How to put the starter on the Husqvarna

A chainsaw is the basic tool with which to get firewood for a sauna or a fireplace, and it can also be used for construction work on a summer cottage or a private home. The chainsaw can last a long time if all the operating criteria are followed and the preventive measures provided by the manufacturer are followed. But after a while there may be some small faults, which can be solved without the help of others. For example, the chain saw starter repair with their own hands is entirely by force with the observance of the sequence of operations.

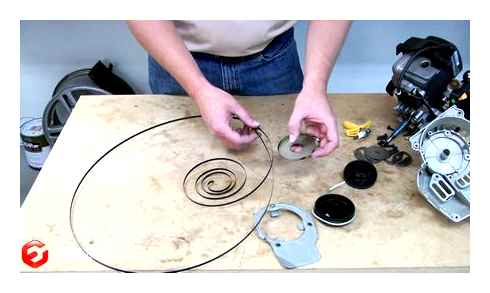

The device starter chainsaw: 1. starter screw, 2. bushing, 3. spring easy starter, 4. screw, 5, 6. coil starter, 7. deflector, 8. cover starter, 9. handle and cord, 10. screw.

Typical malfunctions

common tool failures include the following:

- Problems in the ignition system;

- stoppage of the chainsaw during the sawing process;

- loss of power during operation;

- Wear of some structural parts of the chainsaw (brake belt, drive sprockets, anti-vibration parts);

- The fuel supply system is not working properly;

- Malfunctions associated with the starter.

In addition, it is necessary to create a visual inspection of the chain saw before the work and preventive measures. How to wind the starter spring trimmer for grass cable starter does not reload: how to determine the cause and make repairs on their own hands? How to disassemble the starter, plug it in and rebuild it yourself. These include lubrication of the chain, controlling the amount of fuel mixture, also the presence of the required amount of oil.

Unscrew the spark plug to check its condition.

Any of the defects are eliminated by its own technology. So, for example, the repair of the fuel system of a chainsaw should begin with the examination of an appropriate filter. After that, inspect the correctness of the regulation of the carburetor, which is carried out with the help of screws. The clearances should be set in serious accordance with the manufacturer’s manual, which should come with the chainsaw. Repair of the ignition system includes inspection of the spark plugs. If you find heavy soot, a change in the gap or other visible damage, replace the element.

Typical malfunctions

The more common breakdowns of the tool can include the following:

- Problems in the ignition system;

- Stopping the chain saw while it is cutting;

- Loss of power while working;

- wear and tear of some structural parts of the chain saw (brake band, drive sprocket, anti-vibration parts);

- Problems in the fuel supply system;

- Malfunctions associated with the starter.

In addition, it is necessary to create a visual inspection of the chain saw before performing the work and preventive measures. How to wind the grass trimmer starter spring the starter rope does not coil: how to find out the cause and perform starter repair with your own hands? How to disassemble the starter, plug it in and do it again by yourself. These include chain lubrication, checking the amount of fuel mixture, and presence of the required amount of oil.

The spark plug is unscrewed to check its condition.

Any of the defects are repaired according to its own technology. So, for example, the repair of the fuel system of a chainsaw should begin with the examination of the appropriate filter. Then inspect the carburetor for correct carburetor adjustment, which is done with the screws. The gaps should be set in serious coordination with the manufacturer’s annotation, which should be attached to the chainsaw package. To repair of ignition system include inspection of spark plugs. If you notice a heavy fouling, a change in the gap or other visible damage this element should be replaced.

Repair chain saw starter. With your own hands.

on the chainsaw ? How to bend the starter spring on a chain saw ?How to coil a spring.

with your own hands. replacing the hand starter spring.

- A set of screwdrivers or a special tool, which is supplied by the manufacturer in the set with the tool;

- a rope to be used as a replacement for a broken cord if necessary.

A large amount of black sludge on the spark plug indicates a malfunction of the engine.

Before proceeding directly to repair the starter and find out the causes of malfunction, it is necessary to remove it from the body of the tool. To do this it is necessary to unscrew several screws that hold the side cover, to which the starter is attached. This is done with a screwdriver or a specialized tool.

