The nozzle on the angle grinder for sanding wood. types and application

angle grinder, as a versatile tool for the home craftsman or professional, is used in carrying out a variety of operations for cutting materials, sanding, peeling various surfaces, etc.д. Sooner or later, every owner of this tool asks the question: can the angle grinder work on wood, and what attachments are needed for this?

The angle grinder is a very extensive range of tools in one class, called an angle grinder (angle grinder). The device can have a huge power and work with a disc of 230 or more millimeters. Or feature compact dimensions and modest abrasives of 115 mm.

The disadvantages of a large and heavy tool are obvious: it is difficult to work for a long time. It also requires a great deal of skill and experience to accurately machine wood. It is elementary difficult for a novice craftsman to control a massive and powerful angle grinder. However, with a large processing area or the need to remove a significant amount of material, such an angle grinder is very good.

Small angle grinder also has disadvantages. Its disc diameter to body size ratio does not allow for hard-to-reach areas. In addition, it is difficult to select a large volume of material with such a tool because of low power and overheating.

Many craftsmen for working with wood prefer an angle grinder with a disc diameter of 125 mm. It is explained quite simply:

- this class features angle grinders in a wide range of operating power;

- easy to select a tool with comfortable size and weight;

- there are many accessories and attachments on the market, designed for a standard 125 mm disc seating hole.

In addition, the average power angle grinder provides relative safety for beginners. It will not make you get tired quickly, allow you to more accurately control your movement, reduces the likelihood of rejects on valuable parts.

Some general information

Angle grinder or angle grinder, more commonly known as an angle grinder, is a versatile tool for a variety of tasks:

- Coarse and fine sanding of wood;

- Polishing, sanding surfaces;

- removal of bark, sawing off branches from trees;

- Sawing boards, chipboard, fiberboard, logs.

This richness of tasks to be solved makes the angle grinder the most versatile of all grinders. It is called angular because the axes of the motor and the working wheel are placed at right angles to each other, unlike machines with a right angle.

In this case, the angle grinder. a tool for periodic work around the house, small repairs, replacement flooring. The use of the attachment discs allows you to cut, sharpen, grind workpieces. For regular work with wood, stream production in order to earn money, you need a tool of the professional category.

Technology of sanding boards

In everyday life, it is most often necessary to sand boards. elements of furniture, wall and floor coverings, etc.д. Regardless of what type of machine is used, the technology is always about the same.

Preparation

Before sanding wood, it is necessary to prepare for work. Do the following:

- Sanding paper of various grit sizes is prepared. Mandatory options. 40, 80, 120 and 180 grit. For the fine work will require another 150 and 240.

- Remove dirt and debris from the wood. If necessary, wash and dry. Do not work on wet wood, even if you have chosen the wet type of sanding. This increases the risk of damaging the wood’s surface and structure.

- Work with 120 grit (or 150 grit if the defects are not too noticeable). The purpose of this stage is to remove dirt and glue that adhere, as well as old coatings, including varnish and paint.

- Sand the surface with sandpaper with 180 or 240 grit. This step prepares the wood for the finishing coat.

Primary sanding

First sand the wood as part of the initial sanding, before moving on to the finer work. This is done like this:

- Coarse-grained sandpaper is used. The best grades are 40 or 80. If you use a coarser grit, it will wear off very quickly at this stage.

- The surface is cleaned from wood dust.

- Work with the same grit one more time.

Fine sanding

The next step is the fine sanding of wood:

- Use an abrasive material with at least 120 grit. Keep in mind that the sandpaper will wear down very quickly.

- Ensure rapid sanding movement. If you grind by hand, this step can be difficult. To achieve the right result, the abrasive must move really fast.

This step is often the last one. After the fine sanding the wood is ready for painting. But if you need a better result, it makes sense to continue.

Puttying

The filler step is optional. It is carried out, if after a fine sanding on the wood there are visible defects. It is done like this:

- Take the finest among available sanders (180 or 240).

- Work by hand, even if the other steps were carried out using a grinder.

- Occurring dust is periodically vacuumed or brushed away.

This step is mandatory in the manufacture of furniture or utensils. But before painting, it can be neglected.

Finishing sanding

This step is carried out before painting the wood. Its basic principles are as follows:

- Aim to remove all visible defects.

- Select sandpaper of any grit. depending on how smooth or rough the coating should be.

- Can work as a grinder, and manually.

The result of a finish sanding should be a surface that is fully suitable for painting or varnishing. And also some processes may differ. It all depends on what you need to sand and for what purpose.

