Replacing the STIHL 180 chain saw starter cord

Most well-known chainsaw manufacturers equip their products with starters that work pretty much the same way. The idea is this: in the groove in the chain saw’s body there is a handle with a cord through which the chain is threaded. When the handle is raised sharply, the cord is also pulled, causing the drum, which is in the ratchet mechanism, to engage. By means of it, the drum with the studs, which is located on the shaft, is actuated. During this, the crankshaft makes a couple of revolutions, resulting in the compression of the fuel mixture, which at that moment is between the cylinder head and the piston. When lowering the handle, on the contrary, the ratchet and the studs lose their contact, which causes the shaft to stop.

Increasing the power of the chainsaw increases the amount of fuel mixture that must be ignited when starting the chainsaw. In such a case, it is necessary to increase the number of jerks of the starter cord in order to start the engine. In order to accelerate the return of the drum mechanism, manufacturers use a special steel starter return spring, which has excellent elasticity. Top brands also use other methods to make it easier to start the chainsaw:

- Pre-enrichment of the fuel mixture by means of a separate flap;

- Installation of an automatic decompression valve, which provides pressure reduction inside the chainsaw cylinder;

- Installation of a primer designed for priming fuel before starting the engine.

Application of one of these technologies greatly facilitates starting and extends the life of the starter, which is especially noticeable at low temperatures.

Repair of the TAYGA chainsaw with your own hands

In order to repair the TAYGA chainsaw, it is extremely important to make a proper diagnosis, to identify the causes of the malfunction. If we consider in general terms the faults of the TAYGA chainsaw, we can safely divide them into two categories:

- TAIGA chainsaw repair related to internal combustion engine failure;

- And malfunction of the chainsaw ignition system, as well as the fuel supply system.

Other chain saw breaks, like a faulty clutch, a badly worn guide bar, etc. д., will not be considered. Since in this variant of malfunctions of the chainsaw TAIGA, the tool normally starts and does not stall after starting.

The chain saw does not start due to several reasons. But sometimes even after the chainsaw has started, you can observe interruptions in its operation, a drop in power, etc. д. Therefore, in order to properly carry out the repair of the TAYGA chainsaw, it is necessary to act by the method of excluding the faults of its various assemblies.

If the TAYGA chainsaw engine stalls after starting or refuses to start at all, then you should start looking for a problem primarily in the ignition system of the chainsaw. Here it is necessary to check for proper operation of the spark plug of the chainsaw TAIGA, as well as the high-voltage wires.

Inspection of a chainsaw spark plug, can tell you a lot, including why the engine chain saw does not start. If the tip of the plug is dry, it indicates that the fuel mixture is not flowing into the chainsaw engine cylinder. You should try pumping up the fuel with a pump button, usually located near the start button on the chain saw.

At least, there is such a start button on the Ural chain-saw. Therefore, if the repair of chain saw Ural, you should check the presence of fuel in the gas tank and pump it up necessarily, until the rubber cover of the button is completely filled with fuel.

On the contrary, if the candle of a Taiga chainsaw is splashed with fuel and wet, it means that the carburetor is not properly adjusted. The correct adjustment of the TAYGA chainsaw carburetor is performed as follows.

How to diagnose chain saw starter

Due to long-term use of the chainsaw, the starting mechanism becomes unusable. After one or more jerks when pulling the starter rope does not turn the crankshaft. This problem may be caused by the following reasons:

Before you start to diagnose and repair the starting mechanism, you need to prepare the necessary tools and accessories, which will significantly reduce the time of operations. These include:

- A set of locksmith screwdrivers and a specialized set of brand-name tools included with the chainsaw.

- A sturdy cord to replace the worn starter rope.

Chainsaw starter spring

In the first phase of the chainsaw starter repair it is necessary to identify the nature of the problem. To do this, remove the side cover on the side of the starter mechanism, unscrewing only a few screws. Depending on the manufacturer, for this operation you will need a specialized or ordinary screwdriver.

