About the chainsaw and its inoperability

Chainsaw. The installation itself is not that difficult. But having the smallest initial knowledge is extremely important in order to find and eliminate any defect.

Modern electronics has progressed so much that it has revolutionized the world of instruments. Saws of our day are light and at the same time powerful, equipped with electronic ignition systems ESZ.

Not so long ago, saw ignition systems were cam-type. This carried a lot of disadvantages: heaviness, complexity, high cost, and much more. And the main drawback of the archaic ignition system is the difficulty of the plant. Some saw model systems could not generate enough spark at all to flash at crankshaft speed.

Modern systems are nearly fail-safe. Saw models are lightweight and durable, the reel is made more professionally and will serve its life almost flawlessly. However, there are also problems, but in most cases they can be corrected on their own.

Consider the main types of chainsaw malfunctions associated with the flywheel and the ignition system.

As a rule, the most common ailment of modern chainsaws is the absence of a supply spark. This also directly depends on the shift in the clearance (gap) between the bobbin and the flywheel.

Common installation failures are always associated with internal combustion engines. Problems arise in the fuel ignition system, the fuel intake module, in the internal elements of the engine itself.

As for other units of the chainsaw, malfunctions arise there, as a rule, due to failures of the brake mechanism, poor lubrication, etc.

If startup difficulties are associated with the engine, then the following symptoms are most often observed:

- the motor does not develop the necessary power;

- does not start at all;

- starts, but quickly stalls;

- functions unstable.

As always, experts recommend identifying fault factors in a way of elimination. In other words, you need to go through the chain, diagnosing each node, each link.

Ignition module

Inoperability of the SZ chainsaw is the most common reason why the engine of the tool does not start. It is recommended in most cases to start troubleshooting from here.

- first of all, carefully check the spark plug by carefully throwing off the armored wire from the head and unscrewing the plug from the socket using a special key;

- the second is to check the spark supply by jerking the starter when the armored wire cap is put on the candle;

- clearance check is the main topic of our article (more details below).

So, a spark plug malfunction will be clearly indicated by its phlegm. A wet spark device for igniting the fuel-air mixture indicates that there is an excess of fuel in the system, the carburetor is incorrectly tuned, or there are problems in the SZ.

The candle is checked only after drying. That is, it must be thoroughly cleaned with a napkin, the insides of the internal combustion engine should be dried, the supply should be blocked, and then the starter should be started a couple of times so that excess combustible mixture comes out.

Then the spark device is put in place and everything is checked again.

In general, a spark device can tell a lot about the entire ignition system. If black carbon is observed on the candle, then this indicates violations in the communications of the gasoline mixture supply. Here, either the ratio of gasoline and oil has been violated, or a carburetor readjustment is required. In some cases, this also happens due to low-quality oil.

A dirty candle is cleaned of black carbon with a needle or some other sharp object. Then the electrode is cleaned with emery paper (zero) until a metallic sheen appears. The spark device is returned to its place, everything is checked again.

The next step: checking the spark supply. The skirt of the spark device is brought to the cylinder, the starter is started. If a bluish spark jumps at a distance of 2-3 mm, everything is fine. A spark distance of 0.5-1 mm is already considered a malfunction. There may be no spark at all, and this is also a big problem. Perhaps this is a wire break.

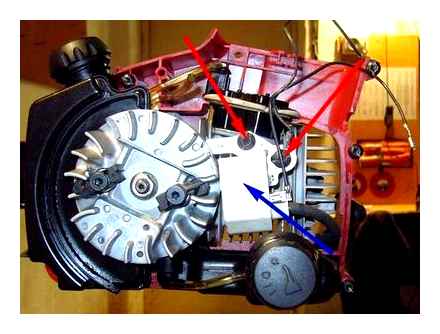

And now we come to the topic of our article. The chainsaw may not start due to a violation of the gap between the ignition and the flywheel magneto. This very gap should be within 0.2 mm. It is very simple to check: a special gasket is placed between the flywheel and the bobbin. If it comes in normally, not too loose and tight, then the gap is normal.

