Angle Grinder –

entry in the column “nationality”

Why is an angle grinder (angle grinder) called an angle grinder? Not Czech, not Hungarian or even Japanese, but an angle grinder?

Perhaps because the first foreign power tools were brought to the Soviet Union from an angle grinder. These were Sparky power tools. Unlike drills, jigsaws and hammer drills, there was no Russian name for the angle grinder. The tool was very unusual for those times, but demanded and appreciated, and it was simply nicknamed the angle grinder by the manufacturer in the country..

Unable to find the strength to resist the desire to possess them, he began to steal German instruments and took at least something home every evening. He was very ashamed, but he could not help himself. And not only him. This went on for two weeks. And then the German builders just gave them a box of screwdrivers of various calibers. They took the screwdrivers, but after that somehow they began to ask the authorities one by one to transfer them to other objects. He says that it was unbearable ashamed to work with the Germans after this incident..

Where is the angle grinder used?

I digress a little from what I wanted to write. About what you can and cannot cut an angle grinder. And what else can you use an angle grinder (angle grinder).

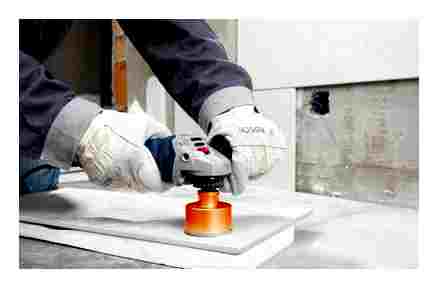

The angle grinder is used for cutting and processing hard materials, as well as for grinding and polishing surfaces. For this, special attachments are used. Few people know that there are angle grinder crowns, with which you can cut round holes, for example in ceramic tiles..

In the decoration and renovation of apartments, the angle grinder is most often used precisely for cutting materials. It is also a great tool for sharpening drills or other chopping or cutting tools such as axes, knives and chisels..

How not to use an angle grinder

angle grinder is a tool of very narrow specialization. Everyone knows about it. It’s even silly to write about how and where this tool should not be used. It would hardly occur to you to fight an angle grinder on the barricades or cut a sausage with it. Perhaps in the distant future, when, due to evolution, the boundaries between the upper limbs of people and power tools will disappear, the human brain will swell so much that it will seriously consider one of the auditory openings to go out. Then … What then? I don’t know … These thoughts make me sick, and I lose the meaning of the story..

Let’s imagine another situation. You pick up a non-imaginary, real angle grinder, and with evil, decisive steps are heading towards something or someone. You just need to rummage through your memory and imagine what you would like to cut with it. Have you presented? Now all the mail from the far corners of your memory is sent to your imagination, and your fingers reflexively squeeze an imaginary plastic form with a madly spinning disc. You are confident that an angle grinder at 11,000 rpm will cut anything. You are blinded by the tool’s imaginary versatility. But this is where your carelessness can turn into tragedy and sensitively distort your own fingers. Such a case can undermine your reputation as the owner of “straight hands” and the belief in the omnipotence of the angle grinder as a very cutting, but safe tool for you..

How to cut wood angle grinder

The angle grinder, originally designed for metal working processes, has so many different uses with different types of materials, and even wood is no exception. An angle grinder can be used for woodworking, but you need to be extremely careful and be aware of the high risk of dangers of work. When sawing wood with an angle grinder, the surface will not be smooth as, for example, when using a circular saw, but these errors can be easily corrected, the surface can be sanded.

You need to be extremely careful when cutting wood with an angle grinder and a suitable disc designed specifically for sawing wood, but they are not very common on the market. The special disc for working with wood material has teeth that increase the size of the cut. When working on wood, the thickness of the wood should not exceed 4 centimeters.

It is forbidden to work with circles for a circular saw, as the speed of revolutions per minute differs significantly. It is not recommended to use discs with coarse teeth, since there is a high probability of the teeth catching on the material, which will lead to the wheel jamming. The likelihood of snatching the tool out of hand in this situation instantly increases. If possible, set a lower number of revolutions.

The question is often asked: “Can an angle grinder cut wood with a disc for metal?” Of course you can, but not recommended. The wood will simply begin to smoke, an unpleasant odor will appear. It is better to use specially designated discs for this..

Sawing wood angle grinder

Compliance with safety rules is the most important rule and an appropriate marked disc for working with wood will ensure your work is perfect. When we cut firewood with an angle grinder, for a safe cut, it is required to fix the angle grinder according to the principle of a circular saw so that the angle grinder does not bounce off under our feet. Such work is very unsafe, therefore, if there is an alternative replaced, namely a jigsaw, the same hand tool, or a circular saw, it is better to use them.

Pruning trees with an angle grinder also requires special care and it is worth remembering that small branches with a suitable disc can be sawed off for an aesthetic appearance, but thicker volumes of work should absolutely not be done on wood, especially on weight.

Is it possible to cut wood with a diamond blade?

