Communities Homemade (garage auto industry) Blog What can you do with a walk-behind tractor? (review of homemade products Drive2)

Perhaps I should start with the Bucephalus project of my pen pal Sanusha. Perhaps the most elegant and simple execution of a light buggy, which is based on exactly the same engine as mine. Lifan 190FR.

Continuing the review of wheeled vehicles, the next candidate on my list was perhaps one of the brightest drive projects with a motoblock engine. a road quadric project from nika67 from Vitebsk. The same motoblock engine with a gearbox is true for 13 horses, plus of course a gearbox from the Dnieper motorcycle, but look what an embodiment! In general, at first glance, it is even difficult to say that the transport of garage production. The ATV seems to have come off the production line.

Well, since such a conversation started from quadrics, the next interesting creation for me was a quad block from St. Petersburg from Miha1508. A six-wheeled quad quietly enters and exits the swamp, as for me it’s just super, ehh my stool can only ride on asphalt

One of the recent and interesting projects that appeared on the drive, for me, was a homemade project from the city of Kiknur (Kirov region) from Karetn. It seems to me that the project from the very beginning was created somehow spontaneously without a special plan of action. The creator periodically turns to the people for a “thought”, which makes the creation look like something like a little “jeep”, for me it is no less interesting than the previous projects, the more it also falls into the category of homemade products with an engine from a walk-behind tractor. According to the author, a 6.5 strong analogue of a Honda is implemented in the project

Homemade three wheeled motorized bike

Also one of the young projects of Drive2 is a creation from Volokalamsk in the form of a go-card from Wowka82. I will say this this is exactly what I wanted to do initially, well, more precisely, what I wanted to come to, but in the end life turned out so that I decided to cut a gibberish.Therefore, for me, this project is the embodiment of my dream, albeit by a different person, but still, I am personally pleased with how this technique “lives”.

Perhaps this is the most original technical application of a motoblock engine! it was perhaps a pleasant surprise for me that such transport can be done independently in a garage! and so I will not darken this hovercraft yes yes! this technique moves on traction from motoblock engines. Previously, it was an independent project, I’m not ashamed to say, my remote mentor Alex5799 from Chelyabinsk, though apparently he was banned, which became a very sad event for me, and now the fate of this unique technique can only be followed in the blog of its creator.

Literally today I came across such a wonderful unit belonging to AleksMlv And despite the fact that the equipment has two wheels, this (note!) not a motorcycle, but a snowmobile! :)) And of course, a 7-horsepower motoblock engine is used as a power plant. Although not homemade, nevertheless, people with hands will be able to repeat this miracle in a garage, so it has all the rights to place in this entry

Another not independent project of the “inhabitant” of Drive2 Impala2, the trike turned out to be great. Unfortunately, you can get to know the creation closely only by talking to the creator. Previously, you could read about this technique in the BZ and the blog, but then the owner considered this information not relevant and deleted it. Now you can be content with only a photo, as in all other creations in this technique, a motoblock engine is also used as a power plant

Doesn’t bark or bite, and carries a bunch of useful things? Well, of course! of course, I almost completely forgot about self-propelled sleds, or in the common people called motorized dogs. From the fresh one on our website there is such an entry from Sever29 about his homemade dog

That’s all for now! if you missed anyone. whistle, I will definitely add. If it was interesting, do not forget to put your thumbs up and share with friends 🙂 All good mood and success in your endeavors!

We make a wood splitter

Among other things, a wood splitter can be made from a walk-behind tractor. To do this, you need to carve a cone on a special machine, as well as a thread. After that, the already finished cone must be mounted on a shaft that has suitable bearings. Then, a flange and an asterisk must be installed at the end of the shaft. It can be taken from the wheel of a motorcycle.

You can fix the cone to the shaft with a bolt. After that, a spacer made of pipes, as well as a pair of nuts, must be installed between the motor and the shaft itself. This will help tension the chain. In order to make supports for the shaft, you can take supports from Zhiguli. The motor must be taken from the walk-behind tractor. With this redesigned structure, you can easily cope with the splitting of firewood.

Motobur

Many fishermen no longer want to go fishing with a conventional drill, so some of them decide to convert a single-axle tractor, which is not needed in winter, into an ice ax. You will not need to apply special efforts for this. You just need to rearrange the wheels of the “Zhiguli”, as well as make a nozzle to set the drill in motion. Then you can safely go fishing. In the summer, the single-axle tractor will be used again for its intended purpose.