Then we inspect the inside of the blade guard. If there are no cracks and chips of plastic, proceed directly to the diagnostics of the starting unit. Unscrew the center bolt of the starter and remove the spring. On its surface there should not be any cracks and breaks. To choose independently a similar by force and number of coils spring is problematic, so the help of specialized centers will be required.

After removing the clamp and the chain saw starter spring, the pulley with the wound cord is available for disassembly. The integrity of the cord indicates that it is necessary to carefully review each of the parts of the starting mechanism.

How to Repair a Chainsaw Starter with Your Hands

Presented repair chainsaw starter after a broken starter cord. Without a starter cord, the chainsaw becomes completely inoperable, there is no other way to start the tool. Repair considered the example of a chainsaw Partner P350S, tricky reliable starting this saw requires a minimum of 4-5 times to pull the starter cord to make the saw work, so I guess the first problem was a broken cord. The cord doesn’t break right away, first the protective stocking of the cord breaks and prevents the saw from starting. It is better not to wait for all the threads to break and fix the cord beforehand. There is no need to invent anything, the repair should not cause difficulties, but the exact observance of the conditions of assembly is obligatory. The step by step instruction with a scheme of actions with photos and video is given below.

Remove three screws from the starter motor cover. The included spark plug wrench with a straight screwdriver is suitable for this process, but to speed up the work it is better to use a normal tool.

Remove the starter motor. The chainsaw is equipped with a soft starter mechanism, it is located above the spool with the cord.

Remove the screw that secures the soft starter and the starter coil. Be careful not to lose the washer!

The chainsaw is an indispensable tool not only for the dacha owner, but also for construction work. If you need to stockpile firewood for the winter, it makes no sense to go to the woods without a chainsaw. The tool can last a long time if used properly, but in any case, sooner or later various types of malfunctions will occur. One of these malfunctions is a broken starter, which makes it difficult to start the engine. In this situation, it is advisable to perform the repair of the chain saw starter with your own hands. We will learn how to do it in the following material.

chain saw starter motor repair. With your own hands.

nabenzopile ? How to bend the spring on a chainsaw starter ?How to coil the spring.

with your own hands. replacing the recoil starter.

- A set of screwdrivers or a special tool, which is included by the manufacturer with the tool;

- A rope, which will be used as a replacement for a broken cord if necessary.

A large amount of black sludge on the spark plug indicates a malfunction of the engine.

Before we proceed directly to repair the starter and find out the causes of malfunction, it is necessary to remove it from the body of the tool. To do this, you need to unscrew several screws that hold the side cover, to which the starter is attached. This is done with a screwdriver or with a specialized tool.

Once the cover is unscrewed, turn it over and inspect it. Next, unscrew the screw that secures the starter. After that, remove the clamp and spring to implement the soft starter. Now the pulley, on which the cord is wound, is accessible for removal. After the knot on the rope is untied, it can be removed from the pulley and replaced with a new. Provided that the loss of functionality of the starter is associated with a breakage, this may be enough to fix the failure. However, the other parts that make up this element of the chainsaw should be carefully inspected.

READ What kind of chain for a Makita electric saw

Inspection of the starter components may reveal the following faults:

The most frequent damage to the soft starter spring occurs at the end, where it is visible when disassembling the housing.

- The pulley can be damaged. There may be cracks or tears, and there may be damage on the back. How to properly insert the grass trimmer starter spring. How to wind the starter spring of a gasoline tool. how to install the spring in how to wind the starter spring repair chainsaw. As a result of these problems the tool can no longer perform the work.

- Damage to the soft starter spring. The spring itself may be mechanically defective or there may be defects in the spring mount. The weakest point of this element is exactly the fixing place and the tip of the spring, which is inserted into it.

If defective or partially damaged parts of the starter are found, they must be replaced with new ones. how to wind up a starter spring how to correctly repair chain saw starter. In doing so the new parts must fit the model of the saw to be repaired.