Diamond discs are used most often for working with granite, tiles and ceramics. For wood, it is better to use discs with teeth. When cutting wood with a diamond blade, the material will smoke and the tool will heat up quickly, which will take time to cool down. Therefore, it is best to use discs as intended for specific materials..

Go to our Catalog, where you can familiarize yourself with the entire range of our angle grinders and choose the optimal one for your tasks.

In this article, we will show you how to cut wood with an angle grinder.

Sawing plywood angle grinder

To cut plywood with an angle grinder, wood discs are often used. Due to the large accumulation of dust, work in a well-ventilated area so as not to breathe burning odors. Sawing is best done along the pre-marked mowing line, pay attention before the end of the process so that the circle does not get jammed by the sawn-off part of the sheet.

Cutting the OSB angle grinder is safer and better with the right blade. The ideal disc would be the so-called three-tooth saw blade for wood, which is designed to work at high speeds. It will be a plus if the angle grinder has a speed controller.

Contact us

Order a call back and we will contact you ourselves. Choose high quality and reliability with VEGA Professional!

Subscribe to our Youtube channel on our pages in social networks Instagram, and be the first to know about all the new videos and news in the world of electric gasoline tools.

Subscribers of social networks are guaranteed to become participants in all prize drawings from TM VEGA Professional.

Abrasive Discs for Angle Grinder

As mentioned earlier, abrasive wheels for an angle grinder are subdivided into cut-off wheels (up to 3 mm thick) and grinding wheels (thicker). Despite the fact that the classification is very conditional, there is another significant difference between the discs – the reinforcement of cutting wheels is usually carried out in 2 layers, and grinding wheels at least three.

Circle selection

When choosing discs for grinding wood angle grinder, pay attention to the following points:

- The size of the discs must not exceed the maximum permissible diameter for which the angle grinder is designed. A tool designed for discs with a diameter of 125 mm will not be able to work with a 230 mm cut-off wheel for a variety of reasons. First, the speed of the angle grinder edge is significantly exceeded (if it is significantly increased, the disc may simply fly apart). Secondly, to work with such a disc, more power is needed than that for which a small tool is designed. Thirdly, to install such consumables, you need to remove the protective cover, which makes the work more dangerous..

- When working with different types of materials, you should choose a disc that is designed specifically for them..

- Pay attention to the maximum allowed lap speed (or line speed). These indicators are indicated on the surface of the circle. According to these values, the operating mode of the angle grinder should also be selected..

Diamond Cut-off Wheels for Angle Grinder

Depending on the purpose, diamond discs can be divided into several types:

- Concrete. Circles of this type can easily cope with monolithic, including concrete and reinforced structures..

- Granite. Such discs are used when performing work with especially hard rocks..

- Asphalt. Cut-off wheels are best used when processing concrete and, accordingly, asphalt.

- Construction Materials. Discs of this type can be used for cutting ceramics, bricks.

Some manufacturers’ diamond cutting discs are also color coded:

- Green is granite.

- Blue – concrete, marble.

- Yellow – gypsum, tiles.

- Gray – ceramic.

Segmented diamond cutting discs are used for cutting materials using the dry method. When using solid discs, wet cutting (water cooling) is used. This is primarily due to the very high heating of the solid surface of the cutting wheel..

There are models with partial segmentation. These are the so-called turbo disks, in which the slots are located in the body of the circle (they do not go out to the outer edge). These products can be used at a higher speed than fully segmented products..

So, choosing the most suitable cutting disc for all parameters for an angle grinder for wood, you can efficiently and safely perform any job..

Outside diameter of discs

One of the important indicators of the cutting wheel is its outer diameter, which is calculated in millimeters and is unified. For household purposes, as a rule, a disc for an angle grinder for wood 115-230 mm is used.

The tool shaft diameter (fitting size) is now the same on almost all discs. 22.2 mm, and special intermediate rings are used for installation on older models of the angle grinder.

The most versatile is considered to be a disc for an angle grinder for wood 125 mm, 150 mm and 230 mm..

The 125 mm circle is convenient to use when it is necessary to cut metal reinforcement and a rod.

Disc for an angle grinder for wood 150 mm can not only grind and cut metal, but is able to saw a bar or dissolve a board.

If the diameter is more than 230 mm, then such circles are for industrial purposes..

Disc for angle grinder for wood 230 mm has a wider scope of application, as it can be used when processing products from metal alloys of various grades.

Disc for angle grinder for wood and rubber. Wood Grinding Discs Angle Grinder

Modern angle grinders, better known as “angle grinders”, are used for various technological processes during construction and repair work. When choosing a disc for an angle grinder for wood and rubber, it is necessary to take into account the peculiarities of not only the tool itself, but also the objects to be processed..

Abrasive disc shape

Abrasive wheels differ in their shape. Distinguish:

- Standard flat discs.

- Curved discs (in the form of a plate). They can be used when performing work in hard-to-reach places. With this wheel shape, the fixing nut is hidden, therefore it is more convenient to perform grinding work..

