Sharpening and setting the saw

The main cutting element of any hand saw. a series of teeth cut into the blade and representing wedge-shaped cutters. Wood, in the manufacture of all kinds of products from it, is sawn along, across and at an angle Θ to its fibers, in this regard, transverse, longitudinal sawing and sawing at an angle to its fibers are distinguished and in each case use the appropriate type of saw, which differs from others in shape teeth.

When transverse sawing, transverse saws are used, the cutting edges of the teeth of which, when moving in the wood, cut its fibers like a knife and form a cut. Longitudinal sawing differs from transverse sawing in that the direction of movement of the saw is parallel to the grain of the wood. The leading edges of the rip saws cut the wood like knives in a plane, and, going deeper, form a cut. When sawing wood at an angle Θ, universal (mixed) saws with teeth that are an intermediate form of teeth for cross and longitudinal saws are used to its fibers.

Saw sharpening

Saw teeth sharpening. a kind of art that requires loyalty of hands, a good eye, and attention. It is not difficult to learn this business, you must have the desire and clearly adhere to the following rules:

- The saw blade must be firmly fixed in a special device made of wood, which is also firmly installed on a well-lit work table. Sharpening saw teeth on stools or knees does not give a satisfactory result.

- You should use a personal file, followed by cleaning the sharpened edges of the teeth with a velvet (with a fine notch) or file. It is desirable that the file is new, sharp and with a fitted handle. If at the right time there was not one, then you can also use a second-hand one, but it must be brushed with a steel brush and rubbed with charcoal so that the file does not get clogged and does not become dull. When sharpening a tooth, the file should grip its metal and remove its layer depending on the pressure. And if it slides over the tooth without removing the metal, then the saw teeth are overheated or the file is worn out. In this case, it is necessary to repeat the sharpening with a new file. If in this case he slips over the tooth, then it remains to take another saw.

- The file handle is clamped with the right hand, and the end of it is held by the left hand and the file is directed to the saw teeth. Working with a file, depending on the type of saw, is described below..

- The pressure of the file on the teeth should be smooth and even and only to one side from you. When returning the file to its original position, it must not touch the teeth..

- It is necessary to try to grind the metal from the edges of the teeth of at least the same thickness, driving the file the same number of times with the same pressure, which allows you to maintain the angles, pitch and height of the teeth after sharpening.

- Burrs form on the edges of the tooth from the side of the file exit, which reduce the sharpness of the tooth, and if they are not removed, then during the operation of the saw, they crumble, and the teeth become significantly dull. To remove burrs, the edges of the teeth are sharpened with a file with a velvet notch and deburred from the side edges with a wet donkey.

- After sharpening the teeth, check their sharpness. Look at the tip of the needle and the edge of the razor blade: they are sharp and do not shine in the light. And if they are blunt, then rounded surfaces appear at the tip of the needle and on the edge of the blade, which reflect light and shine well. The quality control of saw teeth sharpening is based on this principle. To do this, put the saw in front of your eyes and examine its teeth along the blade. If their cutting edges and tops are not shiny, then the saw teeth are sharpened satisfactorily, and if some of the teeth are shiny (this often happens), then they must be sharpened with a velvet file, deburred and re-check the light reflection from their edges and tops..

Cross saws. The teeth of the cross-cut saws are sharpened using a triangular file with a fine notch with a 60 ° apex angle.

To sharpen the teeth, the saw is clamped into a special device that allows its blade to be installed at an angle of 45-50 ° to the plane of the desktop. The file is led parallel to the working table at an angle of 60-75 ° to the saw blade and thus the left edge A1A2B2B1 is sharpened in the first tooth.

Saw teeth are sharpened in several stages. First, with a file, they pass along the left edges of the odd teeth located in the far row, adjusting the hands to the same movement. Then they pass the file along the right edges of the same odd teeth, completing the sharpening of the main cutting edges with very sharp tops. After finishing the sharpening of the odd teeth, the saw blade in the sharpening device is turned over and thus the even teeth that are in the far row are sharpened. When sharpening the teeth of cross-cut saws, it is necessary to carefully ensure that sharp main cutting edges with a dihedral angle φ = 60-75 °, a short cutting edge and a sharp point are obtained in each tooth.

