Preparatory stage

The answer to the question whether it is possible to cut tiles with an angle grinder will be positive, but it is necessary to choose the right attachment (cutting edge). With porcelain stoneware, which is characterized by increased strength, it is better to work with a diamond-coated disc. Ceramic material is easier to cut, but in this case, such a nozzle will work. Use a fine-dust diamond wheel.

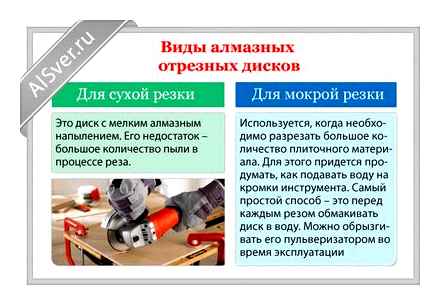

In addition, before starting work, it is necessary to decide which cutting method will be used: dry or wet. In the first case, a lot of dust appears in the process. This is due to the fact that the material is characterized by high density and increased strength. As a result, cutting with an angle grinder is accompanied by the release of a large number of tiny particles into the air.

Alternatively, you can choose wet cutting. In this case, a cooling system is used. water is supplied to the treated area of the finishing material. Working with an angle grinder, it is difficult to organize the cooling of the disc in an automatic mode, for example, as it is implemented in electrical installations (electric tile cutters), where there is a special bath. If you plan to use an angle grinder, prepare a spray gun or a wide container with low sides to cool the diamond disc, which will allow you to lower the cutting edge into water, having previously turned off the angle grinder.

Work on a power tool must be carried out after a thorough inspection. In the process of fitting the tiles, the cutting disc can cause injury, so it is important to check the attachment quality and make sure that all other removable parts are securely installed. The angle grinder should be equipped with a special cover that reduces the rate of dust spreading into the air. To prevent debris from damaging the wall decoration or plumbing fixtures, cover them if possible.

How to properly cut tiles with an angle grinder?

If the question of how to cut a tile with an angle grinder is being decided, a number of nuances should be taken into account so as not to damage the product. In the absence of other tools and equipment (tile cutter, glass cutter, electric machine for adjusting the finishing material), you can use an angle grinder (angle grinder). Its other name is an angle grinder. It is a compact multifunctional power tool that is often used to cut ceramic or porcelain tiles.

How to avoid chips

To cut the tiles evenly and without deformations, you should adhere to the recommendations:

- Masking tape is glued on the site of the planned cut.

- It is recommended to work on the front side of the product, which is due to an increase in the number of chips at the exit of the cutting edge.

- You can cut the tiles with an angle grinder without chips if you do not exert excessive pressure on the surface during the process.

- To protect the cut from chipping, it is recommended to work with a thinner diamond blade.

- The incision is made single.

Angle Grinder Selection Guide

In order to properly fit the finishing material, it is recommended to pay attention to the main criteria when choosing an angle grinder:

- Better to work with a smaller tool.

- Select a model with the ability to adjust the speed of rotation of the cutting edge.

- Large powers allow you to work with large-sized material, but at home, an angle grinder is enough with a load of up to 1 kW.

- The size of the seat for the cutting edge. The optimum is a disc with a diameter of 125 mm. If you use a small diamond wheel, it is used for jewelry operations, but it grinds down faster. Large discs allow you to work with large volumes of finishing material.

It is also worth taking care of choosing the right disks:

How to cut tile or ceramic tiles with an angle grinder

The angle grinder allows you to cut from the product not only areas of the correct geometric shape, but also curved stripes. It can be curves, or even circles. Cutting ceramic tiles with an angle grinder in the case when it is necessary to obtain a circle is more difficult. This is due to the fact that this material is more susceptible to deformation on the cutting line of the cut. Sequencing:

- line of future cuts is applied to the tile;

- the diamond disc is fixed to the tool using a special key that comes with the kit and is designed to install cutting discs with your own hands;

- in order to avoid slipping during the cutting of tiles with an angle grinder, a stop is installed on one side, it can be any relatively heavy object;

- the tile is adjusted on the floor, you can also put the product on the table, but in any case, there must be an emphasis under the tile on both sides, which will allow the cutting edge to go through its entire thickness (otherwise the diamond disc will damage the table or floor finish);

- tiles are cut with an angle grinder by pressing a button.