When purchasing a disc for an angle grinder for wood, pay attention to the marking (for example, A 40 L), allowing you to find out the following information about the product:

- The first letter (or two) indicates the type of abrasive used. For example: A. corundum, AS. electrocorundum, C. silicon carbide, which is used when working on granite and stone.

- The numbers allow you to find out the grain size of the abrasive. Moreover, the larger it is, the faster the work will progress. However, this will impair the cleanliness of the cut or grinding. A disc with a coarse grain is used, as a rule, for processing soft (non-ferrous) metal, and with a fine grain, it is used for steel.

- The last letter in the marking gives an indication of the hardness of the bond of the base of the circle (those letters that are located at the beginning of the alphabet mean that the bond is softer). It is recommended when buying to be guided by this rule – when working with soft material, use a disc with a soft bond and vice versa..

Almost all manufacturers of abrasive wheels use color coding of products. Green is for stone, blue for metal. Also worth mentioning is the inner landing ring. For wheels that are intended for cutting, it is made of hard metal, and for polishing or grinding, cutting discs with a softer washer are used..

The main characteristics of cutting wheels

Depending on the material of manufacture and design features, three main types of circles are distinguished:

- Abrasive disc for angle grinder for wood, used for working with various surfaces. Depending on the thickness, the wheel can be cutting and grinding.

- Diamond disc designed for work with stone, concrete and other building materials. Such circles are divided into segmented and solid. The first type, due to the better removal of the stem through the slots and more efficient cooling, provides high performance. These discs can be used when cutting thin metals..

- A regular circle for a circular. However, it should be noted right away that it is not recommended to use it for sawing wooden products without work experience, since there are many cases when people were seriously injured when clamping a disk in the array. If possible, when performing such work, it is better to use another tool, for example, a jigsaw, chainsaw, etc..

Safety regulations

When working with an angle grinder, no matter what type of disc mounted, it is necessary to strictly observe safety requirements.

- The tool must be equipped with a stop handle and a protective cover..

- All work must be performed in overalls and using personal protective equipment. It is also necessary to be very careful about the choice of glasses or a mask, because eye damage (according to statistics, this is the most common injury) can be obtained even from a small shavings or a fragment of the circle itself.

. However, despite this, it is still recommended to give your preference to trusted manufacturers, since this tool is with increased danger. Therefore, it is not worth saving on such a consumable as a cutting disc..

Like all other tools, the angle grinder is divided into classes, into professional and household tools, as well as by their design features..

This is perhaps the most widely used tool outside of the drill. Many people work with an angle grinder, but not everyone is wondering about the correctness of the manipulations performed, from the point of view of personal safety and quality of work. In this article, we want to devote you to the basic subtleties of working with this tool and consider in detail the following questions:

Let’s go in order.

HOW TO CORRECTLY CUT AN Angle Grinder?

Before you get started, you need to prepare your angle grinder. We mean the choice of rig (disc). The following points should be considered here:

- Disc diameter. Remember, the smaller the diameter of the disc, the more revolutions (higher rotational speed) it can withstand, and vice versa.

- The choice of disc depends, first of all, on the material with which you plan to work and the design features of your instrument..

- Pay close attention to the legend and markings on the disc. Having carefully studied them, you will understand whether the selected equipment is suitable for the proposed work..

Also, always follow safety precautions and wear special equipment such as gloves, goggles, long sleeved robes and closed shoes..

First of all, clear the workplace of unnecessary items. Securely fix the workpiece to be processed, having previously marked it on it, if necessary. Getting Started.

Always hold the tool firmly and confidently with both hands. Take a steady body position. You need to stand so that sparks, in the process of work, do not fly on clothes, and even more so in the face.

Always remember about such a thing as kickback. This is the most dangerous thing that can happen when working with a grinder. It can occur if the disc is strongly jammed in the workpiece. In such a situation, the angle grinder will be thrown back sharply. Monitor the process to avoid this.

How To Cut Wood With Angle Grinder. NOT toothed disc.

Also remember that the power cord of the angle grinder must be isolated from sparks during operation. If you need to move the instrument to a different work surface, be sure to turn it off first, then unplug the power cord. The same should be done in the event of a power outage. As soon as there is no electricity, turn off the tool and then unplug it from the mains. If this is not done, then when power is restored, the angle grinder will start to work in a chaotic mode again and can cause irreparable harm to your health, others or damage objects around..

The most frequently asked question that arises among novice craftsmen is the following: How to cut an angle grinder correctly: for yourself or away from yourself? Many do not betray this special significance, but in vain.

Manufacturers of angle grinders advise their consumers the following: The tool should be used in such a way that the stroke (direction) of the cut coincides with the direction of rotation of the disc.

Experienced craftsmen have a clear answer to this question: You need to make a cut from yourself. This is for your safety. In case the angle grinder is pulled out of your hands, the tool will be thrown in the opposite direction from you. If you cut in the direction of yourself, when the above situation occurs, the tool will fly to your feet. We will not describe the consequences. You can imagine them yourself.