Longitudinal saws. Rip saw teeth in which the angle π

How to sharpen a hacksaw on wood and spread the teeth

Hacksaws of various types are used in everyday work in personal plots, summer cottages, as well as during repairs in which natural wood is used as the main material. The saw requires periodic maintenance. At a certain point, you need to sharpen a hacksaw on wood, since it began to perform its function worse than before. In order not to spoil the canvas and return the tool to its former performance, you need to follow a few simple tips.

How to determine when it is time to sharpen a hacksaw

In order not to shorten the service life of the hacksaw blade, it is necessary to sharpen it only when it can no longer perform a high-quality cut, or requires more effort while working with it. The main signs of a blunt saw are the following:

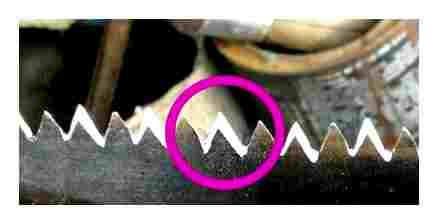

- the tips of the teeth are rounded, their shape is distorted;

- the sound of the saw has changed: there is a feeling that the wood is not cut, but is torn along the fibers;

- the cutting speed has decreased compared to a new hacksaw;

- nicks and scuffs began to appear on the cut;

- hacksaw periodically wedges even with an even cut.

If at least one of these symptoms appears, then the hand saw needs service. This includes both direct sharpening of the teeth and their correct setting..

Do-it-yourself saw sharpening

The saw is prepared for sharpening by fixing it in a vise, the jaws of which should ideally be made of wood so as not to damage the saw surface. Step-by-step instructions for sharpening a hacksaw on wood with your own hands are as follows:

- The hacksaw is fixed as close as possible with the teeth to the jaws of the vice, but so that their distribution is not disturbed when the wrench is clamped at an angle of 90 ° to the surface of the workbench.

- The file is taken in the working hand with the handle, with the other hand it holds the tip from the back. This will distribute the effort evenly..

- The sharpening of a conventional hand hacksaw is performed at an angle of 15-30 ° to the tooth. If the wear is not too strong, the “native” sharpening angle will be clearly visible.

- The angle of the file to the blade should be about 30-45 °. To do this, you need to become so that the working hand is below the auxiliary.

- The file should only move away from itself, with the same effort and number of movements for each tooth. For a sharp file, 3-5 strokes are usually sufficient to straighten a single tooth..

- Thus, one side of the canvas is passed, after which it is turned over, fixed in the same way, and the actions are repeated for the second side.

If, when performing sharpening work, apply an uneven force or make a different number of movements with a file, this can lead to displacement of the teeth in relation to each other, distortion of their size and shape. Ultimately, such a hacksaw will require professional resharpening, or even completely unsuitable for further use..

General requirements for sharpening

Sharpening a hacksaw is a rather painstaking process in which accuracy is important. To make it easier, you should only use good files and needle files that are sharp enough. If the saw needs to be sharpened frequently, the best solution is to have a separate set of tools for this job. Before sharpening, it doesn’t hurt to look at the teeth of the hacksaw. If their shade is darker than the canvas, then they are hardened. Sharpening such a hacksaw on wood will not work.

When sharpening at home, the metal should be removed evenly. An equal number of file passes are made for each individual tooth, regardless of how worn it was before the correction. In this case, you must not change the sharpening angle set by the inclination of the file, or rotate it around its axis. Movements should be made strictly from oneself, since it is with this technology that the effectiveness of removing the metal of the hacksaw is achieved, and the employee can confidently control the tool in his hands.

In order to avoid additional difficulties during sharpening, the saw blade should be firmly fixed in a vice. It is desirable to have a source of direct light, which will allow you not to peer at the results of the work..