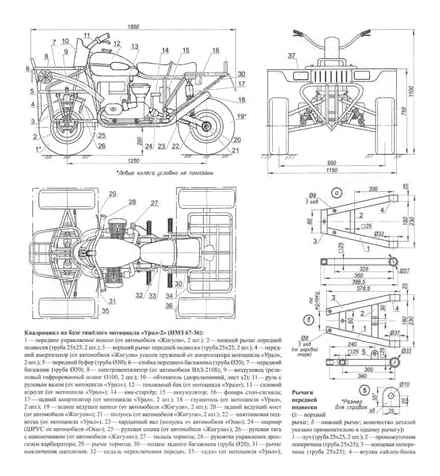

Tips for making a karakat

To assemble a homemade karakat, first you need to decide which technique you can take the frame from. A frame taken from a Ural motorcycle is perfect. Next, you need to make a suspension, as well as a rear-wheel drive. Then you need to use a corner to connect the steering column, side members and a special bracket.

After that, you can start attaching the wheels. You can take rubber from cars such as “Ural” or “KamAZ”. The last is the motor from the walk-behind tractor, as well as all additional systems. it is necessary to connect the brakes and the clutch, and also to take up the system for the emission of gases.

After assembly, it is imperative to test the made karakat. With the help of such a homemade all-terrain vehicle, you can easily drive even to swampy places.

How to properly design a mini tractor?

Breaking a walk-behind tractor into a mini-tractor is carried out in several stages. First you need to tackle the frame. It is made of durable metal, which is cut into pieces of the required length, and then welded together. When the frame is ready, you can start assembling the undercarriage.

If the motor is located in the front, then the width for the wheels can be left the same as in the walk-behind tractor. In order to attach the wheels to the back, you need an additional axle. It is made of the required length, an ordinary piece of pipe is suitable for this, the main thing is that the width fits. Bushings and bearings must be installed at the ends of the pipe. They can then be fitted with wheels.

If the motor is decided to be located at the back, then the width of the wheels must be increased, otherwise the minitractor will not have the necessary balancing. So, you need to remove its wheels from the walk-behind tractor, after which you need to make the bridge a little wider.

To operate the mini tractor, you can take the handles from the walk-behind tractor. However, this will make the converted tractor look like a motorcycle, and it will be a little awkward to drive. For convenience, it is better to install a regular steering column.

The driver’s seat can be made from a sled frame that needs to be welded. In addition, one must not forget to put the headlights, as well as the dimensions. After the complete assembly of the minitractor, it is imperative to lubricate all parts, as well as run it in.

From all this it follows that almost every person, even a little familiar with the technique, can convert a single-axle tractor into a mini-tractor.

Other rework options

In addition, it will also be possible to make other equipment from the walk-behind tractor. For example, you can get a dumper, pneumatic drive or vibrating plate. Also, some craftsmen make a loader or snowmobile from a walk-behind tractor. Many people use walk-behind tractors for harvesting corn.

Motobur

Many fishermen no longer want to go fishing with a conventional drill, so some of them decide to convert a single-axle tractor, which is not needed in winter, into an ice ax. You will not need to apply special efforts for this. You just need to rearrange the wheels of the “Zhiguli”, as well as make a nozzle to set the drill in motion. Then you can safely go fishing. In the summer, the single-axle tractor will be used again for its intended purpose.

Exhaust system

The native exhaust of the Chinese engine did not suit the high volume and smell of exhaust gases. This is because the muffler was almost in front of the face. Therefore, a knee was welded, which connected to the old trike muffler, fixed above on the other side.

Homemade muffler for a Chinese engine

Motobur

Many fishermen no longer want to go fishing with a conventional drill, so some of them decide to convert a single-axle tractor, which is not needed in winter, into an ice ax. You will not need to apply special efforts for this. You just need to rearrange the wheels of the “Zhiguli”, as well as make a nozzle to set the drill in motion. Then you can safely go fishing. In the summer, the single-axle tractor will be used again for its intended purpose.

How to properly design a mini tractor?

Breaking a walk-behind tractor into a mini-tractor is carried out in several stages. First you need to tackle the frame. It is made of durable metal, which is cut into pieces of the required length, and then welded together. When the frame is ready, you can start assembling the undercarriage.

If the motor is located in the front, then the width for the wheels can be left the same as in the walk-behind tractor. In order to attach the wheels to the back, you need an additional axle. It is made of the required length, an ordinary piece of pipe is suitable for this, the main thing is that the width fits. Bushings and bearings must be installed at the ends of the pipe. They can then be fitted with wheels.