The saw flywheel itself is round, and it is impossible to check the clearance with a conventional feeler gauge. It would be more qualified to set the gap according to a special template, but it is not always possible to acquire it. And not everyone can afford to buy a template that is not cheap for a single use.

However, instead of a foreign template, you can use a cut-out strip from a plastic container for 1-2 liters from under the juice.

- the ignition fixing bolts are loosened;

- a plate is inserted between the flywheel and the bobbin;

- the bolts are tightened.

Council. It is recommended to cut the plastic tape where there are no embossed irregularities.

The gap between the ignition coil and the flywheel of the chainsaw

Internal combustion engines are installed not only on cars or motorcycles. They are widely used in various tools such as chainsaws and grass trimmers. In the event of their malfunction, poor start-up, it is often enough to establish the correct clearance between the flywheel and the ignition coil.

How to check the magneto of a chainsaw

Magneto, babin, module is an ignition coil. It may have absolutely nothing to do with tool failures, and the reason is lurking only in the gap or in another. But in some cases, it is she who becomes a factor in violation.

To check the babin itself, you should also, as in the above case, use it by excluding the components from the chain. Or in other words:

- visually assess the condition of the bobbin case for cracks and other visible defects;

- check the cleanliness of the current communications of various nodes and elements;

- diagnose the insulation and serviceability of the armored wiring, the reliability of fixing the fasteners, the absence of rust, etc.;

- visually assess the condition of the spark device cap;

- checking the condition of the candle;

- circuit breaker diagnostics, which is especially important for Chinese-made chainsaws.

Again, as in the above case, certain points are excluded from this chain, thereby finding the cause of the problem.

- The resistance of the magneto is measured. However, this option is not always applicable, since it is necessary first of all to know the resistance parameters. In addition, in order to form the required HE pulse, it is necessary to separate the indicators of the various semiconductor elements. A sign of a malfunction, as a rule, is the ringing of the circuit through the BB wire and minus. Should show either “open circuit” or high resistance.

- The check can be carried out as follows. use a device that checks for the presence of a spark. It is installed in the open circuit between the BB wire of the bobbin and the candles. The disadvantage of this method is that the device is so very expensive, it is used mostly in serious repair services.

- “Dedovsky” method of verification, which will save on an expensive device. It is used at your own peril and risk when there are no other options. The method of checking comes down to the fact that the cap is thrown off the candle, a carnation is inserted into it. The candle is re-inserted. The stud should be 6-7 mm from the cylinder. The chainsaw starts up. A spark is being investigated: it should be bright blue, if not, then this is a sign of a malfunction of the bobina.

The “grandfather’s” method of checking a bobbin has many drawbacks. First of all, this applies to electrical components in the system, which can easily deteriorate. The distance between the cylinder and the stud may differ depending on the different models of the tool.

As for tuning the magneto, it boils down to examining the groove on the flywheel. UOZ for most of the current models of saws does not need to be adjusted. But it is possible to determine its exposure only by the angle between the mark after the groove on the flywheel and the magnets installed, again, on the flywheel.

Competently and accurately set the gap between the magneto and the flywheel. that’s what is more important.

You should be aware that the bobbin on chainsaw systems is installed in the fan fuselage near the flywheel. The coil, in contact with the flywheel magnet, produces energy for a spark.

Replacing the coil itself will be much more difficult, since the installation location is too inconvenient. The installation of a new bobbin should be carried out so that the base of the coil is at a distance of 1-1.5 mm above the flywheel magnets.

In some cases, it is recommended to also check the crankshaft bearing for play.

Constructive components

All engines, whether automotive or other tools using an internal combustion engine, have similar operating principles.

