Husqvarna chainsaw does not start 137 cause

This company is a very well-known brand, so I would NOT advise you to disassemble, provide and configure such equipment yourself. Feel free to call the service center and let the specialists figure it out.

Take off “tube” candles, unscrew a candle.

Under normal mixing, the candle should have an even brownish or gray tint.

Maybe you just “sucked” the cylinder with gasoline, then the candle will be wet.

Pull the starting cord several times. To ventilate the cylinder from excess gasoline. Purge along the way and then massage the candle with the body on the cylinder, it is better to do this in the shade, and see if there is a spark.

Gets dust you need to “suction”, pulling out its traction, pull the cord several times until”.Vyaknula-turn off the suction and start without it.

Doesn’t help. then unscrew the screws “L” and “H” 18 turns, more gasoline will go into the cylinder.

Press the gas several times, the carburetor will spray into the cylinder of gasoline, which may not be enough to start.

Chainsaws and lawn mowers of this brand usually start well. Before you panic and immediately disassemble it to a screw, you need to start with the simplest. The most common problem is with fuel. It is necessary to prepare the correct mixture of gasoline and oil and fill the tank. Remember to move the choke lever to the “closed”. Then, you need to pull the starter cord several times and the saw should start. Doesn’t it start? We assume “oversupply”. We translate the choke lever to the position “open”, we give full throttle and again pulling the cord. Sometimes the saw starts at this stage. If not, just go for a walk, calm down, and start over. And only after the third circle you need to start unscrewing the candle and everything else, if you have experience with two-stroke motors, for example, a moped. If you have no experience, then you need to turn to those who have. In experienced hands, the saw will quickly come to life, and they will also teach how to start.

If the saw started up, worked, the user is experienced, looked after properly, kept it clean, then he will immediately understand that something is going wrong and the saw requires serious repair.

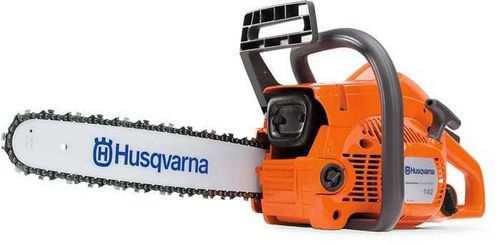

The chainsaw is indispensable in the daily life of the owner. This tool is in great demand and popularity because it helps to facilitate the work of a forester or gardener. Husqvarna. This is a popular company that has been producing quality tools and equipment for further gardening for a long time.

and more people are buying a Husqvarna 137 chainsaw for use in private businesses, households or forestry. The presented products have perfectly proven themselves in large-scale industrial construction.

The manufacturer offers its customers a wide and varied selection of products, but the main direction. This is the development of chainsaws. The Husqvarna 137 saw is the most successful and highest quality model. It is easy to use, lightweight and economical. But at the same time, it has enough power to cope with large volumes of work.

Fuel supply system

Improper use of your Husqvarna chainsaw will NOT allow fuel to enter the master cylinder. This malfunction occurs for several reasons:

- Dirty saw fuel filter;

- Viscous chain oil;

- Clogged special hole;

- Dirty air filter.

To clean the fuel hose of the chainsaw, carefully check the fuel supply. Experts recommend replacing the old hose every three months and buying a new part. If the air hose is dirty, air will NOT enter the system, namely the carburetor. Most often this leads to disruption of the engine’s operation. The filter is cleaned with plain water, but this procedure must be done very carefully.

The part is thoroughly dried and installed in its original place. The Husqvarna 137 chainsaw is sold with an instruction manual detailing how to replace and clean the hoses. If you don’t adhere to the rules, then the situation can be aggravated.

The most common reason. This is a clogged channel or a violation of the integrity of the carburetor membrane. In this case, it is recommended to replace the part and clean the channels. After that, the chainsaw will work without interruption.

Causes of failure of the ignition system

If your Husqvarna saw stops working, the first step is to check the spark plug for functionality. This must be done very carefully using a specially designed hook. First of all, the wires are disconnected from the body of the floor, and it looks at the appearance of the candle.

- If the spark plug is dry, then this indicates that fuel is no longer flowing into the main cylinder. In this case, the malfunction is not in the candle, so you can safely tighten it back.

- When there is fuel splatter on this part, the main problem is the carburetor. This indicates that it was incorrectly adjusted or the launch rule was violated.

