Principles of the electric motor

Such a motor can be both single-phase, which operates from the normal network, and three-phase, which needs additional electricity. When connecting an electric motor, you should always remember about personal safety. For a single-phase motor you have to install a residual current device (RCD) and for a three-phase motor you have to use appropriate capacitors.

For home lawnmowers, you can also use a drill with up to three thousand revolutions. When putting together the design it is necessary to correctly select the power of the haymower to its mowing. Mounted on a base or platform, a cordless or electric drill will perform its tasks well, and the grass will be mowed.

During operation, you should not forget about the intervals of work, because you need to give the motor time to rest to avoid overheating. Such a tool will easily clear the area from the grass and give the lawn an attractive appearance. The platform, on which the engine is installed, should be of optimal size to be able to cut the grass near the wall.

Step by step instructions for assembly

Depending on the starting materials for the electric lawnmower, these steps will differ. One of the most common options is to assemble a mower from an old washing machine. It will be useful to consider a step-by-step instruction just to create such a machine.

The actions should take place in this sequence:

- Making a frame or spars for the engine of the future construction. It should be made of metal or steel sheet 500 by 500 millimeters.

- In the central part of the plate a hole must be drilled for the electric motor shaft.

- From the bottom of the metal plate (members) the perimeter corners are welded. You can also bolt them together. Then the wheels need to be installed. They can be made on their own from plywood or wood, or removed from old devices. They are placed on the shaft (metal shaft).

- After that, the motor must be mounted on the platform. To do this, it should either be welded to the pre-mounted metal corners, or drill holes for the existing holes in the motor itself, and then bolt it together.

- Next, you need to install a handle to control the construction.

- Under the platform is mounted a protective cover for the control.

- A metal blade is installed (homemade or prefabricated). It is attached to the motor shaft.

- To protect the motor from the grass, it is necessary to install a can on its shaft.

All mechanical parts are assembled. Next we need to proceed to the wiring diagram of the design.

The tank for collecting the grass must be installed at the very end. It is made in the form of a box or bag.

Covering the blades with a guard is a must, because it will increase safety during work. Such protection should also be done for the motor to avoid debris and its durability, as well as durability.

Step-by-step instructions for assembly

Depending on the starting materials for the electric lawnmower, these steps will differ. One of the most common options is to assemble a mower from an old washing machine. It will be useful to consider the step-by-step instructions for creating such a machine.

Actions should take place in this sequence:

- Making a frame or spars for the engine of the future construction. It must be made of metal or steel sheet 500 by 500 millimeters.

- In the central part of the sheet should be drilled a hole for the shaft of the electric motor.

- From the bottom of the metal sheet (members) the perimeter corners are welded. And they can also be bolted together. Then you need to install the wheels. They can be made on their own from plywood or wood, or removed from old appliances. They are placed on the shaft (metal axis).

- After that, the motor needs to be fixed to the platform. To do this, it is either necessary to weld it on the pre-mounted metal brackets, or drill holes for the existing holes in the motor itself, and then bolt it down.

- Next you need to install the handle to control the construction.

- Protective cover for controlling is mounted under the platform.

- Metal blade is installed (homemade or prefabricated). It is mounted on the motor shaft.

- To protect the motor from grass it is necessary to install a can on its shaft.

All mechanical parts are assembled. Next, you need to proceed to the electrical circuit design.

The grass catcher box should be installed at the end of the machine. It is made in a box or bag.

Covering the blades with a blade guard is a must as it will increase safety during operation. Such protection should also be done for the motor to avoid debris and its durability, as well as durability.

Design from an angle grinder

There are quite a lot of ways to create such a machine. The easiest is to bolt it to a previously prepared platform or base.

The most common option. is the assembly of such a homemade, using a baby carriage.

- Disassemble the wheelchair, but leave the base with wheels.

- Prepare a board that will lie on the axles of the wheels.

- Secure it.

- Attach the angle grinder to the board with cable ties or clamps.

- The angle grinder needs to be fitted with blades or a trimmer line.

- Attach the switch to the handle.

