Installation of equipment on the coupling

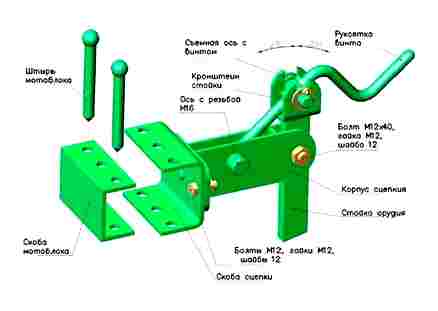

To install additional equipment, it is necessary to mount the hitch axle to the equipment bracket, which, by the way, is removable. Next, an axle is inserted into the outer hole of the hitch. It is necessary to tighten the bolt, aligning the holes on the chassis and the equipment rack. Next, it remains to secure the contact with an M12 bolt and a corresponding nut.

Why do you need a hitch to a tiller. no need to explain, the same adapter, an irreplaceable thing, but nowhere without a coupling.

Do-it-yourself hitch for the tiller

The hitch for the tiller, an indispensable and most important unit in the design, without it, most types of attachments cannot be used. Structurally, this knot may differ, but the most common one can be considered a U-shaped hitch. We will try to tell you how to make it yourself. If you do the coupling to the tiller with your own hands, you need to carefully approach the whole process so that this unit turns out to be of good quality and can cope with pretty decent loads.

Tiller Hitch Drawings

Below are the drawings of a universal hitch suitable for most popular brands of tillers, such as: Celina, OKA, Neva, Salyut, Favorit, etc..

Purpose of the universal hitch in conjunction with the tiller of attachments: harrows, plows, diggers, planters, etc..

Tips for work

Attachments connected to the tiller through a hitch can be easily adjusted for a certain type of work and the specifics of the soil. Thanks to its design, the hitch is adjustable in various parameters. Using the initial settings, it is necessary to set the hitch grooves to “0” of the transverse grip angle, and fix it with a bolt and nut. Also deduce the minimum longitudinal angle of capture. The first few meters when working, watch how the tiller behaves with the tool.

If you need to set a greater depth or, on the contrary, reduce it, stop the tiller, and use the screw handle to adjust the linkage. After these manipulations, you can continue to work, along the way watching the work of the tiller and the tools.

Do-it-yourself hitch to the tiller

For the manufacture of a U-shaped coupling, a metal channel of the required size and thickness is suitable. This mount is located under the steering column of the tiller.

Following the drawings, we drill holes in certain places through them. The bracket and pin will be attached. All parts must be made of high-strength, high-quality steel, and do not forget about the diameter of the holes.

In order to attach a hitch to the tiller, you need a bracket located in the direction of the top or bottom, while its end should not come into contact with the surface to be treated..

Often, working with a tiller implies the use of equipment that does not have a typical type of coupling. Often, additional devices are used for the tiller, with non-standard types of coupling. In this case, additional adapters are used to connect them..

Installing the hitch on the tiller

To the tiller brackets, the hitch brackets are installed using pins. For a more reliable fastening, it is recommended to fix the bracket using M14 bolts.

Tiller hitch video

This video tells about the self-production of the hitch for the Weima 1100D tiller

Homemade universal hitch

The hitch gives great opportunities in the use of various equipment, and made by hand, adhering to the instructions on the drawings, then the service life of this unit is many years.

How to make a do-it-yourself hitch for a tiller: drawings and dimensions of a universal hitch, video

In some situations, you may need to make a do-it-yourself hitch for the tiller. tiller is an essential attribute of any gardener. The purchase of a motor-cultivator is often accompanied by the purchase of related parts: a trailer, a hiller, a plow, a harrow and other parts. In order to attach them to the unit, a hitch is required. Now on the market cultivators are represented by a huge number of manufacturers, but not for every unit you can find a suitable spare part, therefore you can make a hitch yourself.

Diy universal hitch for a tiller

The universal hitch is suitable for most models of tillers, will provide aggregation with attached or trailed equipment without backlash. It is quite simple to make a coupling device, the main thing is to determine the tasks that it should solve, choose drawings and high-quality materials that ensure the strength of the unit.

