Installation of the four-stroke engine on the cultivator Krot. Step by step instructions with photos.

Buying a one or another power tiller or medium single axle tractor, you will be faced with the selection of milling machines, transport wheels, gruntzatepov and extensions for them. Of course, some motor blocks have all these attachments produced by the same company, but sometimes they are of worse quality, for example the Chinese, and you need to put a better quality.

In addition, many models of power tillers and power tillers are not available or are not sold in your area. Therefore, we offer the following information about the shafts on which this equipment is installed to decide the interchangeability of this attachment: CROWN: F 15mm. Pubert MB 31H, Caiman MB 33R, F 19mm. [/COLOR]MK “Leader”, F 19.5mm. “Partner” 5054; Beezone CJD-1004-1, F 20mm. Honda F220, Honda F360, Texas “Hobby” 300 V; DDE V380 II; Triunfo TB30; ZigZag GT408; “Eurosystems” Z2, Champion BC4401, Pubert MB 50H, “Pubert” MB FUN-350, Caiman MB 86R, F 25mm. MKM 75 “Mini Neva”; VIKING VH 400; VH 440; HB445; VH540; HB585; VH660; Eurosystems Z3; MK “Eurosystems” EURO 3; “Eurosystems” EURO 5; “Eurosystems” EURO 3RM; Mole, Salute, Favorit, Tarpan, Master, single axle tractor M-3, Dachnik, “StigaSilex” 75R; Stiga Silex” 500 G; “AL-KO Farmer” MH 5001R ; DDE V700 II; MTD T240; SunGarden T240; T390; Robix156B; Efco MZ 2050. F 25,5mm. MTD T205; T245; T330; T380, F 28mm. DDE V600 II 65HPR; T6.5/900 FB PG Florida, F 30mm. Texas “TX “501; Texas “TX “502;Texas 572 Lilli, Texas “Lilli” 552; “Hobby” 500, Neva MB-2, Neva MK-100; DDE V500, Kaskad, Oka, Luch, Ugra new, FlyRiverCJD1003-4; AF Kipor, F 35mm. Kutaisi Super 610.

Hexagonal socket at 22mm. old Ugra, hexagonal at 23mm. DDE V700 II (DW; DWN; H160WL4); Texas “Futura” 6003; Weima WM 500; T7,5/900 2 FB PG Montana; T7,0/1000 2FBPG Nevada. Hex socket at 26mm. KAMA / KIPOR. 610 and 910 models. 32mm hex. 105 Chinese (dawn and clones); Weima WM 1100.

As you can see from the table, output shafts come in both round and hexagonal, with different diameters. So when performing necessary operation, e.g. for grass mowing, it is better to buy necessary mower and then appropriate single axle tractor to it. RVT

For many decades, agricultural workers have been using a single-axle tractor, which greatly facilitates the performance of heavy work with the ground. This device helps not only to plow, but also to harrow, reap and dip. The electric machine consists of a large number of main and auxiliary parts. One of the most important parts of a power tiller is a pulley, which transmits rotational speeds from the engine to the attachment through the belt. This device allows the machine to move in different directions. In specialized stores you can see pulleys, which differ not only in size, but also in the material of manufacture. Before buying the necessary part, it is necessary to consult with experienced craftsmen or consultants stores, so that the purchased part will not be unnecessary and useless.

Varieties

Manufacturers produce three types of pulleys for power tillers:

- Disc. have a size of 8 to 40 cm;

- with spokes. have a diameter of 18 to 100 cm;

- monolithic. two-stranded have a size of 3 cm, and three-stranded 10 cm.

There are two types of planting holes:

All pulleys have 8 cavities, the quality of grinding determines the wear rate of the working belt.

Types of pulleys depending on the type of gearbox:

You should buy pulleys with a diameter of 19 mm for power tillers with implements, and for more advanced speed machines you need pulleys with a diameter of 13.5 cm or more.

Single axle tractor pulley: characteristics and self-made

The pulley is the component of the motor-block, which is responsible for the transfer of revolution from the engine to the attachment. Power is normally transmitted by the belt. You can also use the pulley to control the rotation of the attachments on the power tiller. We will tell you more about some of the technical characteristics and how to make this part yourself further on.

How to choose a belt for the Neva power tiller?