After all, you can sand the boards for the fence, children’s toys, a house of profiled bar or log cabin. And accordingly, each process should be approached wisely.

Questions remain? Ask them in the Комментарии и мнения владельцев, we will be happy to answer.

How to grind metal properly angle grinder?

Grinding with a drill is possible with special nozzles made of different materials. An electric drill is a universal tool that is used in a variety of jobs. It is used not only for drilling, but also for processing of different surfaces.

Petal sanding disc

With such a petal wheel, mounted on an angle grinder, you can quickly grind wooden surface. For example, the floor is laid with planed board of low quality, when the neighboring boards stick out against each other. You can’t plan these things with a planer. precisely, you can plan but it will still leave a groove, and there is a risk of blunts on the nails / self-tapping screws that are fixed to the boards. And to grind with a petal groove. nice thing. Of course, after the belt sander the result will be better, but it takes several times longer to work with it. Even when a belt sander is available, the first pass of floor leveling is easier to do with an angle sander with this petal wheel, and then finish with a belt sander.

Here is a live example. I have a floor made of board that got a little warped in the storage and drying process. Consequently, it was far from ideal after it had been sharpened. There was an idea of laying the floor with laminate, either by putting plywood on the floor, or just a carpet pad. And then I saw what can be done with an angle grinder and sander, and decided that a simple natural wood floor can be made no worse than a laminate. As good as it gets. you can make it flat and not drag unnecessary plastic into the house. Paint well and enjoy the real wood, albeit with knots 🙂

Photo of the sanding process with a petal wheel:

You can’t see it very well in the photo. The flash lightens the picture. But you can still see that the floor on the right and in the background is untreated, and on the left and in the front. treated. All the differences between the adjacent boards, I sgrind to zero (there were places where these differences in height were up to 2 millimeters). I have to wear a respirator, because an incredible amount of tiny wooden dust rises into the air. The dust, by the way, I collect, so that, mixing it with PVA glue to patch the resulting putty cracks between the boards.

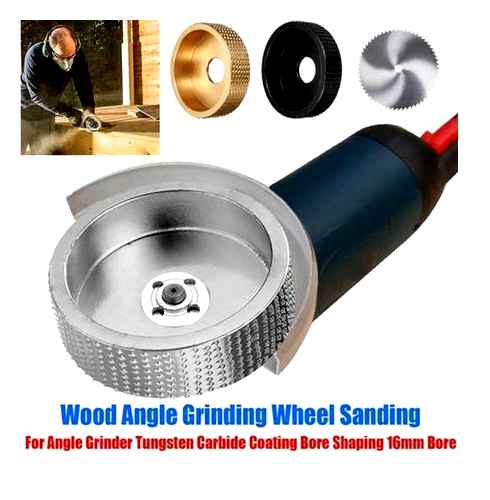

Wood Angle Grinding Wheel Sanding Carving Rotary Tool Abrasive Disc For Angle Grinder

Two or three such circles can grind a room of 20 sq.m.м. It’ll take a few hours. One petal circle costs about 50 p. After the floor can be covered with stain and varnish, paint, varnish, and whatever you want. When I finish my experiments with caulking the cracks with PVA putty with sanding dust, I’ll write about it in more detail.

And here’s the floor that got me thinking about giving up laminate:

Here the wood is just painted with a semi-matte varnish, and I want to darken it with a stain or tex-like compound, and then varnish. And here is a review of the stove Pechora, which is visible in the photo above. Any kind of firewood burns well in it, it burns completely, and a lot of heat is produced.

Petal sanding disc

Here is such a petal wheel, mounted on an angle grinder, you can quickly enough grind a wooden surface. For example, the floor was laid from planed board of low quality, when the neighboring boards stick out against each other. You can’t plan that with a planer. To be exact, it is possible to plan, but from it all the same there will be grooves, and there is a risk to kill the blades of nails / self-tapping screws which are fixed to the boards. And to grind with a petal groove. It’s a nice job. Of course, after a belt sander the result will be better, but it takes several times longer to work. Even when there is a belt sander available, the first pass to level the floor is easier to do angle grinder with this petal wheel, and then finish the band saw.

