter, make an imitation of engine starting several times. The ignition button should be enabled.

- Watch whether the spark appears and what color it has.

Primary checks of the ignition system.

Ahead of time, before testing the ignition module, check the properity of the subsequent parts of the chain:

- Candles and switch

- The condition of the candle cap: should be tightly attached to the candle, the high.voltage wire is aggressively fixed and does not even fly out of the cap and coil, the matteral of the cap does not contain cracks

- The high.voltage wire is not damaged over the entire length, the contacts and connections of the wires are dense and do not even have traces of corrosion

- visually evaluate the absence of cracks and visible flaws on the reel body

- pollution of conductive parts and nodes remove

- By the ability, change refueling: you will like gasoline bad

The meaning of these actions is to exclude the elements of the chain from the list of probable defects to our client, not counting the coil. If our client remains in order to move on.

Most modern models of chainsaws and trimmers for grass do not require installation of ignition time. This angle is determined by the position of a special groove on the flywheel for the key groove to the crankshaft and magnets installed on one flywheel.

It is only necessary to correctly install the gap between the flywheel and the ignition coil. Depending on the model of the tool, the gap can be different. This is usually 0.2-0.4 mm. Since the flywheel is round, the usual automobile probe will not work for this purpose. It would be technically reasonable to expose the gap with a special template.

But it can not always be purchased. The acquisition of such an expensive template for one.time use is unreasonable. Instead of a corporate template, you can use a strip of plastic bottles of water. Cut the strip from the bottle in a place where there is no embossed embossing. Then the actions to install the clearance are approximately the same for the chainsaw and trimmers:

- Loosen the ignition fastening bolts.

- Direct the magnets on the flywheel to the ignition coil

- Clamping the flywheel between the flywheel and the coil, tighten the fasteners.

- Remove the strip

- Scroll the flywheel 360 degrees several times, making sure that it does not cling to the reel anywhere.

All. The gap between the coil and the flywheel is installed.

is impossible and impractical. Below is a list of ignition coils that can be purchased on our website

What is the resource of candles

The spark plugs relate to consumables, that is, they obviously have a smaller service life than that of the chainsaw. Technologically, it is considered the service life of the spark plug for chainsaws. 100 mothers. After this period, it is recommended to change it. In practice, this period can be significantly higher or lower. Above the following conditions:

- When working, high.quality gasoline and oil are used;

- There was no critical overheating of the engine and overwhelming a candle;

- The gap, normal electric arc (spark) is correctly exhibited;

- Prevention measures were taken: “zero” shared contact between the central and lateral electrode, and pollution inside the candle was removed.

On the contrary, they reduce the service life of a candle of poor.quality fuel, overwhelming, pollution. The wrong gap leads to the fact that too long or short arc accelerates the electrodes (electric welding effect).

How and how to lubricate the shafts in the rod of motorcycles

Many new motorcycles, even sold in collection, do not have a lubricant on the shaft of the bar. As a result, it warms up, wears out, a light whistling rattle is gradually added to the sound of a working motor and vibration appears. To protect the technique from premature wear, it is enough to devote 10 minutes and just grease the shaft.

Materials:

First you need to disassemble the bar. In a conventional benzos, it is enough to disconnect it from the upper and lower reducer for this.

If a braid for grass has a collapsible bar, consisting of two parts, then it is even easier. It is only required to remove the connecting coupling in the center and dilute half.

If the braid for the grass has already worked, then when examining the shaft, or shafts in the case of a collapsible bar, you can notice scuffs from the central bushings. Such places and need lubrication.

A small amount of lubrication must be squeezed on a rag or fingers and process the shaft without passes. It is applied with a non.weed layer, but everywhere. Particular attention should be paid to the slots, since they are on the highest load, especially at the time of the knife of the knife braid for grass on stones and other objects.

The greased shaft is inserted back into the stack with a slight scroll. Thanks to this, part of the extra lubricant will remain on the central bushings, where it should be. Rotation will also help the hills to get into their seat on the gearboxes.

If a straight lawn mower with a non.vegetable bar is served, then it is simply attached back to the gearboxes. In the case of a two.part bar, short shafts are inserted into each half. After this, part of the rods join the center. If their slots did not hit, then you can simply twist your lower gearbox with your hand. Further, the jointed rod is clamped back with a coupling.

If the lawn mowing is inflow, such a rod maintenance should be carried out every season. The cord’s lubricant used well withstands high temperature, which excludes oil stoops with long operation of braids for grass. The same composition can also be used for lubrication of gearboxes. In them it can be pressed with a syringe if the tube does not have a nose. The lubrication frequency of gearboxes is higher than the shaft. Typically, manufacturers recommend this every 5 mothers.