Such a construction can be equipped with a protective cover so that the grass does not fly to the sides, or a container for collecting waste.

Self-taught craftsmen throughout history have already come up with a lot of models of homemade machines. They differ in form of assembly and complexity of design. advanced models have the function of adjusting the height of mowing, etc. п. Make a mower with your own hands so that safety is paramount. The trigger should be set in such a way that the machine turns off immediately after releasing it.

Minimehanik

This site uses cookies, by continuing to use this resource, you agree to the terms of google’s privacy policy. Blog is created for people who love, appreciate and serve the minimachine themselves.

Zipper grass trimmer, ECO, Shtenli, gas handle repair.

The previous time we replaced the cylinder with a piston in the Austrian Zipper petrol brush trimmer. During the repair, we found out that this gasoline trimmer is the absolute analogue of many, mainly Chinese-made trimmers, such as: ECO, Defort, Eland, Skiper, Groser, Gunter, KW, Shtenli, Belarus, Ural, Patriot, etc. Therefore, all of the following applies equally to the chainsaw handles of these brands.

According to a customer handle does not work properly, he took it apart, the springs popped out, he did not notice how they were standing, assembled as it turned out. After reassembly, the trigger of the handle became jammed and would not return to its original position when fully depressed, also the trigger would not lock with the button when depressed, the trigger safety button ceased to work.

Both springs are incorrectly installed. The person who assembled the handle had planned that the main trigger spring would interact with the second part of the handle body with its second part.

The second part of the spring was supposed to hook on the plastic side of the handle body marked with a red arrow.

Either during assembly the spring did not catch the plastic board in the planned position or it went out of engagement because of vibration and as a result the trigger did not return to initial position.

The second spring, the trigger locking button spring, was also improperly installed and did not work. So completely disassemble the handle.

Repair of lawnmower’s throttle grip with my own hands

In detail: lawnmower gas handle repair with their own hands from a real master for the site olenord.com.

An indispensable tool of the modern gardener or owner of a private house is a lawn mower, which allows you to effectively and efficiently bring the adjacent territory in order. The period of active use of brushcutters falls in late spring until October. Modern units are equipped with powerful and durable engines, reinforced transmission and basic units. Despite this, physical wear and tear, manufacturing defects or improper use lead to the failure of the grass trimmer. In order to make repairs to the grass trimmer with your own hands it is necessary to have at least a basic knowledge of technology and a little experience in its repair.

The main unit of any gasoline tool is the internal combustion engine (ICE), which by various means transmits the torque to the executive body. In modern grasshopper, a dural bar (tube) is used as a transmission element between the motor and the trimmer head, inside which the drive shaft is located.

Thanks to the high-speed motor, the line speed can be up to 13,000 revolutions per minute, depending on the manufacturer of the grasshopper. In order to prevent mechanical and thermal damage to the gearbox, there is a special opening in the housing for introducing lubricant in the form of ointments. As an owner-assisting strap for continuous operation, all brushcutter models feature a sturdy shoulder strap.

Regardless of the manufacturer, almost every model comes with a line and steel blades.

PVC line cross-section for the grass trimmer can range from 1.5 to 3.0 mm.

The gearbox is made of durable polymer that wears down heavily when we mow, causing breakage. That’s why you should check from time to time whether there is a line in the head and replace it if necessary. It is recommended to buy additional bobbin to quickly replace it with a spool with run out of fishing line.

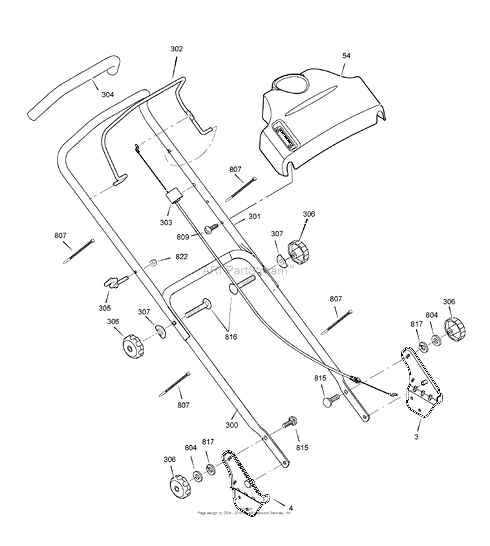

Grass trimmers with an engine on the market today are equipped with a D-shaped, U-shaped or T-shaped handle, where the main controls of the unit are located. With a U-handle, for example, the throttle and the stop/start switch are on the right handle. In the D-shaped version of the handle, the gas adjustment key is placed directly on the boom.