Here is a live example. I have a floor made of board, which in the process of storage and drying is a bit warped. Accordingly, after sanding it was far from ideal. There was a thought to cover the floor with laminate either by putting plywood on the floor, or just a carpet pad. And then I saw what can be done with an angle grinder and sander and decided that a simple natural wood floor can be made no worse than a laminate. How not worse. You can make it flat and not drag extra plastic into the house. Paint well and enjoy the real wood, albeit with knots 🙂

Something new with an angle grinder | Best carving tool

Photo of the sanding process with a petal wheel:

You can’t see very well in the photo. The flash brightened the picture. But still you can see that on the right and in the background is an untreated floor, and on the left and in the front. machined. All the differences between the neighboring boards, I sysfoval to zero (there were places where these differences in height were up to 2 millimeters). You have to wear a respirator, because an incredible amount of fine wood dust rises into the air. Dust, by the way, I collect, that, having mixed it with glue PVA to seal up the received putty cracks between boards.

Two-three such circles can sand a room of 20 sq.m.м. It takes a few hours. One petal circle costs about 50 p. After the floor can be covered with a stain and varnish, paint, varnish just anything. When I finish my experiments with caulking cracks with PVA putty with sanding dust, I’ll write more about it.

And here’s the flooring that got me thinking about giving up laminate:

Here the wood is simply painted with semi-matte varnish, and I want to darken a stain or tex-like composition, and then cover with varnish. And here is a review of the Pechora fireplace stove, as seen in the photo above. Any kind of wood burns well in it, it burns completely, and a lot of heat is returned.

Wood sanding angle grinder

The modern market is overflowing with different kinds of power tools, designed, each for its own purpose. Purchase of expensive equipment is reasonable in the professional sphere. In everyday life you can use the same devices for different purposes and do not spend extra money.

Thus, often in wood sanding is used, the so-called angle grinder. Or an angle grinder, designated by the abbreviation angle grinder.

With special attachments, the tool, originally designed for processing metal, turns into a sander for wood.

How to choose the right grinding wheel on the angle grinder, for wood

There are different angle grinders in various sizes. Accordingly, the disc must be chosen according to size. To fix the disc, the tool has a special nut. Do not take risks and buy “homemade” discs. Buy factory-made discs that are designed for a specific angle grinder model.

Types of nozzles on the angle grinder for wood grinding

There are several types of discs that differ in shape, material of construction and purpose.

Scrubbing brush

The first step in wood processing is rough sanding. For rough grinding, so-called cord brushes are used. The emery wheel is used for removing surface irregularities in wood. Also, to rough sand the surface, which gives the wood its final shape

Roughing wheel

To remove old coatings from the wood surface, including coatings that have been painted over several times, an attachment for angle grinders called a skinning disc is suitable.

A roughing wheel consists of a disc with steel bristles. Arrangement of the metal wire on the disk may be different.

Depending on the desired effect, the metal filaments are arranged along the entire circumference of the disc, either parallel to the tool or perpendicular to the segment, as on a traditional brush.

End disc

To process the edges of the wooden workpiece and oblique cuts, special end discs are used. The processing technique is similar to grinding with a file, but much more efficient than a hand-held tool.

Finishing wood with an angle grinder

The most common type of attachment on the angle grinder for wood sanding, is the petal disc.

According to its name, the design of the disk surface consists of sandpaper petals, trapezoidal shape. The petals overlap, overlapping three quarters of the previous row.

The petal nozzle is used to gently work on a wooden surface.

The disc varies in terms of grit size, depending on the surface finish required.

Finishing wood with an angle grinder

Recently, a universal accessory for angle grinders has been available on the market. The so-called sticky disc is distinguished by its high functionality.

Replaceable discs with the desired grit size are attached to the sticky base of the nozzle. Abrasive changes are quick and easy. No need to change and remove the main grinding head, which is secured with a nut. First you buy a sticky grinding attachment to the angle grinder and to it the interchangeable discs of abrasives, different grits.

The final result of grinding is achieved by consecutive transition of abrasives, from coarse grit. Consistently, to finer

Basic parameters for the selection of angle grinder bits

- Diameter shaft in modern angle grinder is 22.2 mm.

- Outer Diameter. The larger the outside diameter, the faster the machining process, and the longer the service life

- Seating diameter. Set a larger circle on a smaller can be using a special adapter

- Thickness. The thicker the thickness, the longer the segment will last

- Granularity. The fraction must correspond to the type of processing: coarse abrasive for rough work, and fine. for soft processing and creating the finish coating;

- Type of segment. Special sanding heads are suitable for wood surfaces

Safety

When you are sanding wood with an angle grinder, make sure that the disc is properly clamped on the tool. Working tool should not vibrate, so move the angle grinder smoothly, over the surface.

Do not use discs of small thickness when using an angle grinder. Because of the speed of rotation and high load, the wheel can break and injure you or people nearby

Subscribe to our Yandex-Dzen Channel! It will be interesting!