The U-shaped trailer hitch will fit most of the trailer. The main point in creating a hitch is to match the dimensions of the brackets of the tiller itself and the hitch. A feature of the device with a bracket is that the attachment, aggregated with it with a tiller, takes a position a few centimeters below the bracket itself, so it should not be at the level of the cultivated land.

On the Internet, you can find many videos in which the owners of trailers talk about the nuances of working with attachments, including how to make a hitch.

How to make a hitch on a tiller with your own hands

Consider how to do it yourself. A homemade hitch for a tiller will require you to purchase high-quality metal products, which can be channels, you will need to make several holes in them. Or some car parts will do (the trailer hitch can be made from a cardan). If a reinforced mount is needed, then it must be stronger and larger than the usual variety..

The drawings on the Internet are different, so you need to choose the one that suits you.

To make a coupler you will also need:

- fasteners (steel pins, bolts);

- a lever allowing to change the position of the hitch;

- metal welding to attach the shaft;

- drill and drill for metal;

- tape measure or ruler;

- screw installation wrenches.

So, the universal hitch for the tiller includes the following components:

- Two U-shaped nodes of the same size, one of which is equipped with 6 holes, and the other – 8.

- A body (for the creation of which welding is required), which has 2 threads: M12 and M16 and a connecting element with one of the nodes.

- Adjustment lever located in the body and consisting of a screw connected to the bracket and handle. In this case, the bracket should be directed up or down and not create any interference with the operation of the unit..

How to correctly position the connecting unit, you need to look in the instructions for the unit.

The hitch is attached to the tiller with pins that are installed in the holes made in the nodes, while in quality they must be the same as the materials from which the hitch itself is made.

Do-it-yourself hitching to the tiller is performed to connect not only the trailer, but also the plow, hiller and other devices. At the same time, it will be possible to adjust it by adjusting it to a specific attachment..

Before starting work, the device should be checked, tighten all the bolts.

It should be noted that it is not difficult to make homemade couplings on your own, but it is better to purchase a unit by picking up the entire set of attachments and additional equipment for it at once, or at least make sure that such devices exist.

Let’s consider how to choose a hitch for the Tiller Neva. Now you can buy cultivators from various manufacturers, differing in weight, size, quality and performance. Consider the Neva tiller, which is especially popular among gardeners and gardeners, whose production was launched in St. Petersburg back in 2002 at a subsidiary of OJSC Krasny Oktyabr, which produces aircraft.

In the production of chillers, engines Subaru, Briggs Stratton, Honda are used, which have an increased resource and efficiency, which contributes to effective soil cultivation. The device has a fairly simple and understandable gear shifting system even at first use. For Tiller Neva, you can easily pick up various attachments manufactured for a specific brand.

The plant produces several models of tillers, at the same time it divides them into 2 large groups, differing in the gearbox: classic and Multi AGRO.

The main category of users of tillers are retirees, so most often one of the inexpensive, but lightweight and high-quality models is purchased – MB-B6.5 RS Compact, which weighs only 70 kg, is well suited for processing sandy, loamy soils.

Using additional attachments for the unit, you can easily cope with the cleaning of the territory and with the transportation of goods, even over long distances..

How to Build a DIY Travel Trailer – Coupler Install, Hitch, Sway Control (Part 7)

On the Tiller Neva of this model, it is advisable to additionally purchase a support wheel, which will be useful when installing on the lug device, as well as to facilitate the work of loosening the soil due to the fact that it will not allow the tiller to “bury” in the ground.

Tiller hitch types

There are the following types of hitch for tillers:

- Single or double, which are used depending on the amount of equipment attached.

- Reinforced, used for heavy cultivator models. Compared to a single or double version, this type of tiller hitch is much thicker and longer, due to which the attachments will sink deeper into the ground, which will improve the quality of plowing..

- With an adjustable angle of rotation of the shaft, which will facilitate the placement of additional equipment at the required level, this will greatly facilitate the work with the cultivator.

- Versatile, suitable for several models at the same time.