To eliminate such a problem in the chainsaw, it is recommended to thoroughly wipe the spark plug, turn off the fuel supply and turn on the starter. This procedure is performed in order to ventilate the combustion chamber well and eliminate excess fuel. After that, the plug can be replaced in its original place and start the Husqvarna 137 chainsaw.

When the candle is covered with heavy carbon deposits, this indicates the use of low-quality oil. In order for a chainsaw to serve for a long time, it is necessary to buy only tested and certified lubricants. Sometimes users incorrectly calculate the ratio of oil to gasoline, and also set inaccurate adjustment of the carburetor.

In this case, it is recommended to pay attention to the presence of a spark during startup. For this, an ignition cable is installed on the spark plug, the cylinder and the nut are connected. Now you can start the chainsaw starter and then a spark appears. If it is still missing, then the old plug should be replaced with a new one. In rare cases, users come to look for a faulty high-voltage drive or fix a broken connection.

Possible malfunctions of the Husqvarna chainsaw 137

Sometimes a person may encounter some breakdowns of the Husqvarna 137 chainsaw, which can be repaired. Today there are a large number of workshops where specialists are engaged in the repair and maintenance of equipment. But for this work you will have to pay a rather large sum.

Do-it-yourself Husqvarna 137 saw repair without contacting a specialist. When the breakdown is minor, there is no point in going to the workshop and wasting your time. There is a list of the most common problems that the owner of such equipment may encounter. That is why it is advisable to get acquainted with them, so that always fully armed.

Silencer breakage

If the saw engine runs without interruption at low speeds, and when they increase, it stalls, then the problem is associated with the muffler. This indicates a faulty spark arrester. Most likely, it is clogged with combustion waste. To perform cleaning, the first step is to remove and disassemble the muffler. Further, the user carefully removes the formed carbon deposits with a detergent.

After that, experts recommend Drying the part with a hairdryer. At the end of all manipulations, you can install the muffler in its original place.

The Husqvarna 137 saw is simple in design, so many problems can be fixed at home. To do this, you should carefully study the breakdowns and read the instructions. The rules for parsing and installing parts are indicated there. The Husqvarna 137 saw is distinguished by its reliability and sufficient power. It handles even the most difficult tasks and does a lot of work. That is why the presented chainsaw is widely used in large-scale industrial enterprises.

Chainsaws. Uncomplicated and reliable devices.

With proper handling, breakdowns rarely occur and are quickly eliminated if the owner knows where to look for the cause.

And yet, the question of why the chainsaw does not start cannot be answered unequivocally. This tool is at its core. Conventional two-stroke internal combustion engine. For its normal operation, four conditions are necessary: fuel, air, spark and lubrication.

The carburetor is responsible for preparing the air-fuel mixture, the filter cleans the air from dust, the spark creates the ignition unit and the spark plug, and the lubricant is in the gasoline.

The reasons why the chainsaw refuses to start should be sought sequentially, starting from simple ones and moving on to more complex ones. Anyone who immediately rushes to disassemble the carburetor when the chainsaw does not start well when hot is at great risk. It is better to repair and adjust this unit in a specialized workshop, and not on the knee.

By the way, some manufacturers of chainsaws, so that users do not climb into the carburetor to change the composition of the fuel mixture, make the jets unregulated.

For trouble-free operation of the chainsaw, you need to pay special attention to fuel. If the fuel mixture is not properly mixed, even a reliable Husqvarna will not start. In this case, the owner will begin to look for the cause of the malfunction anywhere, but not in the fuel. To eliminate this factor, you must always prepare a fuel mixture from high quality gasoline and the brand of oil that is indicated in the instructions.

It must be done in such quantity that it can be fully developed in 1-2 weeks. If you keep it in the Canister for a month, then gasoline will lose its octane quality and problems with the saw operation are guaranteed to you.

Quite often, chainsaw malfunctions occur due to filling the spark plug with gasoline at the time of starting. This problem is eliminated by unscrewing and drying the candle (without igniting!) The excess fuel is drained through the candle hole, after which they take a 20-30 minute break, then put the candle in place and repeat the start. A good owner always has new candles in stock to exclude this part from the list of suspects when troubleshooting.

The absence of a spark is often caused not only by the failure of the spark plug, but also by poor contact between its tip and the high-voltage wire. If this connection does NOT cause suspicion when checking, but the spark does not appear when the starter is turned on. The electronic ignition unit is to blame. This unit is NOT being repaired, but replaced with a new one.