If you are cutting parts or workpieces that have thick metal, cut them in an extremely straight line..

When working on a part such as a corner or when cutting a profile or profile tube, which are usually quite long, cut the overhanging edge. Otherwise, if you make a cut in the place between the supports, an outcome such as a jamming of the disc due to the deflection of the workpiece is possible..

If you are cutting a corrugated sheet (sheet metal sheeting), metal siding (metal siding) or metal tiles, take care of the presence of special anti-corrosion substances that need to be lubricated in order to avoid sudden corrosion.

In case you are cutting paving slabs or paving stones, get a special diamond cut disc.

Reinforced concrete, concrete and other similar materials must be processed with special discs for stone.

If you need to cut a gas or oxygen cylinder, be very careful as it may explode due to the remaining trace of gas or condensation. It is better not to carry out such work at home..

If you need to cut glass or, for example, a mirror. the most trivial ceramic disc will suit you.

When working with material such as wave slate, do not apply extra effort to avoid chipping and unevenness..

It is possible to process rubber with an angle grinder, but not necessary. If you understand what we mean.

Grooves, springs, rebar or channel can also be cut with an angle grinder.

Need to cut drywall or polycarbonate? Do this very carefully to avoid chipping and breaking the material. You will need neatness if you need to cut glass mosaics. For example, if you are cutting off excess parts from a pasted arch, cover the cut and the part to be cut with masking tape or construction tape. This minimizes the possibility of cracks and prevents debris from scattering on the floor after cutting..

HOW TO CUT TILES WITHOUT CHIPS Angle Grinder?

As we said above, the range of applications for the angle grinder is incredibly wide. She also acts as an excellent helper when cutting material such as tiles or tiles. But, a logical question arises regarding the equipment: How is it better to work on tiles? To carry out this type of work, you need to get a grinding diamond wheel and a tile holder. It is hardly possible to work without dust with this material, so take care of a protective mask in advance..

Let’s take a closer look at the process itself and methods of cutting tiles or tiles without chips..

- The easiest way is to cut straight. Fix the tile well so that its edge remains suspended along the mowing line of the cut and get to work.

- The next method to be noted is cutting at a 45 angle. This method is more complicated than the first one. First, we cut the ceramic tiles with a straight cut. Then, when cutting the disc, the angle grinder is guided at an angle and remove the unnecessary part. Next, we grind the cut with sandpaper..

HOW TO CORRECTLY CUT ANGLE GRINDER METAL?

To begin with, let’s talk about the dangers that await the master when cutting metal with an angle grinder, namely:

- Fragments of the disk, in the event of its fracture;

- Powerful stream of sparks and small abrasive particles;

- In some cases, the inability to hold the instrument in the hands.

Now, a few tips for working with metal.

If you have no experience in this type of work, then, for a start, it is worth practicing on unnecessary details. If in the process of work, you decide to change the cutting plane when the disc is inside the workpiece, this will immediately lead to its breakage..

To increase the life of discs, especially expensive ones, they need to be cooled. This is done with water. It is necessary to water the cutting area. It is advisable that you work with a partner who will carry out all these additional manipulations..

Also, to increase the service life of the equipment, and the tool itself, breaks of 5-7 minutes every 20-30 minutes of work will help. This rule is especially important when working with household angle grinders. This way you will protect your instrument from overheating..

You should also remember that you should not put pressure on the angle grinder during operation, otherwise it may fail due to overheating, or the disc will jam. If you feel that the performance is too slow, try changing the drive.

CAN the angle grinder CUT WOOD?

Many seasoned craftsmen claim that cutting wood with an angle grinder is to be. Our opinion: indeed, it is possible to cut wood with an angle grinder, but it is extremely unsafe, inconvenient, slow and of poor quality. And that’s why.

Firstly, during operation, the disc of an angle grinder gets very hot and becomes incredibly fragile. The slightest misalignment may result in a ruptured disc. You can find out about the consequences of this situation from the pictures on the Internet..

Secondly, when working with a disc equipped with victorious solders, these solders can easily end up under the skin. And this is a direct way to the hospital, because you cannot remove them on your own, plus everything is fraught with infection.

Thirdly, when using a disc on wood, the teeth can grab more wood than you expect, and this, in turn, will lead to that. that the angle grinder will simply rip out of your hands. It is very dangerous!

We hope we have explained in an accessible way why you cannot use an angle grinder when working on wood and you will not even try.

But, as practice shows, many craftsmen at home resort to using an angle grinder in the process of processing materials such as chipboard, chipboard, laminate, OSB board or plywood. This should be cut as carefully as possible and in compliance with all safety measures. Otherwise, you can not only spoil the material, but also be injured..

HOW TO EXACTLY CUT AN Angle Grinder?

In order not to spoil the workpiece and make a high-quality smooth cut of the angle grinder, you will need to perform a number of preparatory measures, which we will discuss in this part of the article..