How to grind with an angle grinder

Don’t forget that sanding always involves a lot of dust. When getting ready for resurfacing, don’t forget about yourself! A mask and a respirator are the best helpers for sanding. It is also possible to find an option where a mask is combined with a good respirator.

The filter of the respirator will clog very quickly, so it is necessary to procure several pieces for rapid replacement. Only after thorough preparatory work can you start sanding.

Sanding wood

Wood is a unique material. He and manually grind pretty good, but with the angle grinder can achieve very good results. Some snobs argue that the angle grinder at all can not grind, but it is from ignorance and ignorance.

The main secret. the grinder is used at minimum speed. If the angle grinder has a speed selector, there will be no problem. At high speed the sandpaper will be very quickly and very tightly clogged with wood. In this mode, it will not be enough even for five minutes of work. Optimum speed of no more than 6000 rpm.

Another trick is not to grind the entire surface of the wheel. If you sand over the entire surface, the wood will leave circular marks. To leave no or minimal sandpaper marks at all, it is necessary to sand only the upper sector of the circular saw. The movements of the machine should be along the grain of the wood.

This method produces excellent results when sanding claddings. The board becomes smooth and does not leave tool marks. Do not get carried away and change the sanding pad on the wheel in time.

A log cabin is sanded in a similar way. Here it is desirable that the support plate is thin at the edge. With such a plate will be easier to sand the narrow joints of logs. Otherwise you will have to finish the work with a chisel.

Working on concrete

If you can not buy a branded protective cover-dust cover with a nozzle for a vacuum cleaner, you can make it with your own hands. To do this, take a used bucket of putty or glue with a diameter a little larger than the circle of the angle grinder. Cut off the bottom part at a height slightly greater than the assembled sanding part.

Cut a hole in the bottom to fit the gearbox and a hole for a plastic plumbing angle grinder. Now connect the hose with a vacuum cleaner and work in peace.

The grinding wheel must be suitable for grinding stone. Concrete and concrete surfaces should preferably be ground using the entire wheel surface. This will save processing time, and well level the surface plane.

Grinding the concrete floor must constantly monitor the plane with a ruler, because of the different density of concrete can make hollows. For processing joints between concrete pours it will be sufficient to achieve one level combination.

Concrete floors and surfaces can be ground very well with a Matrix diamond grinding cup. If the angle grinder is 150 mm, the cup is 125 mm.

Sanding metal surfaces

Grind metal according to different requirements. Most often metal is ground for painting or for further polishing. The basic tool is recognized as a support cup with interchangeable sanding pads. The choice of sandpaper depends on the degree of processing and on the condition of the metal.

During the grinding need to work only part of the disk. There must not remain any untreated areas on the surface.

It is desirable to cover the machined surfaces of ordinary steel with primer. Moisture in the air can coat metal very quickly and cause rust.

What and how to sand wood

During various types of repairs, at the time of manufacture of furniture or wooden things often need to sand the wood. There are many ways, the use of which allows you to grind wood. They have their advantages and disadvantages, some suggest the introduction of hand tools.

It is possible to sand the wood:

- When using an angle grinder there is an option to bring the state of the wood to the desired condition. The angle grinder has an abrasive material represented by a wheel;

- A regular drill is also used if you have set the goal of bringing the wood surface to a suitable condition;

- A flat sander can be a basic design if you set the goal of sanding wood;

- Belt grinders are used for grinding wood with an abrasive material;

- also sanding with hand tools.

Despite the fact that the considered natural material has a sufficiently high hardness of structure, there are many ways to grind, let’s talk about some in detail.

What you need to know when working with angle grinder

Renovation of flooring (parquet), furniture or the facade of the house, where there are wooden structures or individual elements, is performed with the help of an angle grinder for grinding, which is equipped with different attachments. Therefore, it is not surprising that the electric tool in demand among professionals and at home is an angle grinder for wood polishing. But in order to choose the right tool for work, you must carefully study the wooden surface for the presence of fungus, cracks and irregularities. To help beginners who want to know “How to grind wood properly angle grinder” provided video.

Under each model of angle grinder must necessarily pick up the grinding attachment, only then will be guaranteed the safe execution of works and high-quality processing of the surface. Before you start working with the angle grinder (wood sanding), make sure that the disc is properly secured. Move the angle grinder over the surface smoothly and avoid vibration of the tool.

When working with the angle grinder to grind wood is inadmissible use of discs of small thickness (high speed and load leads to a breakage of the circle, which is fraught with injury).