It’s metal, but it’s easy to cut with a knife?

Potassium. Potassium. It’s silver-white metal, soft enough that you can cut it with a knife with just a little effort.

If you need to cut a lot in a straight line, get tin snips like the ones shown here. They cut through metal almost as easily as scissors cut through paper. And the long blades make it easy to cut straight and leave smooth edges. During cutting, one side of the sheet metal will rise and pass through the lower jaw.

Can you melt metal on a slab?

Metal casting. It was easy to buy from a scrap metal dealer (at least it used to be) for next to nothing. It melts at a temperature low enough that it can be melted on a stove with force or with a propane torch.

Potassium. Potassium (K). Potassium is an alkali metal, located below sodium and above rubidium, and is the first element of period 4. It is one of the most reactive elements in the periodic table, so it is usually found only in compounds. It is soft enough to be cut with a knife, and it is the second least dense element.

Types and History of Discovery

The rare earth metals (REM) category includes 15 chemical elements. In the Mendeleev table, they are numbered from 57 to 71. While similar in their chemical characteristics, these rare earth elements are also distinctly unique. Each is characterized by its own technological features.

The rare earth elements have 2 families: ytterbium and cerium:

- Ytterbium family: Tulium, Holmium, Ytterbium, Gadolinium, Disprosium, Terbium, Erbium, Lutetium.

- The Cerium group includes: Samarium, Neodymium, Lanthanum, Europium, Cerium, Promethium, Praseodymium

This division is made on the basis of how the selected components dissolve in salts of sulfuric acids.

A little later the elements were added to the list: Yttrium, Scandium, Lanthanum, Lutetium. Thus, the list of rare earth group metals consists of 16 elements.

Rare earth metals have a long history of discovery. The first study of “yttrium earths” was conducted by Professor of Chemistry Gandolin in the 1790s. He used a mineral found in the mountains of Sweden as his object of study. This type of rock formation was later named in its Honor. Gandolinite.

In the 1840s, Mosander isolated cerium oxide. Five years later, he also obtained the terbium and erbium earths, using the gandolinite that we already know. Promethium was the last of the rare earth family to be discovered. It was researched by Marinsky and Glendenin, who used fragments of uranium fission in a nuclear reactor for their experiments.

Discovery of the rare earth group of metals did not end until the mid-20th century, but effective industrial methods of separating them are still being developed.

The most valuable and expensive of the rare earth group list are:

Rare Earth Metals Distribution

The total amount by mass of rare earth elements in the Earth’s interior is 0.01%, which is relatively large. This is more than titanium and lead combined. The most common REMs are cerium, neodymium, and lanthanum.

The least common rare earth metal is europium. It makes up 0.0012% of the Earth’s mass, which is comparable to such an element as mercury.

At present, about 240 minerals, the chemical composition of which includes rare-earth metals, have been discovered. Sixty-two of these minerals have a combined REM content of up to 10%. They are, by nature, various fluorides, silicates, and phosphates. Despite the large number of minerals, only some of them are suitable for production. These are mainly monazite, bastnaesite, apatite, and euksenite.

The percentage of the ratio between individual rare earth metals in rock formations is quite variable. Monazite and bastnaesite contain mostly elements of the cerium subgroup; the apatites contain mostly monazite and bastnaesite. yttrium.

Mining

The main REM deposits are in what is now China, the United States, and Russia. According to expert data, REM reserves worldwide are in the order of 120 million ounces. tons. It is worth noting that China accounts for half of this mass.

Some scientists claim that the ocean floor is teeming with rare-earth-based minerals. They estimate that there are about 130 billion. tons of their reserves. It is not yet clear how accurate their assumption is. Production at this stage of development does not have equipment that can work at such depths.

Getting

There are several options for processing minerals:

The products of these reactions are various types of chlorides, oxides and sulfates, which serve as starting materials for obtaining pure rare earth metals. For this purpose, methods of chemical reduction with calcium, magnesium and potassium are used. This involves precipitation, ion exchange and fractional crystallization. Distillation and vacuum melting are used for purification of rare earth metals from impurities.

