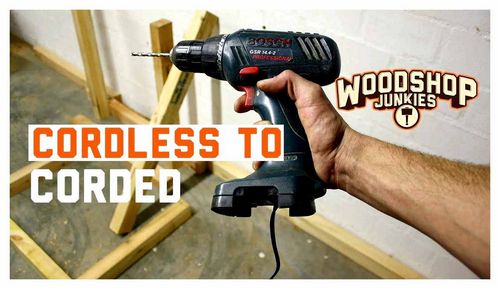

Converting a screwdriver to a network using laptop charging

In the event of a battery failure, a household screwdriver can be switched to mains power by making some changes to its design. This does not require a lot of expenditure of finance, time and effort. The positive nuances of this transformation are obvious: you do not need to constantly charge the battery, and at the same time, Forced downtime will go away. After all, the shortest duration for charging the device is more than 3 hours.

If you need to connect the screwdriver to the network, you can use the charger from an old laptop. It has similar characteristics to a screwdriver and can be easily found in every home or workshop. But, still check what output voltage is shown in your charging. In this case, chargers for 12-19V are suitable.

Scheme of your actions:

- From a failed battery pack We take out unusable batteries.

- We take charge from the laptop.

- Cut off the connector and strip the wires from insulation.

- Soldering bare wires or wrapping them with electrical tape.

- We make an outlet for the wire in the case.

- Assembling the structure.

This manipulation will allow you to use the screwdriver at any moment, and without stopping for charging.

Why do you need to remodel a mains-powered screwdriver

In order for you to be able to use a screwdriver at any time without unnecessary wires, even in the most inaccessible places, the mobile screwdriver is converted to a network.

Methods for converting a cordless screwdriver into a network vary in complexity. One of them is that powering the charging from a laptop requires practically no knowledge and skills. To mount a computer power supply, you need to be able to handle a soldering iron, and to repurpose a Chinese adapter, you must be able to handle a measuring device. In addition, there are several more ways to convert a cordless screwdriver directly to the network.

Namely:

- Using a power supply device from a personal computer instead of a battery;

- Gave new life to car battery;

- Applying, as source, a power supply from halogen lamps;

- By connecting the Chinese 24V power supply board.

For brainy craftsmen, it is NOT difficult to perform such manipulations. If you are NOT confident in your abilities, then it is better NOT to take risks and seek the help of a knowledgeable specialist.

Convenient mains screwdriver: features of use

The cordless cordless screwdriver is a great helper in your home. Almost everyone who he has never let down can agree with this. Those whose work stopped halfway have a completely different opinion. This tool will help you always and everywhere, but exactly until the battery is NOT discharged. over, the quantity in it is limited. In moments of idleness, the battery can also deteriorate. Batteries typically last no more than three years. When this time expires, it has to be changed or sent to the museum of obsolete things. The situation is possible if you convert the screwdriver into a network one. There are enough ways to do this.

Mains transformers of THESE brands are of high quality and reliable in operation. In addition, they are quite compact, lightweight, and do not complicate the work with the tool. Their load characteristics are close to those required for a standard screwdriver. In their design there are 2 input and output wires, which allows supplying power to halogen lamps and other types of electricity consumers with a voltage of 12V. However, to use the converted device, you must adhere to some rules.

Here they are:

- Let the appliance rest for 5 minutes every 20;

- We fix the cable in the elbow with our hand so that He does not interfere with the work;

- Clean the power supply from dust;

- DO NOT use too much extension cord;

- Do not use the device without grounding;

- It is forbidden to use a converted device for work at height.

Before each start of work with the converted device, make sure it is working properly.

How to convert a cordless screwdriver to a network 5 solutions to the issue

How to convert a battery device to a 220 volt screwdriver

Today the screwdriver belongs to the devices that we very often use in everyday life. It is also irreplaceable in production. This device is suitable for a variety of electrical and construction work. With its help, furniture and other items are assembled, the design of which requires threaded connections.

The reason for this decision is also the fact that when the device is not used for a long time, the battery is discharged independently, which leads to breakdown of the screwdriver due to the destruction of some elements. It is impossible to repair a failed battery, and it is not always possible to purchase a new one. Often, component parts can be purchased only from the official representatives of the manufacturer. Accordingly, the cost of a new battery will be almost equal to the cost of a new screwdriver. Therefore, some craftsmen come to the decision to re-make the screwdriver in the network.