Leveling Height

After the setting has been made, the hacksaw must be checked for the same height of the teeth. Since the force could be applied unevenly to it, there is a chance of the appearance of teeth with less wear, which will protrude above the rest..

How to Sharpen a Saw in 5 Minutes | Paul Sellers

To identify these teeth on a hacksaw, you can use a simple method. It will need thick paper or cardboard along the length of the cutting blade. The sheet must be laid on a flat surface, for example a table, well leveled, and then forcefully press the cutting part of the blade against it. Prongs that are knocked out of the general row will make deeper dents in the surface..

This makes them easy to spot and correct before sharpening. To remove excess height, various files are used. During this work, you should strive to preserve the shape of each hacksaw tooth as much as possible..

Tooth setting

It all starts with checking the distance between the teeth. It is designed to prevent the saw from wedging in the cut. It should be adjusted to the type of wood with which you most often have to work. If you have to work with hard wood, the teeth are set apart at a distance of 1.5-2 times greater than the thickness of the blade. For soft wood, the teeth of the hacksaw should be separated by a distance of 2-3 times more.

One of the key points in routing is maintaining uniformity. If the saw teeth are bent at different distances from the center, this will lead to permanent wedges and a deterioration in the quality of the cut and the speed of cutting wood. Therefore, it is recommended to use a device for setting the teeth, which is called “setting”. Thanks to the stop, it is impossible to bend the tooth to a greater distance than provided by the standard.

The teeth are divided into two groups through one and are bent sequentially along the entire length of the cutting side of the blade. First, this procedure is carried out for one group, in which the set teeth must be bent in a certain direction, then it is repeated for the opposite direction..

Required sharpening tool

To perform such a seemingly simple operation, you will need a rather impressive list of tools. However, if one of them is not at hand, you can try to find a replacement for it. What you cannot do without is a workbench with a vice, since only with their help the saw can be rigidly fixed for work. The rest of the list looks like this:

- device “wiring”, which, if absent, can be replaced with high-quality pliers. In this case, you will have to determine the approximate distance from the center for each tooth yourself;

- a sharpening bar with sandpaper or a set of files and files;

- hammer;

- additional light source;

- in some cases, you may need a caliper and protractor to make accurate measurements.

A separate mention is the method of sharpening hand saws using an angle grinder. In this case, you will need the presence of the angle grinder itself, a workbench and a pair of clamps, since the blade will need to be fixed horizontally.

There are a number of signs that indicate that the teeth are dull:

- The blade regularly gets stuck in the wood.

- When sawing, the sound changes, it becomes more “dull”.

- The shade of the teeth changes.

- Material resistance increases significantly.

- The ends of the teeth are noticeably rounded.

- The blade leaves the cut line.

How to sharpen a hacksaw yourself

A hacksaw for wood today is the most common carpentry tool that is used both in professional activities and in solving many domestic issues. Despite the fact that many functional and productive electric tools have appeared, its popularity has not decreased at all and, like hundreds of years ago, a hacksaw is an almost irreplaceable device. Unfortunately, in the process of use, the teeth of the saw blade become dull and it becomes impossible to work with the tool. Fortunately, this can be easily fixed by sharpening a hacksaw, and this can be done without using special equipment with your own hands..

How to sharpen a hand saw for wood

Height adjustment of the teeth

All cutting ridges must be the same size so that cutting performance does not degrade. Longer teeth are heavier and wear out faster, while shorter ones don’t even touch the wood.

The broaching of the web becomes twitchy, uneven, more energy is spent. Accuracy of the cut is impaired, the cut surface becomes rougher.

The adjustment is carried out before the start of sharpening. To make sure that none of the teeth protrude, you can do this: press the canvas against a sheet of paper laid on the table.

The tops of the teeth will be imprinted on the sheet, and you can adjust their height using the gaps in this pattern. To do this, hold the saw in a locksmith’s vice and file off too long teeth with a file..

Sharpening process

For sharpening, the saw must be firmly fixed so that it does not vibrate when exposed to a file. Otherwise, the quality of work will be low.