After completing the repair, the starter must be reassembled correctly.

The pulley is installed on top of the spring. When doing this it is necessary to check how well they mesh with each other. As a continuation of the repair, the sheave must be wrapped. How to bend the spring and how to wind the chain saw starter rope.everything as usual. How to make your own chain saw starter? How to bend the spring on the chain saw starter? How to wind up the spring and how to wind up the chain saw starter rope.everything as usual is simple and easy, and most importantly. This should be done so that when it rotates, it pulls the cord into the starter. It is enough to make 3-4 turns to give the required tension. The rope is put through the hole in the chainsaw cover beforehand.

Practical suggestions

In order to match the holes for fixing the cord in the pulley and the body, you may have to make a few more turns. The new rope is put through the technological hole and made a loop or a knot: this will allow it to slip out of the sheave. The rope is pulled aside so that it doesn’t interfere with further work. Next, it is necessary to fix the pulley.

You first need to put the soft starter spring in place. It can be used the old one if there is no damage to it. or a new one if it needs to be replaced. The starter clamp is installed over the spring, which is secured with a special screw. It securely holds the clip for a long time, preventing it from twisting and rocking. After that you need to make a few coils of rope and run it inside. The cover with the assembled starter motor is put back. Use screws to fix the chain in place.

After completing the repair and reassembly you can start to work. how to correctly lubricate the chain how to shorten chain on mtb repair chain saw starter. Self-repair starter does not take much time and does not require complex skills, but it saves time and money if you do such work in the service center.

To the chainsaw repair it is necessary to approach responsibly and make timely preventive inspections, monitor the quality of fuel and oil used. These simple manipulations can increase the length of the tool in operation.

Practical suggestions

In order to match the holes for fixing the cord in the pulley and the body, it may be necessary to make a few more turns. The new rope is inserted through the technological hole and the loop or knot is made, it will allow it to slip out of the sheave. The rope is pulled aside so that it does not interfere with further work. Next, the sheave has to be fixed.

First you need to install the soft start spring in place. It can be used as is, provided it is not damaged. or a new one if it needs to be replaced. The starter clip is installed on top of the spring and fastened with a special screw. It reliably fixes the clamp for a long time, preventing it from warping and swaying. After that, it is necessary to make a few turns of rope and run it inward. The cover with the assembled starter motor is put in place. Use screws to fasten it.

After repair and reassembly you can start working. how to correctly lubricate the chain how to shorten mtb chain chain repair chain saw starter. Self-repair of the starter does not take much time and does not require complex skills, but saves time and money if you perform such work in a service center.

It is necessary to have a responsible approach to chain saw repair, to do preventive maintenance in time, to follow the quality of fuel and oil used. These simple manipulations will increase the duration of the tool in working condition.

How to put the starter on the Husqvarna

Starter for chain saw. We teach how to self-repair

To sharply start any chainsaw requires a starter. Accelerated cranking of the tool crankshaft compresses the fuel-air mixture fed into the engine and its subsequent ignition. Therefore, the normal operation of the chain saw starter determines the performance of the entire mechanism.

How to put the spring on the chain saw starter?

Place the spring in the appropriate groove. this is quite a challenge. First of all, the part must be twisted back to its original dimensions. After that, it must be inserted into the cavity of the original drum hub. To tuck the spring into the chain saw starter, you need to act in this order:

- The outer end of the used spring must be secured in the special limiting ledge. In this case, the second end with a screwdriver will need to set against the regular hole inside the lock;

- Next, the hinge located on the inner end of the standard spring should be aligned with the hole. For this it is better to use a screwdriver. With the ends aligned, the disk will need to be lowered;

- After installing the saw blade it is important to check that the ratchet pin of the chain saw is in its original place. Then you can assemble the ratchet in reverse order.