How to choose a candle of ignition for a trimmer for grass

On gasoline trimmers, both two.stroke internal combustion engines (ICE) and four.stroke. Alas, the ignition system there is no different from each other, because the repair and adjustment of this accounting system of ignition of fuel will be similar for various types of internal combustion engine.

The ignition system of a two-stroke ICE consists of 2 parts: flywheel and coils (magneto). The figure below shows how they look.

There is a impeller on the flywheel, which works like a fan for cooling a motor. Also on one side of the flywheel are unchanged magnets, in the figure are shown by the arrow.

When the flywheel rotates in the coil, an electronic current is produced, which serves for a spark on the spark plug. The spark occurs just when the magnets are specifically under the magneto.

Sometimes, when the engine does not start, the ignition will need to be adjusted. Of course, at first it is necessary to check the serviceability of a candle and a high.voltage cable with a cap.

It is necessary to adjust the ignition on a two.stroke engine in order to ensure timely ignition of fuel in the combustion chamber of the motor. Below is a scheme from which the mechanism of operation of the internal combustion engine can be understood from.

The spark in the candle should appear at the time of compression of the fuel piston, when it does not reach the top of the upper dead point (VMT). When the piston passes through the VMT, the fuel consistency is ignited, and as a result, the piston goes down under the influence of energy of the explosion.

If, for any reason (in the main thing, this happens due to the shift of the flywheel to the shaft relative to its initial position), the fire of fuel occurs earlier than the piston passes, then it is fraught with back, and the crankshaft scrolls in the revolutionary direction. Such a movement can destroy the starter node, cut off the launch cord, etc.D. In our version there is a premature ignition of fuel.

Use a screwdriver unscrew 2.4 bolt (one hundred percent should not be twisted), holding the magneto. Turn the flywheel with such a makar so that the magnets are upstairs. Further, in order to correctly set the best gap with a flywheel and coil, use an ordinary visit or a calendar. If you have neither one nor the other at home, then to configure the ignition, use a sheet of A4 paper, turning it twice (ultimately, you will get a 4.sheet thickness). This thickness will be enough to get the best gap and adjust the ignition. Stuck a business card or paper between a coil and magnets. The magnetic field will pull the coil to the flywheel. Holding the magneto with your fingers in this position, tighten the bolts holding it. Give a business card. After that the ignition on the trimmer will be adjusted.

How to assess the condition of the candle visually

The first sign of a candle failure can be found immediately, without even twisting it from the cylinder. a dark belt on a white insulator right above the turnkey hexagon. This means that the candle has lost tightness, and combustion products break to the surface. Such a candle must be replaced immediately and without options.

Nagar rating

It is generally accepted to assume that with normal operation of the entire ICE and the candle there should be a coffee-chocolate-colored carpet on it. However, this is not always the case. Nagar of this color appears only at high temperatures and after a certain time of continuous operation.

For example, if you saw thick logs at high speeds for about an hour, then there may be a carcass of this color on the candle. And vice versa, the chainsaws will start quite normally and work for some time at small speeds.

If I drank for some reason, you can turn the candle and see that it is a little wet from non-burning fuel and dark. However, this is by no means an indicator that it was the candle that failed.

Promotization of a candle

In addition to ignition of fuel, the spark plug performs another passive function. ensures the tightness of the combustion chamber, without which the working compression is impossible and the normal operation of the engine is impossible. Depressurization is evidenced by the appearance of a dark belt on the insulator, as mentioned above.

Depressurization occurs exclusively with mechanical destruction. That is, the candle is a candle is cracking or even falling apart. The prerequisite for this may be both defects in manufacture and extreme operation with strong overheating and sharp cooling. For example, when working in severe frost, the candle is first hot. The engine is jammed, the candle cools sharply. If the cycle is repeated, the insulator may not withstand.

The same can happen when water gets or when hit.

Nar between the electrodes

Freight is formed for the following reasons:

- non.combustible impurities in poor.quality gasoline;

- undesirable components in poor.quality (fake) oil;

- Dust entry through a poor.quality air filter;

- low combustion temperature with a long operation of an unheated engine at idle or in the cold;

- Problems with exhaust gases.

In a word, the poor work of the candle cannot be the cause of the carbon. On the contrary, soot can cause problems in the work of a candle. If it is formed between the electrodes where the spark arises, then it can work as an isolation gasket and the spark will disappear. That is why the contact in this place is recommended to be carefully cleaned with sandpaper-nulevka after 50-70 mothers or when soot occurs.