Due to the presence of many nodes and parts, the repair of the grass trimmer with their own hands involves the elimination of breakdowns that prevent its normal operation. It’s worth mentioning the most basic faults of gasoline-powered braids:

- The grass trimmer engine does not pick up speed;

- Failure of the cylinder-piston group (CPG);

- Faults in the ignition;

- There is no connection between the engine and the trimmer head;

- Mechanical knocking when the engine is running.

- Repair of the gas cylinder of the lawnmower

The main component of any internal combustion engine is a cylinder-piston group (CPG), which can fail due to component wear and tear or low-quality fuel mixture.

Lubrication of friction units in a lawn trimmer is performed by adding a certain proportion of oil to gasoline. This may be caused by old oil precipitating out in the form of sludge. In this situation, when starting the grass trimmer, the motor is greatly overheated and in a matter of minutes, the most expensive breakdown occurs. To eliminate the resulting failure will require the replacement of the cylinder and piston, namely: the piston, packings, cylinder and piston rings. If you are not a master of internal combustion engine repair and do not have experience with technicians, it is unlikely to fix the engine without the help of a specialist. You can read more about the stages of grass trimmer piston repair here.

If the lawn mower ignition fails, the spark on the plug is lost and, consequently, does not ignite the fuel mixture.

It is important enough in this situation not to rush with the replacement of the coil, because the cause of the breakdown may be the lack of contact in the switch on the control handle.

An important point when searching for malfunctions of the grass trimmer ignition will be the diagnosis of the mesh, where the distance between the side and the central electrode should be 0.5-0.7 mm. In addition, it is necessary to pay attention to the o-ring of steel on the plug, the loss of integrity or deformation of which can lead to etching of air from the combustion chamber and, consequently, a decrease in the power of the grass mower.

If the replacement check of the electrical circuit, the spark plug and its contacts did not give positive results, then it is worth paying attention to the ignition module of the grass trimmer, namely the gap with the flywheel. Regardless of the design and manufacturer of the lawn trimmer, the distance between the ignition coil and the flywheel should be no more and no less than 0.2 mm. To restore the optimal value of the gap will need to relax the bolts fixing the coil and a special measuring gauge exhibit ignition trimmer for grass.

A clear sign of engine power system malfunction is the absence of traces of fuel mixture on the spark plug electrodes, which may be due to the following defects:

Components of the grass trimmer fuel system

- due to a clogged hole in the gas tank, a vacuum is created, which prevents the normal flow of gasoline into the carburetor;

- due to poor fuel quality and ingress of foreign particles, the fuel filter installed in the tank is clogged;

- the mixture does not flow into the combustion chamber as a result of a clogged carburetor.

You can quickly determine the cause of malfunction by removing the fuel hose leading to the carburetor. If the fuel mixture flows in a thin stream, you should pay attention to the carburetor. If there is no flow, clean the breather plug (small hole in the fuel tank lid) with a fine needle or replace the fuel filter.

If the fuel leaks into the carburettor, it must be cleaned or readjusted. Adjusting the grass trimmer carburetor involves restoring the optimal mixing of the fuel mixture.

Grass trimmer carburetor with adjustment screws

To do this, pay attention to the three adjusting screws: high speed (H), low speed (L) and idle (LA). To start the adjustment, tighten the screws H and L completely and release them one turn each. After starting the engine and give it 10 minutes to warm up to adjust the power system in operating mode. After warming up the engine, press the gas pedal key to the stop (12 000 rpm). Restore the idle speed by unscrewing the LA screw. Once the grass trimmer head has begun to rotate, you must tighten the screw until it stops.