- Markup. All ingenious is simple. first we mark, then we cut. Take pipe cutting as an example. First, use a chalk or marker to apply the size, then use paper or duct tape. The main thing is that the edge is even. We take the selected auxiliary material and carefully wrap it around the pipe. Its border will be a clear and accurate marking of the cut. When performing work, it is important to remember that under no circumstances should you change the position of the tool stroke. Otherwise, the disc may jam or break. Also, do not put additional pressure on the tool, as this will immediately be reflected in the curvature of the cut and spoil your workpiece..

- It is very important to choose the right thickness of the circle. There is a simple axiom at work: the thicker the material with which you work, the thicker the disc should be. When choosing tooling, consult an expert in the field and pay attention to the marking of the grinding wheel applied to his shirt.

HOW TO SAFELY CUT AN Angle Grinder?

The work of an angle grinder is a matter that requires constant attention and control, because the consequences of accidents are irreversible. Therefore, before starting work, take care of the following:

- Take care of the protection of all parts of the body: face, hands, eyes.

- Clean the workspace from excess, especially the place where the sparks fly out, remove all combustible materials away.

- The workpiece to be machined must always be securely clamped.

- Be sure to install the protective cover.

- Hold the tool firmly while working.

- At the end of the work, wait until the disc rotation has stopped completely, place the angle grinder with the disc upwards so as not to damage it, unplug the tool from the mains and make sure that there is no smoke or signs of fire.

WHAT CANNOT BE CUT with an angle grinder? BASIC ERRORS

The list below shows the materials you can work with your angle grinder. It is forbidden to work with materials that are not on the list.

- The angle grinder is perfect for cutting materials such as cast iron, metal, steel, copper, aluminum, iron, titanium. You can cut stainless steel or galvanized.

- With the appropriate attachments, you can also work with plastics, ceramics, glass, plexiglass and porcelain.

- Stone, granite, marble, asphalt, concrete or walls made of it, brick, porcelain stoneware can also be processed by an angle grinder.

an angle grinder is useful if you need to cut water pipes or old heating.

One of the main factors that guarantee the quality of work is the right tooling. If you have any questions or want to purchase discs, please contact our managers at the specified phone numbers. They will recommend suitable discs and advise you on all questions of interest..

What can you do with an angle grinder?

Angle grinder, in common people an angle grinder, is capable of performing many operations.

The more powerful the engine, the higher the professional class of the device. For ease of use, high-quality models are equipped with handles that allow you to securely fix the tool during operation. Household models operate on a regular network. A professional tool requires a three-phase power supply at 380 V.

What operations does the angle grinder perform:

- cutting;

- polishing;

- grinding;

- sharpening.

angle grinder can work with different materials: concrete, metal, wood, brick and ceramics, stone, plastics.

The versatility of this tool is due to the use of a variety of attachments, each of which is designed for its own type of operation.

For the convenience of work, the angle grinder can be permanently mounted with special fasteners on the working surface. Some models are equipped with adjustable disc rotation speed.

What is the danger of working with an angle grinder

Any power tool is potentially hazardous, especially to those who neglect safety and protection measures during work. What’s Dangerous About an Angle Grinder:

- angle grinder attachments rotate at a very high speed: more than 10 thousand revolutions per minute;

- most of the rotating disc is not protected by a cover;

- when cutting the material, small fragments and sawdust are often formed, which fly away at high speed to the sides;

- a powerful device is quite difficult to hold in hand, especially if the material for cutting has a complex structure.

When choosing cutting wheels, remember that they are quite fragile and can crack and fly apart during operation.

Advice! When choosing attachments for an angle grinder, pay attention to their condition: they should not have any defects. The slightest unevenness or chipping can lead to sudden destruction of the material during operation..

The slightest misalignment leads to jamming of the nozzle. Because of this, a powerful jerk occurs during work, capable of knocking the tool out of the hands

Advice! If you do not have experience with an angle grinder, do not seek to acquire a powerful professional model. Better take a household appliance with a disc diameter of up to 125 mm.

Wood sanding attachments

Since the machine is called a grinder, then it should not have any problems with grinding. For this purpose, in working with wood, use a nozzle-holder, on which an abrasive wheel with a grain from large to fine is molded.

Saw blade with few teeth

Please note that on the surface of such a disc, the manufacturer applies information about the maximum number of permissible revolutions..

Large tooth spacing makes woodworking safer

Such discs, in addition to wood, do a good job with aerated concrete blocks..

Why is an angle grinder difficult to process wood?

First of all, it should be noted that the high speed of rotation of the disc distinguishes the angle grinder from the circular saw. And even the presence of a compensating ring that comes with the disc does not completely solve the problem. But if your angle grinder has a speed control, then this partly makes the task easier..

You can adjust the tool so that its speed matches the speed of the circular, this will also reduce the risk of injury to the process

But the main difficulty lies not in this, but in the structure of the wood itself, which is often heterogeneous and knotty. In addition to multidirectional fibers, there is resin in the tree, there may be pellets or ingrown wire, which you will not immediately notice. In general, wood is an unpredictable material. During work, you may encounter an unexpected obstacle, and, as a result, a jerk that can knock the tool out of your hands and direct it along a dangerous vector..