Peculiarities of obtaining rare earth metals

Pure extraction of rare earth metals from the earth is not possible. This is due to their high chemical activity. Under natural conditions, they form multi-atomic complex compounds that make up the rocks. Currently, we know about 250 minerals containing rare-earth elements. And no more than 60 of them are of commercial interest. The rest have a pure metal content of less than 5%, and their processing is not profitable.

Metals of the rare-earth group occur very often in the same deposit. Therefore, when raw materials arrive at a rare earth plant, the first thing to do is to examine the percentage of different elements in the mineral. The results will help to determine which processing to subject the raw material to the maximum economic benefit.

Obtaining rare earth metals is divided into several stages. First of all, complex compounds are decomposed into component parts. Thermal decomposition reactions are used for this purpose. They allow for the isolation of dichatomic metal compounds that are subjected to further processing. The most common application is the reduction of chloride or fluoride with the more active metal (calcium, sodium, lithium). Also used in electrolysis, ion chromatography, or extraction.

Rare earth metals are used in many industries. Oxides of lanthanum, cerium, praseodymium and neodymium are used in glassmaking to make glass more transparent. The metals in this group are also used to produce heat-resistant and acid-resistant glass. Rare earth elements are part of pigments used in the paint industry. Lanthanum is used in automotive applications to produce batteries for hybrid cars.

In the military, substances are used to make explosives. Neodymium, samarium, yttrium, europium and erbium alloys are used to produce high-power permanent magnets.Rare earth elements are added as additives to certain types of alloys to give them the properties they need. These metals in particular make the material heat resistant and more resistant to corrosion. In their pure form they are practically not used because of their high cost.

Rare Earth Metals

The group of rare-earth elements (REE) includes a family of 14 elements with numbers from 58 (cerium) to 71 (lutetium), located in the 6th period of D. И.Mendeleev’s group of elements after lanthanum and similar to it in properties. Therefore, lanthanum is usually included in this group, and the elements are called lanthanides Ln (t. е. similar to lanthanum). In addition, the lanthanides are joined by chemical anologues of lanthanum. Group 3 elements scandium and yttrium. The latter are closer in properties to the lanthanides than scandium, and usually accompany them in minerals[9]. The lanthanides are similar to each other in their physical and chemical properties. This is due to the peculiarities of the structure of their electron shells: as the charge of the nucleus (increasing the serial number), the structure of the two outer electron levels of the lanthanoid atoms is the same, since the transition from one element to another is filled with electrons deepest electron level 4/ (Table 3).9). The maximum possible number of electrons on the /-level, which is 14, defines the number of elements in the lanthanide family.

In the normal state, the lanthanoid atoms (except for gadolinium and lutetium) have no electrons in the M-shell (see Fig. 1). table.9). However, the transfer of an electron from the 4/ level to the 5d level requires a small expenditure of energy. The characteristic lanthanide family oxidation state (3) is due to the transfer of one electron from the 4/-level to the SD-level. In this case two outer shell 6s electrons and one shell 5d electron participate in valence bonds. In some lanthanides, in addition to the oxidation state 3, the oxidation states 4 or 2 are also observed. These “anomalous” valences are explained by differences in the bonding strength of electrons on the 4/level, depending on their number.

The bonding strength of electrons increases as the 4/-level is filled by half (up to seven electrons) or when it is completely filled to 14 electrons. Therefore, the most stable configuration of the 4/-level is characterized by gadolescal atoms for trimmer and lutetium. Degree of oxidation 4 is evident in cerne and praseodymium (the first /-electrons easily pass to the Srf-level) and in terbium n dysprosium, following gadolinium. Oxidation degree 2 is observed for samarium, europium, and ytterbium, t. е. elements with a number of electrons on /-level, close to 7 or 14.