Materials and tools required for this:

- Charger from this screwdriver;

- His native battery;

- Soft stranded electrical cable;

- Soldering iron and solder;

- Insulating tape;

- Acid.

To begin with, you need to solder the lagging ends of the cable to the terminals of the charger. You need to know that copper wires of a cable with brass contacts can be soldered only after they have been treated with acid. Experts recommend using special solder, but sometimes the simplest methods are used in the form of acid treatment.

How to make a screwdriver from the network

When the batteries stop working due to the fact that they have simply outlived their life, many begin to wonder how they can fix the situation and remake their old cordless screwdriver into the network with their own hands. After all, it is no longer possible to repair a battery with a destroyed element, and the cost of a new one is almost equal to the purchase of a new screwdriver. But zealous and skillful owners came up with a way out. to power the screwdriver from the mains. Some could even invent a device that works simultaneously from the mains and from the battery. But it’s best not to.

Alteration of the cordless screwdriver in the network with your own hands

My own experience: with our own hands we are converting a cordless screwdriver into a network one. With a minimum of tools, known and almost free. We use the power supply from an old laptop.

Power supply and some theory

Forums and search on the Internet prompted me the standard fate of a person, who decided to make a network screwdriver with his own hands from rechargeable batteries. this is a long study of the theoretical part (in the absence of specialized or even technical education, as it was with me), a quick search for the necessary switching power supplies. understanding that he will spend a couple of thousand rubles, and the choice in favor of buying a new Screwdriver for replacement.

Indeed, let’s look at the theory. My PRORAB was powered by a 12V battery, the markings on its engine said the same. The manufacturer, according to tradition, does not indicate the power of the device, since the figures are not very impressive against the background of wired counterparts. After that, it was necessary to estimate with what parameters the power supply unit for the Screwdriver would be needed.

Measurement of the consumption of the motor at failure showed that it would take about 100 VA in order to show the maximum performance. Approximately the same parameters of the guru advised on the forums for 12 N / m of torque. take the impulse 8-10. The cost of such a block comes out in 1000 g., Plus wires, a plug and other strapping, which is also a bit too much.

The solution was found quite simple. if you don’t have your own power supply, then it will definitely be at work. over, practically in any company. after all, there is an IT department everywhere, which, most likely, maintains and repairs employees’ laptops. That’s where I went. In the rubble of electronics “for release” there was a bunch of power supplies with a variety of parameters. There were no outputs for 12V, and in the end I settled on a unit from a Toshiba laptop with output parameters of 15V / 5A, or 75VA, which are quite suitable for me. An interesting option was Sony with 19V, but the Chinese did not want to strain so seriously.

Soldering and packaging

We begin to collect what we have prepared.

- We put the soldering iron to warm up, but for now we put a wire from the power supply into the hole in the battery case. In the photo, I additionally put one of the cans so that it supported the wire and did not let it sag, and for the company. improved the body balance;

- We install the bank approximately in the place where it will stand, and try on the wires. After trying on in a comfortable position (the wire can be pulled through the body further), we start soldering. Do not forget that the current is constant, and you should check the polarity before connecting the wires;

- Soldering both wires and insulating the soldering points with electrical tape;

- We install the jar with the terminal in its place, placing the wires inside so that you can assemble the body completely;

- A cut off piece of the plug’s wafer, pushing it tightly into the hole in the battery case to fix the wire in it;

- Assembling the battery case.

By the way, before soldering, you can check the performance of the entire system. For example, I clamped the wires with ordinary clothespins (after all, it is household work, and not DIY in a ready-made workshop) and connected the upper part of the battery case to the Screwdriver.

This concludes our work, you can check the product and show off to everyone what a good cordless screwdriver turned out to be from cordless.

Alteration of cordless screwdriver

Actually, to rework.

Since I had a completely finished power supply unit with a sufficient wire length (1.8 meters), I decided NOT to build it up and NOT try to transfer the unit to the battery case, as originally planned. The foreman also did not want to worsen the good weight distribution, so he decided to leave the battery as it is, just put the wired power into it. It turned out as well as possible:

- Mains supply Screwdriver;

- Excellent balancing. with a heavy bottom;

- The ability to disconnect the “mains” battery and connect a fresh.

Perhaps the creation of such a “network” battery is a promising idea for a more industrial volume, as a reserve for a set of cordless tools.

Further, turning my story from a record of how I was preparing, into an instruction for people who are just planning to repurpose their cordless screwdriver into a network.