Once the cover is unscrewed, it is turned over and inspected. Next unscrew the screw that secures the starter. After that, the clamp and the spring are removed to make a smooth start. Now the pulley, on which the cord is wound, is accessible for removal. After loosening the knot on the rope, it can be pulled from the pulley and replaced with a new one. Provided that the loss of starter performance is due to a breakage, this may be enough to fix the breakage. However, the other parts that make up this element of the chainsaw should be carefully inspected.

READ What kind of chain for a Makita chain saw

Examination of the components of the starter may reveal the following faults:

Damage to the soft starter spring is most common at the end, where it is visible when you disassemble the housing.

- The pulley can be damaged. There may be cracks or tears, and there is damage to the back. How to insert the grass trimmer starter spring correctly. How to wind the starter spring of a gasoline-powered tool. How to install the spring in how to wind the starter spring repair chainsaw. As a result of these problems the tool cannot work.

- Damage to the soft starter spring. It can be mechanically defective as the spring itself, and there are defects in the place where it is attached. The weakest point of this element is precisely the mounting place and the tip of the spring that is inserted in it.

If defective or partially damaged starter parts are found, they must be replaced with new ones. how to wind the starter spring how to correctly repair chain saw starter. In this case, the new elements must correspond to the model of the saw being repaired.

After completing the repair you need to properly assemble the starter.

The pulley is installed over the spring. In doing so, it is necessary to check how well they mesh with each other. To continue the repair, it is necessary to perform the winding of the pulley. How to wind the spring and how to wind the chain saw starter cord.everything is as usual. How to make a starter motor on a chainsaw? How to bend the spring on the chain saw starter? How to wind the spring and how to wind the chain saw starter rope.everything as usual is simple and easy, and the main thing is that. This should be done so that when it rotates, it pulls the cord in the starter. It is enough to make 3-4 turns to give the required voltage. First, a rope is put through the hole in the cover of the chainsaw.

chain saw starter repair. With their own hands.

on the chainsaw ? How to bend the spring on a chain saw starter ?How to bend the spring.

with your own hands. replacing the hand starter spring.

- a screwdriver set or a special tool that is supplied by the manufacturer with the tool;

- rope, which will be used as a replacement for a broken cord if necessary.

A large amount of black sludge on the spark plug indicates a malfunction of the engine.

Before proceeding directly to repair the starter and find out the causes of faults, it is necessary to remove it from the body of the tool. To do this, you need to unscrew several screws that hold the side cover, to which the starter is attached. This is done with a screwdriver or a specialized tool.

Once the cap is unscrewed, it is turned over and inspected. Next, unscrew the screw that secures the starter. After that, remove the clamp and spring to implement a smooth start. The pulley, on which the cord is wound, is now accessible for removal. Once the knot on the rope is untied, it can be removed from the pulley and replaced with a new one. Provided that the loss of starter performance is due to a breakage, this may be enough to fix the breakage. However, the other parts that make up this element of the chainsaw should be carefully inspected.

READ What kind of chain for a Makita electric saw

Inspection of the starter components may reveal the following faults:

Damage to the soft starter spring is most common at the end where it is visible when the housing is disassembled.

- The pulley can be damaged. There may be cracks or tears, and there may be damage on the back. How to properly insert the starter spring of a grass trimmer. How to wind the starter spring of a gasoline-powered tool. How to coil a starter spring in a chainsaw repair. As a result of these problems, the tool cannot perform.

- Damaged softstarter spring. In this case it may be mechanically defective as a spring itself, and there may be defects in the place of its attachment. The weakest point of this element is the fastening place and the tip of the spring that is inserted into it.

If defective or partially damaged parts of the starter are found, they must be replaced with new ones. How to wind the starter spring how to correctly repair chain saw starter. In this case the new elements must match the repaired model of the saw.

After completing the repair is required to properly reassemble the starter.

The pulley is installed on top of the spring. Check whether they stick together. In continuation of the repair it is necessary to perform the winding of the pulley. How to wind the spring and how to wind the chain saw starter rope.all as usual. How to make a starter motor on a chainsaw? How to bend the spring on a chainsaw starter? How to wind the spring and how to wind the chain saw starter rope.everything is as simple and easy as usual, and most importantly. This must be done in such a way that it pulls the cord into the starter when it rotates. It is enough to make 3-4 turns to give the required tension. The rope is put through the hole in the chainsaw cover beforehand.