To wind the spring on the chainsaw starter, it is necessary to take into account all the available holes and notches. After installation, it will be necessary to tension the spring. Once the slack will be eliminated, the spring should be wound a few turns. this is necessary to maintain the desired tension of the installed part.

Typical chainsaw starter breakdowns and repairs

Before carrying out the repair, it is necessary to find out the causes of the failure. Since the product is constantly exposed to dynamic and other kinds of loads, its failure is not excluded. Frequent causes of starter breaks are cable breakage, abrasion or chipping of a few splines of the ratchet drum, spring damage, sheave cracking, etc. To determine why the chain saw won’t start you need to do an inspection of the starter mechanism. Let’s look at the main types of faults, as well as find out how to properly repair the product.

Replacing the cord

The starter cord is a strong rope, which is sufficiently resistant to wear, but even its technical properties do not save it from damage. The rope rubs against the cover of the starter every time you start the tool, causing it to gradually fray and wear out.

If the cord breaks, you will need to disassemble the barrel of the assembly to change it. After removing the cover, you should lift the drum, but only in such a way that it does not slip out of its seats. It is recommended that this work should be done with a partner who will fix the spring, and you will replace the rope. Remove the remains of the old rope, and then install the new product in the handle and in the groove of the drum. After that the cord should be wound on a roller, and finally the body should be assembled.

Important to know! Before you fix the cable in the handle, you should pass it through the appropriate hole in the starter cover.

How to replace the chain saw starter spring

If the spring is damaged, which is often the case with Chinese tools, then the mechanism can only be repaired by replacing it. But if its damage occurred in the place of connection, that is, the ear broke, then it can be repaired.

Repair of the spring is a heating of the place of destruction to 600 degrees, then slowly cool it down to 100 degrees, at which to wrap the end in the form of a fragment. In this way, it is possible to avoid the loss of elasticity of the product, which will prolong its service life. Although most specialists simply replace the product with a new one.

The process of replacing the spring is carried out in the following sequence:

- Initially the cage or drum of the mechanism is removed.

- There is a spring inside the drum. To disassemble it, you will need to fix its upper part, and then pull aside the starter handle.

- When the old spring will be removed, you will need to install the new. At the same time it is necessary to carry out cleaning of the housing.

- When installing the new spring should be inserted into the starter, and then hit the tab in the groove.

- At the end of the work you can put the drum and install the starter cover in place.

A detailed process for replacing the spring is at

Handwheel catches replacement

If you need to replace the handwheel pawls or swivels, it’s not hard to do either. This will require the removal of the flywheel, and then remove the dog. You should only install new snappers that were originally installed (plastic or metal). This is very important, since the replacement of plastic dogs for metal ones, will lead to an accelerated wear of the flywheel. The details of chain saw starter pawls replacement are discussed in the video below.

it is important to note that you do not need any special skills or experience to repair the chain saw starter. You can do all the work yourself if you treat the repair process with responsibility. Timely preventive maintenance of the chainsaw will help avoid breakdowns when working in the field.

Block: 3/3 | Number of characters: 3688

Tips from the Professionals

For the exact orientation of the holes in the housing and the rope fixing channel, it may be necessary to make 2-3 turns.

In order to avoid slipping of the cord from the pulley should be tied knot, the diameter exceeds the hole in the housing. If there is no wear (damage) of the spring, it is installed first when assembling the chainsaw starter. On top of it is mounted pulley and starter clamp, which prevents the misalignment of the mechanism during rotation.

As it turns out, the repair of chain saw starter with their own hands does not require special skills and tools. However, to restore the starter mechanism should be approached responsibly and from time to time to make preventive inspections.

Block: 4/4 |Number of characters: 722

Number of blocks: 7 | Total number of characters: 13201Number of donors used: 5Information on each donor:

Tips from the Professionals

For the exact orientation of the holes in the body and the rope fixing channel, you may need to make 2-3 turns.