Another weak place of candles is an internal gap in the circle between the insulator and the iron body carrying “minus”. If it is clogged with conductive mud or soot, then the closure of the plus and minus can occur not between the electrodes, but inside the candle case.

About the formation of a soil between the electrodes of the candle and the connection of an undesirable result with the quality of the fuel mixture are told in

Cliff of the central electrode

Among normal candles, such a defect is extremely rare, that is, almost never. It means that the candle just fell apart, but they did it unknown where and how.

The central electrode is a whole copper rod flooded with ceramics of the insulator. During the operation of the chainsaw, there are no loads and efforts that can somehow stretch or press on this rod. That is why you need to hardly try to make the light of the ignition so that the central electrode breaks off it.

What are the spark plugs on the Champion grass trimmer

GALLLOL number (characterizes the operating temperature of the candle).

Examples of using candles with different viburnum numbers:

YCC. configuration and type of electrode (CU. copper core, pt. platinum coating, if not indicated. standard electrode)

gap between electrodes.(all sizes are given in mm; none. without marking)

Distribution of Champion sports candles in the dimensional range

Champion spark plugs. characteristic signs.The service life of lights of ignition. fakes will be shorter than the service life of the original Champion products. Low quality products significantly worsen the operational capabilities of the car. The calibration number of candles-fakes undoubtedly does not correspond to the potassium number of original champion candles. The side electrode of a fake spark plug can easily break off and disable the entire engine.

one. The insulator must be a cream-white snow-white insulator may indicate a fake.

The chopper of the insulator must correspond to the image.2. The metal champion melting case is made by the cold hood, so its surface has a uniform dull gloss of the cloth of the fake candles is obtained by turning, which gives it a characteristic sheen and can be determined to the touch.3. A sloping roller is applied on the CHAMPON.four. Champion candles have higher corrosion resistance than candles of other manufacturers. Fake candles corrode much faster.5. On the welded connection of the side electrode with the candle body, the seam is almost invisible. rough seam cleaning indicates a fake.

Package.Each original packaging should contain the Champion and Opera logo. if other signs are applied on the package on a characteristic white background, which has the form of a “bow”, then this is a fake.Since 2000, packaging will be produced with the Federal Mogul logo.Always check the bar the code on the package. it should start with numbers 50 10 874 weeks Champion presented a new high.quality packaging on the market. the samples are presented in the photo. The graphic power supply is specially performed very difficult-in order to complicate the task for the manufacturers of fakes.

Candles for trimmers

The spark plug tester 42-087 will allow you to check the spark plug and check the presence of ignition problems before replacing any parts.

Product information

Analogs: Champion RCJ6y; Bosch WSR6F; NGK BPMR7A, BRISK PR15Y.

Suitable for Stihl and Husqvarna, Echo 3050, 3500, 350WES.Universal candle 77-307-1 is suitable for the more chain and trimmers.

The distance between the electrodes: 0.6 mm;

How To Use a Spark Plug Gap Tool. Video

Suitable for chainsaws and benzosos Stihl and Husqvarna.

The spark plug of Oregon is specially designed for use in chainsaws, benzotrimers and lawn mowers. They work very reliably in incomplete load mode, as well as at maximum speed, which is one of the main requirements.Special design provides durability and high vibration resistance.

Spend of the ignition for 2-clock engines Oregon 77-307-1 are produced in accordance with the requirements of ISO/TS 16949: 2002.

What kind of ignition gap should be on the chainsaw?

The average is considered to be a distance equal to at least 0.2 and not more than 0.4 mm. In case of violation of the correct gap, the base ignition system will not be able to generate the spark required for timely instant ignition of the refueling fuel mixture in time.

The candle is universal. Used in chainsaws and motorcycles of all models. Candle thread diameter 14mm. Gap between electrodes 0.8 mm.

What is the ignition gap on the chainsaw of Stihl 180?

Pay attention to the gap between the flywheel and magnets. If the magnets are absent or do not correspond to the original form. this suggests that the destruction of the flywheel has begun and it should be replaced. The optimal gap between the flywheel and magnets is 0.3-0.5 mm.

Connect the tester or control lamp to the “mass” and to the output of the ignition coil, connected by brown-red (usually not necessarily) wire with the terminal “1” of the switch. With a good switch, the tester arrow, included in the voltmeter mode, will deviate, and the lamp will light up (the ignition is turned on).

The lawn mower starts poorly? Adjust Magneto’s gap

As the experience of operating benzos, in particular Chinese production shows, they often have problems in the launch system, so they are often difficult to start. Problems are usually related to the flywheel magneto.