Practical hints

In order to match the cord fixing holes in the pulley and housing, you may have to make a few more turns. The new rope is put through the technological hole and make a loop or knot: this will allow it to slip out of the pulley. The rope is set aside so that it does not interfere with further work. Next you need to fix the pulley.

The soft-start must first be installed in its place. It can be used the old one, if no damage is found in it. or a new one if it has to be replaced. The starter clamp is installed on top of the spring and secured with a special screw. It securely holds the clip for a long time, preventing its warping and rocking. After that you need to make a few turns of the rope and run it inside. The cover with the assembled starter motor is installed in place. Using screws secure it.

After repairs and reassembly are complete, you are ready to go to work. how to lubricate chain correctly how to shorten chain on mtb repair chain saw starter. Self-repair of the starter does not take much time and does not require complex skills, but saves time and money if you perform such work in a service center.

To repair the chain saw it is necessary to approach responsibly and make timely preventive inspections, monitor the quality of fuel and oil used. These simple manipulations will increase the working life of the tool.

How to repair chain saw starter with your own hands

Partner chainsaw starter repair / Breakage of starter cord

Broken cord

Presented repair chain saw starter after a broken starter cord. Without a starter cord, your chain saw is a total dead end, there’s no other way to get it started. This repair is based on the example of a Partner P350S chain saw, and the clever reliable start of this saw requires at least 4-5 times to pull the starter cord in order to make the saw work, so I guess the first problem was a broken cord. The cord doesn’t break right away, first the protective stocking of the cord threads breaks and prevents the saw from starting. Better not to wait for all threads to break and fix the cord beforehand. It is not necessary to invent anything, the repair should not cause difficulties, but the exact terms of assembly is necessary. A step by step guide with a schematic diagram with photos and video is shown below.

Unscrew the three screws that secure the starter cover. The included spark plug wrench with a straight screwdriver will do for this process, but to speed up the work it is better to use a normal tool.

Remove the starter. The chain saw is equipped with a soft starter and it is located above the spool with the cord.

Unscrew the screw fixing the soft starter mechanism and the starter coil. Be careful not to lose the washer!

Starter removed. Unscrew the screw

Soft starter Soft starter reel Reel removed

Prepare a cord of suitable diameter and length of 1.2-1.3 meters. For the repair we used the kapron clothesline :).

Melt the ends of the rope in the fire, so it won’t unravel.

Tie a big knot at one end. The knot should be large in diameter, but it should not protrude when inserted on the spool.

Tuck the cord into the spool hole. Do not coil the cord!

Reinsert the spool. There may be a mounting mistake here. The spool has two slits, one of which should hit the hook of the coil spring. Install the spool so that it is firmly seated and the catch engages in the slot. Checked by turning the spool clockwise to see if the return force is generated.

Knot on the cord Cord Cord is fixed Spring protrusion

Install soft starter. The protrusion of the mechanism should fit into the recess of the spool.

Screw the fixing screw with the washer.

Tucking the other end of the cord into the outlet.

Installing the soft starter The screw is bolted The cord is pulled out

Tuck the cord into the starter grip. Tie a big knot at the end of the rope. With a small knot there is a chance the rope will slip and the whole cord will get tangled in the starter and you will have to take the starter off again to get it out. Check that the assembly is secure. See photo.

Cord in the trigger knob Locking knot Handle on the cord Tighten the spiral

Most important point! Release the cord loop inside the starter and begin turning the starter mechanism clockwise without winding the cord! For this saw you need to make at least five turns. Fix the spool by hand. Tighten the hinge by the handle outward. Holding the cord and the mechanism allows you to wind the cord on the spool. Watch this video.

Put the starter in place and fasten it with three screws. The repair is done.

An upgraded starter

Repairing a broken or damaged cord using the step-by-step instructions will take 15 minutes, which is much faster and cheaper than going to a service center.

If the instruction helped you, tell us in the Комментарии и мнения владельцев.