Homemade TRIMMER Scooter / DIY

If the motor is decided to be located at the back, then the width of the wheels must be increased, otherwise the minitractor will not have the necessary balancing. So, you need to remove its wheels from the walk-behind tractor, after which you need to make the bridge a little wider.

To operate the mini tractor, you can take the handles from the walk-behind tractor. However, this will make the converted tractor look like a motorcycle, and it will be a little awkward to drive. For convenience, it is better to install a regular steering column.

The driver’s seat can be made from a sled frame that needs to be welded. In addition, one must not forget to put the headlights, as well as the dimensions. After the complete assembly of the minitractor, it is imperative to lubricate all parts, as well as run it in.

From all this it follows that almost every person, even a little familiar with the technique, can convert a single-axle tractor into a mini-tractor.

Snowmobile

This design serves to make it easy to move around in the snow. This will require wide enough wheels. The caterpillar can be obtained from an old snowmobile. She will be able to fit under the wheels of the walk-behind tractor. The snowmobile itself is made from a frame, tracks, some suspension elements. The mount can be used from a walk-behind tractor. This makes an excellent snowmobile, which is also suitable for hunting in the swamps. Therefore, the result is both a swamp vehicle and a snowmobile.

Motorized towing vehicle

Sometimes, when buying a factory motorized towing vehicle, you have to face many disadvantages. Therefore, most often they are made by hand. They are strong enough if you use a single-axle tractor for this. This design will do its job perfectly, and will also save fuel. In addition, it will be possible to attach compartments to such a structure in order to fold the necessary tools.

Tricycle from a walk-behind tractor

Consider how to make a tricycle from a walk-behind tractor. The creation of such a transport will differ quite a bit from the construction of an ATV. The only thing is that a scooter or a motorcycle can be used as a frame, and the single-axle tractor itself will be located under the driver’s seat or immediately behind it. Similarly, the construction of a trike.

A tricycle is any three-wheeled vehicle from a bicycle to a car, and a trike is a three-wheeled motorcycle. At the same time, some experts argue that “trike” from American English is translated as “tricycle“.

There is also a buggy with a walk-behind tractor engine. A do-it-yourself buggy is not created as often as the units discussed above.

- trumpet;

- wheels from trailers, carts, scooters, sidecars or ATVs;

- wheel hubs, steering wheel, rear axle, brake disc;

- braking system;

- uniaxial tractor;

- seat.

The manufacturing process itself resembles previous homemade products.

So you can use conventional cultivators. Just a few additional parts, a little cunning, ingenuity and imagination, and you can make all kinds of ATVs with your own hands that are not afraid of ravines, hills or even swamps.

How to make a karakat from a walk-behind tractor with your own hands

Even the simplest version of the karakat is capable of speeds up to 70 km / h and can easily pass any off-road and withstand all the loads assigned to it. He will be able to perform all these functions due to a strong suspension, which can be easily made from steel pipes connected by hinges and welding.

No expensive materials are needed to make such a unit. It remains only to slightly adjust to the manner of driving this vehicle.

Consider how to make a karakat from a walk-behind tractor with your own hands. In the process of creating a karakat, the following stages can be distinguished:

- Frame fabrication. it is advisable to use a single-axle tractor of medium or high weight (using a Neva walk-behind tractor is the best option for making such equipment), using this you will get a good quality all-terrain vehicle with three or four wheels. Some designers use spare parts from a Ural or IZH motorcycle as a frame.

- Suspension and Rear Axle Construction. The suspension structure consists of two parts connected by hinges. At the request of the developer, it is possible to design the front and rear suspension, ensuring their high independence.

- Production and installation of wheels is the most expensive and longest assembled part of a karakat.

- Most craftsmen do not buy ready-made discs, but use homemade products, which are tires and low-pressure chambers (it is preferable to use these products from trucks: Ural, KamAZ or from their trailers).

- Installation of the engine and systems (brake, clutch, output of combustion products).

Before its full use on the off-road, the manufactured device should be tested.

Tips for making a karakat

To assemble a homemade karakat, first you need to decide which technique you can take the frame from. A frame taken from a Ural motorcycle is perfect. Next, you need to make a suspension, as well as a rear-wheel drive. Then you need to use a corner to connect the steering column, side members and a special bracket.

After that, you can start attaching the wheels. You can take rubber from cars such as “Ural” or “KamAZ”. The last is the motor from the walk-behind tractor, as well as all additional systems. it is necessary to connect the brakes and the clutch, and also to take up the system for the emission of gases.

After assembly, it is imperative to test the made karakat. With the help of such a homemade all-terrain vehicle, you can easily drive even to swampy places.