Battery preparation

A little more work with the battery.

- Remove from the Screwdriver, untwist the case;

- We remove all mechanical parts. We see the battery banks held together (hello to the Chinese) with tape. We take out the cans from the battery;

- We bite off two contacts and remove the upper bank on which the battery terminal is held. then we will perform all operations with it, and leave the rest of the block of cans as ballast. One wire has already been soldered to the connector, add a second one and wrap it with electrical tape for reliability;

- The finished case: a drill in it with a hole with a radius slightly smaller than the available wafer from the cut off plug on the power supply.

This completes the preparations. We have:

- Battery case with hole;

- Battery bank with a terminal and two outgoing wires from it;

- Power supply cable with stopper wafer and two insulated wires.

It’s time to collect.

Preparation, materials and tools

My version of the alteration is quite simple, because a minimum of tools and materials were needed.

- Cutter or knife;

- Pliers;

- Soldering iron.

I will make a reservation that the alteration is quite household / handicraft, and real masters will use a soldering station here, a crimp for stripping and other accessories, but the manipulations performed in the kitchen are quite worthy and are elementary home tools.

- Electrical tape. where without it;

- Wire. for such a current, 0.5 mm 2 is enough;

- A drop of solder (if you solder at all, you can use a clamp).

Before starting work, I insulated my place. they laid it out with newspapers so as NOT to make the living room and used a wooden substrate for safe soldering.

Preparing the power supply

The first step is to prepare the laptop power supply. All preparation consists in removing the plug, which fits to the laptop and preparing the wires for soldering.

- We cut off the plug, but do not throw it away. it has a soft plastic wafer on it, which will still be useful to us.

- Use a knife to clean the outer insulation

5 centimeters of wire;

After insulating the wires, the preparation of the power supply is completed, we proceed to the battery.

Background

Once upon a time, moving to a new apartment, I will receive as a gift a so-called “household screwdriver” under the brand name PRORAB 1112 B1N. This is a simple Chinese device, hundreds of types of which are sold in our construction and not very supermarkets. He played his role in the move. he was also a mixer, and was used to assemble furniture and tighten screws on thresholds, after which he was undeservedly forgotten. In use, I got the commonly used Hitachi DS12DVF3, and PRORAB, along with its Chinese battery, was forgotten on the loggia.

Three years of storage on the freezing loggia did not spare the banks, and after the discovery of the shura during the spring cleaning, it was no longer possible to use it. there was enough strength for a couple of self-tapping screws. At the same time, there was work for the auxiliary screwdriver / drill. during the manufacture of household furniture it is very annoying to change the equipment.

So I came up with the idea of converting an old cordless screwdriver into a network one. This had to be done, of course, with our own hands. the new Foreman costs 1500, the replaceable battery for it. 1200 The choice of the owner sparingly, as they say, is obvious. we redo it with our own hands in the network.

My example of converting a cordless screwdriver into a network is very handicraft. a minimum of tools, no preparation and poor knowledge of the materiel, but the result is that the network PRORAB has been successfully working for half a year, helping with household chores.

Making a do-it-yourself network screwdriver is surprisingly easy, and if you use a little ingenuity, it’s also very cheap. I tried it myself and would advise anyone who made it to the end of this story.

Remote power supplies

There are several types of power supplies that can be used as a power source for cordless screwdrivers. Let’s consider some of them.

- Power supply unit from a personal computer. You will need a power supply unit from a PC of the “AO” format. Such a power supply unit differs from others in that it always has a 220V power supply button. Also, such power supplies have an advantage in that the power indicated on it always corresponds to the actual power, in addition, such power supplies have good protection against overloads and a cooling fan. We need a power supply with a power of 300-350 W, and the current in the 12 V circuit must be at least 16 A. To remake such a power supply, it is necessary, firstly, to remove the protection from switching on by unscrewing the power supply case. To perform this work, you need to find a green wire on the power supply connector and connect it by soldering or a jumper to any black wire located on the same connector. Secondly, in the MOLEX type connector (it is smaller), we leave only the yellow (12 V) and black (body) wires, the red wire (5 V) Remove. Further, with a flexible wire with a cross section of at least 2.5 mm and the length you need.Connect the wires of the power supply unit to the terminals of the Screwdriver. It is very important to observe the correct polarity here, so the cable must first be marked.