Special attachments for angle grinders

There are stone and metal discs. For working with tiles, it is recommended to use the second option with a diamond coating. In addition, the discs are available in different designs and designs. There are models:

- Solid. They can be smooth or abrasive. Most often used for dry cutting. However, you can periodically wet the surface of the cutting wheel with water. Solid discs are more suitable for processing the edge of the product.

- Segmented. consist of several parts. It is not recommended to use them for edging, as the probability of chipping increases. Segmented discs have holes for cooling, so there is no need to use water.

- Combined. This is a nozzle that can be used for both dry and wet cutting.

Safety engineering

An angle grinder is a tool that, if used incorrectly, can cause injury. For this reason, safety precautions should be followed:

- The disc immersed in the material must not rotate too fast. This will lead to chipping. It is recommended to adjust the tile with an angle grinder at a low speed of rotation of the disc: from 3000 to 3500 rpm.

- The length of the power cord should not be less than 2 m, which will allow you to move freely when working with an angle grinder.

- Do not hold the tool in an upright position. However, he can escape from the hands and cause injury.

- Before performing work, put on a protective mask and goggles, a hat, gloves, overalls, closed shoes.

- You need to hold the tool firmly in your hands, but you must not put pressure on the tile during cutting, since it can simply fly apart.

- The adjustment of the finishing material should be carried out in the direction away from you.

- If dry cutting is done, it is best to work in a well-ventilated area as a lot of dust is released during the process.

- When switched on, do not lower the angle grinder into water.

How to get rid of dust when cutting tiles

Cutting tiles with an angle grinder is not very difficult, but it generates a lot of dust. There are techniques that can help reduce dust formation. Specialists use special tile cutters for this, but buying them for a one-time job is impractical due to the high cost. Therefore, when processing parts, the craftsmen act differently. First, a layer of glaze is cut through. it almost does not produce dust, the main dust appears when a layer of fired clay is processed. Then it remains to gently break the ceramic tile and process the edges with an abrasive material.

A common way to get rid of dust is to moisten the workpiece. To do this, water is constantly poured into the working area with a diamond wheel. After each pass of the tool, fill the seam with water or install a special device for supplying water to the working area. This device attaches directly to the protective cover of the angle grinder. As a result, the workpiece is processed without dust.

Cutting porcelain stoneware

When performing repairs, not only walls are lined. Ceramic granite tiles are laid on the floors in the bathroom and toilet. an artificial material that replaces granite and marble. Its cost is several times less than natural, but in terms of hardness and abrasion, porcelain stoneware surpasses them. Recently, it has become widespread. It can also be cut with an angle grinder.

To do this, you need to know the basic methods of processing material at home.

- Choose the right cutting tool. It should be written on what it is used for: porcelain stoneware, hard ceramics, etc.

- To reduce chips, choose a disc with a continuous cutting edge. The thickness should be minimal.

- Choosing a cut-off wheel with a high diamond coating height.

- the angle grinder must have a speed controller.

After choosing the tool, prepare the workplace and begin to cut the porcelain stoneware with an angle grinder. To do this, you need to perform the following steps.

- Place material on a flat surface with thin foam or similar material underneath.

- Fix the tiles securely to the surface with clamps.

- To reduce chips, glue masking tape and make markings, along which it is necessary to cut off the excess part.

- Prepare the vacuum cleaner to remove dust.

- You need to cut from the front side, moving the grinder away from you.

- It is recommended not to cut along the marked mowing line, but slightly to the side. This is done for the subsequent grinding of the end face of porcelain stoneware to remove irregularities and chips.