Lanthanides (rare earth elements) are subdivided into two subgroups: cerium [(La), Се, Pr, Nd, Pm, Sm, Eu] and yttrium [Gd, Tb, Dy, Ho, Er, Tu. Yb, Lu, (Y)]. This division was firstly based on difference in solubility of double sulfates formed by lanthanides with sodium or potassium sulfates. Subsequently was established a periodicity in the change of some properties within the family of lanthanides, corresponding to their division into two subgroups.

Thus, we observe approximately similar changes in the stability of the valence states in both subgroups, as well as in the coloration of the ions: the coloration of the solutions of the three-charged ions of the first seven elements is close to that of the next seven ions in reverse order (Table. 9). The change in the magnetic properties of the three-charged ions also has a periodic nature.

In contrast to the above properties, some properties of the elements change continuously. Thus, as the order number increases, the radii of atoms and ions continuously decrease (cf. tabl. 9). This phenomenon, called the “lanthanide contraction,” explains the gradual decrease in the basicity of elements from cerium to lutetium, and explains the difference in solubility of lanthanide salts and stability of their complex compounds.

Brief information on the history of lanthanides discovery

The history of the discovery of REE is complicated. At first mixtures of lanthanide oxides (“earths”), isolated from minerals, were considered as one element. The first “yttrium earths” were discovered by the Finnish chemist Gadoln in 1794. In a mineral found in Sweden (near Itterby), later called gadolinite. A few years later, in 1803, the history of the discovery of REE. The German Klaproth and at the same time the Swede Berzelnus isolated a new “cerite earth” from the “heavy stone bastnaise. For a long time, the yttrium and cerium earths were considered identical. Subsequently, during 100 years all lanthanides except element with order number 61 were discovered and isolated from yttrium and cerium grounds. The latter, which turned out to be radioactive, was not obtained until 1947. Marinsky et al. from uranium fission fragments in a nuclear reactor and called by them prometium.

Although the discovery of the lanthanides was completed by the early 20th., Many of them have not been isolated in a sufficiently pure form and have been little studied. In the 1950s, efficient industrial methods of separating the lanthanides were developed. Nowadays all lanthanides are produced not only as pure compounds, but also as pure metals.

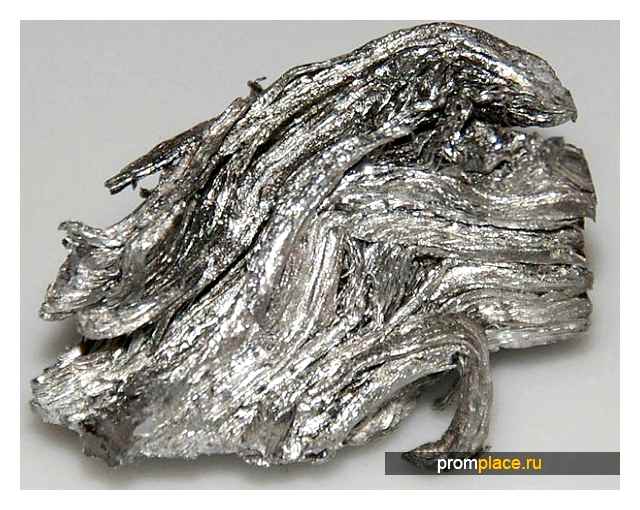

Lanthanides. Silver-white metals. Some of them are slightly yellowish in color (e.g., praseodymium and neodymium).

Melting points of cernium subgroup elements are lower than those of yttrium subgroup elements. It is noteworthy that samarium, europium, and ytterbium, which exhibit valence 2, have significantly lower boiling points than the other lanthanides. High thermal neutron capture cross sections for gadolinium, samarium, and europium should be noted (Table 3). 10).

High purity lanthanides are ductile and easy to deform (forging, rolling). The mechanical properties strongly depend on the amount of impurities, especially elements such as oxygen, sulfur, nitrogen, and carbon. The values of the time resistance and modulus of elasticity of the yttrium metals (with the exception of ytterbium) are higher than those of the cerium metals.