Remember that inspecting the spark plug provides important information. If it is dry, it means that fuel is NOT entering the cylinder and you need to check the entire chain of its supply, starting from the carburetor. Black carbon deposits indicate improper adjustment of the carburetor, feeding too much fuel into the mixture or in the overflow of oil into gasoline.

If the chainsaw starts and stalls when you press the gas, this indicates poor fuel flow. The cause may be a clogged fuel filter or carburetor jet. The first node can be checked and cleaned very quickly, but in the second case it is better to trust the specialists.

Disassembling and cleaning a chainsaw carburetor requires experience and care. Therefore, it is usually taken only by the owners who have already repeatedly and successfully performed this procedure.

The air filter should also be taken care of so as not to look for the cause of the chainsaw malfunctioning in the wrong direction. If it is clogged with dust, then you cannot count on easy start-up and stable operation.

This valve equalizes the pressure in the gas tank as fuel is consumed. When it becomes clogged, a vacuum forms in the tank and fuel stops flowing into the carburetor. This disease is treated by cleaning the breather with an ordinary sewing needle.

Removing the breather from the list of suspects is easy. To do this, disconnect the fuel hose from the carburetor and see if fuel is leaking from it. When gasoline flows in full stream. The breather is clean, if the fuel does NOT flow from the gas line or flows out very slowly, then the cause of the malfunction is established.

Many owners of new Stihl chainsaws are frightened by the increase in idle speed after the first tanks of gasoline are used up. Experts consider this behavior of the saw to be normal and indicate that the engine and carburetor running-in is normal. Therefore, do not rush to contact the service, but just slightly reduce the engine speed with the idling screw of the carburetor.

If the power drops and the chainsaw stalls at idle, do not forget to check the muffler, as the exhaust can be clogged with resinous deposits. Cleaning the exhaust port and muffler eliminates these problems.

It is especially unpleasant for the owner when all Possible reasons seem to have been eliminated: a new serviceable plug is installed, the carburetor is cleaned neatly and correctly, the fuel is normal, but the chainsaw still DOES NOT want to start.

In this case, you need to look into the cylinder-piston group. Visual inspection of the cylinder and piston in this case helps to find the cause. If chips or scuffs are visible on them, the saw will function normally only after replacing THESE components. This problem can be eliminated by boring the cylinder for a new oversized piston.

If there are visible defects on the cylinder and piston, then the piston rings are checked. For this, the piston is inserted into the cylinder and slightly shaken by the connecting rod. If play is felt, then the rings are worn out and need to be replaced.

Chainsaw breakdowns often occur due to insufficient chain lubrication due to oil line leakage and clogged channels. Therefore, if the chain becomes dry, it is necessary to urgently clean the channels that supply oil to the tire. Then an inspection of the joints of the pipes with the oil pump fittings is carried out. If there is a strong leakage of oil from the points of contact or cracks on the oil lines, the pipes are changed, and the joints are sealed with a high-quality sealant.

Some parts of chainsaws must be changed after the expiration of the passport service life. Therefore, DO NOT forget to look at the instructions, where they are clearly spelled out. Such parts include the tire, the drive sprocket, the chain, parts of the anti-vibration system.

If the replacement is not done on time, the wear of these components will negatively affect the serviceable parts of the chainsaw. For example, a long delay in changing a drive sprocket results in increased vibration, which quickly breaks down the crankshaft bearings.

Therefore, it is necessary to regularly check the working depth of the teeth, which does not have to exceed 0.5 mm. The bus link is usually enough for 3-4 chains, after which it also needs to be replaced.

Useful for the correct operation of the chainsaw:

Possible malfunctions of the Husqvarna chainsaw 137

Sometimes a person may encounter some breakdowns of the Husqvarna 137 chainsaw, which can be repaired. Today there are a large number of workshops where specialists are engaged in the repair and maintenance of equipment. But for this work you will have to pay a rather large sum.

Do-it-yourself Husqvarna 137 saw repair without contacting a specialist. When the breakdown is minor, there is no point in going to the workshop and wasting your time. There is a list of the most common problems that the owner of such equipment may encounter. That is why it is advisable to get acquainted with them, so that always fully armed.

Fuel supply system

Improper use of your Husqvarna chainsaw will NOT allow fuel to enter the master cylinder. This malfunction occurs for several reasons:

- Dirty saw fuel filter;

- Viscous chain oil;

- Clogged special hole;

- Dirty air filter.