Following these simple recommendations, you can cut the floor tiles with your own hands.

Safety engineering

To ensure safety when cutting tiles, the following requirements must be met:

- use a protective cover;

- hold the angle grinder firmly, do not turn it vertically;

- use appropriate PPE. overalls, goggles, respirator, gloves, etc.;

- work outdoors or in a well-ventilated area.

In addition, it is necessary to observe electrical safety techniques, do not use a faulty tool with broken insulation of the case and wire. Before cutting the tiles with an angle grinder, prepare the workplace, provide appropriate conditions. lighting, ventilation, etc. Compliance with these simple rules will allow you to avoid injuries and get the job done without harm to health.

Ceramic tiles are often used as a cladding material for interior and exterior surfaces. She is not afraid of moisture, the effects of aggressive cleaning agents, practically does not lend itself to mechanical damage and does not need special care. Most often it is used in the process of cladding a bathroom and a work area in the kitchen.

In some cases, it is required to independently cut the ceramic tiles into fragments of the desired size and shape. Equipment such as a tile cutter or an angle grinder comes to the rescue.

However, these works are almost always accompanied by the appearance of a large amount of dust. If this is not critical in the process of carrying out a large-scale renovation, then what to do if the tiles need to be cut in a clean room?

Avoiding dust?

The generation of large amounts of dust is an integral process accompanying cutting tiles or tiles. There are two ways to get rid of dust:

- using a vacuum cleaner;

- wetting the tile surface or supplying water directly to the cutting tool. wet cutting.

The first option is ineffective, since the rotation of the disk at high speed gives the smallest particles of material high speed and energy. The vacuum cleaner simply does not have time to capture them. Moisturizing gives the best results. It is done by filling the notch with water, passing it with an angle grinder and repeating the procedure. Another option is to supply water through a thin tube to the disc or work area. This method is most effective, allowing the disc to cool and prevent dust from scattering.

Cutting paving slabs

Technically, such a tile consists of concrete filled with crushed granite. Therefore, in order to properly and evenly cut paving slabs, a segmented or combined diamond blade, designed for hard materials, should be used. Paving stones generate a lot of dust, so cut outdoors.

It is recommended to allocate a site at some distance from the place of storage or laying of paving slabs so that the settling ardor does not spoil the color of the material and does not require cleaning. You should also take care of the availability of appropriate clothing and protective equipment. glasses and a respirator. The cutting process itself is not very difficult. the usual technique of solid cutting or scoring followed by splitting is used (if the thickness of the tile is too thick for through cutting).

Important! Dust generated when cutting paving slabs is capable of eating into the surface. If it comes into contact with tiles that have been laid or prepared for laying, they should be immediately cleaned with a stiff brush and moved to another place.

How to cut tiles with an angle grinder without dust

Laying tiles is not complete without the need to adjust its size to the size of the existing planes. Usually a tile cutter is used for this purpose, but not all home craftsmen have one, and the purchase of this tool is not always advisable. Sometimes you need to fit one or two tiles, and it is easier to solve this problem with other methods. There are several options. from using a glass cutter to drilling the desired shape. Most of the methods have too serious disadvantages, especially if you need to separate a narrow strip.

Sawing paving stones with an angle grinder

Having a private house, it becomes necessary to lay paving slabs or paving stones, which must be cut to size. For this, a universal device is also used, which is available in almost every home. an angle grinder.

Paving stone processing has its own characteristics, but basically it is carried out in the same way as cutting porcelain stoneware. The main differences are that the work is done outdoors. Material processing should be carried out on a separate site: the resulting dust settles on the laid paving stones and can spoil its appearance. If this happens, you should immediately sweep it off with a stiff brush.

To cut the paving stones, choose a diamond blade for concrete processing. The angle grinder should be held at right angles to the workpiece and the diamond wheel should be moved exactly along the mowing line. It is necessary to cut the tiles to a depth of a little more than half, and then just break and trim.