All lanthanides and lanthanum are paramagnetic, some of them (gadolinium, dysprosium, holmium) exhibit ferromagnetic properties. a-lanthanum goes into superconductivity at 4.9 K, /3-lanthanum. at 5.85 K. Other lanthanides do not exhibit superconductivity, even at temperatures below a tenth of a degree Kelvin.

Lanthanides are chemically active. They form strong oxides, halides, sulfides, react with hydrogen, carbon, hydrocarbons, carbon oxide and dioxide, nitrogen, phosphorus. The metals decompose water (slowly in cold, more rapidly when heated) and are readily soluble in hydrochloric, sulfuric and nitric acids. At temperatures above 180. Lanthanide oxides are rapidly oxidized at 200°C in air, resulting in an oxidation rate of 200°C.

Lanthanide oxides are chemically robust and melt at high temperatures. For example, Се02 melts at about 2500 °C, La203. above 2000 ° C.

Lanthanide hydroxides 1m(OH)n have a basic character and are sparingly soluble in water and alkali. Accordingly to the reduction of basicity in a number of lanthanides from cerium to lutetium the pH of beginning of hydroxides sedimentation decreases from 7.82 for cerium to 6.82 for lutetium.

Rare earth metals

The group of rare-earth elements (REE) includes a family of 14 elements with numbers ranging from 58 (cerium) to 71 (lutetium), arranged in period VI of D. И.The group of rare-earth elements which follow the Mendeleev’s one after lanthanum and are similar to it in their properties. Therefore, lanthanum is usually included in this group, and the elements are called lanthanoid Ln (t. е. similar to lanthanum). In addition, the lanthanides are joined by chemical anologues of lanthanum. Group 3 elements scandium and yttrium. The latter is closer in properties to the lanthanides than scandium, and usually accompanies them in minerals[9]. Lanthanides are similar to each other in physicochemical properties. This is due to the peculiarities of the structure of their electron shells: as the charge of the nucleus (increasing the serial number), the structure of the two outer electron levels in the lanthanoid atoms are the same, since the transition from one element to another is filled with electrons deep lying electronic level 4 / (Table 9).9). The maximum possible number of electrons on the /-level, equal to 14, defines the number of elements of the lanthanoid family.

In the normal state, lanthanoid atoms (except gadolinium and lutetium) have no electrons on the M-shell (see. Table.9). However, the transition of an electron from level 4/ to level 5d requires a small expenditure of energy. Typical for the family of lanthanides the degree of oxidation (3) is due to the transition of one electron from the 4/-level to the SD-level. In this case the valence bonds involve two outer electrons of the 6s shell and one electron of the 5d shell. Some lanthanides have, in addition to oxidation degree 3, also oxidation degrees 4 or 2. These “anomalous” valences are due to differences in the bonding strength of the electrons on the 4/-level, depending on their number.

The bonding strength of the electrons increases as the 4/-level is filled to half (up to seven electrons) or when it is filled completely with up to 14 electrons. Therefore the most stable configuration of the 4/-level is characteristic of the gadolescal atoms for trimmer and lutetium. The degree of oxidation 4 is evident in cerne and praseodymium (the first /-electrons transfer readily to the Srf-level) and in terbium and dysprosium following gadolinium. Oxidation degree 2 is observed for samarium, europium, and ytterbium, t. е. In the elements with a number of electrons on /-level, close to 7 or 14.

Lanthanides (rare earth elements) are divided into two subgroups: cerium [(La), Се, Pr, Nd, Pm, Sm, Eu] and yttrium [Gd, Tb, Dy, Ho, Er, Tu. Yb, Lu, (Y)]. This division was firstly based on the difference in solubility of double sulfates formed by lanthanides with sodium or potassium sulfates. Later it was established that there is a periodicity in changes of some properties within the family of lanthanides, corresponding to their division into two subgroups.