But do not be upset if you cannot find a hitch for your cultivator – you can do it yourself. Some craftsmen are even able to make the whole tiller with their own hands, so it will not be difficult to build an ordinary coupler. For example, a hitch for a tiller, made by hand from a crosspiece, used parts and spare parts. On the Internet, you can easily find drawings of couplings for a tiller, the main thing is to correctly calculate the dimensions. The most popular is the U-type hitch.

DIY tiller plow hitch

The plow is one of the most important attachments for a tiller. However, the manufacturer does not always provide a hitch in the kit. It will not be difficult to make a hitch for a plow with a tiller; you can use the simplest type of drawings – a U-shaped hitch.

Depending on how much power the tiller has and what kind of land the plow will work on, a more or less durable hitch will be needed. There is always a tremendous load on this node, so it must be made of high-quality materials, especially if heavy soil is to be worked..

What type of hitch for attachments and trailed implements do you use??

Possible problems

However, like any other thing, tillers can break. Especially if they are of poor quality. Below we will tell you about the repair of the tiller.

So, all problems can be divided into several categories:

Fuel is not being supplied correctly. To solve the problem, check the ignition and clean the gas tank, as well as the entire fuel supply system. Try starting the tiller again. If this does not help, then you can flush the fuel cock and tank with clean gasoline, and then blow out the connecting hose located near the carburetor..

Broken carburetor. This can also be signaled by a problem with the fuel supply. In order to repair a part, check the condition of the bracket and the float. Adjust the design with a screwdriver in case something is wrong. Also check if the valves are in good condition..

Gearbox problems. Constant noises can become an indicator. This indicates that the oil level is too low. If simply adding oil from the noise did not save you, then you should flush the entire system and change the brand of the oil to be poured..

In addition, check how firmly the transmission elements are holding. If the fastening is not tight enough, tighten the bolts. Or if you find any defects, be sure to replace the broken parts..

Another breakdown option may be a problem with the engine – the ignition pedal fails (eliminated by removing carbon deposits), or they can be caused by breakdowns in the spark plugs or the electrical network. Unfortunately, nothing can be fixed here. You just have to replace the part.

Why make a tiller with your own hands?

So, what are the advantages of a custom-made tiller? First, it will provide tremendous assistance in processing (in particular, plowing) the land and will reduce time and labor costs..

In addition, if you can make an all-terrain vehicle out of it, it will help you to travel long distances and into the most difficult-to-reach places. In addition, it consumes quite little fuel (5 liters is enough for half a day of intensive work).

You can use the unit for transporting goods up to 300 kg (for this you will need to attach a trailer for the tiller), harrowing the soil, harvesting, removing snow and debris, distributing fertilizers over the site.

With due diligence, a home-made device in its characteristics will hardly differ from an expensive imported one.

DIY tiller – how to make a simple and reliable homemade tiller for the household (105 photos)

Many have country cottages with land plots where all kinds of vegetables and fruits are often grown. And in order to facilitate the hard work of the gardener, many decide to purchase a tiller.

However, it can be quite costly to purchase. Therefore, in order to reduce costs, many decide to make a homemade tiller with their own hands. Yes, this seems like a rather difficult task, but in fact, a lot of people can cope with it..

- Why make a tiller with your own hands?

- Manufacturing process

- Equipment

- What you need to know?

- Wheels

- Basis of construction

- Engine

- How to make a mini tractor?

- Where to begin?

- Possible problems

- Conclusion

- Do-it-yourself photo of a tiller

What you need to know?

So, before starting work, try to study at least a little the structure of the internal combustion engine..

We recommend that you familiarize yourself with several factory models, their internal structure. This will help you better understand the manufacturing process and reduce the risk of injury..

Wheels

Pick up parts and assemblies – they should be close at hand and in good condition. Size them correctly – the wheels must be correctly matched to the engine and suspension. Otherwise, you won’t be able to make a good product..

How to make a mini tractor?

However, in addition to the tiller, you can also make a mini-tractor. Do it yourself too! To do this, you will need a Neva tiller and other small parts: metal fasteners and sheets, pipes, wheels (2 pcs), a seat, a welding machine and a set of tools.

Manufacturing process

How to make a tiller with your own hands? Not that difficult. First, determine what needs you will be using it for. The power of the engine and the design as a whole will depend on this..

