Method Classic miter box

The classic miter box is a U-shaped bed with slots in the opposite sides. A part of a suitable size is inserted into this stock and sawed off with a hacksaw through the slots in the sides. The idea is not new, the tool is already several hundred years old, but despite the simplicity, not everyone knows how to properly cut the corner of the ceiling plinth using such a miter box.

Not everyone knows how to cut a ceiling plinth in a corner using a classic miter box.

Tip: when trimming, the ceiling plinths are applied to the side of the miter box that is closer to you, and the floor plinths, on the contrary, must be applied to the side of the tool farthest from you. This is not a dogma, but it is much easier to work this way.

It is easier to work with skirting boards, since the miter box lies on a horizontal plane, it is easier for you to orient yourself in the position of the skirting board. People most often make mistakes when trimming the ceiling fillet, it is simply incorrectly put into the tool. There is a simple but important rule here.

Important: the side of the ceiling fillet, which touches the wall, should be directed to the upper edge of the side of the miter box, and that part of the plinth that borders on the ceiling is placed on the bottom of the miter box.

As you know, there are 2 sides to the corner, so, in order to make less mistakes, train yourself to insert the bar that will be mounted on the right side of the corner into the miter box on the right, and the bar that is attached to the left, put it into the miter box on the left. Details about the intricacies of using a classic miter box are described in the video in this article.

How to properly trim the inner and outer corners of the ceiling fillet.

In addition to the classic U-shaped miter box, there are two more types of similar designs. a professional and a rotary tool. As for the professional version, only masters use it. The device is quite bulky, but it turns at any angle and has a hacksaw that can be fixed in the desired position.

Professional miter box with the ability to fix the hacksaw and part.

The swivel device can be safely called a “” miter box. The only advantage here is the ability to clearly fix the angle of rotation of the bar. On the one hand, it is easy to work with it. set the corner, put it on the plinth and cut it off. But on the other hand, you need to get used to such a tool, if you do not have experience with a hacksaw, then you should not take a rotary miter box.

Tip: when choosing a classic U-shaped miter box, firstly, do not take Chinese products. And secondly, try to buy models with the possibility of rigid fixation of the part inside, one of these models is shown in the photo below.

A miter box with the possibility of fixing a part inside is much more convenient to work.

Pattern Crop method

Most often, both ceiling and floor skirting boards need to be cut at 45º. If there is no specialized tool nearby, then an impromptu miter box can be drawn on a notebook leaf. From the school geometry course, we know that the diagonal of any square in relation to the base has an angle of inclination of 45 degrees.

The 45º angle can be set by attaching the plinth to the diagonal of the square.

Next, you need to draw a square and draw 2 diagonals in it. these will be the required 45º. You just have to correctly attach the plinth to the leaf and mark it. True, in order to cut off the plinth exactly without guides, you need a good eye and a right hand.

Three working ways to trim skirting boards

For floor and ceiling skirting boards, the trimming instructions are almost the same. But if on the floor the curved corner can be covered with something, then on the ceiling this is already a problem, so we will pay more attention to how to cut the ceiling plinths.

Important nuances

If you tried as best you could, but a small gap at the junction still “got out” do not be discouraged. In wooden fillets, such a gap is easily covered with furniture wax. To cover the gap on the baseboards made of polyurethane, foam, plastic or gypsum, a putty is perfect. Naturally, the color of the composition should match the color of the skirting board.

All cracks in the area of the ceiling fillets are sealed with putty.

Wide ceiling fillets are certainly beautiful, but they can only be mounted on perfectly flat walls. If the plane of the wall in relation to the ceiling is a wave, then it is better to buy narrow polyurethane fillets, they are elastic and will smooth out this drawback.

Perfectly flat walls are needed for a wide fillet.

Most of the questions arise about how to cut the wallpaper for the ceiling plinth. There is nothing complicated here: the wallpaper is glued with a slight overlap on the baseboards and when the wall is completely glued, take a large spatula, put it in the corner and cut off the excess along the blade with a knife.

How to cut wallpaper for a ceiling plinth with your own hands.

But keep in mind. neither the knife nor the spatula can be torn off the wall until you have passed the entire plane. That is, they put a spatula from the corner, cut off the wallpaper along the length of the blade, and then, without taking the blade off the wall, move and cut it until you reach the next corner.

How to cut a skirting board at any angle and without gaps. 3 working ways from a practitioner

There are more than enough tips on how to cut a plinth at 45 degrees on the net now, the only bad thing is that most of them are given by people who have never done this. Next, from the point of view of practice, I will tell you how to cut skirting boards at the corners with your own hands in 3 options, and you will learn about both traditional methods and folk universal recipes.