Thus, we observe approximately similar changes in the stability of the valence states in both subgroups, as well as in the coloration of the ions: the coloration of the solutions of the three-charged ions of the first seven elements is close to that of the next seven ions in the reverse order (tabl. 9). The change in the magnetic properties of the triple-charged ions is also of a periodic nature.

In contrast to the above properties, some properties of the elements change continuously. Thus, as the order number increases, the radii of atoms and ions continuously decrease (cf. Table. 9). This phenomenon, called the “lanthanide compression”, explains the gradual decrease of elemental basicity from cerium to lutetium, and explains the difference in solubility of lanthanide salts and stability of their complex compounds.

A Brief History of the Discovery of the Lanthanides

The history of the discovery of REE is complex. At first, mixtures of lanthanide oxides (“earths”) isolated from minerals were taken as one element. The first “yttrium earths” were discovered by the Finnish chemist Gadoln in 1794. In a mineral found in Sweden (near Itterby), which was later named gadolinite. A few years later, in 1803, the lanthanides were discovered. German Klaproth and at the same time the Swede Berzelnus isolated a new “cerite earth” from the “heavy stone bastnaise. Yttrium and cerium earths had long been considered identical. Subsequently, during 100 years all lanthanides except the element with order number 61 were discovered and isolated from yttrium and cerium lands. The latter, which turned out to be radioactive, was not obtained until 1947. Marinskii et al. from fission fragments of uranium in a nuclear reactor and called by them prometium.

Although the discovery of the lanthanides was completed by the early 20th century, the melting points of the., Many of them were not isolated in a sufficiently pure form and were little investigated. In the 1950s, effective industrial methods of separating the lanthanides were developed. At present all lanthanides are obtained not only as pure compounds, but also as pure metals.

Lantanoids. The metals are silvery-white in color. Some of them are slightly yellowish in color (e.g., praseodymium and neodymium).

The melting points of cernium subgroup elements are lower than those of yttrium subgroup elements. It is noteworthy that samarium, europium and ytterbium, which exhibit valence 2, have much lower boiling points than the other lanthanides. High thermal neutron capture cross-sections of gadolinium, samarium, and europium should be noted (Table 3). 10).

High purity lanthanides are malleable and easily deformed (forging, rolling). Mechanical properties strongly depend on the amount of impurities, especially such elements as oxygen, sulfur, nitrogen, and carbon. The values of the time resistance and modulus of elasticity of the yttrium subgroup metals (except for ytterbium) are higher than those of the cerium subgroup metals.

All lanthanides and lanthanum are paramagnetic, some of them (gadolinium, dysprosium, holmium) exhibit ferromagnetic properties. a-lantane transitions to superconductivity state at 4.9 K, /3-lantane. at 5.85 K. Superconductivity in other lanthanides has not been detected even at temperatures below a tenth of a degree Kelvin.

The lanthanides are highly reactive. They form strong oxides, halides, sulfides, react with hydrogen, carbon, hydrocarbons, carbon oxide and dioxide, nitrogen, phosphorus. The metals decompose water (slowly in cold, faster when heated) and are readily soluble in hydrochloric, sulfuric and nitric acids. At temperatures above 180. At 200°C, the metals quickly oxidize in the air.

Lanthanide oxides are chemically robust and melt at high temperatures. For example, Се02 melts at about 2500 °С, La203. above 2000 °C.

Lanthanide hydroxides 1m(OH)n have a basic nature and are slightly soluble in water and alkali. According to the decrease in basicity in a number of lanthanides from cerium to lutetium, the pH of the beginning of precipitation of hydroxides decreases from 7.82 for cerium to 6.82 for lutetium.

Rare earth elements and minerals list

Rare earths are important and most expensive components of magnetic, optical and electronic devices produced in military and aerospace industries: drones, guided missiles, laser guided satellite communication devices, etc.д. They are called “vitamins of industry”. After all, these metals are used in the most important materials and processes, albeit in small amounts.