To clean the fuel hose of the chainsaw, carefully check the fuel supply. Experts recommend replacing the old hose every three months and buying a new part. If the air hose is dirty, air will NOT enter the system, namely the carburetor. Most often this leads to disruption of the engine’s operation. The filter is cleaned with plain water, but this procedure must be done very carefully.

The part is thoroughly dried and installed in its original place. The Husqvarna 137 chainsaw is sold with an instruction manual detailing how to replace and clean the hoses. If you don’t adhere to the rules, then the situation can be aggravated.

The most common reason. This is a clogged channel or a violation of the integrity of the carburetor membrane. In this case, it is recommended to replace the part and clean the channels. After that, the chainsaw will work without interruption.

Causes of failure of the ignition system

If your Husqvarna saw stops working, the first step is to check the spark plug for functionality. This must be done very carefully using a specially designed hook. First of all, the wires are disconnected from the body of the floor, and it looks at the appearance of the candle.

- If the spark plug is dry, then this indicates that fuel is no longer flowing into the main cylinder. In this case, the malfunction is not in the candle, so you can safely tighten it back.

- When there is fuel splatter on this part, the main problem is the carburetor. This indicates that it was incorrectly adjusted or the launch rule was violated.

To eliminate such a problem in the chainsaw, it is recommended to thoroughly wipe the spark plug, turn off the fuel supply and turn on the starter. This procedure is performed in order to ventilate the combustion chamber well and eliminate excess fuel. After that, the plug can be replaced in its original place and start the Husqvarna 137 chainsaw.

When the candle is covered with heavy carbon deposits, this indicates the use of low-quality oil. In order for a chainsaw to serve for a long time, it is necessary to buy only tested and certified lubricants. Sometimes users incorrectly calculate the ratio of oil to gasoline, and also set inaccurate adjustment of the carburetor.

In this case, it is recommended to pay attention to the presence of a spark during startup. For this, an ignition cable is installed on the spark plug, the cylinder and the nut are connected. Now you can start the chainsaw starter and then a spark appears. If it is still missing, then the old plug should be replaced with a new one. In rare cases, users come to look for a faulty high-voltage drive or fix a broken connection.

Husqvarna chainsaw does not start 137 cause

This company is a very well-known brand, so I would NOT advise you to disassemble, provide and configure such equipment yourself. Feel free to call the service center and let the specialists figure it out.

Take off “tube” candles, unscrew a candle.

Under normal mixing, the candle should have an even brownish or gray tint.

Maybe you just “sucked” the cylinder with gasoline, then the candle will be wet.

Pull the starting cord several times. To ventilate the cylinder from excess gasoline. Purge along the way and then massage the candle with the body on the cylinder, it is better to do this in the shade, and see if there is a spark.

Gets dust you need to “suction”, pulling out its traction, pull the cord several times until”.Vyaknula-turn off the suction and start without it.

Doesn’t help. then unscrew the screws “L” and “H” 18 turns, more gasoline will go into the cylinder.

Press the gas several times, the carburetor will spray into the cylinder of gasoline, which may not be enough to start.

Chainsaws and lawn mowers of this brand usually start well. Before you panic and immediately disassemble it to a screw, you need to start with the simplest. The most common problem is with fuel. It is necessary to prepare the correct mixture of gasoline and oil and fill the tank. Remember to move the choke lever to the “closed”. Then, you need to pull the starter cord several times and the saw should start. Doesn’t it start? We assume “oversupply”. We translate the choke lever to the position “open”, we give full throttle and again pulling the cord. Sometimes the saw starts at this stage. If not, just go for a walk, calm down, and start over. And only after the third circle you need to start unscrewing the candle and everything else, if you have experience with two-stroke motors, for example, a moped. If you have no experience, then you need to turn to those who have. In experienced hands, the saw will quickly come to life, and they will also teach how to start.

If the saw started up, worked, the user is experienced, looked after properly, kept it clean, then he will immediately understand that something is going wrong and the saw requires serious repair.

The chainsaw is indispensable in the daily life of the owner. This tool is in great demand and popularity because it helps to facilitate the work of a forester or gardener. Husqvarna. This is a popular company that has been producing quality tools and equipment for further gardening for a long time.

and more people are buying a Husqvarna 137 chainsaw for use in private businesses, households or forestry. The presented products have perfectly proven themselves in large-scale industrial construction.

The manufacturer offers its customers a wide and varied selection of products, but the main direction. This is the development of chainsaws. The Husqvarna 137 saw is the most successful and highest quality model. It is easy to use, lightweight and economical. But at the same time, it has enough power to cope with large volumes of work.