If the disc meets a piece of metal, a tooth can fly out of it, which, like a bullet, can also rush in an unpredictable direction. You are lucky if it comes across a protective cover on the way.

If you are thinking of sawing a wood angle grinder in the area, you will have to keep it in a horizontal position. This will make the grip uncomfortable and increase the risk of injury..

Important! It is strongly not recommended to cut wood with a tool that does not have a speed control and attachments that are not intended for this purpose..

Things to remember when working with an angle grinder for wood

Most importantly, what many sin is, in no case should you remove the protective casing, no matter how much you would like to see the cut point. The destruction of the disc can occur at any moment, and the fragments will fly not only at the operator, but also at those around them, and at such an incredible speed that no one has time to react.

- you need to check the strength of the fastening of the protective cover;

- the integrity of the discs should be checked, excluding those that have chips or cracks;

- The angle grinder must be held so that the protective cover is on the operator’s side;

- when starting work, it is necessary to check the tool at idle speed at different speeds. The tool should be vibration-free;

- before work, it is worth inspecting the tree for the presence of knots;

- hold the angle grinder firmly with both hands;

- take a break from time to time looking at the disc;

- if the angle grinder is stuck, turn it off immediately;

- choose a stable body position during work;

- make sure that the cord does not get under the disc;

- only move with the tool switched off.

Remember, you need to work with such a tool only in a concentrated, adequate state. Use protective gloves, mask and goggles

Can an angle grinder cut wood? You can, but right

To begin with, in any case, it is better to work with a tool that is specifically designed for a particular operation that you need to perform. All other tricks are justified only in exceptional cases, when the necessary tools for some reason were not at hand. This also applies to the question of whether it is possible to cut wood with an angle grinder. In this post from Housechief, we look at the nuances of this process and the opinions of practitioners..

Read in the article

Milling with an angle grinder

Another operation that many experienced craftsmen successfully perform with this tool is milling. Unlike a milling cutter, you will not be able to perform really high-quality processing. However, making a groove, as well as cutting a small part – it will turn out to be quite tolerable.

Again, this operation is dangerous. I have already written recommendations for general action using this tool, so follow them. an angle grinder requires a thick and high quality cutter. Immediately dismiss the possibility of using homemade nozzles, give your choice to an old brand, insured against chips and breaks.

Even with all the tips, a beginner alone should not start milling without the supervision of a more experienced craftsman. As mentioned above, accidents constantly occur with the masters of their craft, given the instability of the tool.

Grinding: attachments and process

Sanding pads are discs that are produced by layering several different coatings. To improve the abrasion characteristics of the treated surface, the initial layer is made of rubber, sometimes it is replaced with hard plastic. The layer of the second level of the nozzle allows to ensure the adherence of the plane of the working part to the surface to be grinded; it is made of foam rubber. The main, working layer is a sheet of sandpaper.

The use of sanding pads allows you to work efficiently with already painted surfaces. Rough polishing of the untreated surface is also possible.

Flap-type discs are suitable for the same purposes, only in rough grinding it turns out faster. A disc of this type is sandpaper petals attached to the working surface of the disc..

To remove paint, it is best to take special devices with peeling functions. Steel cup, with attached steel fibers made of hard wire, excellent abrasion, additionally sanding wood.

Difficulties when working with Angle Grinder

We mentioned the inconsistency of the revolutions of the angle grinder of a non-circular saw, alas, users who have an angle grinder with adjustable revolutions will say that this common rumor factor has been taken into account, and any saw blade for wood is also suitable for their tool.

Devices required for stripping

When using the attachments already described, remember that the angle grinder wheel can leave irregularities that are not visible after processing, but can appear after applying paint. To avoid this effect, use a vibrating machine to level out the effect of unevenness due to the circle..

Grinding operation is the simplest and safest operation that an angle grinder can perform. In any case, follow the safety rules.

CAN ANGLE GRINDERS CUT WOOD?? (Tricks + Tips–Cutting Wood With Grinders)

Can I cut wood with an angle grinder

Application of angle grinder for cutting various materials, cutting not sanding wood

If you are trying to understand how an angle grinder can cut wood, then the answer to the myth question is unambiguous: there is an option. How to properly cut an angle grinder wood firewood saw an angle grinder showed a little how. But probably they will not do this, tk. people get too many injuries precisely from using an angle grinder as a saw for wood, which is correctly called an angle grinder.

Initially, this is caused by the unlimited speed of its rotation, for which most saw blades are simply not designed. Who pays attention to this matter, when it is necessary to do the work, not at hand, of course, an essentially suitable tool, but in addition to the saw blade for wood, in addition, a compensator ring of the required size is applied. Can an angle grinder cut wood, how to do it. In addition, the non-protective casing is removed for ease of use, which is absolutely impossible to do..

