Why is the spark missing on the power tiller?

Magneto on a single axle tractor by the mechanism of work is identical to the ignition coil. it is responsible for causing the spark.

Check the magneto motorblock can be checked in the following way:

- Remove the cap from the top of the candle and insert a nail. All manipulation must be done very carefully, so that after rechecking the spark plug can be mounted in place again;

- The nail is placed 7 millimeters from the unit cylinder;

- Return the spark plug to its standard position and start the engine of the power tiller;

- During the start, a spark must be created. At the same time, it will be strong, with a blue color. If the characteristics of the spark differ, it is an indication that the failure is not eliminated.

When checking the magneto, it is fundamental to follow the following rules:

- The spark plug is not turned out one hundred percent. This can provoke a loss of compression, the flywheel will spin much faster;

- this method is ineffective if an electrical ignition system is installed. Problems can also arise with the main nodes of the system;

- The distance between the spark plug nail and the cylinder varies depending on the specific construction of the machine.

Self-repair

A single-axle diesel tractor is sometimes difficult to start after purchase. The cause is air in the fuel system.

The following steps are performed:

The single axle tractor also starts badly if there is no fuel in the combustion chamber. The spark plug is completely dry.

Such a breakdown is eliminated as follows:

- Old fuel is drained out;

- The gas tank is thoroughly flushed;

- The air filter is cleaned of blockages;

- The hose that supplies the fuel is blown out;

- The carburetor jets are blown;

- The tank is filled with fresh fuel;

- The fuel tap is closed;

- The air pipe in the gas tank is blown.

To re-start the machine manually, pump the fuel by pushing the primer bulb a couple of times. After starting the engine, it needs time to warm up. After that the power tiller can be fully used.

The internal combustion motor will start, after the following steps:

The cause of the failure may be in the intake and exhaust valves. If the seats are loose, they are adjusted by turning the screw clockwise.

To prevent the engine from malfunctioning, clean the walls of the muffler regularly from accumulated carbon deposits. Compressed air is used for this purpose.

No spark on the power tiller: troubleshooting options

The most common cause of malfunctions on a power tiller is ignition system malfunction. The problem can be related to the cap, magneto, spark plug or high-voltage wire technique.

If the spark is gone, you need to do the following:

- Check the ignition system for blockages. Often there is no spark because water or dirt got in;

- Check for contact between the main electrode and the spark plug cap;

- Verify the integrity of all electrodes, the presence of a gap between them. Use a special dipstick. The optimal gap. 0.8 millimeters;

- Remove the soot from the insulator and metal parts of the ignition assembly;

- Unscrew and check the spark plug for oil spots. Oil stains and thick soot must be thoroughly cleaned and the spark plug dried. It is also necessary to dry out the cylinder of the unit, by pulling the starter cord;

- If after diagnosis the cause of the malfunction is not identified, the spark plug must be replaced. Such a part has a low price, but it is advisable to give preference to more expensive options. They are characterized by reliability and durability.

All the described troubleshooting methods are suitable for power tillers of the following brands: Mole, MB-1 and MB-2, Neva, Kaskad, Agro, Zubr, Salyut.

Single axle tractor Agro does not start

In this case, it is necessary to carefully check whether all the parts are in place, as well as how strong the fixation.

The breakdown may occur due to stagnation of the equipment after winter or due to fuel problems. For example, outdated or low quality oil.

There is also a possibility that the diesel engine of the motorblock does not work due to:

In addition, if the problem concerns the ignition, to fix it, you can apply such actions:

- If the spark is missing or not strong enough in power, you need to adjust the condition of the electrodes and the intermediate gap. The standard adjustment gap is 0.8 mm.

- If the compression ratio is low, simply replace the unserviceable parts.

- when adjusting the valves, it is important that the inlet and outlet valves fit snugly against the seat.

- The final point is to clean the muffler.

If the plough is damaged it is very important to install it correctly afterwards. To adjust the plow, you can perform the following, simple operations:

- secure the hitch with 1 kingpin where the backlash is horizontal and at a ratio of 5-6 degrees;

- Adjust the depth of plowing, the norm is to deepen by 5-7 cm;

- then proceed to unscrew the adjusting screw so that the plow touches the ground;

- then you need to unscrew the screw back until the rear of the hitch is 2.5 cm.

No spark on the power tiller. sort out the problem

Another common reason that a single-axle tractor does not start is a problem with the unit’s ignition system. Troubles can hide in the cap, magneto, spark plug or in the high voltage wire of the agricultural machine.