Silencer breakage

If the saw engine runs without interruption at low speeds, and when they increase, it stalls, then the problem is associated with the muffler. This indicates a faulty spark arrester. Most likely, it is clogged with combustion waste. To perform cleaning, the first step is to remove and disassemble the muffler. Further, the user carefully removes the formed carbon deposits with a detergent.

After that, experts recommend Drying the part with a hairdryer. At the end of all manipulations, you can install the muffler in its original place.

The Husqvarna 137 saw is simple in design, so many problems can be fixed at home. To do this, you should carefully study the breakdowns and read the instructions. The rules for parsing and installing parts are indicated there. The Husqvarna 137 saw is distinguished by its reliability and sufficient power. It handles even the most difficult tasks and does a lot of work. That is why the presented chainsaw is widely used in large-scale industrial enterprises.

Chainsaws. Uncomplicated and reliable devices.

With proper handling, breakdowns rarely occur and are quickly eliminated if the owner knows where to look for the cause.

And yet, the question of why the chainsaw does not start cannot be answered unequivocally. This tool is at its core. Conventional two-stroke internal combustion engine. For its normal operation, four conditions are necessary: fuel, air, spark and lubrication.

The carburetor is responsible for preparing the air-fuel mixture, the filter cleans the air from dust, the spark creates the ignition unit and the spark plug, and the lubricant is in the gasoline.

The reasons why the chainsaw refuses to start should be sought sequentially, starting from simple ones and moving on to more complex ones. Anyone who immediately rushes to disassemble the carburetor when the chainsaw does not start well when hot is at great risk. It is better to repair and adjust this unit in a specialized workshop, and not on the knee.

By the way, some manufacturers of chainsaws, so that users do not climb into the carburetor to change the composition of the fuel mixture, make the jets unregulated.

For trouble-free operation of the chainsaw, you need to pay special attention to fuel. If the fuel mixture is not properly mixed, even a reliable Husqvarna will not start. In this case, the owner will begin to look for the cause of the malfunction anywhere, but not in the fuel. To eliminate this factor, you must always prepare a fuel mixture from high quality gasoline and the brand of oil that is indicated in the instructions.

It must be done in such quantity that it can be fully developed in 1-2 weeks. If you keep it in the Canister for a month, then gasoline will lose its octane quality and problems with the saw operation are guaranteed to you.

Quite often, chainsaw malfunctions occur due to filling the spark plug with gasoline at the time of starting. This problem is eliminated by unscrewing and drying the candle (without igniting!) The excess fuel is drained through the candle hole, after which they take a 20-30 minute break, then put the candle in place and repeat the start. A good owner always has new candles in stock to exclude this part from the list of suspects when troubleshooting.

The absence of a spark is often caused not only by the failure of the spark plug, but also by poor contact between its tip and the high-voltage wire. If this connection does NOT cause suspicion when checking, but the spark does not appear when the starter is turned on. The electronic ignition unit is to blame. This unit is NOT being repaired, but replaced with a new one.

Remember that inspecting the spark plug provides important information. If it is dry, it means that fuel is NOT entering the cylinder and you need to check the entire chain of its supply, starting from the carburetor. Black carbon deposits indicate improper adjustment of the carburetor, feeding too much fuel into the mixture or in the overflow of oil into gasoline.

If the chainsaw starts and stalls when you press the gas, this indicates poor fuel flow. The cause may be a clogged fuel filter or carburetor jet. The first node can be checked and cleaned very quickly, but in the second case it is better to trust the specialists.

Disassembling and cleaning a chainsaw carburetor requires experience and care. Therefore, it is usually taken only by the owners who have already repeatedly and successfully performed this procedure.

The air filter should also be taken care of so as not to look for the cause of the chainsaw malfunctioning in the wrong direction. If it is clogged with dust, then you cannot count on easy start-up and stable operation.

This valve equalizes the pressure in the gas tank as fuel is consumed. When it becomes clogged, a vacuum forms in the tank and fuel stops flowing into the carburetor. This disease is treated by cleaning the breather with an ordinary sewing needle.

Removing the breather from the list of suspects is easy. To do this, disconnect the fuel hose from the carburetor and see if fuel is leaking from it. When gasoline flows in full stream. The breather is clean, if the fuel does NOT flow from the gas line or flows out very slowly, then the cause of the malfunction is established.