After that, make drawings of a homemade tiller. Pay close attention to all the details. Draw them clearly and clearly. This will significantly reduce the time that you spend on manufacturing and assembly, as well as reduce the number of possible errors at times..

Where to begin?

First, make drawings of the future tractor. You can find the finished scheme in the public domain on the Internet. Then make a frame from tubes and metal fasteners.

It is desirable that it has a movable part so that the trailer can turn. After that, make a body from a sheet of metal..

The sides should not be too high – about 25 cm. Now you can proceed with the final assembly: attach the seat, attachments. Test drive time – if everything goes well, then feel free to get to work.

Equipment types

It is important here to start with the fact that all equipment that is attached to the front of the tiller is considered attachment. Trailed devices are all elements that are connected to the device using a special hitch located at the back. When making a do-it-yourself hitch for a tiller, it is important to take into account one more fact. This group falls into two categories. The first category includes highly specialized equipment, and the second category. multifunctional.

Device categories

For example, a harrow or a potato planter can be used as a hitch. These devices belong to the first category. Landing and steering mechanisms are ranked as the second type. In other words, this is equipment that is only intermediate between the tiller and some other device. These items are considered universal and are often referred to as adapters..

Trailers deserve special attention. It is believed that this is a highly specialized technique, since it can only be used for the transportation of goods. In fact, you can use a trailer to transport almost any item, which significantly expands the functionality of the device. It is also worth noting that it is the trailer that is a prime example of an adapter that has an elongated shape, at the end of which there is a wheelset. A capacious body is installed on top of this element, which serves for the transportation of goods. Currently, there are many different variations, differing in shape, maximum carrying capacity, type of wheelset.

Assembly recommendations

The most important point, as mentioned earlier, is the material from which the tiller hitch is made. In this case, he will decide everything. Therefore, it is recommended to carefully select the raw materials..

In the selected piece of material, you need to make several holes through which the parts will be connected using fasteners. You also need to have a bracket on hand, which will also be used to make the hitch. Experts recommend bending its long end either up or down so that in the future it does not interfere with the next steps. However, here it must be borne in mind that under no circumstances should he touch the ground..

Another simple but important tip. this is to take the factory model as a sample. If in the future you need to attach a non-standard attachment to the tiller, you will have to use an adapter.

The simplest construction of motoblock homemade products is called a pipe-in-pipe coupling. It is made according to the following principle. A pipe with a smaller diameter must be welded to the end of the workpiece. It is with the help of this part that the coupling will take place. Another element of similar dimensions is welded from the opposite end. This part will serve to connect the tiller directly. This type of attachment is considered not only reliable, but also provides excellent mobility..

Coupling assembly

To install the towbar with your own hands, do the following. The brace of the device is aligned with the corresponding mount. It is usually located under the wheel of a tiller. After that, the mount is fixed with a pin. The most reliable option is the use of a spacer bolt with dimensions of 12 by 60 mm.

After that, it is necessary to mount the removable axle of the hitch on a plow, trailer or other. To fix the hitch with your own hands, you must insert a threaded axle with a diameter of 16 mm into the hole obtained. A screw is screwed onto this element. It is also necessary to drill holes on the sides, into which bolts measuring 16 by 40 mm are also inserted..

Do-it-yourself trailer for a tiller: drawing, recommendations for manufacturing

Before moving on to the question of how to make a tow hitch, you need to figure out what they are. The thing is that the tiller has clutch assemblies both at the front and at the rear. In this regard, there are various devices that can be connected. In addition, the equipment differs in its functionality..

What you need to know?

In order to successfully operate a trailer or other device, it is very important to have a strong hitch element. It is he who is the trailing device with the help of which the equipment is moved due to the power of the tiller..

There are a lot of options for making a trailing device for a tiller with your own hands, but it is best to use the simplest and most functional one. It is necessary to use high-quality steel as a material for manufacturing so that it can withstand enormous loads. It is best to use a channel to create a hitch if it fits in size and thickness. A simple option is the U-shaped hitch for the tiller.

