How and what to cut tiles (tile, ceramic) at home with and without a tile cutter. we explain thoroughly

When you perform various construction works yourself there is often a need to cut ceramic tiles at home. For this purpose it is not necessary to have a professional tool. tile cutter.

Immediately we should say: We are not talking about constant work and large volumes, but about small batches or in general.

How to cut tiles without a tile cutter

When you perform various construction works yourself there is often a need to cut ceramic tiles at home. It is not necessary to have a professional tool for that. a tile cutter. Let’s say right away: We are not talking about constant work and large volumes, but about small batches or piece products in general. In such cases, it does not make sense to buy an expensive tool, it is quite possible to do with improvised means.

- Cut in a straight line. In doing so, you need to distinguish where the cut is coming from. If there is less than 2 cm to the edge from the cutting line, such a cut can be considered a shaped cut;

- Round holes in tiles of different diameters;

- Shaped cutouts;

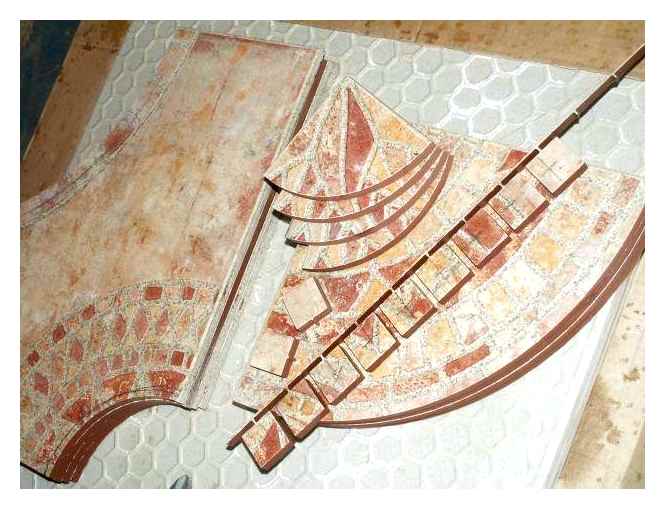

- Mosaic elements. If there are requirements for precise geometric shapes, this type also refers to shaped cuts. Otherwise, it is actually crushing the tile into pieces. Items are placed in a bag and with a heavy tool (hammer, sledgehammer) are crushed to the desired proportions. Non-ceramic tiles may be an exception.

Alternative tools and their features

How to cut ceramic or tile tiles without a tile cutter? There are several popular tricks that are sure to help you. So, to cut ceramic tiles can be the following tools:

- angle grinder. It is a handheld grinder that can be used for cutting metal, wood, tile and other materials when replacing the nozzle. Even porcelain tile can be handled with it. A diamond-coated disc is used for the work.

- Glass cutter. The handheld glass cutter is a tool that is comparable in size to an ordinary writing pen. Despite its diminutive size, it works well on tile, particularly glazed tile. However, it requires clarity and confidence in action.

- Drill. This tool is used to make holes or create roundings. You can use an ordinary drill or special attachments such as a drill bit or ballerina.

- Pliers. The tool’s sharpened edges can cut through the upper layer of the tile and create a line for the notch trimmer. Most often used to create a shaped cut, but you can also make a straight cut, but it takes a lot of time and effort.

Basic tools for tile trimming

You can also use an electric jigsaw, a circular saw with a diamond disc, and even a simple sharp nail for the job.

Only diamond tool bits are suitable for working with tile. Toothed saws and weak drills will not do the job and can damage the material.

Since it is necessary to cut floor tiles without using a tile cutter with a sufficiently strong and powerful tool, the best for this task will suit an angle grinder. Such a device is available to most home craftsmen. If you want to use it for cutting ceramic tiles change the tool head for a diamond-coated disc. Mostly a disc is used for dry cutting, but you can leave it for wet cutting if you will be working on a wet base using water.

Tile can be cut with an angle grinder, but this method requires certain skills, otherwise there is a great risk of damaging the material

The material to be cut must be the face side. Direction of the tool should be toward you. Before you begin the work, you need to mark the line for the trimmer cut and fix the tile so that it does not move during the work and at the same time nothing interfered with the passage of the cutting element. Hold the angle grinder level to achieve a straight cut. If you have to make a 45-degree cut, lock the tool in position on your side.

The blade guard is there to protect you from injury, and should the blade come off, it will catch the impact. But extra care must be taken to wear personal protective equipment. Respirator or mask will protect you from dust and construction goggles from small splinters.

The easiest and most affordable way to cut tiles without a tile cutter is to use a handheld glass cutter. It works on the same principle as a mechanical glass cutter, but you have to do all the operations yourself.

The best way to cut tiles is with a glass cutter with a diamond tip or equipped with a roller made of tungsten and cobalt alloy.

How to cut tiles with a handheld glass cutter:

- To do the work you must first draw a trimmer line along the face of the cut.

- Apply the ruler and place the glass cutter to the farthest edge from you.