Many owners of new Stihl chainsaws are frightened by the increase in idle speed after the first tanks of gasoline are used up. Experts consider this behavior of the saw to be normal and indicate that the engine and carburetor running-in is normal. Therefore, do not rush to contact the service, but just slightly reduce the engine speed with the idling screw of the carburetor.

If the power drops and the chainsaw stalls at idle, do not forget to check the muffler, as the exhaust can be clogged with resinous deposits. Cleaning the exhaust port and muffler eliminates these problems.

It is especially unpleasant for the owner when all Possible reasons seem to have been eliminated: a new serviceable plug is installed, the carburetor is cleaned neatly and correctly, the fuel is normal, but the chainsaw still DOES NOT want to start.

In this case, you need to look into the cylinder-piston group. Visual inspection of the cylinder and piston in this case helps to find the cause. If chips or scuffs are visible on them, the saw will function normally only after replacing THESE components. This problem can be eliminated by boring the cylinder for a new oversized piston.

If there are visible defects on the cylinder and piston, then the piston rings are checked. For this, the piston is inserted into the cylinder and slightly shaken by the connecting rod. If play is felt, then the rings are worn out and need to be replaced.

Chainsaw breakdowns often occur due to insufficient chain lubrication due to oil line leakage and clogged channels. Therefore, if the chain becomes dry, it is necessary to urgently clean the channels that supply oil to the tire. Then an inspection of the joints of the pipes with the oil pump fittings is carried out. If there is a strong leakage of oil from the points of contact or cracks on the oil lines, the pipes are changed, and the joints are sealed with a high-quality sealant.

Some parts of chainsaws must be changed after the expiration of the passport service life. Therefore, DO NOT forget to look at the instructions, where they are clearly spelled out. Such parts include the tire, the drive sprocket, the chain, parts of the anti-vibration system.

If the replacement is not done on time, the wear of these components will negatively affect the serviceable parts of the chainsaw. For example, a long delay in changing a drive sprocket results in increased vibration, which quickly breaks down the crankshaft bearings.

Therefore, it is necessary to regularly check the working depth of the teeth, which does not have to exceed 0.5 mm. The bus link is usually enough for 3-4 chains, after which it also needs to be replaced.

Useful for the correct operation of the chainsaw:

We Analyzing Possible Causes Of Breakdown

Find out why the tool cannot be started in the instruction itself. But the instruction does not always come.

Although each model has its own characteristics, in general they are all similar. So I will tell you about the possible breakdown reasons and possible solutions for different tools.

Checking the breather and cleaning it.

The breather is another element, from the improper operation of which the chainsaw may not start or stall during the sawing process. This element is located on the fuel tank cap in the area of the air hole. This is a kind of valve that does not allow gasoline to flow out and equalizes the air pressure required for the free flow of fuel into the carburetor.

If the breather is dirty, the working chainsaw stalls, and when started it refuses to start. The thing is that air stops flowing through the hole. As a result, a negative pressure (vacuum) is created inside the fuel tank, which prevents the flow of gasoline into the carburetor.

Defining the problem is pretty straightforward. Disconnect the fuel hose from the carburetor and see what happens to the gasoline. If it flows out freely in a good trickle, then everything is in order with the breather. If it is absent or it flows weakly and intermittently, then the reason for the identification. The breather is clogged with dirt. You can solve the problem by cleaning the air hole with a regular needle or a powerful jet of compressed air.

What to do if the chainsaw continues to start?

If the initial inspection did not give anything or the defects were eliminated during the search, and the chainsaw does not start further, then you need to look for more serious reasons. It is best to identify and eliminate such breakdowns in a service center. However, with experience, you can find and eliminate them yourself. What to diagnose and check?

- Compression in the cylinder;

- Compression in the crankcase;

- Carburetor operation.

In the first case, checking the compression in the cylinder will make it possible to find out the state of the cylinder-piston group (CPG) of the chainsaw, who DO NOT WISH to start cold. For this you need a compressometer. The device is screwed into place of the spark plug and the engine is idle. The measurement shown allows you to judge the state of the CPG. In the absence of a compressor, the compression in the cylinder can be determined offhand as follows:

- Place your finger on the candle hole;

- Try starting your chainsaw engine.

Put your finger to the spark plug hole and pulling the starter, you can check the compression in the cylinder

If you feel that your finger is pulling strongly into the candle channel, then the compression is all right. The absence of vacuum in the chamber indicates a malfunction. The cylinder-piston group needs a more detailed inspection, which will give an idea of the condition of the piston and cylinder, piston rings and bearings.