Execution method

The cutting technique depends on the material, thickness and cut configuration. The easiest way is to split the tiles in two in a straight line. To make curved, closed or open cuts, you will have to strain and perform more time-consuming procedures.

Let’s consider how to cut a tile with an angle grinder in a straight line:

- the cutting line is marked on the front surface with a marker.

- The tile is fixed on a flat hard surface so that the cut line runs over the edge of the base. This will help break off part of the tile after making the cut to the desired depth.

- Turn on the angle grinder, wait a couple of seconds to reach the maximum rotation speed.

- Carefully make an incision by sliding the angle grinder towards you. The disc touches the surface from the outside so that the thickness of the tool does not reduce the width of the tile.

- Hold the tool firmly and do not allow it to vibrate or swing from side to side. This will ensure a smooth and clean cut without chipping.

It is often necessary to cut at an angle in order to close the surfaces tightly when facing the outer corners of the walls. Consider how to properly cut ceramic tiles at an angle of 45 ° at home with an angle grinder:

- mark the line of the cut with a marker.

- Fix the tile on an even and rigid base so that the cutting line is outside the table.

- Cut tiles in a straight line.

- Rotate the angle grinder at an angle and gently process the edge until the desired bevel is achieved.

- Finally bring the edge to the desired state using a grindstone (bar).

In order to make a curly cut, you must:

- draw a cutout shape on the tile surface.

- Fasten the tiles so that the cut-out is free.

- with an angle grinder, carefully make several cuts along the contour of the figure. Alternatively, make a deep cruciform cut along the central axes and gradually trim the inner part, approaching the edges.

- When the shape of the cut is as close as possible to the required state, the final revision is made using a file or sandpaper with a coarse grain.

Large openings (for sewer pipes or other communications) are performed as follows:

- the center of the hole is marked and a hole with a diameter of 3-4 mm is made using a special drill.

- A circle is outlined on the front and back sides, which must be cut.

- On both sides, cuts are carefully made along the contour of the future hole. The depth of the cuts is 2-3 mm. It is not recommended to do more, as there is a threat to go beyond the border of the circle and spoil the edges.

- Through cuts are made in the central part of the hole, after which pieces of tile are carefully broken off with pliers along the cut line of the cut.

- Finishing the edge of the hole is made using sandpaper rolled into a roll.

Cutting installed marble tile with angle grinder indoor without dust

Open cutouts in tiles are easiest to make with a fixed angle grinder. The technique resembles working on a grinding machine. the disc rotates in a vertical plane, the tile is fed onto the tool and cuts are made along the edges. After that, the central part of the cut is removed and its inner edge is cleaned.

Important! Making cutouts and holes is a complex procedure that requires accuracy and precision. You should not rush, rushing will lead to damage to the material.

Instruments

There are many ways to cut tiles. For this, special tools are used. For example:

- tile cutters;

- nippers;

- glass cutters;

- drills with appropriate attachments;

- angle grinder.

Each option has its own characteristics, advantages and disadvantages.

For example, the tile cutter is a very popular tool used for this purpose. It can be performed in three variations:

- electric;

- manual;

- tile cutter tongs.

The first option is more suitable for the conditions of mass work. This means that the volumes must be large. Such a device is capable of even the most durable materials from which tiles can be made.

In the process of cutting the material, water is supplied, which makes it possible to get smoother edges, do not heat the material and do not dilute the dust. The only drawback of such a device is its high price. over, one-time work is not for him. Better to rent an electric tile cutter.

As a result, the hand model is a fairly popular model. But in this case, everything will have to be done by hand. An alternative is the tongs cutter. The tool is designed for thin metals. In this case, there is another drawback. subsequent processing of the ends is required. grinding. And this is not always good.

A glass cutter, a drill, as well as wire cutters, can also be used to cut tiles. In the first case, there is a limitation in the thickness of the products. As a result, the tiles may not cut through. The drill together with the nippers allows you to get a good cut.