The science of how to properly trim ceiling skirting boards in corners is not as difficult as it might seem.

A few words about tools and materials

Floor skirting boards are now made of wood or polyvinyl chloride (PVC), in other words, plastic. Ceiling fillets have a slightly larger list:

The range of ceiling skirting boards is much wider than that of the floor direction.

- Polyurethane. these skirting boards have good elasticity and can bend around radial and other curved surfaces, but in any case they need to be cut at clear angles;

- Foam plinths are the simplest budget option, the price of foam plinths is low and they are cut very easily;

- PVC. the principle is the same as for floor skirting boards, but the range is much wider;

- Wooden. similar to the floor ones, only here there are still wide models;

- Gypsum. with the advent of polyurethane and polystyrene, gypsum ceiling fillets receded into the background, firstly, they are heavy, and secondly, fragile. But in fairness, it’s worth mentioning them.

Since it is impossible to properly cut the ceiling plinth and its floor counterpart without a good tool, we will dwell on this issue in a little more detail.

The best, almost perfect tool for trimming all kinds of skirting boards and more is the swing miter saw. The high-speed disc makes smooth and precise cuts, and the bed in these units can be rotated at any angle. The only problem is the serious cost of this tool.

The miter saw is almost the perfect tool for trimming skirting boards and more.

It is believed that one of the best hand tools for accurately cutting small pieces of wood is the backsaw. In principle, this is true, but to be honest, a really high-quality saw, even with the current assortment, is not easy to find. If you still decide to buy a similar tool, then take a saw with a fine tooth.

The bow saw is convenient when working with a miter box.

In theory, foam and polyurethane can be cut with any sharp and sturdy knife. But at the same time, you need to have a firm hand and at least a little experience in cutting foam. Plus, it is very problematic to cut wide fillets with a knife.

Without experience, making a clear cut with a knife is very problematic.

Personally, in the absence of trimming, I only use a hacksaw for metal. It is suitable for cutting absolutely any material, from styrofoam to wood. By the way, they often ask the question of how to cut a plastic baseboard for the floor, and so. take a hacksaw for metal and you definitely won’t be mistaken.

For trimming skirting boards, a hacksaw for metal is considered one of the best tools.

Method Applied universal

45º trimming is common, but what if you need a different angle and only have a hacksaw and a pencil? It turns out that there is a very simple way out of this situation. Plus, this method is universal, it is suitable for both external and internal corners.

over, I can assure you that those angles that visually seem to be straight, in fact, have deviations by a couple of degrees. As a result, you buy a good tool, cut it off at 45º, and when joining, the gap between the skirting boards “comes out”. This problem disappears here. And then, using an example, consider how to cut the ceiling plinth in the inner corner.

Take a fillet, apply it to one side of the corner and use it to guide 2 mowing lines, along the wall and along the ceiling.

Tip: to make the mowing line unobtrusive, they can be carried out not with a pencil, but, for example, with a nail or the edge of a knife.

All three methods described by me work, the choice depends on which tool you have in stock and what your professional skills are. If after watching the video you still have questions, welcome to the Комментарии и мнения владельцев, than I can, I will help.

If you are not confident in your abilities, then for both floor and ceiling skirting boards there are connecting elements that allow you to do without trimming.

How to make a corner of a ceiling plinth without a miter box

Few people in apartments or houses have angles of exactly 90 °. Small deviations are easily corrected after fitting. But not always. Then you have to mark everything “in place”. under the ceiling.

You will need a finely contoured pencil (hard. it is not so visible on the ceiling, but leaves quite clear marks near), a small piece of plinth, a ruler and a good stationery knife if you work with polyurethane (polystyrene) baguettes or a metal saw to work with other materials.

Apply the plinth to the corner, draw along the outer edge with a pencil. Apply to the other side of the corner, also mark. You have a cross on the ceiling, the center of which marks the place where the plinths of the ceiling plinth should converge (look at the photo). Having installed a piece of plinth in the corner, which will be glued there and resting it with its end on the wall, transfer the mark to it.

How to make corners on skirting boards without using special tools

Now take a ruler and connect the edge of the skirting board with the marked mark. If you just put the plinth on the table and cut along the mowing line, the two parts in the corner will still not fold: the inner part will interfere. It can be trimmed later by trying on the ceiling. The second way is to set the piece to be cut on the table with the piece that will be on the ceiling. And cut along the mowing line, but holding the knife at an angle of about 45 °. It will still be necessary to correct, but much less (and less chance of error).

Repeat the same operation with the second bar. Put it against the desired wall, rest the butt against the adjoining wall, mark the place where the cross is drawn, draw the line and then cut it off. Correction Carried out “dry” without applying glue.