They fix the hacksaw blade vertically, often in a vice, in homemade clamps, but if there is neither one nor the other, then you can do without them.

Fixing method without special devices – “at the edge of the workbench”. The hacksaw blade is laid so that only the saw teeth hang from the edge of the table. However, the handles of the saw are always thicker than the blade, and therefore the place next to it cannot be put tightly to the workbench. Therefore, you need to use the corner of the table, and then the saw handle will not interfere.

If there is a clamp, then you can fix it like this.

And this is a method without a clamp, fixation is done only by the hand of the sharpener. It is quite convenient and safe..

Fixing the saw without a clamp

A file or a file is taken in the right hand, and, pressing the hacksaw blade with his left hand, they begin sharpening.

Sharpen the saw teeth through one. The movement of the file with this method is made upside down. The file is applied to the sharpened tooth and is forced downward with a downward movement..

The file must be held tilted in two planes. In the horizontal direction, it is about 30 degrees. Vertical – about 60 degrees. The angles of inclination are individual for each saw, because they can differ both in the shape of the tooth and in its size.

How to Sharpen a Woodworking Handsaw | Paul Sellers

Sharpening the left edge of the tooth.

Sharpening the left edge of the tooth

Sharpening the right edge of the tooth.

Sharpening the right edge of the tooth

This is what should be obtained: to the right of the file pointer – processed teeth, to the left – no.

To the right of the file pointer – processed teeth, to the left – not

Improvements to the quality of sharpening

The above was a classic option that anyone can use. There is a way to make the sharpening process more efficient and easier.

When using a multi-axis vise with a rotating bed, you can fix the blade so that you only have to move the file in a horizontal plane.

Chainsaw and hacksaw sharpening

When it comes to sharpening a chainsaw, then for this you should use 2 files: one round and the other flat.

To sharpen a hacksaw, you need to do the following: you need to take a file of the appropriate size.

First, pass them on one side of the hacksaw, then hold the same number of times on each tooth. If necessary, the process must be repeated. Sharpening the saw so that it cuts well is not difficult. You just need to use high-quality materials for this..

How to sharpen a saw on wood?

Saw tooth shape for cutting wood.

In order to sharpen a saw on wood, you need to stock up on a file that has 3 edges. A triangular file is required in order to be able to sharpen the teeth. The file should be at an angle in the cutting edge. As for the value of such an angle, it should be between 45 and 60 degrees. To make it more convenient, it is strongly recommended to sharpen the teeth on one side, and then proceed with similar actions on the other side. If you do everything in this way, then, thanks to the same type of movements, the whole process is carried out with greater ease..

When such a process is carried out, certain rules must be observed:

- It is best to do this alone, without interacting with other people. Any background noise must be excluded.

- All careless movements should be avoided, as any of them can not only cause damage to the instrument, but also cause significant harm to health..

- If the saw moves to the side during cutting, this indicates that the setting of the teeth is uneven. This can be corrected by increasing the deflection of the teeth on the side to which the saw is pulling..

How to sharpen a circular saw?

Circular saws sharpening scheme.

If we are talking about a circular saw, then sharpening must start from the rear surface. The whole process is carried out as follows:

- The sharpening of the disc can be carried out directly in the machine, or you can remove the disc from the machine.

- If sharpening is carried out by the first option, then it is necessary to remove the plug from the socket in order to prevent the consequences of starting the machine, and this can always happen.

- The disc must be wedged, for this, thin wooden beams are placed on both sides, they must be pressed against the teeth.

- The marker marks the lateral side of the tooth, from which you should start sharpening. Thus, there will be no mistakes when working..

- A prerequisite for such a process should be extreme accuracy..

How to sharpen a saw yourself without difficulty?

The hand saw is truly one of the most indispensable tools on the farm, but even the best saw dulls over time. Sharpening it yourself is not at all difficult at all, you do not need to have any special skills for this – you just need to strictly follow the recommendations. For sharpening you need the following tools:

Sharpening a hand saw for wood.