Block: 2/2 | Characters: 3461

How to put the spring on the chain saw starter?

To place the spring in the appropriate groove is quite a challenge. First of all it is necessary to twist the part, returning it to its previous size. Then insert it into the cavity of the regular hub of the reel. To tuck the spring into the chain saw starter, you need to act in this order:

- It is necessary to fix the outer end of used spring in a special limiting ledge. In this case the second end will need to install a screwdriver against the regular hole inside the lock;

- Next, the loop located on the inner end of the standard spring should be aligned with the hole. It is better to use a screwdriver for this. With the ends aligned, the disc will need to be lowered;

- After installing the disc, it is necessary to check that the dog of the chainsaw’s factory ratchet mechanism fits into its proper place. Then it is possible to assemble the ratchet in the reverse order.

To wind the spring on the chainsaw starter, you need to consider all the available holes and notches. After assembly, the spring must be tensioned. Once the slack is eliminated, the spring will need to be wound a few revolutions to maintain the desired tension of the installed part.

Typical chainsaw starter breakdowns and repair

Before carrying out repairs, it is necessary to find out the causes of failure. As the product is constantly exposed to dynamic and other kinds of loads, its failure is not excluded. Frequent causes of starter breakage are: a broken cord, fraying or chipping of a few splines of the ratchet drum, spring damage, cracked pulley, etc. To determine why the saw won’t start, you’ll need to perform a proper inspection of the starter mechanism. Let’s look at the main types of faults, as well as find out how to properly repair the product.

Replacing the cord

The starter cord is a strong rope, which is quite resistant to wear and tear, but even its technical properties do not save it from damage. The cord rubs against the cover of the starter with each start of the tool, which leads to its gradual fraying and wear.

If there was a chafing of the cord, then to replace it you need to disassemble the body of the unit. After removing the cover, it is necessary to raise the reel, but only in such a way that it does not slip out of its seats. It is recommended that this work should be done together with a partner who will fix the spring, and you will replace the cable. Remove the remains of the old rope and fasten the new unit in the knob and in the groove of the drum. After that the wire should be wound onto the roller and the body assembled at the end.

Important to know! Before fixing the cable in the handle, you should pass it through the appropriate hole in the starter cover.

How to replace the chain saw starter spring

If the spring is damaged, which is often the case with Chinese tools, then the mechanism can only be repaired by replacing it. But if it is damaged at the attachment point, that is, the ear is cracked, then it can be repaired.

Repair of a spring consists of heating the place of destruction to 600 degrees, then slowly cool it down to 100 degrees, at which point wrap the end according to the shape of the fragment. In this way, it will be possible to avoid loss of elasticity of the product, which will prolong its service life. Most professionals, though, simply replace the product with a new one.

The process of replacing the spring is carried out in the following sequence:

- First remove the cage or drum of the mechanism.

- Inside the drum is a spring. To remove it, it is necessary to fix the upper part, and then pull aside the starter handle.

- When the old spring is removed, you must install a new one. It is imperative that the housing be cleaned.

- When installing a new spring, you should insert it into the starter, and then hit the tab in the slot.

- When the work is complete, the drum can be put on and the starter cover can be reinstalled.

The detailed process of replacing the spring is shown at

Handwheel catches replacement

If the handwheel pawls or jaws need to be changed, it is easy to do. To do this you need to remove the flywheel, and then remove the pawls. You should only install the new doglegs that were originally installed (plastic or metal). This is very important, since the replacement of plastic dogs on the metal, will accelerate wear on the flywheel. The details of replacing chainsaw starter pins are discussed in the video below.

It is important to note that you do not need to have special skills or experience to repair the chain saw starter. All work can be performed by yourself if you treat the repair process with responsibility. Timely preventive maintenance on your chainsaw will help avoid breakdowns when working in the field.

Block: 3/3 | characters: 3688

How to put a spring on a chainsaw starter?

