Cutting tempered glass at home

Tempered glass is considered one of the most common materials. To increase its strength, hardening technology is used. After carrying out such a procedure, the degree of workability of the material is significantly reduced. When considering whether it is possible to cut tempered glass, we note that only with the use of Special technologies can the appearance of a defect be avoided. Today, cutting of tempered glass can be carried out at home, for which a variety of tools are used.

Tempered Glass Cutting Instructions

The high strength and hardness of the surface means that quite serious problems can arise during cutting. When considering how to cut tempered glass, you should pay attention to the following points:

- The workpiece is prepared by annealing. This technology provides for uniform heating of the surface. Due to this, the stress that forms inside the material at the time of its hardening is eliminated. Due to this voltage, it becomes much more difficult to achieve the required dimensions.

- The annealing process involves heating water to a certain temperature, after which the workpiece is lowered into it. It is worth considering whether to cut car glass or decorative use should be at different temperatures, it all depends on the brand of material.

- The exposure time of tempered glass in water can vary significantly. In some cases, it takes about an hour, the most difficult versions are kept for a month.

- After reaching the required temperature, the product cools slowly. The work is performed slowly, due to this, the likelihood of the appearance of even the smallest defects is excluded.

- As soon as the surface temperature has decreased, glasses can be put on and cutting can be carried out using a glass cutter. Similarly, you can cut glass for your phone.

- Before cutting, the marking should be done. Smooth and precise lines are achieved when using a square and other measuring instruments.

- Press on the material with moderate force, as a high load can lead to serious defects. The cut is carried out quickly, it is not recommended to re-try to make the line due to the fact that such actions can lead to splits and cracks.

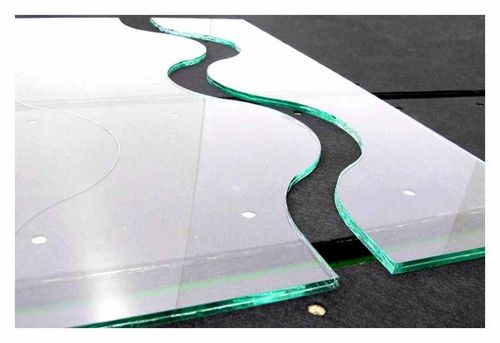

- At the time of cutting, you should be careful, as you will not be able to make the cut line again. After obtaining the required mowing line, a rod is placed under it, with a sharp push the product is divided into two parts.

With careful work, you can get a high-quality cut. Finish the end surface with a grinding stone.

Required tools

As previously noted, cutting of tempered glass can only take place with the use of special equipment and tools. It is as follows:

- Special furnace for tempered glass processing.

- Thermostat.

- Square.

- Surface marker.

- Grinding stone.

- Special glass cutter.

- Rod with a diameter of 6 mm, made of wood.

- Goggles designed to protect the eyes. During cutting, chips may form and fly away from the cutting zone.

Tempered Glass Cutting Angle Grinder

With the help of special equipment, tempered glass can be cut with precise dimensions and high quality ends.

Preparatory stage

When considering how to cut tempered glass, the preparatory phase should be considered. Careful preparation allows achieving high quality. Cutting tempered glass at home is carried out taking into account the information below:

- During the production of the material, zones with internal stress areas are formed. With rapid heating and cooling, such areas are redistributed. The glass becomes more viscous inside compared to the outer layer.

- At the time of processing, the workpiece must be securely fixed. For this, a wide variety of devices can be used.

- The surface of the tempered glass must be free of contaminants. An example is oils or paints, which can significantly reduce the quality of processing.

In general, we can say that getting ready for work is quite simple. However, without special tools and equipment, cutting will NOT be possible.

Tempered glass properties

Before the processing of tempered glass is carried out, its main characteristics should be considered. These include:

- The structure is characterized by high mechanical strength. Due to this, they can be used for glazing balconies and loggias.

- Strength and hardness allow the material to be used in the manufacture of furniture and other products.

- To improve ordinary glass, heat treatment is carried out in a special oven. The medium is heated at 670 ° C.

- The thermal resistance index is significantly increased. In the manufacture of various devices, which are operated at elevated temperatures, tempered glass is often used. When heated, the hardness indicator remains unchanged.

Application of tempered glass

As the results of the conducted research show, the strength index of tempered glass is 7 times higher than that of ordinary glass.

Nuances when cutting at home

When considering how to cut tempered glass at home, you need to pay attention to choosing a more suitable tool. The following glass cutters have become widespread:

- Diamond are used very often today. Due to the use of durable and hard material, the tool can serve for a long period. From time to time it is necessary to sharpen the cutting edge when using a special whetstone.

- Roller. Cutting tempered glass at home is often done with a similar tool, as it is ideal for the job in question. The set may include 6 rollers, which are often made of cobalt and tungsten. By combining a large number of rollers made of durable and wear-resistant material, the cutting task is greatly simplified.

- Oil is similar to the version with rollers, but the design has a special container for storing oil. When the work is done, lubricants are added to the cutting zone, which greatly simplifies the cutting process. That is why this version is used more often than others.

Before direct work, you need to check the degree of sharpening of the cutting edge. When using a worn-out tool, the processing quality is significantly reduced, there is a possibility that the created cutting line will have insufficient depth.

# Spoiler # end_spoiler