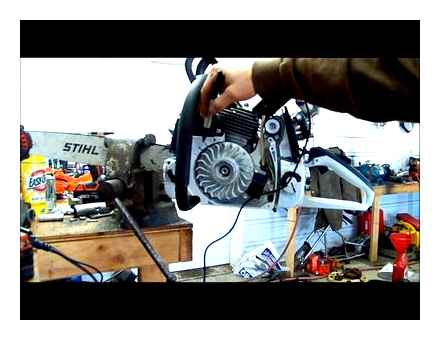

#16 Yamaha Jog. first start. STIHL chainsaw ignition on a scooter

There are no exception such famous chainsaws and are used with pleasure by consumers like Goodluck, STIHL or Husqvarna.

The drive in them is a familiar internal combustion engine, respectively, a fuel tank, an engine and a working body that directly performs work, as well as other attachments that help in control.

Sometimes during operation, some problems may arise, in this rather reliable tool like a chainsaw.

How to set the ignition on a chainsaw

In this review presented to your attention, we will try to reveal the question that arises among many owners of chainsaws. In the process of using such a tool, the consumer may encounter a situation in which it is necessary to correct the ignition timing. Over time, the breaker may fail, the coil also does not last forever, although it serves much more and it is quite difficult to disable it. So let’s figure out how to set the ignition on a chainsaw.

The question arises, what to do then?

Here are some common cases:

- The chainsaw will not start;

- If it starts, it works intermittently;

- Not enough power to work properly.

Ignition

The main problem in this group is the engine.

Ignition is one of the main elements affecting the trouble-free operation of the tool. Therefore, we will first consider this particular block.

Gone are the days when a cam-moving contact breaker was in control of the ignition, which supplied a spark to the spark plug.

It was not a very reliable system due to the many elements that affected the operation of the engine. The chainsaw, with no visible malfunctions, could simply stop starting. And we could observe a picture of constant tugging at the winding cord. To date, manufacturers have switched to contactless ignition systems.

They have fewer moving parts and no contacts that need to be exposed periodically, often failing. The reel used on a modern chainsaw will work until the end of the service life of your tool. The chainsaw has become much more reliable and easier to maintain.

Possible malfunctions

If the saw does not start, the first thing to check is the spark plug that ignites the fuel in the cylinder. Start by removing the high voltage wire that the candle is connected to. Then unscrew the candle itself from the cylinder cover and inspect its condition. When working properly, the candle should be dry and small deposits on the light-colored ceramics:

- If the plug is wet, there is a problem with the carburetor. It is necessary to adjust and set the fuel level in it;

- Carbon deposits on the walls of the plug are dark or black in color, it means malfunctions in the piston group.

If you did not find any visible reasons for the malfunction here, the candle is dry, light carbon deposits continue to go from the opposite direction. Since this is the final point of ignition of the working mixture. Now check if the spark is coming to the spark plug. This is the ignition system block.

Checking if there is a spark will not pose any particular problems, for this it is enough to take the high-voltage cable to which the candle is connected, bring it to the cylinder block with a small gap between them, so that you can notice the spark slipping between them. Then we pull the starter starter cord, and watch, there is a spark and what color it is. A working spark plug should give a spark that looks like lightning. How it looks, look at the photo offered to your attention, everything is clearly visible on it.

If no spark is observed, check with a control lamp, if there is no probe, high-voltage cable. A break is possible in the place where it was bent most often. If the wire is in order, it is possible that the problem is an incorrect ignition angle. It may be too early or too late in both cases, the chainsaw starts well and will not work.

Now let’s try to set the correct gap between the movable and fixed contact. Ideally, it should be 0.2 mm. You can check with a probe, since it is not a deficit.

This was a description of the malfunctions of the older generation of chainsaws. The new generation includes modern chainsaws from Goodluck, STIHL and Husqvarna.

Modern systems

Modern systems are equipped with chips that handle all of the above problems. The method of self-setting the ignition timing depending on the engine speed and the power transmitted to the cutting element. This significantly saves fuel without sacrificing power. It is also much easier to start the saw, regardless of weather conditions.