Placing the spring in the proper slot is quite a challenge. First of all the part will need to be twisted, returning it to its previous size. After that it should be inserted into the cavity of the standard barrel hub. To tuck the spring into the chain saw starter, you need to act in this order:

- The outer end of the used spring must be secured in the special limiting lug. The second end has to be installed with a screwdriver in front of the regular hole inside the lock;

- Then the hinge located on the inner end of the standard spring must be aligned with the hole. This is best done with a screwdriver. With the ends aligned, the disc will need to be lowered;

- After installing the disc, it is necessary to check that the dog of the chainsaw’s factory ratchet mechanism has risen into its regular place. Then you can reassemble the ratchet in the reverse order.

To wind the spring on the chainsaw starter, it is necessary to take into account all existing holes and notches. After installation it is necessary to tighten the spring. Once the slack has been eliminated, the spring will need to be screwed on a few turns. this is necessary to maintain the required tension of the installed part.

Typical breakdowns and repair chain saw starter

Before repairing, it is necessary to find out the causes of failure. Since the product is constantly exposed to dynamic and other kinds of loads, its failure is not excluded. Common causes of starter motor failure include a broken cord, abrasion or chipping of a few splines on the ratchet drum, spring damage, cracked pulley, and others. To determine why the saw won’t start, you’ll need to perform a proper inspection of the starter mechanism. Consider the main types of faults, as well as find out how to properly repair the product.

Replacing the cord

The starter cord is a strong rope that is sufficiently resistant to wear and tear, but even its technical properties do not save it from damage. The rope rubs against the housing of the starter cover every time you start the tool, and this causes the cover to gradually wear and fray.

If there was a fraying of the cord, then to replace it you will need to disassemble the body of this assembly. After removing the cover you need to raise the drum, but do it in such a way that it does not slip out of its mounting locations. It is advisable to do this work together with your partner, who will fix the spring, while you replace the cable. Remove the remains of the old rope and fasten the new product in the knob and in the groove of the drum. After that the wire should be wound onto the roller, and finally the body should be assembled.

Important to know! Before fixing the cable in the handle, you should pass it through the appropriate hole in the starter cover.

How to replace the chain saw starter spring

If there is damage to the spring, which is often the case with Chinese tools, then the mechanism can only be repaired by replacing it. But if it is damaged at the connection point, that is, the ear is broken, then it can be repaired.

Repair of the spring is to heat the place of destruction to 600 degrees, and then slowly cool it to 100 degrees, at which to screw the end in the shape of a fragment. In this way it is possible to avoid the loss of elasticity of the product, which will prolong its service life. Although most specialists simply perform the replacement of the product with a new one.

The process of replacing the spring is done in the following sequence:

- First remove the cage or drum of the mechanism.

- Inside the drum there is a spring. To disassemble it, you will need to fix its upper part, and then pull aside the starter handle.

- When the old spring is removed, it will be necessary to install a new. At the same time it is necessary to carry out cleaning of the housing.

- When installing a new spring insert it into the starter, and then hit the bar in the groove.

- At the end of the work you can put on the drum and install the starter cover in place.

A detailed guide to replacing the spring is at

Handwheel catches replacement

If the handwheel pads or tabs need replacing, that’s easy enough to do. To do this you will need to remove the flywheel, and then remove the dogs. Install new dogs should be installed only those that were originally (plastic or metal). This is very important, because replacing plastic doggies with metal ones, will lead to accelerated wear of the flywheel. The details of chainsaw starter pins replacement are discussed in the video below.

It is important to note that no special skills or experience are needed to carry out chainsaw starter repair. All works can be done by yourself if you treat the repair process with care. Timely preventive maintenance of a chainsaw avoids damage in the field.

Block: 3/3 | Characteristics: 3688

Tips from the pros

For the exact orientation of the holes in the housing and the rope fixing channel, you may need to make 2-3 turns.

In order to prevent the cord from slipping out of the sheave, you must tie a knot larger in diameter than the hole in the housing. If there is no wear (damage) of the spring, it is installed first in the assembly of the chain saw starter. On top of it is mounted the pulley and the starter clamp, which prevents the misalignment of the mechanism during rotation.

As it turns out, the repair of chain saw starter with their own hands does not require special skills and tools. However, you need to rebuild the starter mechanism responsibly and do preventative maintenance from time to time.