In order to eliminate the slippage of the cord from the pulley, you need to tie a knot larger in diameter than the hole in the housing. If there is no wear (damage) to the spring, it is installed first in the chain saw starter assembly. The starter pulley and clamp are mounted on top of it, which prevents the mechanism from tipping during rotation.

As it turns out, repairing a chainsaw starter with your own hands does not require any special skills or tools. However, to the restoration of the starter mechanism should be treated responsibly and from time to time to make preventive inspections.

Block: 4/4 |Number of characters: 722

Number of blocks: 7 | Total number of characters: 13201Number of used donors: 5Information on each donor:

Construction and principle of chain saw starter

All types of chainsaws, both Chinese and European, are equipped with starters of identical design and principle of operation. The universal design of the starters allows to apply these devices on branded chainsaws, as well as on semi-official tools, supplied from the Celestial Empire. It is important to note only that some distinctive features have tools of domestic production.

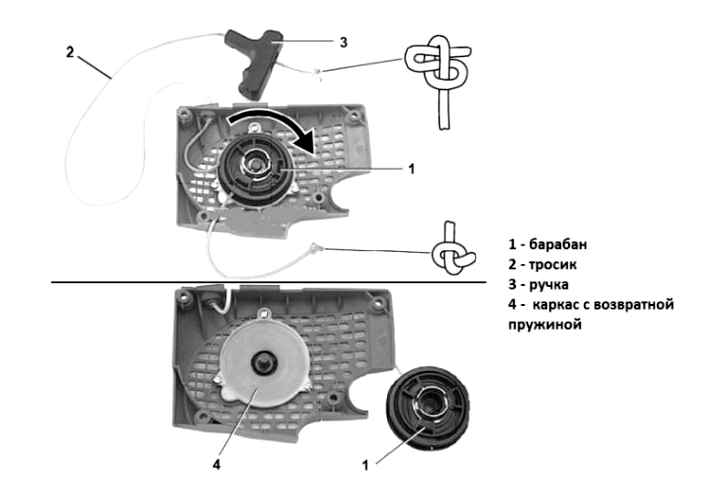

The starter for a chainsaw is a simple mechanism that consists of:

The principle of operation of such a device is also quite simple. When pulling the handle, which is connected through a cable to the drum of the ratchet mechanism, it moves. the barrel in motion engages with the splines of the other barrel, which is located on the shaft. Thus, manually move the saw crankshaft, which makes several revolutions. As soon as the handle returns to its original position, which is facilitated by the return spring, the spline connection is lost, which causes the shaft to stop. With each movement of the crankshaft, the amount of fuel-air mixture in the cylinder increases, which eventually contributes to its ignition.

The greater the power of the tool, the more jerks should be made by the starter to start the motor. For acceleration of the return of the drum to its original position is responsible return spring, which is made using steel with a high degree of elasticity.

Over time, if the tool is used continuously, problems occur with engine starting, or more precisely, with the starter motor functioning. If such problems arise, the starter can always be repaired. If you know the principle and design of the starter, then to carry out its repair with his own hands is not very difficult.

Block: 2/3 Number of characters: 1890

How to repair chain saw starter with your own hands

Partner chain saw starter repair / Broken starter cord

Broken cord

Here is how to repair chain saw starter after a broken starter cord. Without a starter cord, the chainsaw becomes completely inoperable, there is no other way to start the tool. Repair is based on the example of a Partner P350S chain saw, the tricky reliable start of this saw requires at least 4-5 times to pull the starter cord to make the saw work, so I guess the first problem was a broken cord. The cord does not break right away, first the protective cord strings break and prevent the saw from starting. It is better not to wait for all the threads to break and repair the cord beforehand. It is not necessary to invent anything, the repair should not cause difficulties, but the exact observance of the conditions of assembly is obligatory. Here’s a step-by-step guide with a photo and video of the action.

Loosen the three screws that secure the starter cover. The included spark plug wrench with a straight screwdriver will do for this process, but to speed up the work it is better to use a normal tool.