- Car battery charger. If you have an analog charger with manual adjustment of voltage and charge current, then alteration is NOT required, just connect it via a cable to the Screwdriver terminals and adjust the voltage according to the Screwdriver voltage. And also we must not forget about the polarity of the supplied voltage.

- Laptop charger. This method is simple as it requires almost no technical knowledge. If there is an unnecessary charger from a laptop that is suitable for voltage, then after checking its output voltage, you can connect the charging to the contacts of the Screwdriver. To do this, you need to disassemble the battery pack Screwdriver and remove the worn out batteries from there. Having made a hole in the case of the battery pack, it will pass the wires from the charger there and connect them to the screwdriver contacts, while observing the required polarity. I applied a 220 volt network to the charger, you can start work Screwdriver.

- Car battery. This method is used when wires are removed from the Screwdriver for connection from a network device. It is enough to connect them observing the polarity with the terminals of the car battery in order to continue working Screwdriver.

- Homemade power supply. In order to make a portable home-made power supply yourself, you need knowledge in the field of radio engineering, as well as be able to read electrical schematic diagrams. In order to make a homemade power supply, you need a power transformer. Such transformers were previously used in tube TVs, as well as in other similar household appliances. The primary winding power of the transformer should be 205-300 W. The voltage of the secondary winding must be selected within 18-30 V. The cross-section of the wires of the secondary winding must withstand a current of at least 15 amperes. A diode bridge or a bridge assembled from SEPARATE diodes must also be rated for the corresponding current. Losses at the diode post are approximately 1.5 volts, respectively, the output will be close to the required voltage. You can practically select the required voltage using a conventional incandescent lamp with a voltage of 220 V and a power of 100 watts. By connecting it as a load, the required voltage must be achieved by the number of turns of wire on the secondary winding of the transformer. Next, the assembled power supply unit must be placed in the case and the low-voltage wires must be brought out to the connector for connecting to the Screwdriver. It is also important to install fuses in the primary and secondary circuits of the transformer, thus protecting the power supply from short circuits.

DIY network screwdriver

The biggest advantage of the cordless screwdriver over the cordless one is its portability and portability. But he also has a very big drawback. the low energy capacity of the battery. With strenuous work, charging the battery The screwdriver lasts about forty minutes, then it needs to be charged. The number of charge-discharge cycles in batteries is limited, as a result of which the battery becomes unusable. With rare use of the Screwdriver, the battery self-discharge and the destruction of its components.

A failed battery cannot be repaired, and purchasing a new one can be problematic due to the variety of models and lack of standardization. And even if it is possible to find the required battery model, then its price is comparable to the price of a new Screwdriver and this raises the question, is it necessary to purchase a new battery or can you do something else.

All this pushes screwdriver owners to the question of how to convert a cordless screwdriver into a network.

Alteration of a cordless screwdriver on a network do it yourself

The most common and indispensable tool for working in the country, garage or at home is the Screwdriver. And also it is very much in demand when performing various construction and electrical work in professional workers, who, by the nature of their activity, have to deal with structures that have threaded connections.

Network Screwdriver Options

For cordless screwdrivers, there are two options for converting a cordless screwdriver to a mains supply. The differences between the options are more related to the electrical schematic part than to the operational part, therefore, when choosing a method of alteration, you need to focus mainly on the availability of the element base and your preferences.

- First, you can use an external power supply. In this case, there are restrictions on the dimensions of the power supply, its weight and electrical safety, since the Screwdriver is supplied with low voltage.

- Secondly, you can place the power supply in the battery case. In this case, all the pluses of the first option turn into minuses. The plus in this option will be that during the work it is not necessary, along with the Screwdriver, also carries the power supply.

Built-in power supplies

- Now there is an opportunity to purchase a ready-made power supply, which has the necessary characteristics, and most importantly, dimensions. Having chosen a suitable power supply, carefully removing it from the case and placing it in the case from the battery a screwdriver. Depending on the layout, you may have to make a number of alterations, for example, install the transformer in a different location and lengthen the wires to the circuit. Here you need to Pay attention to the fact that the elements of the circuit do NOT touch the metal parts of the transformer. It is advisable to install the power elements of the circuit on radiators, it is also advisable to drill holes in the battery case for better cooling.

- And also experienced radio amateurs develop their own various options for how to remake a screwdriver for mains operation, assemble various power supply circuits and place them in the battery case.

Although the screwdriver, converted from battery to network, loses in mobility, it compensates for this by the fact that in this case you can forget about constant recharging of the battery. And also, you don’t have to think about what to do in a situation when the battery fails.