Hitch

There are a huge variety of different devices on the market that serve to couple the tiller and any device. It is only important to choose the right one so that it fits the specific adapter. However, if this is not possible, then it is quite possible to make a towing device with your own hands. Although this process will take a lot of time and effort, the result is worth it..

It is very important to remember a few basic rules here. The very first thing. this is the engine power of the tiller itself. If a do-it-yourself hitch is too heavy, then, naturally, the tiller will not budge it. Most often, a do-it-yourself hitch is made for a car with dimensions of 1 by 1.15 meters. Using such a trailer, you can transport no more than 3 quintals of cargo at a time. If the volume of the tiller engine is 5 liters or more, then the dimensions of the trailer can be increased by 25-35 cm.

If the farm uses a very powerful tiller, the size of the hitch can be increased up to three meters. However, in this case, most likely, you will have to install an additional wheelset and reinforce the body. In addition, you will need to use more durable and expensive materials in the production of a do-it-yourself trailer hitch for a tiller.

Do-it-yourself hitch for a tiller

The great advantage of a home-made device is that the owner takes into account his requests and makes it based on the input he needs: tiller model, load, attachment parameters.

But the first thing to consider is that in any case there will be an increased load on this node, so it is important to pay careful attention to the dimensions, design and level of strength of all parts of this part. Correctly specified parameters of the device will provide the most reliable aggregation with the tiller, the necessary mobility of the unit and the durability of its use..

When deciding on the design, pay attention to the dimensions of the towbar of your tiller and the features of the attachments (already available and the one that is planned to be purchased). The primary task is to ensure maximum compatibility of the unit with all necessary attachments and trailers. Equally important is the ease of use and the possibility of aggregation with equipment with different parameters..

The main working part, as a rule, has a U-shape and serves as a bracket, which, through the holes in it, is fixed to the chiller. The attachment stand is attached to the other side of it..

Before assembling the hitch, carefully read the instructions.

Blueprints

Assembling a hitch for a tiller with your own hands involves the use of drawings. There are quite a few different options available, but it is optimal to take the most suitable one as a basis and adjust it taking into account the parameters of your technique. The drawing should show the following details:

- two U-shaped components, identical in all respects, but with a different number of holes – 6 in one, 8 in the other;

- body, including two threads with diameters M12 and M16 and equipped with a connecting structure for fastening with one of the nodes;

- adjustment component – a lever located on the body of the part, its design consists of a screw connected to the bracket and for convenience has a handle; it is important to provide for the correct direction of the bracket – only up or down and in such a way that it does not interfere with the operation of the tiller;

Since the unit in any case provides for a connection with a hitch, the details of the placement of the connection can be studied in its standard instructions.

Required tools and materials

There is a certain set of tools that are required to make a coupler, but they do not include anything exotic. Usually, everything that is required to assemble such parts is on the farm of any owner who cultivates his land plot. The following tools are required:

- welding machine;

- Angle Grinder;

- drill or drilling machine, drill bits for metal;

- measuring instruments (tape measure, ruler, square);

- keys;

- fasteners (bolts, studs).

It must be emphasized that in this case it is very important that the holes that you will drill into the parts exactly coincide with the bolts and studs – a backlash in diameter is undesirable, since it will shorten the service life of the used attachments and trailers. At the same time, during the manufacturing process, it makes sense to first make holes in the part with a smaller diameter (from 5 mm), and then expand with wider drills (up to 12-16 mm, depending on the diameter of the bolts) – this approach will speed up and facilitate this part of the work, at the same time allowing you to align the holes as accurately as possible.

For the manufacture of the case, you can use a channel of a suitable size, and if there is none, you can cut out a part from a metal sheet.

The option of an adjustable hitch is very convenient – this design will allow you to attach attachments of different classes, generations and brands. Even if at the moment this design is not relevant, do not forget that different devices may appear on the farm over time, and the possibility of convenient aggregation of any of them will significantly expand the choice, allowing only to proceed from the desired performance characteristics of the equipment..

DIY Tiller Hitch

Auto mechanic specializing in agricultural machinery

Some owners of small agricultural machinery purchase it, initially counting on the versatility of the unit, others buy it for one specific purpose, and over time they can expand the range of tasks that a tiller can do. But in any case, the fulfillment of most of the functions on the arable or adjacent plot is provided by various attachments, which are attached with the help of such a part as a hitch to the tiller and, in fact, serves as the key to its versatility..