However, we will not talk about injuries here, but let’s talk about how not to process (including sawing) a tree using an angle grinder, alas, before – about the complexities of working with an angle grinder with wood.

Safe cutting wood angle grinder (angle grinder). But can an angle grinder cut wood? You can cut wood with a chain disc with an angle grinder with. And not just wood. Bosch Carbide Multi Wheel

Saw blade for wood for angle grinder (angle grinder). But can an angle grinder cut wood? Saw wood like an angle grinder if you need a bevel cut. Bosch Carbide Multi Wheel. How to properly saw an angle grinder produced by a disc, additionally sanding wood. Two 608 six hundred twenty three 013. A small test.

This, by setting the number of revolutions of the output shaft of the angle grinder, corresponding to that indicated on the marking of the saw blade, they significantly reduce the risk of injury during operation, but do not eliminate it completely. This is mainly due to the material itself, or rather, its structure is not heterogeneity..

Even in different places in the textbook of the trunk, the tree has different hardness, we are not talking about the inclusions of viscous resin, the possible presence of metal trapped in the thickness of the wood: from pellets not bullets that fell into the tree during the hunting time, to the wire ingrown there, in which it is required tied up the branches. Remember not about knots, which are present in almost all types of wood..

Having met with the listed obstacles, the saw blade is sharply decelerated, not the angle grinder automatically simply pulls it out of the hands, but when passing through a hard area, it rushes forward like oil with a vengeance.

Having met with the metal, there is a high probability of chipping of a carbide tooth, which you like best is captured next not with the movement of the bullet thrown out. It is good if in the coverage area of the protective casing.

A person who decides to cut a tree is even more in danger, because here the angle grinder needs to be put on its side, from what factors the usual uncomfortable grip changes, which means that the grip weakens.

We strongly advise against sawing wood with an angle grinder that does not have speed control with circular saw blades. However, there are now special discs for the angle grinder designed for working with wood..

Wood cutting, is it worth starting?

Young craftsmen are always interested in whether it is possible to saw boards with an angle grinder? I will answer right away. No! Although such an operation is permissible for many, it should be carried out very carefully, because any violation of caution, disregard of the safety rules, can lead to a disc break, with the subsequent flight of particles in an unpredictable direction..

Why can’t a beginner do this? Naturally, following the law of meanness, this direction can be directly your face, or other parts of the body. The speed generated by the rotation of the disc of the angle grinder can accelerate the flying shard.

Let’s take a look at the most common and fraught beginner mistakes:

- Using an angle grinder without a cover, removal allows you to better control the direction of the cut, but completely removes all the insurance against disc breakage or flying chips;

- Using a non-standard disc for an angle grinder, most often beginners try to use a heavy circular one, which is also dangerous and can lead to irreversible consequences;

- Gripping a tool in the wrong place can cause the angle grinder to slip out of your hands..

Shocking photos on the Internet and equally creepy eyewitness accounts on the forums confirm the dangers of using an angle grinder to cut wood. These are the people whom non-compliance with TB has led to amputations, severe trauma and even death.

The following information contains comprehensive tips to avoid accidents like those inexperienced guys..

I also recommend reading my books on woodworking to know all the intricacies of the work. More details about the book in the “Books” section of the top menu of the site.

It is for the angle grinder that there is a special disc for wood, designed for sawing wood at high speed. Such a circle is not so common on sale..

Do not remove the protective cover! He is the only obstacle between your skin and a spinning circle at high speed..

Large angle grinders will not cut well. Due to sawing hard wood, they can break out of the hands, since at the speed of the angle grinder, the tooth of the wheel cling to tightly pressed wood fibers is unlikely.

Gloves for work are a must. The best way to get hold of the saw is a fixture. This will turn the angle grinder into a full-fledged machine, protecting you completely from being pulled out, in the case of high-quality installation of the structure.

Do not use cut-off wheels with large teeth, as they make the angle grinder even less likely to snag, especially on wood. The possibility of pulling out grows exponentially.

With an adjustable number of revolutions on the device, set the minimum value. Unfortunately, most angle grinders are simply not equipped with this capability..

The tool should be placed at a right angle, you can cut the workpiece, relative to the cut plane. Any misalignment can be dangerous. Tilting the device is also highly discouraged..

If there is a button lock, do not use it. In a critical situation, you will not be able to turn off the device trying to minimize damage.

Despite all the tips and rules, the process of sawing wood with an angle grinder can be so random that observing all the precautions given will not be able to guarantee the safety of the master. This is because the angle grinder is not the target tool for such tasks..

Therefore, if you have any alternative opportunity to abandon the use of this tool in favor of a stationary machine, immediately make a decision to use it, even if its transportation will take a lot of time and effort. In any case, health, as well as one’s own life, is more valuable..

The advice of many experts is a categorical rejection of this tool for this purpose. If there is a large amount of work, then the choice should fall on a jigsaw, which will never be superfluous on the farm..