The chainsaw may not start on a cold one due to the lack of compression in the engine crankcase. The main prerequisite for this is damage to the gasket placed between the cylinder and the crankcase. It is quite easy to detect the lack of compression:

- Disconnecting the top tube from the carburetor;

- Pour gasoline into an ordinary cork;

- By immersing the removed tube in the fuel;

- Tugging the starter several times.

If fuel is sucked in from the cap when starting the chainsaw starter, then everything is in order with the compression. If not. See gasket.

If the fuel is drawn in, then everything is in Pryadko. The gasket is intact. Otherwise, you will have to purchase a repair kit and replace it. How to do this see why the Chinese chainsaw does not start:

Starting the tool can be complicated by improper operation of the carburetor or its breakdown. It often happens that during the sawing process the fastening screws loosen and air is sucked into the cylinder. Check that the carburetor is securely attached. Inspect it for fuel leaks. There can be a lot of reasons for the malfunction. It is possible to pinpoint the malfunction, eliminate it and fine-tune the carburetor only in a service center.

After going through the step-by-step troubleshooting of the chainsaw engine, you can find the malfunction, fix it yourself and successfully start your working tool. DO NOT take on jobs that you are NOT confident in. Trust the troubleshooting to specialists from the service center.

Husqvarna chainsaws are indispensable helpers on the farm. With the help of gasoline powered vehicles, you can perform a variety of jobs related to construction, logging and simple delimbing. With proper handling of the tool, it will serve for a long time, but during operation, as a result of intense loads, various malfunctions occur.

If minor breakdowns are detected, they do not go to service centers and workshops, Husqvarna chainsaws are repaired independently, while it is necessary to investigate and disassemble the probable causes of defects and ways to eliminate them.

How to thin your Husqvarna chainsaw gasoline

For productive work and an increase in the service life at high power, the proportion of oil and gasoline for the chainsaw is observed, measuring the ratio of the ingredients of the fuel mixture with a measuring tank. When cooking even a small amount, a small inaccuracy affects the quality of the fuel.

For dilution, use high-quality gasoline with a minimum octane number. RON 90. If the parameter is less than the recommended one, the motor starts knocking, which leads to its overheating and increased load on the bearings. With constant work at high speeds, gasoline with an increased indicator is chosen.

2-stroke oil is recommended.

To properly dilute gasoline for a chainsaw, use the following mixing scheme:

- For motors with cylinder displacement up to 80 cm³. 1:50 (2%), i.e. 5 liters of gasoline. 0.10 l of oil;

- For engines with a volume above 80 cm³. 1:33 (3%), i.e. 5 liters of gasoline. 0.15 l of oil.

Checking the spark on the spark plug and troubleshooting.

The first step in finding the reasons why the gasoline saw won’t start is to check the spark on the spark plug. There are many factors that affect the performance of this element. However, the main ones at the initial stage of instrument troubleshooting are:

- Incorrect carburetor adjustment;

- The presence of more than it should be, the amount of oil in gasoline;

- Clogged air filter.

All of them contribute to the formation of carbon deposits on the spark plug electrode. In 50 cases out of 100, the saws DO NOT start on cold due to the absence of a spark due to carbon deposits on the electrode and their corrosion. As a result, the gap either decreases or increases.

Checking the spark plug in an idle chainsaw

Checking for a spark is fairly easy. This will require:

- Remove the tip of the high-voltage wire;

- Unscrew the candle;

- Put the tip back on;

- Lean the candle with a skirt to the cylinder;

- Start with a starter.

If a good spark is observed between the electrodes at the time the chainsaw engine starts, then everything is in order with the ignition unit. If it is not there, then it is worth cleaning the element itself and checking the gap of the electrodes. If necessary, using a special probe Adjust the distance between the contacts.

There may be no spark on the spark plug for other reasons. Of the main faults that affect the poor start of the chainsaw and the unstable operation of the internal combustion engine at idle, which the tool can stall, the following can be attributed:

- Overfilling the spark plug channel with fuel;

- Lack of contact between the high-voltage cradle and the tip of the candle;

- Failure of the ignition unit.