Often, the owners of agricultural units find that the factory equipment is far from perfect, the design of the coupling is not suitable for the current needs of the land economy, or is simply not reliable enough. Fortunately, there is always the option to equip your tiller with a hitch that will maximize your performance..

The hitch can be done by yourself

Tiller hitch selection

Any attachment or hitch for a tiller, be it a harrow, hiller, mower, trailer or any other equipment, is attached with a hitch. If the basic part is not suitable, the owner has a choice – to purchase a suitable one or to make a hitch for the tiller with his own hands. In any case, when deciding which version of the node can most closely match the tasks that the unit performs, a number of points must be taken into account, including:

- features of a tiller or cultivator;

- the scope of the unit – the functions that it performs;

- equipment that must be aggregated with it;

- loads;

- the need for versatility.

Based on this, you should carefully familiarize yourself with the most frequently used structures and navigate in the choice, based on the features of the one that is best suited in this case..

In this video, you will learn more about the hitch:

When choosing a hitch for a tiller, it is worth taking as a basis the most suitable type of part. There are several types:

- single / double – used in the presence of different types of weights, depending on which ones are used and in what quantity;

- reinforced – optimal for heavy units; its distinctive feature is that it is more massive – it has a greater thickness and length, which allows additional equipment to go deeper into the ground;

- adjustable – providing the ability to change the angle of the shaft, due to which you can adjust the level of attachment attachment and thereby increase the efficiency of work;

- universal hitch – allowing aggregation with several models.

If the hitch to the tiller of the desired design is not on sale or there are some of your own requests for it, it is not so difficult to make it yourself, since we are talking about a fairly simple device. Some craftsmen, who prefer to make many “accessories” to the tiller with their own hands, make a “pipe-in-pipe” coupling for the tiller trailer, make it from a cardan, from a crosspiece, from other improvised parts left over from various mechanisms. The owners of such devices note that it is not difficult to make such a unit, and share their experience and drawings of the coupling for the tiller.

Step-by-step instruction

To make a universal joint, you need the most even horizontal surface – a workbench or work table. The scheme for manufacturing a trailer device (hitch) for a tiller is as follows:

- Make the markup in accordance with the drawing: mark the contours of the parts on the workpiece.

- Use a drill or drilling machine to make holes according to the markings. Make sure of their accuracy using a caliper and a bolt (stud), which will be used for fastening. Achieve the optimum bore diameter where there is no play or jamming of the fasteners. Countersink the holes – this will facilitate further work and protect you from injury.

- Weld the joints. It is best to use electric welding, in which heating occurs only at the joints without much damage to the working qualities of the metal.

- Assemble the part. Connect the bracket and channel with bolts. If your design has an adjustment mechanism, fix it as well..

Important! Fasteners, with which the hitch is fixed to the tiller through the holes in the nodes, must be of the same quality and strength as the part itself.

Let us remind you once again that the part is manufactured in order to maximize the versatility of the tiller. With an optimally suitable hitch, convenient aggregation and long-term efficient operation of any mounted or trailed equipment, including a plow, harrow, hiller, potato planter, various types of mowers, trailers and any other devices, is possible. And since the fastening elements on different equipment may differ, which often complicates the possibility of their compatibility with the tiller, it is the successful design of the hitch and the possibility of its adjustment that solve this problem..

After assembling the part, it is important to attach it correctly. The installation rules are simple enough, but it is important to adhere to them. The actual connection of the equipment to the tiller is reduced to a very simple action: you need to align the holes of the hitch and the hitch and fix them with bolts or pins. Radial holes allow you to adjust the position of the connector during operation. After installation, you need to tighten the elements of the threaded fastening of the unit with the tiller. After that attachment is connected.

After the initial aggregation of devices, a final commit will follow, which must be done immediately before starting work. The adjusting components (screws) should be loosened, the optimum fixation level should be found, and then tightened with wrenches. Depending on the design, a removable threaded axle can be installed on the bracket, into which an M16 screw is screwed.