Next, we will consider the option of using an angle grinder in more detail.

Instructions on how to cut

angle grinder is the popular name for an angle grinder. Not everyone knows that people began to call this tool that way since the 70s. It was at this time that the first samples began to arrive in the Union. And they were called “Eltos-angle grinder“.

In general, an angle grinder is a multifunctional tool. It is capable of processing materials thanks to the diamond wheel. The unit allows you to perform not only straight, but also figured cuts.

Cutting ceramic tile dust free without a vacuum

Recommendation: It is not necessary to cut the tiles to the full thickness. If you make an incision line, then the product will break very pliable.

Of course, when compared with the results of a tile cutter, an angle grinder has more fragmented edges. At the same time, preparatory manipulations are not needed to carry out the process.

The disadvantage is that you cannot do without dust and chips. The only thing is that they can be compensated for with a protective casing of the tool itself, personal protective equipment, as well as using a special disc. For example, a good cut quality, practically no chips can be provided by a disc designed for metal processing. This is largely possible due to the reinforced relatively smooth surface.

Tiles are easy to cut with wet cutting attachments. This will allow you to get the absence of chips, as well as a flat and smooth cutting surface. In this case, the nozzle must be new, and the cut itself must be made from the back of the tile.

How to cut tiles with an angle grinder: no chips or dust

Tiling is almost impossible without cut rows. As a rule, they are located along the edges. Very often, the need for cutting tiles appears at doorways, in the places where pipes are located, and so on. where neat laying is required. And for these purposes a special tool should be used. The correct choice of the device will allow you to get high-quality pieces, and therefore, to make the styling at a high level.

Preparation

If an angle grinder is used for cutting, it is recommended to check the tool for damage and function before the procedure. You need to insert a disc to work on cement or metal. There is certainly a difference between them, but not significant.

It is necessary to inspect the tool itself, otherwise some flaws can ensure poor-quality work.

Do not forget about personal protective equipment. This means that you should also wear a hat on your head, protective gloves on your hands, and clothes on your body to protect your eyes. glasses. The latter is perhaps the most important. After all, dust, small fragments can get into the eyes with very fast rotation of the disc of the angle grinder. This could be a dangerous injury. Therefore, you should think about your own safety first.

Chips and dust are inevitable?

You can put it this way. Indeed, everyone can perform certain manipulations to reduce such negative phenomena.

Additionally, you can watch video and photo materials about this. After all, a lot depends not only on the tool itself, attachments to it, but also on the cutting technique. This aspect also affects the presence of chips and dust.

Be that as it may, but it is important to devote enough time to this moment. And then the result will please you with the high quality of work.

Notched neckline

It is often necessary to cut a round hole in a tile. You can do the job correctly with an angle grinder with certain skills. To do this, mark a hole on the workpiece and circle the fishing line with a felt-tip pen, mark the center of the circle. They begin to cut at a slight angle, slowly, along the inside of the mowing line, gradually passing along the entire circumference. Then they cut through the sectors, take them out in turn, trimming the ceramics if necessary. Finally, the edges are processed with a file, getting an even circle. Such processing is called a dry cutter.

Such holes, as a rule, are cut for sewers or ventilation.

When performing shaped processing of a workpiece, it is easiest to make rectangular cuts. In order for the cuts to be smooth, without chips, it is necessary to regularly change the cutting wheel. If you use segmented discs, then chips will appear on the cut mowing line.

Cutting porcelain stoneware

When performing repairs, not only walls are lined. Ceramic granite tiles are laid on the floors in the bathroom and toilet. an artificial material that replaces granite and marble. Its cost is several times less than natural, but in terms of hardness and abrasion, porcelain stoneware surpasses them. Recently, it has become widespread. It can also be cut with an angle grinder.

To do this, you need to know the basic methods of processing material at home.