You repeat exactly the same steps for the outer (protruding) corner. Now you know another way to make a corner of a ceiling plinth, and without a scissor or other special devices.

How to get the correct angle

Most of the problems when working with skirting boards arise in the design of corners. Since the surface of the products is complex, it will not be possible to simply cut off at the desired angle: it is also necessary to cut so that they dock and, preferably, without large gaps. In reality, there are several ways to make the corner of a ceiling plinth perfect (or almost).

How to cut ceiling plinth in corners

The quality of the ceiling finish greatly affects the appearance of the room. Therefore, they try to do everything perfectly, or very close to it. The finishing touch to the design is the ceiling plinth. They give the finish a complete and holistic look. The strips themselves are mounted on flat surfaces simply: on a special white glue, but problems arise with the design of the corners. Without knowing how to make the corner of the skirting board correctly, a lot of material deteriorates. How and what to cut it in the corners and tell you.

How and how to cut

Working with skirting boards made from different materials means using different cutting tools. When working with a wooden skirting board, it is more convenient to work with a saw on wood. All others, including plastic ones, made of foam and other polymers, are better cut with a blade for metal. The result is a smoother cut, less burr. Saws are usually used when working with a miter box.

Corner design looks attractive

When working with polystyrene skirting boards without special devices, they are cut with a good office knife. Its blade is quite thin and even, the cut is smooth, not wrinkled. If you use a saw with polyurethane or polystyrene, do not press hard: you can wrinkle.

In general, in order to get used to the tool and material a little, take a piece and practice on it: cut, saw, trim. So there will be fewer problems when working.

What is it made of and what is it called

The very first skirting boards on the ceiling were made of plaster. They were cast in special molds and then installed on the ceiling with mortar. Such figured ornaments were called fillets. Today, you can rarely see them: they are expensive, and outwardly they are almost indistinguishable from the cheaper options. And the name is almost lost.

The most popular ceiling skirting boards are made of polyurethane or polystyrene. They are inexpensive, look great, are easy to install, have a wide range of profiles and patterns. The width can be from 5 mm to 250 mm. They are used in almost any room, decorated in any style. An exception is wooden houses with a corresponding interior. Wooden products are most often used here. the style dictates its conditions.

There is also a similar plastic finish. It is mainly installed in bathrooms. But even in damp rooms, you can safely mount polyurethane strips. they are not afraid of damp.

You need to cut the ceiling plinth in the corners of any material in one of the ways described below. The only exception is plastic skirting boards: you can arrange such a corner only using ready-made corners.

Using a miter box

If the corners and walls in the room are even, you can use a special carpentry tool. a miter box. This is an inverted U-shaped chute in which the mowing line is marked for cutting at 90 ° and 45 °. The part in which you need to make a gash is laid inside, a saw is inserted into the guides. The part is held in place, cut at the desired angle.

This is what the miter box looks like. Can be plastic, wood or metal

In the case of skirting boards, not everything is so simple: they must simultaneously adhere to two surfaces, therefore they must be pressed against one or the other wall of the miter box. When working with ceilings, they are pressed in the side closest to you.

The sequence of actions when finishing the outer corner, you need to make a gash at an angle of 45 degrees. Place the miter box in front of you. Trying on how the plinth will be located, determining which part of it will be attached to the ceiling. In order not to get confused and cut off the ceiling plinth correctly, place the strip that will be located on the right on the right, the one on the left on the left.

How to cut a corner on a ceiling plinth: install it correctly in a miter box

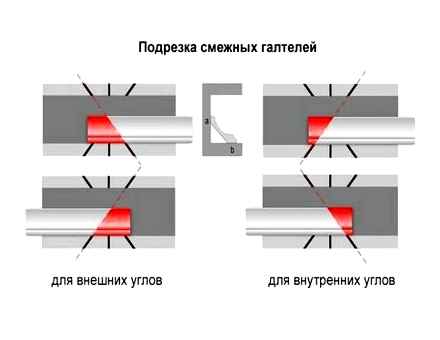

Press the part that is on the ceiling to the bottom of the miter box. The other side is closer to you and raised. Lean it on the wall of the device so that it does not stagger when cutting. That is, the front part of the skirting board turns out to be turned away from you. Do the cutting direction as shown in the photo below. By folding the two cut pieces together, you get a protruding outer or outer corner.

First put the sawn-off parts in place “dry”, without applying glue. If the geometry of the corner is not so perfect, you can tweak it a little with a knife. It is easier to cover small errors with a special putty.

The situation is very similar with the inner corner of the skirting board. First you try on which side will be on the ceiling, press this part to the bottom of the miter box, lean the second part on the wall closest to you and make cuts as shown in the photo below.