And there are a few more recommendations to be made. To preserve the working qualities of the metal and increase the durability of the part after assembly, it is advisable to cover with an anti-corrosion compound or paint for metal.

Considering the possibility of adjusting the structure in different ranges, it is possible to set radius grooves and fix them to zero. After starting work, it is necessary to carefully observe the connection during the first meters of movement and, if necessary, make additional adjustments. The presence of a control lever allows you to change the level of fixation and fix the attachment for a greater or lesser plowing depth.

Self-help tips

It is necessary to perform operations, focusing on the drawing of the hitch for the tiller. But the equipment is configured individually, taking into account the power of the tiller and the characteristics of the soil. With the universal hitch, adjustments can be made on a fairly large scale.

Hitch for Tiller Neva, MTZ, Farmer, Salute requires testing. You need to walk three to five meters, carefully monitoring the operation of all equipment, including the tiller.

To control the tillage depth, the tiller movement must be stopped. Using the screw handle, equipment adjustments can be made. Only then can the movement be resumed, but it is still possible to assess the functional readiness of the entire device. To adjust the lateral grip angle, slightly loosen the nut that was installed with a twelve diameter bolt. Next, the angle changes as required, after which the nut and bolt are tightened.

It is necessary to monitor the tightness of the threaded connections before starting work. And after their end, the threads must be cleaned and lubricated every time after use..

Creature

Using drawings, you can create a coupling for a wide range of applications. A channel of optimal dimensions can be used as a material. This type of “P” mount is located under the steering wheel of the device.

In order to create a product, you need to make several holes to secure the pin and bracket. For this, the diameter is selected. The pin must be steel, high strength.

A bracket is required to connect the fixtures and the tiller. Its end is directed up or down: so as not to create obstacles for the mounted elements. But he should not come into contact with the cultivated soil..

In some cases, additional devices with unconventional types of coupling are used for the tiller. To make contact, it is recommended to use special adapters..

Sleeve Hitch Cultivator | CC-56BH

Tiller universal hitch

Hand cultivation is becoming less common today. As a rule, only a few processes remain in which the technique cannot be applied. In other cases, villagers or summer residents are guided by the use of the necessary equipment. For small areas, the use of a tiller is very relevant. Such a compact but functional device makes it possible to implement basic processes that require significant physical effort. For example, when planting and harvesting potatoes.

Choosing a universal mount

We will understand a certain part of it – the coupling. Let’s consider what it can be, especially a universal option that is suitable for the main models: Salute, Farmer, MTZ, Neva and others. We will provide a drawing, video and photo materials on the coupling for the tiller, as well as instructions on how to implement the task with your own hands.

Installation

Installation on a tiller is quite simple. It is necessary to install the hitch bracket in the block bracket, secure with a pin. It is recommended to use spacer bolts – for a secure installation.

To install optional equipment, mount the hitch axle, which is removable, on the equipment bracket. Further, an axle is inserted into the outer hole of the hitch. It is necessary to tighten the screw until the holes on the chassis and the equipment stand are aligned. It remains to secure the contact with a bolt and a nut. The most commonly used diameter is twelve.

About the node

Its main task is confident contact between the attachment and the tiller itself. There are several types of hitch. However, the most popular type is the U-shaped. Such a universal hitch for a tiller can be made independently or purchased ready-made. If increased loads are planned, then it is better to do the knot with your own hands. This will allow for this aspect in the design..

As noted above, there are enough manufacturers of tillers, but it should be noted that the design of these devices is, by and large, identical: there are only small deviations in one direction or another. Therefore, it is required to manufacture a universal hitch that can be used on various models when the need arises..

Self-realization – many benefits

Indeed, having made a hitch for a tiller with our own hands, we open up more possibilities for ourselves. As already noted, you can more accurately select the characteristics for a specific tiller model, taking into account its features. At the same time, there are ample opportunities for setting and adjusting: having provided an appropriate design, you can change the position of the elements in a wider range, which expands the possibilities of using the tiller.

This can be used to implement a hitch for the tiller plow and any other additional equipment that will help to work the land more efficiently: with less physical and time costs, as well as more precise actions and improved efforts..