The chainsaw itself has become simpler and more efficient and does not require expensive repairs. Ignition coils made using modern technologies and using new materials have literally become eternal.

In addition to everything read here, a video is offered for a complete acquaintance with the material given.

HOW-TO Fix A Chainsaw With No Spark. Ignition Module Replacement

2 Комментарии и мнения владельцев on the entry “How to set the ignition on a chainsaw”

I bought a STIHL chainsaw, it practically did not work for it. just repairing. Can’t get.

The device and principle of operation of the chainsaw ignition system

The standard ignition system for a carburetor engine consists of:

- magneto;

- spark plug;

- an electrical cable connecting them to each other;

- engine shutdown keys.

Magneto is a type of alternator that supplies electricity to spark plugs. It consists of a stationary winding of an inductor and a permanent magnet attached to a flywheel that rotates with the crankshaft of a gasoline engine. A moving magnetic field creates an electromotive force in a low-voltage winding, which is converted by a transformer into a voltage with a potential sufficient to generate a spark.

For contact magnets, the first terminal of the high-voltage winding is connected to the spark plug, and the second is connected to the ground through a mechanical switch. At a certain moment, a special structural element divides the contacts, which leads to a sharp increase in the voltage in the network and a spark slip in the interelectrode space of the candle.

To prevent overheating and oxidation of the breaker contacts, a capacitor is connected to the electrical circuit.

The ignition circuit of a chainsaw with a contactless magneto is based on the operation of a control coil, which plays the role of a voltage supply regulator. The electronic unit also includes a diode, a capacitor and a thyristor that transmits a current with a voltage of a certain magnitude. When it is opened, the capacitor is intensively discharged, forming a current in the turns of the primary winding, which is inducted into a high-voltage voltage, giving a breakdown on the spark plug installed in the cylinder. The electrical network operates in a pulsed mode in time with the rotation of the crankshaft and the translational movement of the cylinders.

Ignition timing

The mechanical device and the factory setting of the magneto ensure that the discharge time of the spark plug coincides with the optimal position of the moving piston. For four-stroke gasoline engines, spark breakthrough must occur even before the piston reaches top dead center. this is due to the fact that the process of complete ignition of the air-fuel mixture takes a certain time. The speed of movement of engine parts is comparable to the speed of fuel ignition, so the piston has time to travel a certain distance from the moment the spark breaks through to the moment the burning gases create extremely high pressure.

There is an ignition timing for each engine. It is equal to the rotation of the crank, expressed in degrees, from the moment of breakdown in the interelectrode space of the spark plug until the moment when the piston is at top dead center. This indicator depends on many parameters, including the design features of the engine and the properties of the fuel mixture.

In practice, during the mass production of an engine at the factory, individual adjustment of the ignition of each product is not made, but the corresponding marks are set on the rotating parts, which must be aligned during installation.

When is the ignition setting required? There are the main symptoms of a system crash:

- the engine will not start;

- the motor works, but with noticeable interruptions;

- there is a decrease in tool power.

In these cases, you should not rush to contact the service center. Try to adjust the ignition yourself first.

The procedure for checking and adjusting the correct operation of the engine

The most vulnerable element of a carburetor engine is the spark plug. It also allows you to judge the probable causes of malfunction of individual units of a gasoline engine. The following procedure is recommended.

-

Dismantle the spark plug and inspect it. A dry candle with a slight brown tint of the electrodes can be considered serviceable.

When installing a new electrical module on the engine, the magneto gap must be adjusted. The optimal distance between the flywheel and the ignition coil is 0.2-0.4 mm for most chainsaws.

To be sure, it is recommended to carefully study the documentation for the purchased model and follow the manufacturer’s requirements.

With such a small gap, it will not be possible to use an available measuring tool for direct measurement. In practice, a Husqvarna saw uses a template in the form of a spacer cut from thin, flexible sheet material of the required thickness. It is clamped in the space between the flywheel and the coil when it is installed, and then pulled out.