To choose the right drive belt for popular modifications of motor blocks Neva, it is necessary to strictly follow the instructions described by the manufacturer in the manual. There are several important points to be studied before buying the elements:

- length of drive belts. can vary depending on the purpose and place of installation of the elements in the overall design of the motoblock;

- brand-manufacturer. experienced users advise to give preference to products developed by well-known brands. Buying parts of unknown brands is not recommended due to their unreliability and low resistance to wear;

- Cost. it is important to choose original elements. The price for them can be several times higher than low-quality copies, but it will pay off in the form of increased reliability and durability of branded parts;

- marking. in order not to make a mistake when choosing a new belt, you need to study in advance the number of the element, which was installed on the single-axle tractor.

When selecting drive elements, do not try to compare the tension level of the old and new belts. This will not bring results, and in some cases will encourage the user to buy a part that is too long.

How to choose a belt for the motor-block Neva?

In order to choose the right drive belt for popular modifications of Neva motoblocks, it is necessary to strictly follow the instructions described by the manufacturer in the manual. There are several important points to be studied before buying the elements:

- The length of the drive belts. can vary depending on the purpose and place of installation of the elements in the overall design of the power block;

- brand-manufacturer. experienced users advise to give preference to products developed by well-known brands. Buy parts of unknown brands is not recommended due to their unreliability and low resistance to wear;

- The cost. it is important to choose the original elements. The price for them can be several times higher than low-quality copies, but it will pay off in the form of increased reliability and durability of branded parts;

- Marking. in order not to make a mistake when choosing a new belt, you need to study in advance the number of the element that was installed on the single-axle tractor.

When choosing drive elements do not try to compare the level of tension of old and new belts. This will not work, and in some cases will encourage the user to buy a pulley that is too long.

Pulley: Characteristics and properties

Pulleys are available in a wide variety of sizes and made of many different materials. They are attached to the main shaft of the electric motor. If you are going to buy a part, pay attention to the size of the installation place. You can buy a new belt and choose the pulley on a single axle tractor clearly according to the parameters. This mechanism is made mostly of aluminum, cast iron or dural. These raw materials are used because they have an excellent level of strength and are resistant to mechanical damage. Also in stores you can see pulleys for power tillers made of plywood, plastic or textolite.

The main difference between pulleys for the motoblock gearbox is the number of knobs. When using a lever for control, the belt can be switched from one to the other. This allows you to adjust the speed of movement, which creates a special convenience during the cultivation of the soil. Two-arm or three-arm parts for power tillers are usually used in agriculture.

And also the unit is divided into categories according to the type of gearbox: there is a pulley driven for the motoblock, and there is a leading. Different sizes of mechanisms are required for different units. In order to install the attachment equipment, fit pulley 19 mm for a motor-block, for heavier units need parts with a diameter of 135 mm.

For electric motors only three types of mechanisms will fit:

- Pulley for motor-block with diameter 25 (three-arm) is monolithic;

- Up to 100 cm with special spokes;

- discs. up to 40 cm in diameter.

There are two types of seating aperture: cone-shaped and cylindrical.

Belt dimensions for Neva power tillers. what to pay attention to?

When selecting a driving element, the number of the part installed on the single-axle tractor Neva used in the farm plays an important role.

To avoid purchasing errors, it is necessary to:

- Remove the faulty drive belt using a special device and strictly following the procedure specified in the instructions;

- Inspect the surfaces of the element for factory markings. they are usually in white, blue or gray;

- In some cases the marking on the element may be missing. this is due to the heavy wear of the part. If so, it will be necessary to measure the belt length with two rotating tensioners;

- Locate the size of the appropriate belt;

- To buy a new part and install it in the construction of the power tiller Neva.

The most common difficulty users have is finding the dimensions of new belts. To exclude possible errors, you need to use the table:

It will prompt which drive belts are suitable for installation on the camshaft and crankshaft of motor blocks Neva MB-1 and MB-2.

How to change the belt on a Neva power tiller?

The simplicity of the base unit of MB-1 and MB-2 modifications allows replacing the defective drive elements without having to seek help from a specialized workshop.