The IUPAC (International Union of Applied and Theoretical Chemistry) Green Book, provides a list of 17 rare earth metals. These:

Industry uses common acronyms for rare earth elements:

Where are found in the periodic system

Rare earth elements, translated rare earth elements

7-71: lanthanum to lutetium, plus yttrium, 9, scandium, 1

Light rare earth elements, translated as light rare earth elements

7-62, ranging from lanthanum to samarium

Heavy rare earth elements

3-71: ranging from europium to lutetium, plus yttrium

These elements were lumped into one group because of similar characteristics. They form simple substances with the following properties

- Silver or gray, with a strong metallic luster;

- malleable and soft;

- Active, especially at elevated temperatures or in fine grinding.

Rare earth metals have certain differences, so they are used for different purposes. Here is a brief description.

Valuable properties of the metal and its compounds

Refractory, increases strength of materials, enhances luminescence

Increases the heat resistance and durability of materials, improves the quality of luminescence

Accelerates cracking of oil, increases plasticity, heat resistance and chemical stability of materials

Enhances conductivity and plasticity of metals, gives a pinkish glass color, catalyst

Improves properties of superconductors and alloys, gives pale green color to glass, used in lasers and for production of pigments

Improves the quality of glass and alloys, dissolves plutonium, increases contrast, used in magnets, lasers and emitters

Capable of luminescence, used in atomic batteries, reactor rods, for air ionization

Improves properties of rods for nuclear reactors, magnets, infrared-absorbing glass, fire-resistant materials

Improves quality of microchips, memory cards, superconductors, alloys and ceramics

Strong paramagnetic properties for ultra-low temperatures, used in semiconductors and X-ray machines

Necessary for superstrong magnets and ultrasonic emitters, catalyst of oxidation reactions

Increases plasticity and magnetic properties of materials, catalyst in petrochemistry, for obtaining red phosphors

Gives superconducting properties to magnets, uses in lasers, activates phosphors

Improves the quality of optical fiber, magnetic alloys, glass, special ceramics

Used in lasers, magnetic carriers, defectoscopy, diagnostic devices

Improves thermoelectric and magnetic properties of materials, provides lightness of semiconductors

Increases power of magnets, superconductivity, heat resistance

But in terms of mining, they are really rare-earth. Because they are not often found in concentrated and economical form.

How rare metals differ from rare earths

In addition to rare earths, there is another group of rare metals. There are 18 of them in total, including 4 such metals that can be produced as concentrates after enrichment: beryllium, niobium, lithium, tantalum. The other 14 are called by-product microcomponents, or scattered rare metals.

Rare metals vary widely in production and applications.

Approximately how many tons are produced in the world each year

In carbide form for construction, abrasives, alloys in nuclear reactors

Glass, castings, ceramics, batteries for electric cars, drugs

Alloys with lead and other metals, for the production of medicines

Glass, pigments, photocopiers, drugs, fertilizers, solar cells

Pyrotechnics, superconductors, prosthetics, dental implants, crockery, cubic zirconia

Capacitors for electronics, alloys for aircraft turbines, medical implants

Liquid crystal displays, touch and flat screens, smartphones, computers

Nuclear reactors, guidance systems, satellite equipment, X-ray machines, blow molds

Alloys, solar cells, semiconductors

Infrared and fiber optics, solar cells, Japanese PET bottles

Semiconductors, lasers, LEDs, microcircuits, safe substitute for mercury

Heat transfer fluids, electrolytes, measuring equipment

Electric and hybrid cars, metal halide lamps

Airplane engines, rockets, lead-free high-octane gasoline, X-rays, photoflash, tumor treatments

Batteries, rechargeable batteries, corrosion-resistant coatings

Also rare metals include thallium.

Minerals with enough m rare earths to mine are called rare earth minerals. The first such mineral was discovered in a mine near the Swedish village of Itterby. It consists of a mixture of the rare-earth ytterbium, cerium, and other less valuable substances.