For those who are unfamiliar with this unit, we remind: this system consisting of ignition coil, spark plugs and flywheel with magnets. We have to deal with the clearance of Magneto, more precisely, with the gap of the ignition coil and its guaranteed exhibition. It is because of it that problems arise in Chinese units, which for several years were operated in domestic conditions or in the conditions of the Housingire. But it happens that even in new products it is difficult to start, especially for cold. And in this case, usually problems with the launch are related to the gap of magneto. Most people who operate the lawn mowers expose the Magneto gap of 0.4 mm, as recommended by many manufacturers. What will happen if this gap is adjusted and set 0.25 mm? It turns out that when it is reduced, the electric spark becomes thinner, smaller and practices every beat even with slow speeds of the Magneto flywheel.

That is, consciously reducing the gap, we thereby increase the likelihood of a normal launch of the lawn mower without any excessive physical exertion and shortness of breath even when starting a cold engine.

Gap and procedure for its exhibition in different cases

As a template, a strip of the required width and length carved from a conventional plastic bottle, for example, from under Pepsi-Cola, can be successfully used to put a gap of magneto.

It is only necessary to install it last, so as not to damage when carrying out repair work, using the same hair dryer for any purpose. After all, if it is crumpling from the effects of hot air, then there is no need to talk about the accuracy of the gap of Magneto. It is with the help of a spacer carved from a plastic bottle that you can with high accuracy set the Magneto gap 0.25 mm, since its thickness is exactly the same. To make sure of this, it is enough to fold the strip four times and measure its total thickness with a caliper, which will be exactly 1.0 mm. We put a spacer cut from a plastic bottle on the magnets of the Magneto flywheel, set the ignition coil in place and fix it with strong bolts of 8 by 8, after filling the holes with a thread on the case with a threaded latch.

We apply it on the bolts, twisting which, you must not forget to fix the terminal of the mass. It is better to use an electric screwdriver at the same time. We squeeze the bolts with a regular hand screwdriver with a hexagonal bat to the limit, since the use of a M-shaped hexagon can lead to a breakdown of the faces of bolts.

It remains, turning the flywheel with magnets, remove the plastic spacer and, continuing to rotate it, check the quality (uniformity) of the clearance when it turns from 0 to 360 degrees, which, with this approach, is ideal. Some use the Magneto’s gap folded by half a photochex leaf, which is also permissible, but the use of a spacer from a plastic bottle gives the best result. over, it can be used reusads dozens of times.

It remains only to install body parts and you can run the engine to test how it starts and works. Sometimes during operation, the ignition reel reels are deformed to the magneto housing, which does not allow you to reliably install it, since the holes in the coil and on the engine body do not coincide.You can, of course, try to straighten out the defect, but it will be more reliable to put a new coil, especially since it is not too expensive.All further actions are similar to the above case, unless the heads of fastening the spark plots can not be under the hexagon, but for the wrench and the cross.shaped screwdriver. But this does not change the essence of the matter: the tightening of these bolts should be guaranteed to be reliable, as in the first case. To evaluate the quality of the work done, it is necessary to make sure there is a spark between the electrodes of the candle visually after the final assembly of the engine. To do this, we connect it to the mass and begin to turn the engine using the starting device of manual or electric. The check for the spark has one nuance. If you sharply pull behind the kicks starter, then the spark will appear even with slightly faulty magnets of magneto and even completely non-working ignition coils. In this case, the presence of a spark is not yet an indicator of the serviceability of the ignition system.The quality of sparking can only be judged by its appearance, when the flywheel Magneto does not rotate too quickly, for which the kicks starter should not be pulled, but evenly and not to pull.

Only in this case, the engine of the benzotrimer or chainsaw will be started without problems, both in the morning and throughout the entire working day (respectively, the so.called hot or cold launch). If there is no spark with a slow movement of the starting device, then, most likely, you will have to change the ignition coil, set the gap of magneto or change the candle.The practice of putting a gap on benzos and chainsaws described above for five years has justified itself completely. There have never been complaints from users after such a repair. This really helps when starting not only Chinese gasosos, but also European and even branded. At all units, regardless of the manufacturer, putting the Magneto clearance 0.25 mm instead of 0.40 mm recommended by manufacturers, gives excellent results. Some people offer gaps 0.10-0.15 mm, but this. After all, there is a certain thermal expansion of the parts of the ignition system, the housing itself, the gas mower or chainsaw crankcase, and such a small gap can disappear altogether, which can lead to breakdowns (burning out), first of all, the ignition coils. Therefore, a gap of 0.25 mm is from all points of view optimal.