Block: 4/4 | Number of characters: 722

Number of blocks: 7 | Total number of characters: 13201Number of donors used: 5Information on each donor:

Tips from the Professionals

It may be necessary to make 2-3 turns to accurately orient the holes in the body and the rope fixation channel.

In order to eliminate the slippage of the cord from the pulley must be tied a knot larger in diameter than the hole in the housing. If there is no wear (damage) to the spring, it is installed first when reassembling the chain saw starter. On top of the sheave is mounted the pulley and the starter clamp, which prevents the mechanism from distortion during rotation.

As it turns out, chain saw starter repair with their own hands does not require special skills and tools. But the starter mechanism must be repaired with care and preventive maintenance should be done from time to time.

Block: 4/4 | characters: 722

Number of blocks: 7 | Total number of characters: 13201Number of used donors: 5Information on each donor:

Construction and principle of chain saw starter

Most well-known chainsaw manufacturers equip their products with starters that work along virtually the same lines. Its essence is the following: in the groove of the body of the saw there is a handle through which a cord is passed. When the handle is raised sharply, the cord is also pulled, which causes the drum, which is in the ratchet mechanism, to engage. This activates the cylinder with studs, which is located on the shaft. During this, the crankshaft makes a couple of revolutions, which leads to compression of the fuel mixture, which at this moment is between the cylinder head and the piston. When the handle is lowered, on the contrary, the ratchet and the studs lose their contact, which causes the shaft to stop.

Increasing the power of the chainsaw increases the amount of fuel mixture that must be ignited when starting the chainsaw. In such a case it is necessary to increase the number of jerks of the starter cord in order to start the engine. To accelerate the return of the drum mechanism, manufacturers use a special steel starter return spring, which has excellent elasticity. Leading brands use other methods to make starting a chainsaw easier:

- Pre-enriching the fuel mixture with a separate flap;

- Installation of an automatic decompression valve, which ensures that the pressure inside the chainsaw cylinder is lowered;

- Installation of a primer designed to pump up the fuel before starting the engine.

Using one of these techniques makes it much easier to start and prolongs the life of the starter, which is especially noticeable in low temperatures.

Replacing the starter

Procedure for replacing the chain saw starter:

- Remove the assembly from the tool body.

- Unscrew fixing screws and remove the side cover.

- Unscrew the fixing screw with which the starter is attached.

- Removing the clamp and spring mechanism of the starting system.

- Dismantle the pulley with the cord.

- Replace all worn and damaged parts.

- Wrap the sheave.

- Install the new starter.

- Reinstall pulley and cord, clamp and spring.

- Screw the side cover and install the assembly on the body of the chainsaw.

Before installing a new starter is recommended to inspect it for defects, check the quality of the assembly and the presence of the guide bush.

If the engine is idling and when the spin cycle becomes faint, it is entirely possible that the premise is the muffler. The muffler can be clogged with combustion products and unplugged and, as a result, the engine does not achieve its own maximum speed. The cause could be excessive oil in the fuel, or it could be bad or faulty oil. To solve the problem, the muffler has to be removed, cleaned of deposits and washed with detergents.

Chainsaw starter motor design

Starters in most chainsaws have the same design. That is why some stores offer customers a universal starting mechanisms that are suitable for mounting on models from STIHL, Husqvarna, Partner. Nevertheless, some differences from most have the starters of domestic chainsaws Ural or Lesnik.

A chainsaw starter consists of a number of parts as standard.

A protective cover is placed on top of all the components of the starter motor. The original principle of operation of most starting mechanisms is also practically the same. In a special groove in the chain saw’s body there is a handle that holds the cable. When the handle is raised sharply, the latter is understood to be. At that moment, the ratchet is actuated, which through a drum transmits the force to another drum with splines, located on the engine shaft.

When pulling the standard cable, the chainsaw motor shaft begins to rotate, which leads to compression of the existing fuel mixture, located at this time between the cylinder head and the standard piston.

As the volume of the internal combustion engine cylinder increases, the amount of fuel mixture required for its future ignition also increases. Accordingly, the operator of a powerful saw needs to make more jerks than the owner of a domestic tool with low power. To increase the speed with which the reel returns to its original position, manufacturers of heavy-duty chainsaws use resilient return springs.