In order not to have to resort to adjusting the ignition, operate the tool carefully, avoiding knocks. In particular, this applies to chainsaws with electronic chips in the ignition system, since they are very sensitive to mechanical damage.

How to set the ignition on a chainsaw?

Quite often, owners of chainsaws are faced with a problem in which the engine of the tool does not start. One of the main reasons for this breakdown is a malfunction of the ignition system, namely, a failure of the factory settings of the unit.

First of all, the owner of the saw will need to unscrew the protective rubber cap and check the spark plug under it. It is possible that it is flooded with oil, which prevents the flow of current to the candle. In such cases, the problem lies not in the ignition system, but in the fuel system, namely, in the depressurization of the channels.

However, if the spark plug is completely dry, then it may be necessary to install the ignition on the chainsaw. To do this, unscrew the candle and dismantle the protective cover. After that, it is necessary to measure the gap between the flywheel and the ignition coil. The instructions for each of the chainsaw models indicate the optimal clearance between these elements. In most cases, it is between 0.2 and 0.4 mm. Since the handwheel of the tool has a round shape, it will not be possible to use an automotive dipstick to adjust the gap. It is best to use a special template in the form of a spacer for this purpose. However, finding it is not easy. Therefore, many experts advise using a cut out strip from a plastic bottle as a template.

Chainsaw ignition adjustment is quite simple;

- First, loosen the bolts securing the elements of the ignition system;

- Place the plastic bottle plate between the spool and the flywheel;

- Tighten the bolts all the way.

The device and principle of operation of the chainsaw ignition system

The ignition system of modern chainsaws consists of a list of important parts. The main structural elements are:

- Spark plug;

- Flywheel magneto;

- Wiring;

- Power button.

The ignition system also includes an ignition coil, an interrupter and a capacitor. The coil is responsible for turning on the core and winding the transformer. Candles in the construction of nodes consist of side and center electrodes, an outer casing and an insulator.

The breaker and coil winding in the structure are connected in series. The breaker is turned off due to the presence of a cam on the crankshaft of the chainsaw. The ignition magneto is located to the left of the crankcase and is secured with a nut and two studs.

In the process of starting the chainsaw, a magnetic field is generated with the help of the flywheel magnets, which crosses the coil. Provided that the contacts of the primary winding are in a closed state, a weak current is generated in the ignition system. If the contacts are in the open state, then the magnetic field is not formed, which leads to the appearance of a high voltage in the secondary winding. Subsequently, the current is supplied to the candle, which ignites the fuel to start the chainsaw.

Chainsaw ignition system. device, check and adjustment

The ignition system of a chainsaw is a series of parts that generate a spark when the engine of the tool is started. In most cases, the ignition system is a fairly reliable unit, but sometimes, for various reasons, some of its parts fail. Let’s explore the features of repair and adjustment of the main elements of the chainsaw ignition system.

How to check the ignition coil of a chainsaw with a multimeter?

A special device. a multimeter. will help to accurately determine the breakdown of the chainsaw ignition system. It will make it possible to determine if there are breakdowns in the coil and other elements of the unit. The procedure is as follows:

- To begin with, you need to set the multimeter so that the arrow of the device is located at the 200 ohm mark;

- After that, you need to open the instruction manual for the chainsaw and study the optimal resistance indicated there for the primary winding of the ignition coil. As a rule, this indicator ranges from 3 to 5 ohms;

- Next, you need to connect the primary ignition coil to the device. If the indicators of this part of the coil are normal, we begin to check its secondary winding;

- We study the operating instructions again, and look at the optimal resistance indicators indicated for the secondary winding. It is worth noting that this part of the element has large indicators, so the multimeter should be adjusted so that its arrow is located next to the 20K indicator;

- Next, we connect the device to the hole in the coil, into which the wires are inserted. If the multimeter shows normal readings, then the coil is fully functional. However, if the resistance on the device display is far from the parameters specified by the manufacturer, then the coil will have to be changed.