Using a car battery charger

The principle is the same as with the introduction of a computer power supply. You need to purchase an old charger for the starter batteries. The modern fashion for compact impulse chargers has left analog linear devices with manual control of voltage and charge current behind board. Therefore, such a device can be purchased on the automotive market for a symbolic cost.

Charger MAX INTER

It’s good if the voltage can be adjusted smoothly. in this case, your makeshift power supply will fit any screwdriver.

Converting it to a power tool is reduced to connecting the input of the electric motor to the power terminals of the charger.

We build in a ready-made power supply

To do this, you need to purchase a ready-made block with suitable characteristics and dimensions. There is enough such good on the radio market.

Take the body with you and go to the fitting. When the desired power source is purchased. carefully Separate it from the case.

By placing a screwdriver in the battery box. All components Must be securely fastened.

If necessary, extend the wires between the control board and the transformer. If the circuit touches the metal parts of the transformer during operation, a short circuit will occur.

Since the space in the case allows. spreading the board and transformer for better cooling. Whichever quality power supply you choose, the load will be high and overheating is possible.

It will not be superfluous to fix additional radiators on the power control microcircuits. Operate the screwdriver for a long time, unplug it and touch the radio parts on the control board.

You yourself will understand which elements need heat removal. Holes for air circulation can be made in the housing.

Do-it-yourself alteration of the power supply unit will not take much time, and the cost of the purchased module is incomparable with restoring the battery’s performance.

Making a homemade power supply

If you are familiar with the principles of building electrical circuits, you can make your own power supply. Scheme giving general concepts. in the illustration.

The transformer can be picked up from an old tube TV, or other household appliances. Power for 220 volts 250-350W. The main thing is the power supply. donors should not be pulsed.

The voltage on the secondary winding is 24-30 volts. The secondary winding is made from a wire of the corresponding section.

However, if the current of the output winding is not less than 15 amperes (see the transformer specification). is there nothing to worry about.

After losses on the diode bridge (1-1.5 V on the diode), you will get the required output value.

If you have an electrical engineering education. We will make the calculation yourself. Or in a practical way: by connecting a 220 volt 100W incandescent lamp as a load, measuring the output voltage. E

If it exceeds the requirements of the screwdriver. Reduce the number of turns of the secondary winding of the transformer.

Battery case power supply

Mobility remains, you are limited only by the length of the network cable. The only problem is how a sufficiently powerful transformer is squeezed into a small case.

Remember Ohm’s law again, and understand that a powerful 220 volt electric motor can be compact.

Conversion of a cordless screwdriver to a mains supply

- Battery drawbacks

- There is a way out. reworking the screwdriver in the network

- External power supply

- Battery case power supply

- DIY screwdriver alteration

- Using a power supply from a personal computer

- Using a car battery charger

- Making a homemade power supply

- AC adapter for screwdriver in battery housing

- We build in a ready-made power supply

- Homemade power scheme

Those who have used a cordless screwdriver have appreciated its convenience. At any time, and not getting tangled up in wires, you can crawl into hard-to-reach niches. Until the battery runs out.

DIY screwdriver alteration

Consider the option with a remote power supply.

Using a power supply from a personal computer

On the radio market for a small cost, you can buy an old power supply from a personal computer. We need a version of the “AO” format, which had to be turned off with the key after exiting the operating system.

Experienced users remember such system blocks. The advantage of such a PSU is also that it indicates an honest power. If it says 300W, then you can safely remove 15-16 amperes from the 12-volt output (again referring to Ohm’s law). This is enough to power an average screwdriver.

Such blocks have a power button in the kit. Another advantage is the presence of a cooling fan and an advanced overload protection system.

If you will hide the power supply in a beautiful case, do not forget to leave a hole for ventilation.

The connection is very simple. Black wire (-), yellow wire (12V).

Limitations. a screwdriver with a supply voltage above 14 volts will NOT work.

AC adapter for screwdriver in battery housing

If your tool is NOT too powerful, you can place the power supply in the handle or case from damaged batteries.

External power supply

Idea Not as absurd as it might seem. Even a large and heavy step-down rectifier can just stand near the outlet.

You are equally tied to the power supply, and to the stuck mains plug. And the low-voltage cable can be made of any length.

IMPORTANT! Ohm’s law says. with the same power, decreasing the voltage. Increase the current! Accordingly, the 12-19 volt supply cord should have a larger cross section than 220 volts.