- File (flat and round).

- Pliers.

- Sharpener.

If the saw is sharpened correctly, then there is no doubt that it will function properly. However, saws that are designed for woodworking not only become dull over time, but often go dull on the market. This situation is especially true for those tools that have large teeth. Thus, for those for whom the efficiency of the saw is an important issue, sharpening must be taken care of in advance..

The process of setting the saw teeth

Band saw teeth set.

If you need to ensure free movement of the teeth, you need to start setting them. The teeth should be bent in different directions in turn. The distance should be the same and the routing should be used. The tooth must be bent in the middle of its height with the setting. If there is no wiring at hand, then an adjustable wrench can be used in this capacity..

- If the saw is not set well enough, it must be diluted first. If you use a specialized wiring for this, then it is not difficult to do this. However, there may not be such a wiring at free disposal, so you can use ordinary pliers for this..

- The saw must be clamped so that its teeth are directed upwards, the whole process along the blade should be visible, this is how all actions should be carried out.

- Every second saw tooth should be bent in different directions, and with each movement, the pliers should tilt at an equal angle.

- If from the very beginning the layout is already present to some extent, then the main task is to increase it. This is especially true for large saws. If the tool is small (such tools are most often used for those works where increased accuracy is needed), then the factory wiring in most cases is quite sufficient..

Now you know the basic nuances of sharpening a saw. Good luck to you!

How to sharpen a hand saw

After the divorce, the saw must be sharpened. This procedure does not require special equipment; here you can do with an ordinary triangular file. The sharpening technique with this tool is as follows. The file is taken with one hand by the handle, with the other by the tip of the tool and moved away from you, pressing the teeth smoothly and evenly, then in the opposite direction, without touching the teeth. Handsaw teeth need to be sharpened on both sides, from top to bottom.

After sharpening, burrs can form on the edges of the teeth, which will negatively affect the operation of the tool, chipping and dulling the teeth. They must be removed with a fine cut file..

During operation, the saw becomes dull, so sometimes the teeth are sharpened with an emery bar. Continuous sharpening evens out the setting so that the saw remains in working order, the setting of the teeth must be repeated periodically. However, it is not necessary to overhaul and sharpen the teeth too often..

Hand Saw Routing Methods

It is best to do this on special equipment – an adjustable machine. On it, using the indicator, you can determine the correct deviation of the tooth, so the work can be done in a matter of minutes.

If the machine is difficult to find, you can manually spread the hacksaw. However, it will take a lot of time and effort to complete the procedure, and besides, you cannot do without a special tool – wiring, which you can make on your own. It is a metal plate with a sawn groove 1.5 mm wide and 5 mm high. The saw is clamped in a vice and with this groove they grip the tooth of the tool and retract it in the desired direction.

This must be done in a specific order. First, the teeth are deflected through one in one direction, then the rest in the other. In this case, there should be no distortions, and the teeth should be unbent symmetrically. Not the entire tooth is bent, but only its tip (that is, its third part), otherwise it may break. The width of the setting should be equal to twice the thickness of the blade, if the teeth are spread too wide, then the hacksaw will go tight, and too much wood will go into the sawdust. In addition, if the setting is incorrect, the tool will “wedge” and an even cut will not work..

You can also spread the saw with a screwdriver or chisel. The tool is placed between the teeth and turned, the saw should also be clamped in a vice before this.

How to dilate and sharpen a hand saw

When working with wood, a tool such as a hand saw or a hacksaw is often used. Over time, the blade will wear out, making the sawing process more difficult. In this case, it is necessary to open the saw. This procedure consists in the fact that the teeth are unbent in different directions manually or automatically..

Caring for your hand saw

It is necessary to be able not only to make a divorce and sharpening of the saw, it is equally important to store it correctly. When the saw is not in use for a long time, it must be kept in a dry and warm room, otherwise, if moisture gets on it, it may rust. Even if the tool is treated with special agents, this will not guarantee that it will not corrode..