- Press down and in one steady motion guide the trimmer line. You only have one try. Do not press down hard on the cutter.

- Knock on a wooden handle to form a break trimmer fishing line.

- Position the tile so that one part of it is overhanging.

- Press down on the edge of the tile and break it along the drawn line.

If you manage to make a deep enough cut, the break will be straight and neat, without chipping on the front side.

The glass cutter is the easiest and most affordable way to cut tiles at home

It is not reasonable to use a glass cutter for large amounts of work.

How to make a curve

Sometimes you need to prepare tiles for laying around pipes or plumbing. Then the question arises. how can you shape-cut tile without a tile cutter. With an electric tile cutter to do it quite simply, but how else can you perform such a task?

Figuratively cut tiles can be done in several ways:

How to cut the material with an angle grinder, jigsaw and glass cutter is in principle quite clear. And here’s how to get by with just pliers? To do this, you need to draw a fishing line for the trimmer of the future cut. You can make the task easier and scratch it off with a nail. Then take pliers and start breaking off unwanted material in small pieces. The best way to cope with this task are cutters with carbide clamps.

Inconvenient areas and shaped cutouts are performed using pliers

As for the drill, you can use an ordinary drill bit to mark the contour, and then nail the excess with the same wire cutters. A more effective way to make holes of any diameter is to use special nozzles: feather, ballerina, crown, etc. д.

Manual tile cutter

This tool allows you to cut tiles in a straight line or diagonally with a cutting width of 5 millimeters or more. It can be used to cut floor and porcelain tiles. It consists of a base and a carriage with a diamond blade, a wheel that slides on slides. It has a larger diameter for deeper cuts than the glass cutter. blade can be replaced as it wears. when choosing a tool it is desirable to buy a mechanism with bearings that ensure smooth sliding of the cutting mechanism.

For breaking off the notched strip, a flat metal strip is fastened to the base at the edge, and a small T-shaped lever behind the cutting blade. It is he who presses on the tile after the cut.

Tile cutting begins by aligning the material on the base along the marked line. Then it is firmly fastened. The carriage is driven by hand, making a single cut. The tile is then split into pieces by pressing on the handle. This method sometimes results in small chips, which can be masked with grout.

Using an electric tile cutter

It is an expensive professional tool that cuts any tile equally quickly, smoothly and accurately. Cutting in straight and 45° angles, drilling holes and recesses, and shaped cuts are all possible with this method. The strips cut are less than 5 millimetres wide. The cut edges are smooth, slightly rounded.

Some models work with the tile with one side dipped in water, others require only regular wetting along the cut. This method prevents the formation of dust.

The cutting process consists of the base plate, the blade and an electric motor:

- The tray is filled with water at the level of the cutting disc, so it was lowered into it by 2-3 centimeters (for submersible models).

- The tile is clamped and slowly moved under the chisel along the marking. The effort must be even to avoid chips and jamming of the motor.

- To cut the angle, repeat the procedure twice in sections with the desired angle.

Like any similar tool, the electric tile cutter requires compliance with safety requirements and the use of protective equipment.

For quality work it is necessary to change worn discs and water in time.

Tile separation with pliers

If you do not want to get a neat line for the separation trimmer, you can use pliers or wire cutters. This method is very easy: starting from the edge, you need to begin breaking off pieces of material until the desired tile size is obtained. The method is not neat. It often happens that the tool breaks off a large piece from the desired part. But in the absence of any other method, you can get by with this variant as well.

All of the described methods of cutting tiles are quite effective for a single use. And yet, when for professional use in the frequent repair of facilities is better to buy a traditional tile cutter.

Tools for cutting tiles

Qualitative and productive cutting of this flooring is carried out by an electric tile cutter, which is equipped with a diamond cutting wheel with water supply. The use of such technology allows you to reduce physical effort and dust.

But in most cases at home resort to the use of other tools. This is due to the fact that acquiring a tile cutter for laying tiles is not always an expedient occupation.

The following tools can be used to cut tiles:

In addition to the basic tool, tile cutting tools are used:

- drill;

- tape measure;

- marker;

- A ruler-angular;

- table (with a perfectly flat surface and without sand grains or other debris);

- file;

- sandpaper;

- puncher;

- diamond disc.

Now directly about how to cut tiles with each tool.

Drill bits and accessories

Strictly speaking, a drill is not suitable for cutting a strip. Drill bits and various accessories will cope with drilling holes of different diameters in the tiles.

Holes of small diameter under dowels are made for the attachment of shelves, cabinets, decorative elements. Large holes are needed to bypass pipes, meters, etc.

To work with ceramics is better not to use an ordinary drill bit, but a lance-shaped tile drill bit, in common parlance called a “feather. It’s easy to cut through a layer of glaze and the top layer of ceramic, and it digs into it so that it passes through the tile without chipping on the surface.

When you have passed the ceramic, replace the “feather” with a concrete drill bit and continue the work.

Diamond tipped drill bits. excellent bits for drilling holes for outlets, switches, meters.