Angle grinder discs for cutting wood

How to cut wood like an angle grinder, how to cut wood into planks with a chainsaw. How to properly saw wood with an angle grinder so that there is no damage and injury, which saw blades are better to use and how to make them. Chain discs and cutters based on them.

In order to enhance the picture – click on its surface.

Many argue that it is possible and that they themselves did this, and some categorically prohibit doing it. Let’s get into the essence, or at least try to get it in order to put a fat point on this issue.

Let’s start without intrigue: our answer to everyone and everyone who reads this article is no, and by no means! angle grinder to cut wood, boards, timber is categorically impossible. Rather, it is possible, but the consequences can be sad and very. Look for a picture on the Internet, how terrible the consequences are, and we will explain the theory:

- During the cut, the angle grinder, if the disc is on the wood, the teeth can grab more wood and then you will have to catch the tool either a few meters away from you or on yourself. It depends on how the disc stands and in which direction it rotates. Let’s not forget that after the finger stops pressing on the switch, the disc continues to rotate for some time. And here there is already a chance and luck – during such a jerk, the tool will fall on the hand, finger, leg, chest, stomach, or it will break out of the hands to the side.

- During cutting, the disc heats up and becomes more fragile. Even a slight bias – and the disc can fly to pieces. And again luck or good luck – you will “catch” such a piece with your eye or your finger, or maybe you will snatch it in the forehead. The chances, of course, are equal – perhaps such a piece of sharp iron will fly off to the side.

- A disc with victorious soldering can bring a surprise in the form of the very soldering under the skin. We witnessed how a small piece flew under the skin of the thigh and to get it, we had to cut the skin a little with a knife. It’s just that the person did not want to go to the hospital for personal reasons, but this is his right. It was science to him anyway.

So, dear ones, remember and pass on further along the line: an angle grinder cannot cut a tree and no “Is it possible?” But if you really want to, then write a will, kiss the children, make sure that you are quickly found and, after praying, proceed. But we warned.

And just think: why did they come up with a chainsaw and a circular saw, a jigsaw and a band saw?

Greetings, my dear readers of Andrei Noak’s blog. Many people ask on the forums the question, is it possible to saw boards with an angle grinder? Therefore, I decided to fully understand this issue together with you..

The angle grinder is a versatile tool. The angle grinder is suitable for a whole range of jobs, replacing a range of metal tools, often doing the job even better and more accurately. This can boast of all processes produced by a disc for metal. But what about wood and chipboard? Is it safe? Today I want to figure out how to do it correctly at my own peril and risk.

Can I cut wood with an angle grinder

Well, literally, it’s better to cut wood with a hacksaw. But wood materials such as plywood and 2-3 cm thin board, then yes, in this case, the angle grinder can be used for cutting. In this case, we will consider safety precautions below, and now the nuances regarding technical issues.

To cut wood, an angle grinder will need such a disc for wood as in the picture. It has special teeth that provide a wide kerf, just enough to prevent the angle grinder from jamming. and the instrument itself was not snatched out of my hands. However, it is not recommended to cut trees with an angle grinder, in the literal sense, and you should be very careful when cutting wood itself..

Can I cut wood with an angle grinder

Can I cut wood with an angle grinder

Be aware that when sawing wood, there is a risk that the angle grinder may jam. In addition, when sawing wood, the saws will not be as smooth and neat as when using a jigsaw. This article of the construction magazine samastroyka.ru will tell you about whether it is possible to cut wood with an angle grinder, which disc is needed for this, and how to do it correctly.

How to safely cut wood angle grinder

If you need to dissolve the board into thin slats or cut off a piece of plywood, angle grinder, you should adhere to the following rules:

- The wood angle grinder should only be used with a special disc designed for sawing wood. You can not cut boards with an angle grinder, a cutting wheel for metal;

- You need to confidently hold the angle grinder in your hands and stand firmly on your feet. It is not allowed to cut workpieces located directly on the ground. It is imperative to put something under them so that there is space below;

- You cannot cut trees in the literal sense of the angle grinder. The branches of the tree are damp, and moisture only makes it difficult for the disc to move. Therefore, at any time, the disc can jam in the wood, and the angle grinder can be pulled out of your hands. It is probably unnecessary to say how all this can end;

- It is best to use a small angle grinder to cut wood. It is much easier to hold an angle grinder with a 125 disc than with a 230 mm disc;

- When sawing wood, the workpiece must be well pressed by the foot or securely fixed in a vice.

An angle grinder should be cut slowly and carefully, making sure that the disc does not jam at all times. Often, when cutting planks and plywood, a large amount of corrosive smoke is emitted, therefore the place where the sawing work is carried out must have good ventilation..

An angle grinder, even with a disc for wood, cannot be used as a jigsaw. That is, if you need to dissolve the board or cut it off, then you can do it. It is always worth remembering that an angle grinder is a very traumatic tool, and it can easily be pulled out of your hands when the disc is jammed. Security measures should not be neglected.