- Carefully remove the old belt, being careful not to damage the tension pulleys and other important nearby parts. To do this, you must sequentially remove the protective shield and the main factory cover, built for additional belt protection;

- Carefully remove the spring from the structure, which is necessary for tensioning the driving element;

- Remove the screw fasteners and OEM stops that serve to hold the belt to the original engine pulley;

- Inspect the position of the shaft handle of the power unit and the gearbox. they should be strictly in the same plane. In Neva MB-1 and MB-2 motor blocks, deviations in the location of the knobs are possible by no more than 0.1 mm;

- If there is a need, adjust the location of the pulleys by gently moving the engine in its longitudinal plane;

- Adjust the idler pulley installation location. this is necessary for proper tension of the belt to be installed;

- Install the new drive element. it is important to start putting the belt on the side of the gearbox part of the power unit. Video will tell in detail about the own-hand replacement of the drive element.

The belt replacement procedure is performed the same way for the Neva MB-2 motoblock, as well as for its counterpart MB-1. In each case, before installing the new element, it is important to inspect the place of installation and thoroughly clean it from debris, if necessary.

Belt size

Everyone knows that different power tillers use different in length and width components.

Below is an example of what size belts on the Cascade motoblock:

According to practice, the front travel belts of a Cascade power tiller wear out more than the front ones. However, when replacing one belt, it is still advisable to change two belts at the same time. If the unit is used actively, the procedure for replacing this element may be approximately once a year.

Nowadays belts for Cascade motocultivator are made of such materials as rubber and polyurethane.

Belts on the Neva single axle tractor: features, dimensions, tensioning

All models of power tillers are of two types. One functions by a chain drive and the other by a belt drive. If a second design is installed, the torque from the engine is transmitted to additional attachments. Belt transmission realizes the tasks of clutch and transmission. You can install the belt on the Neva single axle tractor and adjust it yourself.

Installing any components on the agricultural device is not a labor-intensive job.

Before replacing the belts on a Cascade power tiller yourself, it is best to read the instructions.

To save time and nerves, and to make a correct replacement of this component, it’s better to use our tips and do everything in order.

- Put in neutral gear and turn off the motor of the device.

- To turn off the motor.

- Remove the protective guard.

- Remove the belts to be replaced. Remember that it is advisable to change all elements at the same time. That’s why when installing the belts of the reverse on the Cascade power tiller, install also for the front.

- Install the new components. To do this, remove the pulley. Then the part to be replaced is pulled onto the gear pulley. After that, install the engine pulley.

- Check if the belts are correctly positioned on your Cascade.

- Put the protective cover back on.

Follow safety rules when you change the belts on your power tiller. That’s all. the parts are installed and the machine is ready for use.

Features of belts for “Neva” power tillers

The range of motorcycles is quite wide. Accordingly, the selected belt to the Neva motor-block must match the model of the used agricultural equipment.

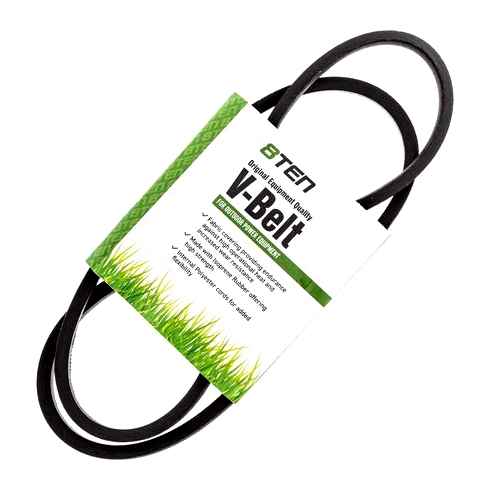

The MB-1 and MB-2 power tillers often have a V-belt transmission. It is thanks to the V-belt transmission that the unit is able to move forward and backward. If the v-belt mechanism of the machine fails, the single-axle tractor will not be able to function properly.

MB-1 power tillers have forward and reverse gears. MB-2 models move forward only. Because of this difference, identical belts cannot be used.

The drive belt is not difficult to choose if you pay attention to the following nuances:

- The type selected must match the model of machinery;

- belt dimensions;

- part tensioning stage;

- V-belt type.

If you look at the above data, you can choose the right belt for a particular model of power tiller.

The types of belts installed on the technique:

To simplify the selection process, it is worth using the table. This table shows the correspondence between the belts and the models of machines.