The first thing to do when inspecting the ignition system is to carefully check each part for blockages. If there is no spark, then the reason for this is often the ingress of moisture or dirt on the elements of the ignition system. Also the machine often fails to start because there is no way to create a spark. this is caused by poor contact between the center electrode and the spark plug cap.

If you do not find dirt and moisture in the ignition system, and the single axle tractor does not start, be sure to check the integrity of the electrodes and the gap between them. As a rule, a special dipstick is used for this. Ideally, the gap should be 0.8 mm. If necessary, remove the soot from the insulator and metal elements of the ignition system.

If the machine won’t start and none of the above procedures have helped, then the spark plug of the power tiller will need to be replaced. The cost of replacement parts is low, but when buying, we advise to give preference to more expensive plugs. they will last many times longer than cheaper counterparts. All of the above methods are suitable for repair of power tillers Krot, Neva MB-1 and MB-2, as well as Kaskad, Zubr, Agro and Salyut.

Useful video materials

Different brand motor blocks produced by famous brands differ from each other by the design of the built-in ignition system. To know how to properly adjust this important element, we offer a video. Which contain the correct procedure for adjusting the ignition system on the most common models of power tillers.

For power tillers of the brand Neva:

For agricultural aggregates produced by the brand Ural;

For power tillers of the brand Salut:

For agricultural aggregates Honda:

For the model range produced by the company Cascade:

Old power tiller starting up with fire क्या ऐसा करने से पावार टिलर स्टार्ट होगा ?Will it start/not ?

For power tillers of MTZ brand:

Why the single-axle tractor does not start?

Despite all the reliability of modern power tillers, sooner or later they break down, so the unit can not be started and continue working on the site. We suggest studying the most common breakdowns of agricultural machinery, as well as methods of their elimination with their own hands.

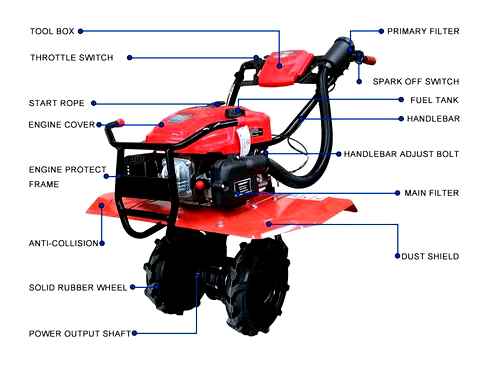

Before the start of the season, both gasoline and diesel single axle tractor needs to be prepared. For this purpose, the owner of the machine should make sure that all the necessary parts for work are present in the construction of the machine, and that each of them “sits” tightly in its regular place.

Often many power tillers equipped with a Subaru engine or other well-known brands of engines refuse to work after a long winter downtime. If the machine has been stored in cold and wet conditions, it will most likely fail to start before the start of spring works. This is due to a number of such faults:

- Oxidation of contacts in electrical wiring;

- Violation of the integrity of the insulation of the wiring;

- Oil and fuel watering;

- Debris in carburetor jets.

Before actually starting the single axle tractor, the tractor owner should first carefully examine all connections on the machine. Check the throttle, reverse and clutch cables for soft movement. If during the inspection you find clips or kinks in the cables, you must not start the single axle tractor.

Check the oil level in the oil sump before starting the tractor for the first time. If there is no lubricant, it will cause severe damage to the piston group. Judge for yourself: at 1400 rpm on the crankshaft./min., It will only take a fraction of a second for it to form a few burrs on the cylinder surface.

Why Small Engine Shuts off and Doesn’t Start Until Its Cool

Oil left over from the winter is one of the main causes of instability in the machine’s engine. To be convinced that the single-axle tractor is poorly started for this very reason is quite simple. after start white smoke will fall out of the exhaust pipe for several seconds, after that the machine will stall. Do not forget that both diesel and gasoline single axle tractor bad start because of insufficient oil. Some models of units are equipped with low-level protection, the owners of other machines should independently monitor the volume of oil inside the tank.

Another important factor is the gasoline that you use to refuel the motoblock. If you regularly pour fuel of the wrong brand, which is advised by the manufacturer of the machine, this can also be the reason for the lack of starting it.

Moto-block repair with his hands

All malfunctions of a power tiller can be divided into two categories. Malfunctions of the engine and malfunctions of all other nodes and mechanisms. often than not the owners of these multifunctional machines have to deal with the first. Before repairing your power tiller with your own hands it is desirable to get acquainted with the scheme of your power tiller.