How to make an inner corner of a ceiling plinth using a miter box

And again, first try on without applying glue, if necessary, slightly adjust. Then apply a thin bead of glue to both surfaces that will adhere to the wall or ceiling.

Your own version of how to use the miter box correctly is shown in the video.

With decorative corners

There is one more, the easiest way. For skirting boards made of polyurethane or polystyrene, use ready-made, factory decorative corners. They are installed in a corner, strips are glued to them closely. It is very easy to cut them if necessary: by a few millimeters with an ordinary clerical knife.

Examples of finished corners for fillets

How to join in corners

If the installation of the first corner is completed, we can assume that you have already learned almost everything. “Almost”, because you still need to learn how to join the corners and cut the planks to length. When some part is already glued and a small distance is left to the corner, how not to be mistaken with the length? The answer is simple: leave stock.

At first, you can cut a piece 10-15 cm longer: it will be possible to redo it several times if something does not work out right away. Then you make a corner in the way described above, try it on dry, adjust everything so that the result suits you. Only then can you attach the already cut strip to the corner and mark the place to which it can be shortened. You need to trim at exactly 90 °. It is not necessary to use a miter box. Just try to put the knife (hacksaw) perpendicular to the surface.

Plastic Ceiling Cladding. 2 Part Coving Trim

Method two. no additional tools

For the inner corner, you can use the simplest way of perfect joining. by marking on the ceiling. Another example of how to cut a corner nice and even.

- Apply a fillet to the ceiling, firmly pressing its even edge into a corner.

- Draw a line along the long side of the plinth on the ceiling.

- The same action is done with the adjacent part on the other side.

- Mark the point of intersection of lines.

The end result is an even 45 ° angle when you draw the line from the point of intersection to the edge of the part. Note that the above marking method works only for perfectly flat corners.

Inner corner

- Making the right measurements.

- We install the plinth strip in the miter box so that this position exactly coincides with the placement on the ceiling.

- The plinth should be firmly pressed against the opposite wall of the miter box. Hold and press with your free hand.

- We put a hacksaw at an angle of 45 ° in a special hole and cut off the part.

- The adjacent part must be cut in the same way, only in a mirror image, as shown in the photo.

When cutting soft materials (PVC, expanded polystyrene), use a metal hacksaw or an ordinary construction knife. Then the work will be neat and with smooth edges.

Outside corner

- Measure the length of the plinth from the nearest wall to the outer corner, leave the fishing line on the wrong side with a pencil, indicating the desired length. It should be noted that the edge (its upper part) should protrude slightly outward.

- The plinth is moved to the miter box and cut off.

- The adjacent bar also needs to be measured with a margin and cut off in a mirror image to the first part.

Trying on the ceiling plinth: the joining of the parts should be perfectly even. If the result is not achieved and there are irregularities at the joints, you can trim the edges with an ordinary knife to a perfect fit.

How to cut the corner of a skirting board evenly

A beautiful and neat edging of the ceiling hides the joints between the coverings and is an additional element of the room’s decor. But in order for the ceiling plinth to look really beautiful, you need to be able to qualitatively join its corner joints. How to cut the corners of the ceiling plinth evenly can be found in our article. Related article: how to properly glue the ceiling plinth with glue and putty.

Tommy’s Trade Secrets. How To Fit Coving (Internal Mitre)

The first way is with a miter box

Professional miter box with rotary hacksaw

The miter box usually looks like a tray with vertical holes for a hacksaw. It can be made of wood, metal or plastic. This tool is the oldest and simplest carpenter’s tool for cutting wood pieces at 90 ° and 45 ° angles. There are types of such a device for professional work, with a rotary mechanism, in which the cutting tool can be rotated and fixed in any position.

How to cut a ceiling plinth correctly

Ceiling corners are divided into internal and external, the method of joining on them is slightly different.

If necessary, you can make a miter box with your own hands. To do this, you need three trims from plywood or boards of the same size. First, they are applied in the form of an inverted letter “P” and the corners are marked. Then, according to the marking, slots are cut out for a hacksaw almost to the very bottom, and the boards are twisted.

other methods

With a good eye and accuracy of hand action, you can use a homemade template that resembles an imitation of a miter box. To do this, take a thin board or thick plywood and draw a layout in the form of a horizontal rectangle. Using a protractor, mark 45 ° on the right and left sides of the rectangle. Draw mowing lines connecting opposite edges. You can now cut off the ceiling plinth using this layout. The actions are simple and similar to the description above in the first option. Only the ceiling parts should not be inserted, but placed on the drawing and the hacksaw should be combined with the layout of the layout.

Special accessories for docking