How will a cold chainsaw start if the candle channel is constantly flooding with gasoline? To eliminate the problem at the time of starting the tool, you can use the following algorithm:

- Unscrew the candle with a special key;

- Wipe it with a clean and dry cloth;

- Dry for 20.30 minutes;

- Remove carbon deposits with a file and adjust the gap between the electrodes;

- Drain the remaining fuel from the spark plug channel and dry it;

- Collect everything and try to start the mechanism.

If there is no spark and poor contact of the high-voltage tube with the spark plug tip, check the connection. The check can be done using a conventional tester. If a defect is found and it is eliminated, the chainsaw should start without any problems.

If the check showed that the contact is reliable, and the saw does not start further, look for the cause in the ignition unit. As a rule, a faulty unit cannot be repaired or restored. A complete replacement is required here.

There are sparks

The absence of a spark is caused by a complete failure of the spark plug and a poor connection between the tip and the high voltage wire. If, when checking the contact, no defects are detected, and the sparks are comments when the starter is turned on, change the electronic ignition system.

Ignition system

Do-it-yourself repair of the “Husqvarna 240” chainsaw, and of any other model, should begin with troubleshooting the ignition system.

First of all, experts recommend getting and inspecting the candle. The state of this element will indicate deficiencies in the operation of the fuel system.

- If the plug is completely dry, it means that the fuel mixture does NOT enter the cylinder. In this case, the spark plug is screwed into place and the fuel system is repaired.

- If the spark plug is heavily flooded with a fuel mixture, then the rules for starting the unit may be violated, or the carburetor may be poorly adjusted. It is necessary to shut off the fuel supply and start the starter. This is done in order to remove excess fuel. The candle must first be cleaned with a sharp object, then washed with detergents, dried with a hairdryer and reinstalled. After that, the tool is launched and its work is checked.

- If there are no fuel residues on the spark plug, then it must be cleaned, washed and checked for a spark. Its absence may indicate a violation of the gap between the flywheel and its magnetic circuit or a breakdown of the ignition module.

A malfunction in the ignition system may be due to the use of poor oil or an incorrect ratio of gasoline to oil.

Fuel supply system

If fuel does NOT enter the chainsaw tank, there may be two reasons for this:

- Clogged filter.

- Lid clogged.

In this case, the fuel is not supplied in full, and the tool Will not start or will start and immediately stall. The repair consists in cleaning the air filter and cover.

The filter must be removed very carefully so that the dirt that clogs it does not get into the carburetor. It is cleaned and washed with ordinary detergents.

Do-it-yourself Stihl chainsaw repair

This brand is very popular among both individuals and professionals. This easy-to-use and reliable tool can last a long time without repair. There are situations when the Stihl chainsaw” does not start or stalls immediately after the plant. What to do in THESE cases, you can find out by looking at the instructions.

Carburetor repair

The heart of any chainsaw is the carburetor, with which most tool breakdowns are associated.

Do-it-yourself repair of this unit consists of disassembly and cleaning. If the breakdown is serious, then contact the service center for help.

Most often, tool malfunctions are associated with the introduction of low quality gasoline or oil. To protect the carburetor from damage, you must follow some preventive measures:

- Start the chainsaw strictly according to the instructions.

- It is not recommended to store gasoline in a plastic container. This will help to avoid heavy carbon deposits.

- The fuel mixture cannot be stored for a long time, as it loses its quality over time.

DIY chainsaw repair “Husqvarna” and “Stihl”:

Chainsaws, simple in design and reliable in operation, are very popular among owners of private houses and summer residents. When handled correctly, this tool will last a long time and rarely break. over, it will NOT be difficult to eliminate the cause of the chainsaw malfunction with your own hands, especially if you know where to look for the cause.

Chainsaws “Husqvarna”. Major malfunctions

The tool of the Swedish manufacturer is able to transform hard work into a simple task. Chainsaw models Husqvarna 137, Husqvarna 240 and Husqvarna 365 are distinguished by three features:

- High engine power;

- Improved engine filtration system;

- Ability to absorb unnecessary vibrations.

If the tool is operated strictly according to the instructions and its malfunctions are eliminated in a timely manner, then it will delight with reliable and stable operation. Correctly performed repairs with original spare parts will allow you to use the saw for a long time.

The main prerequisite for a chainsaw breakdown is most often engine failures, which can manifest as follows:

- Does not start;

- Unstable idle;

- Starts up and immediately stalls;

- Don’t have enough power.

In this case, the malfunction should be sought in the ignition system, piston group or fuel system. Often the reason for poor tool performance can be associated with the clutch, braking system, lubrication mechanisms, tire.