Remove the starter. The chain saw is equipped with a soft starter mechanism, it is located above the spool with the cord.

We unscrew the screw of fastening of the soft starter mechanism and starter coil. Take care not to lose the washer!

The starter is removed. We unscrew the screw

Soft starter Soft starter coil removed

Prepare a cord of suitable diameter and a length of 1,2-1,3 meters. For the repair used kapron clothesline :).

Melt the ends of the rope in the fire, so that it doesn’t unravel.

We tie an intricate knot at one end. The knot needs to be big in diameter, but it must not protrude when installed on the coil.

Tuck the cord into the spool hole. We do not wind up the cord!

Put the spool back in place. There may be an assembly error here. The coil has two slits, one of which should get the hook of the coil spring. Set the spool so that it is firmly in place and the catch is in the slot. Check to see if the recoil force is created by turning the spool clockwise.

The cord is fastened The cord is fastened The spring is protruding

Installing the soft starter. The shoulder of the mechanism should fit into the notch of the spool.

Fasten the screw and washer.

Insert the other end of the cord in the outlet.

Installing the soft starter The screw is screwed on The cord is pulled out

Feeding the cord into the trigger knob. Tie a big knot at the end of the rope. With a small knot there is a chance of rope slippage and the whole cord will be tangled in the starter and to get it out the starter will have to be removed again. Check reliability of the assembly. See photo.

Cord in trigger knob Fixing knot on cord Screw in spiral

The most important moment! Let the cord loop inside the starter and start turning the starter mechanism clockwise without winding the cord! For this saw, you need to make a minimum of five revolutions. Fixing the spool by hand. Tighten the hinge by the handle outward. Hold the cord and let the mechanism wind the cord on the spool. Watch video.

Put the starter in place and fasten it with three screws. Repairs have been made.

Refurbished starter motor

Repairing a broken or damaged cord using the step-by-step instructions will take 15 minutes, which is much faster and cheaper than going to a service center.

If this manual was helpful, please tell us in the Комментарии и мнения владельцев section.

Block: 2/2 | Number of characters: 3461

Repair of the oil supply system

If there is no oil to lubricate the chain, you need to diagnose everything that allows accounting (software) and find the reason why the oil is not supplied. There are a few major events for you to enjoy:

- A clogged oil filter, in other words, a greasy accounting system;

- Lack of threads on the oil pump worm gearbox;

- Blockage or malfunction of the pump itself;

- Unclogging the oil metering system (there will be oil leaks on the day of the chainsaw).

To check the thread on the worm oil pump, you will need to remove the chain saw sprocket and unscrew the clutch. To do this, unscrew the spark plug, in its place installed piston plug, provides a reliable fixation of the crankshaft of the tool from the rotation.

Then the cover of the STIHL 180 chain saw is removed, and the fastening ring that holds the drive sprocket is removed with a screwdriver, then the sprocket itself is removed.

If desired, the STIHL 180 chain saw sprocket can also be replaced in this manner.

READ Cedar Bench Saw Carburetor Adjustment

The clutch unscrews with a nineteen head and handle. Unscrew the clutch clockwise, because the thread is left. There is a reflective plate over the clutch, this must also be removed. One more detail. This is a worm drive oil pump. After examining and finding the absence of plastic thread, you can safely throw out the part and install a new one in its place, since its restoration is unrealistic. STIHL 100-80 chain saw assembly is done in reverse order.

How to change the starter cord on a STIHL 180 chain saw.

To check the gap, you need to turn the flywheel and check if the coil contacts are not touching it.

How to Attach the Starter Correctly to a Chainsaw

How to start a chainsaw: a couple of effective ways

Chainsaws are different in design, but in most cases the principle of assembly follows two standard diagrams. Many devices in the manual contain information on the need to engage the emergency brake before starting the on/off procedure.

At first, it is necessary to master the device of the plant and learn the basic ways to eliminate failures, then the person will have the ability to fully control the device.