Power tiller repair

For part of the information that may be useful when repairing a power tiller, see the article Design of a power tiller.

Engine malfunctions

There are two main types of faults of this type. Refusal of the engine to start and its unsatisfactory operation (interruptions, non-recovery of power, spontaneous stopping).

Engine does not start. If it is a gasoline engine, when looking for a malfunction, you must consistently check all possible causes of the malfunction, viz:

- Switching on ignition.

- Fuel in the tank.

- Opening of the fuel tap.

- Condition of the carburetor choke (when starting a cold engine, it must be closed).

- Fuel flow into carburetor. To do this, fill the float chamber by pushing down the float button (fuel should start pouring out of the hole in the float chamber cover), or disconnect the fuel hose from the carburetor and check that gasoline is flowing freely. If the fuel runs too thin or does not run at all, it could mean the fuel filter in the tank is dirty or the tank lid air valve is clogged. Repair of the motoblock in this case will be reduced to cleaning the filter or valve.

The arrival of fuel in the engine cylinder may indicate the state of the candle, which in any case should be checked when searching for malfunctions in the ignition system. The candle is unscrewed from the cylinder cover, having previously disconnected the wire, and inspected. If it is dry, it means that the fuel mixture is not supplied to the cylinder. And if before it was found that the carburetor receives gasoline, then the reason for the failure to start the engine may be in the carburetor. Contamination of his mesh-filter, clogged nozzle or some other malfunction. Whatever it is, the carburetor needs to be removed, disassembled and cleaned, but this device is very complex and before repairing it, you should at least look at the carburetor schematic.

Cascade motoblock carburetor

A wet spark plug is an indication that fuel is getting into the cylinder. Sometimes the single axle does not start with too much fuel mixture, so if there is too much gasoline on the spark plug you need to dry the cylinder by giving the engine a good “cranking” with the hand starter with the spark plug turned out. before doing this turn off the fuel supply.

if the spark plug is polluted with sludge, it should be cleaned with petrol and fine sandpaper. Also check the gap between the electrodes and adjust it if necessary according to the operating manual. Usually the gap should be about 0.8 mm.

After that, you must check that there is a spark. connect a wire to the spark plug, press its metal part to the cylinder head and imitate starting the engine with a starter. If the spark plug is good, there will be a spark between the electrodes. Sometimes the spark spark occurs but is so weak that it is not enough to ignite the fuel. If there is any doubt about the strength of the spark, you should check the engine operation with a new spark plug.

Lack of spark can mean a faulty spark plug, lack of contact in the electrical circuit, a gap between the ignition coil and the ignition coil, a faulty electronic ignition coil. All these elements should be checked. Faulty spark plugs and coil should be replaced.

If single axle tractor is equipped with electric starter, engine may not start due to discharged battery, blown fuse, defective starter. Check battery charge, replace fuse, repair or replace starter.

The engine does not develop power. If the engine starts but fails to develop power (fails to operate smoothly, stops or fails to pick up speed under load) the following problems may be the causes of unsatisfactory work.

The air filter is clogged, causing insufficient air flow into the carburetor and producing an over-enriched fuel mixture. Proper maintenance of your power tiller requires periodic cleaning of the air filter, but very dusty conditions may require more frequent cleaning. Check the condition of the air filter and depending on the filter material clean using one of the following methods. Paper filter is cleaned by lightly tapping on something hard and blowing with a vacuum cleaner, foam filter is washed in water with detergent and dried, mesh filter is blown with a vacuum cleaner, etc.д. Filters need to be changed as they reach the end of their useful life.

Air filter on SunGarden walking tractor

Low fuel quality. Bad fuel change to one recommended by the manufacturer.

Faulty ignition system. Check the ignition system as described above. Clean the spark plug and adjust the gap between the electrodes, check for damage to the electrical circuit and the gap between the coil and the magnetic core (if the instructions for repairing the power tiller provide for this).

Sometimes the engine can not develop power due to clogged muffler of combustion products. In this case, take the silencer apart and check its condition, if necessary rinse it in petrol and clean it with a lime detergent. The non-disassembled silencer should be dried with a hair dryer after washing. The engine oil contains carcinogenic substances, so do not clean it dry if you inhale them. When removing the muffler, the engine exhaust port is plugged with a clean rag.

Dirty or improper adjustment of the power tiller carburetor. Remove and clean carburetor, then adjust it if it is required by the manual.