- Choose the right cutting tool. It should be written on what it is used for: porcelain stoneware, hard ceramics, etc.

- To reduce chips, choose a disc with a continuous cutting edge. The thickness should be minimal.

- Choosing a cut-off wheel with a high diamond coating height.

- the angle grinder must have a speed controller.

After choosing the tool, prepare the workplace and begin to cut the porcelain stoneware with an angle grinder. To do this, you need to perform the following steps.

- Place material on a flat surface with thin foam or similar material underneath.

- Fix the tiles securely to the surface with clamps.

- To reduce chips, glue masking tape and make markings, along which it is necessary to cut off the excess part.

- Prepare the vacuum cleaner to remove dust.

- You need to cut from the front side, moving the grinder away from you.

- It is recommended not to cut along the marked mowing line, but slightly to the side. This is done for the subsequent grinding of the end face of porcelain stoneware to remove irregularities and chips.

Following these simple recommendations, you can cut the floor tiles with your own hands.

Cutting tiles and porcelain stoneware with an angle grinder

Every master who is engaged in wall cladding with ceramic tiles knows that it is impossible to lay them without cutting. This is true both for wall cladding and for laying porcelain stoneware on the floor. But not everyone knows that you can use a regular angle grinder (angle grinder) for trimming. Let’s consider how to perform this operation correctly and without chips.

What discs are used for cutting tiles

For cutting ceramics, special discs are required, which can be stone or metal with diamond coating. Stone ones are rarely used, as they are rather thick and quickly grind off, and during work they generate a lot of dust. The cost of stone discs is several times less than metal discs, but experts prefer to work last.

How to Cut Tile Without Dust.- by Home Repair Tutor

- solid;

- segmented.

It is preferable to process ceramics with solid discs. When working with such discs, there is a time limit: they cannot continuously cut for more than 1-1.5 minutes. Then let it cool down with the angle grinder running at idle speed.

Segmented for cutting paving stones, porcelain stoneware, natural stone or concrete.

The segments are designed for better cooling of the tool during operation.

How to get rid of dust when cutting tiles

Cutting tiles with an angle grinder is not very difficult, but it generates a lot of dust. There are techniques that can help reduce dust formation. Specialists use special tile cutters for this, but buying them for a one-time job is impractical due to the high cost. Therefore, when processing parts, the craftsmen act differently. First, a layer of glaze is cut through. it almost does not produce dust, the main dust appears when a layer of fired clay is processed. Then it remains to gently break the ceramic tile and process the edges with an abrasive material.

A common way to get rid of dust is to moisten the workpiece. To do this, water is constantly poured into the working area with a diamond wheel. After each pass of the tool, fill the seam with water or install a special device for supplying water to the working area. This device attaches directly to the protective cover of the angle grinder. As a result, the workpiece is processed without dust.

Cutting ceramic products

To cut tiles with an angle grinder, you need to master three cutting directions.

Sawing paving stones with an angle grinder

Having a private house, it becomes necessary to lay paving slabs or paving stones, which must be cut to size. For this, a universal device is also used, which is available in almost every home. an angle grinder.

Paving stone processing has its own characteristics, but basically it is carried out in the same way as cutting porcelain stoneware. The main differences are that the work is done outdoors. Material processing should be carried out on a separate site: the resulting dust settles on the laid paving stones and can spoil its appearance. If this happens, you should immediately sweep it off with a stiff brush.

To cut the paving stones, choose a diamond blade for concrete processing. The angle grinder should be held at right angles to the workpiece and the diamond wheel should be moved exactly along the mowing line. It is necessary to cut the tiles to a depth of a little more than half, and then just break and trim.

Straight cut

It is not difficult to master it, at the same time the cutting line is clean and without chips. When performing the work, the tiles are securely fixed on a flat surface, marked with a pencil or felt-tip pen. The part to be cut should hang freely from the table. The cutting tool is at right angles to the workpiece. Carefully, without jerking, drive the angle grinder slowly along the marked mowing line. The tool should be moved towards you so that the marked line is visible.