The world’s leading sources of REE. the following minerals:

- bastnaesite. lanthanum, yttrium, and cerium are produced from it, Mountain Pass area in California, Bayan Obo in China;

- Monazite is source of cerium, praseodymium, gadolinium; they are mined in Australia, the USA, China, Brazil, Krasnoufimsk (Sverdlovsk region);

- Loparite. mostly cerium-lanthanum, to a lesser extent neodymium and promethium, found in Karelia, the village of Lovozero, in the Baikal region and Tuva;

- lateritic ion-adsorption clays. yields yttrium, dysprosium, gadolinium, neodymium; deposits in China, Madagascar, small deposit in Primorsky Krai.

Rare earth group metals

The Rare Earth group includes the following elements:

- Scandium. 21st element of the Periodic system of elements. Gets its name from the Scandinavian Peninsula where it was first discovered.

- Yttrium. 39th element in the system. It takes its name from a metal deposit in the Swedish village of Itterby. Several more elements of this group later received names, which were somehow connected with the deposit.

- Lanthanum. It is the 57th element, which gets its name from the Greek word for “hidden.

- Cerium. 58th element. Named after Ceres, the Roman goddess of fertility and crops.

- Praseodymium. 59th element. Contains green light in its spectral analysis, due to which it got its Latin name “green twin. Was part of didyme together with neodymium, hence the name “twin.

- Neodymium. 60th element, which has the Latin name “new twin”.

- Promethium. Element 61, named in honor of the ancient Greek hero Prometheus, who gave fire to mankind. This element was isolated during the artificial fission of uranium.

- Samarium. 62nd element. Isolated from the mineral Samarxit, hence its name.

- Europium. 63rd element. Named in Honor by the Goddess of Europe.

- Gadolinium. 64th element. Its name is connected with the scientist Johan Gadolin, the discoverer of the rare-earth metal group.

- Terbium. 65th element, which got its name from the name of the deposit where it was first found. Itterby, which is located in Sweden.

- Dysprosium. 66th element, which in Latin is called “hard to find.

- Holmium. 67th element, named after the city of Stockholm.

- Erbium. 68th element. It takes its name from the town of Itterby in Sweden.

- Tulium. 69th element, named after the old Scandinavian name.

- Ytterbium. The 70th element, again its name is associated with the Swedish village of Itterby and its deposit.

- Lutetium. 71st element, which is named after Honor the old name of Paris.

Elements beginning with the 57th element are named the metals of the lanthanum series.

History of Rare Earth Discovery

In nature, all rare earth metals exist only in the form of oxides. The oxides had previously been called terra, which means “earth”. Therefore, when pure metals could not immediately be obtained from the oxides, they became known as “rare earths”, that is, rare earths. By doing this, scientists were trying to emphasise their scarcity in nature. What they didn’t know was that most of the rare earth metals were extremely common in the Earth’s crust.

The very discovery of these metals is still shrouded in mystery. It is believed that the priority in this area belongs to the Finn Juhan Gadolinu, who in 1794 in a deposit near the Swedish village of Itterby, first found a mineral, which included he described yttrium. At the same time as Gadolin, two other Swedish chemists also studied rare earth metals. Berzelius and Hisinger. Their discoveries overlapped and intersected. At the time, no metals were ever obtained in their pure form, they were all complex oxides.

Nash, D.И. Mendeleev, creating his work “Fundamentals of Chemistry,” recognized the presence of only six rare-earth metals: yttrium, lanthanum, cerium, erbium, terbium, and didyme, as the elements praseodymium and neodymium were then called. And, even the existence of terbium was put under question by him. By the end of the XIX century, the situation with the rare earth elements has cleared up, and they were assigned a place in the periodic system of elements between barium and tantalum.

Industrial use of rare earth metals

For a long time, the rare-earth metals were considered boring and chemically uninteresting The situation changed radically, when in the 1960s, the technology of separation of pure metals of this group on the basis of uranium isotope separation technologies appeared. Scientists immediately noted the magnetic properties of these elements. At that time, global industrial production was no longer conceivable without transformers, electric generators, motors, and other appliances that used electromagnetic induction.