Belt dimensions for Neva power units

When selecting power belts, special attention must be paid to their dimensions. You can use the table provided to determine the correct part. Beforehand, it is worth measuring the distance from the pulleys to the rollers, to which the new element will be mounted. This gives you more accurate belt dimensions.

The Neva MB-2 and MB-1 are characterized by a different location of the belts. That’s why the parts installation scheme will be different.

Belt tensioning on the model MB-1 is carried out in a certain way:

- First remove the cover from the V-belt mechanism;

- Carefully remove the back plate from the pulley;

- Loosen the spring-loaded pulley with a wrench;

- The old element is disassembled and the new one can be installed;

- The pre-dismantled spare parts of the machine are installed.

It is worth considering how to replace the belt for units of the MB-1 model range:

- The shield and cover of the V-belt system is taken out;

- The pulley bolt is loosened and the reverse belt is removed;

- The bolts that hold the bracket in place are loosened;

- The forward drive belt is removed;

- New elements are installed and tensioned, everything is fixed and previously removed parts are returned into place.

Belt adjustment on the Neva MB-2 motor-block is done as follows:

- Cowl is removed;

- The screw loosens the tension of the regular belt;

- All screws holding the bracket to the machine housing are removed;

- The old part is pulled out and the pulleys are adjusted;

- Before installing the belt, the areas between the elements are thoroughly wiped and the hoses are blown out;

- A new belt is installed. One end is connected to the gearbox shaft, the other end to the pulley, located in the motor;

- The design can be fully restored.

details about how to tension the belt on the Neva motor-block, you should learn from the proposed video.

Basically, a new element is stretched when the motoblock breaks. Much less frequent replacement in advance to prevent malfunctions during machine operation. In any case it is necessary to perform work on changing the belt carefully, because if you overtighten it, its breakage is inevitable.

In order to tension the belt on the Neva MB-2 motoblock, we will need:

The tension of the drive belt on the MB-1 motor-block looks a bit different. It is made with the help of a clutch lever, which is often installed on the left handle.

For the new motoblock MB-1, which is just preparing for operation, the course of action will be as follows

- unscrew the clamp screw;

- put the lever on the left side of steering wheel aligning its fastening with the clamp fasteners;

- tighten the fasteners with a screw coupler;

- turn the clutch adjusting screw, watch its tension: with the load created by the fingers of your hand, its deviation must not exceed 10 mm.

Belt adjustment on the “Neva” MB-1 motoblock after repair or replacement of belt transmission, is reduced only to the adjustment of the clutch lever screw. Proper adjustment will be evidenced by the immobility of the gearbox pulley when the motor is on and a slight sagging of the belts when the clutch handle is lowered.

For power tillers “Neva” MB-2 and MB-1 it is important to check the serviceability and make tensioning of belt gears after every 25 hours of work.

Varieties

To ensure optimal tension and long life, not only the entire belt transmission, but also the transmission, the size of the belt unit must be exactly matched to a particular modification of power tiller. If you put extremely long products, as well as very short ones, rather quickly worn down and create unnecessary load on the engine or gearbox. For example, the belt transmission “Mole” 750 mm is put on the units with a domestic motor.

In addition to the above, before buying the product should be checked from the outside: the belt should not have any damage, scratches, protruding threads, breaks. Quality is the product, which retains a distinctive factory pattern, and which can not stretch his hands.

A few more details about using the machine

One day I’ve noticed that the machine is pulling to the side and I have to make some effort to straighten it and keep it on the same level. I did not immediately understand what it was, but it turned out to be very simple and ridiculous.

The thing is that the cutter can be attached to the shaft on either side, that’s how the mounting is arranged, but either side is not right! A burr should plunge into the ground with its sharp cutting edge, and this is understandable, but through negligence the burr was inverted on one side of the cultivator and it entered the ground with its blunt edge.

Be careful when powering the tiller.

As a result, a properly installed tiller cut into the ground well, but the other side of the “rested” That’s motokultivator and dragged to the side!

Pay attention to the direction of the fastening bracket

Cutter is attached to the shaft of the cultivator with a “pin” with a fixing clamp, here it is necessary to watch for it too. When installing the bolt, the lug must not come loose when it hits the ground.

Correctly install the attachment pin.

And here is an example of how the pin clip is not properly deployed.

Example of improper installation