Steel rims

Steel cutting discs. thinner and more durable. The most expensive varieties are diamond-coated. These discs cut the most durable type of tiles. porcelain stoneware.

Three methods of applying diamond chips are used:

- Soldering with silver solder. These diamond discs have the lowest cost, usually used in everyday life. Disadvantage: when heated, the silver solder loses its strength and diamond spraying wears out quickly. Therefore, the service life is relatively short.

- Geometric snapping. The edge of the disc is strongly heated by electricity and diamond powder is embedded in it. With this method of spraying, the service life is significantly increased. The price of the disc, in comparison with the previous version, is higher, but for everyday use it is quite acceptable.

- Soldering with a laser. Expensive heavy-duty wheels that can cut materials of any hardness for a long time. Cost. from 9 to 25 thousand rubles. Used in industry.

Recommendations for choosing a cutting steel disc for ceramic tiles:

- thickness. no more than 2 mm: then the cut will turn out to be even;

- the width of the cutting edge (diamond spraying) is greater than the thickness of the tile;

- The recommended speed indicated on the disc corresponds to the rotational speed of the angle grinder.

The second way to connect the vacuum cleaner

This method consists in connecting a construction vacuum cleaner to an angle grinder using improvised means.

polypropylene drainage branch with a diameter of 50 mm, at 45 degrees;

reinforced scotch tape (for greater reliability);

The described components for this method can be replaced by any suitable analogs.

Notched neckline

It is often necessary to cut a round hole in a tile. You can do the job correctly with an angle grinder with certain skills. To do this, mark a hole on the workpiece and circle the fishing line with a felt-tip pen, mark the center of the circle. They begin to cut at a slight angle, slowly, along the inside of the mowing line, gradually passing along the entire circumference. Then they cut through the sectors, take them out in turn, trimming the ceramics if necessary. Finally, the edges are processed with a file, getting an even circle. Such processing is called a dry cutter.

Such holes, as a rule, are cut for sewers or ventilation.

When performing shaped processing of a workpiece, it is easiest to make rectangular cuts. In order for the cuts to be smooth, without chips, it is necessary to regularly change the cutting wheel. If you use segmented discs, then chips will appear on the cut mowing line.

What disc to cut ceramic tiles with an angle grinder

Different discs for an angle grinder are geared towards different materials. Several types can be used for tile cutting. Let’s consider them in detail.

Angle 45 0

Docking is often necessary, which means cutting the material at an angle of forty-five degrees. This angle can only be obtained with a large workout. But you can use this technique: first, cut the workpiece in a straight line, and then gently process the edge at the desired angle with a disc, sandpaper or sharpening stone.

Combined discs

Combination blades allow for both dry and wet cutting.

- the quality of the cut is lower than that of a solid one, but higher than that of a segment one;

- continuous operation time. less than that of a segment, but more than that of a solid.

Combination discs are easier to clog with dust than others. And if it is enough to rotate the segmented and solid discs for cleaning by 180 degrees, then this is not allowed with the combined one. For cleaning, they cut concrete or sand-lime brick.

Sawing paving stones with an angle grinder

Having a private house, it becomes necessary to lay paving slabs or paving stones, which must be cut to size. For this, a universal device is also used, which is available in almost every home. an angle grinder.

Paving stone processing has its own characteristics, but basically it is carried out in the same way as cutting porcelain stoneware. The main differences are that the work is done outdoors. Material processing should be carried out on a separate site: the resulting dust settles on the laid paving stones and can spoil its appearance. If this happens, you should immediately sweep it off with a stiff brush.

To cut the paving stones, choose a diamond blade for concrete processing. The angle grinder should be held at right angles to the workpiece and the diamond wheel should be moved exactly along the mowing line. It is necessary to cut the tiles to a depth of a little more than half, and then just break and trim.