Waterjet cutting

If you have to do voluminous work and need to cut hard ceramic floor tiles, but there is no angle grinder, or tile cutter, it is better to use the services of firms engaged in sawing construction materials. The optimal option. waterjet cutting.

With this method you can cut with your own hands even the most complex shaped elements in the home. The idea is that the face of the tile is fed at a high pressure thin stream of water, mixed with the finest solid abrasive particles, such as sand. Computerized control of the process allows you to work even with the most complex templates.

In this article we have considered several ways how you can cut tiles at home without a tile cutter. Each method is good in its own way. The choice of a particular alternative method depends on the amount of work with tile and the skills of the master. With these tools, you can do without the purchase of a special tile cutter.

Particular attention should be paid to safety when working with the “angle grinder

If you want to make holes and semicircular cut lines at home, use a drill with special attachments, wire cutters with carbide clamps.

To make holes in the tiles use a special nozzle on the drill

The peculiarity of work with tongs is to “bite off” fragments of ceramic along a pre-drawn contour. Remember that only small pieces should be separated. In any case, it is important to grind after such procedures.

It is recommended to use the invaluable experience of experts

To cut the material when carrying out tiling works in the home conditions it is necessary to have the following tools:

- flat surface;

- a guide ruler with a right angle at one end, the so-called “angle piece”;

- drill bit with pobedite tip;

- glass cutter, office knife;

- “tile-cutting pliers”. miniature pliers with a tile-cutting wheel on one side and a transverse convex plate on the other;

- a drill with nozzles in the form of “crowns”;

- a jigsaw with a diamond wire;

- “angle grinder”.

It is important to remember that before cutting the tile material should be prepared. If you soak the ceramic tile for thirty minutes before working with it, you can solve the problems of dust, brittleness and increase its malleability.

To qualitatively cut off a piece of tile, you need to make a clear groove on the glossy surface and then break it with a quick confident motion. It can be done without difficulty with the help of various tools: glass cutter, drill bit with a pobedite tip, cardboard knife and a guide ruler. The order of action in all cases will be the same:

Glass cutter. the most accessible tool for cutting tiles

- We put the tile on a flat surface with the inside side down;

- Make the necessary markings and draw a clear line for the trimmer with a pencil with the help of a “square”;

- Draw a groove along the ruler, pressing with medium force on the glass cutter or drill bit;

- Put a drill bit under the notch trimmer fishing line, press on the tile from both sides and break it. Alternatively, you can break a tile by placing it on the edge of the table along the cut line and pressing sharply on it.

It is much easier to break tiles with the “pliers with the wheel” because they are designed specifically for this purpose. You just have to put the cross plate on top so that the notched groove is exactly in the center of the pressure plate, and then squeeze the tongs. In this case a qualitative break is obtained.

Clamp the tile with the pliers in the center on the marked line and press down on the handles

At home you can make quite suitable tools for cutting tiles, if there is no possibility to use a special tool. For example, a drill bit with a 6 or 8 millimeter diameter pobedite tip can be sharpened on a diamond wheel like a pencil. The main thing here is not to chip off the pobedite coating and make the edge without edges. The rounded shape of the tip allows you to make deep cuts, when you put it to the side of the “angle”.

All of the above methods are suitable for cutting wall tiles, but in cases of work with thicker floor tiles with a dense structure, it is necessary to resort to the help of other tools.

For example, it is advisable, along with the improvised tools to use “angle grinder”. At the same time, in order to complete it, the most suitable are discs for cutting granite with a smooth crown and diamond discs, which allow you to quickly cut tiled material.

The process of cutting with an angle grinder is quite simple and accessible even to non-professionals

The sequence of work may be as follows:

- First, you need to draw with a glass cutter or a special drill a sufficiently deep line for the trimmer. To do this, you can run a few times on the outer surface.

- Then using an “angle grinder” you must begin to carefully cut along the outer edge of the notch. It is desirable to go no deeper than 3 millimeters. Carrying out such a procedure 2-3 times, you can get a quality cut.

Cutting floor tiles can be carried out in a different way:

- On a glossy surface also draw a groove with the same improvised tools.

- We turn the tile and make an incision on the inside exactly at the outer marks with an “angle grinder”.

- After breaking, it is advisable to sand the edges with sandpaper.

Straight and curved tile cutting can be performed with the “angle grinder” with a diamond disc. The productivity of such work is comparable to an electric tile cutter. Although the quality of the cut with the “angle grinder” is inferior, but if you need to carry out mobile work of large volume, this tool is indispensable. After the cut, you will need additional measures to grind.

Particular attention should be paid to safety when working with the “angle grinder

If you want to make holes and semicircular lines of the cut at home, use a drill with special attachments, wire cutters with carbide clips.

To make holes in the tiles use a special nozzle on the drill

The peculiarity of work with pliers is “biting off” fragments of ceramics along a pre-drawn contour. It should be remembered that it is necessary to separate only small pieces. In any case, after such procedures it is important to make grinding.