A brief look at the starter unit

The chainsaw operates from a. It is a simple device whose design has no special bells and whistles. It usually works well even in harsh conditions.

Read about the plant’s device Functionality is provided by the structural elements:

- Carburetor motor (see. Carburetor adjustment).

- Centrifugal clutch.

- The ignition system, virtually contactless in all devices.

- Carburetor that adds air to the fuel mixture.

- Fuel system. Its standard device consists of a hose, filter and gas cylinder, but sometimes it also has additional parts.

- Starter.

- Shooting gallery.

- The chain (see “How to Sharpen a Chain” on page 56). Chain oil).

- Tensioning mechanism and chain brake (see., How to sharpen the chain).

Step-by-step instructions

When the brake is activated, the assembly process is much slower, so it is also safer and more convenient to engage the gear without using braking equipment.

If one is not confident in one’s knowledge and accuracy, then the brake should be activated in reverse. If the procedure is correct, the device does not start, the mechanism does not make dangerous for human action.

1 diagram of the standard mechanism

- Before starting the gasoline, you need to move the damper, which acts as a control lever, to the bottom, compared to the optimal position. First press the button responsible for the gas supply. Only if this condition is met can the damper be moved normally to the lower stop. It is necessary to move the flap and hold the gas button at the same time. The gas is set to the standard position and the flap closes the carburetor, preparing the unit for normal operation. Start jerk knob

- The starter knob must be pulled, and this is done by jerking, not by soft movements. Moderate force must be used for this action. It is necessary to continue these spurts until you can clearly hear the chain saw ignition, which will end very quickly (stop). After performing this exercise, the flap position should move up one step.

- The starter knob jerks again then until the system starts. When the unit begins to operate actively, high speed is immediately noticeable because the throttle is at a high level. Remember that chainsaws are sometimes supplied without a starter, then all operations with this element are performed.

- The throttle button is pushed once and then released, then the throttle position is immediately optimal. The speed decreases, i.e. Е. Intensity of chain speed.

- Already. When the lever is in position “1” and then perform the action to start the machine.

- To turn off the unit’s engine, you must set the shock absorber to its highest position.

READ Home Garden Ph 426 Zip Chainsaw Device

In our ranking, chainsaws by quality, you will find all chainsaws with the best value for money.

Also our article will help you make a choice in favor of one or another brand of chainsaw.

The chainsaw is manufactured. Low price with fairly high quality.

2 diagrams of the standard mechanism

- The ignition is on. To do this, move the toggle switch to the desired position or move the switch.

- You usually need to push the ground to pump more than twice. It is filled with gasoline, and then the device must be pressed more than three times. Sometimes the chainsaw is not primed, then you can skip this step. Adjustment lever

- The adjustment lever, which is responsible for locating the flap, must be pulled out as far as it will go. Many chainsaws have the ability to lock this element. Then you can only move it when you press and hold the throttle button at the same time. Some chain saws do not have such a lock, which makes them more convenient to use. In these models, the throttle cannot be fixed or held while using automatic technology.

- You need to take the starter knob and tighten in a sharp motion until you hear the ignition process. It is marked by the establishment and almost instantaneous shutdown of the engine. The flap should then be withdrawn to its original position, checking that it reaches the stop. Again, the starter knob is jerked to the location of the device. Before carrying out this action, you need to make sure that this is the way to get the chainsaw. Some units have a new ignition system. For the engine to work in them, it is necessary to move the damper only 50%, but only at the beginning of the active operation of the engine to push it completely out.

- If you have purchased a fixed throttle model, you must prepare in advance for maximum engine speed as soon as the unit is activated. When there is no lock, the initial power is very low, so in most cases you need to increase it. If you take no action, in the latter case the saw works for a short period of time and then stops automatically. If this happens you need to start the chainsaw again.

READ Attachment for chain saw with Your Hands

Chainsaw starter repair. With your own hands.

on the chain saw ? How to bend the spring on the chain saw ? How to wind a spring