For a long time, carbon iron and iron-cobalt alloys were the basis for creation of magnetic materials. When technologies of industrial separation of rare-earth materials were developed, the price of many of them fell sharply, and it became possible to use them in the production of magnetic alloys.

In addition, with the development of science, it became possible to artificially grow single crystals of some metals of this group. The properties of some rare earth metals have been discovered: they possess tremendous magnetic energy and can be used to create powerful permanent magnets. These metals themselves can change their dimensions when magnetized. These metals include dysprosium, samarium, gadolinium, and others. Magnetic alloys made of these metals are used in the manufacture of computers and computing equipment. Industrial interest in the properties of rare earth materials to this day remains huge.

Without rare-earth metals, it would be impossible to produce energy-saving light bulbs, hybrid cars, guidance and night vision systems, and unmanned aerial vehicles. These metals are also used in stealth technology.

Reserves of rare earth metals in Russia

In Siberia, in the massif Tomtor, which is located on the border between Yakutia and Krasnoyarsk region, scientists from Novosibirsk discovered one of the world’s largest deposits of rare earth metals, which was subjected to research and development. Many scientists believe that without the industrial development of the deposit Russia will have to forget about the way of improvement and development of innovative technologies.

It is in Tomtor, in a relatively small area can be found rare earth metals worth over a quarter of a trillion dollars. Even if only one of the metals is developed and extracted, the deposit will still be profitable. A kilogram of ore from this deposit is worth more than a kilogram of butter. This is because the rare earth metals that are in it have these magical properties, which are very valuable in high-tech industries. No country can progress without high-tech production, so Russian scientists consider development of the Tomtor deposit a priority for the country. Developed deposit of rare-earth metals in Russia is Levozersky mine in Murmansk region.

In addition to Russia, China, the United States and Kazakhstan have significant reserves of rare earth metals. Development of deposits of rare earth metals is quite a troublesome business. Very often these deposits are contaminated with radioactive thorium and uranium. They are removed by technical acids. It is true that sometimes the leakage of radioactive substances is so significant that the deposits have to be shut down. This happened in the USA, in Montana.

Rating of rare-earth metal values

Most rare earth metals, despite the name, are widely distributed in alumina and granitic rocks. They are widely used in industry and engineering. But there is a small group of these metals, which have a high value due to their small presence in minerals of the Earth’s crust and expensive technologies of their extraction. These metals are components of many precision instruments, and their use is indispensable for the development of modern nanotechnology. That’s why there’s so much interest in these rare earth metals around the world. The list of the most valuable rare earth metals is as follows:

The most expensive of the metals represented is lutetium. Terbium Terbium oxide was first isolated by the Swedish chemist Mosander in 1840. Pure terbium was only obtained at the beginning of the last century by the French scientist Urbain. Terbium is a rare and expensive element and is currently mainly used to study its own properties and applications.

Terbium is isolated from a mixture of rare earth elements by ion chromatography or by extraction. It is a silvery white metal that is resistant to room temperature conditions. Terbium is a unique element with a number of astounding physical properties.

Nowadays the use of terbium is justified in the creation of magnetic alloys, which have the property to change the size, in the production of thermoelectric materials, in laser technology, in electronics as a phosphor, in the design of magnetic refrigerators. Terbium is also used as a high-tech oxidation catalyst, and as a coating on silicon for microelectronics. Neodymium This metal was discovered in 1885 by the Austrian chemist Welsbach. Previously, it had been thought that there was a single element, didymium. But Welsbach succeeded in separating didimium into praseodymium and neodymium.

The value of palladium

Discovered in 1803, palladium is exceptionally silver-white, melts easily, does not tarnish, and does not corrode. The metal is extremely rare in nature, and is mostly mined from nickel, silver, and copper ores. South Africa is considered the largest supplier, but palladium is also mined in small quantities in Russia.

Palladium is one of the rarest metals on earth

Palladium is extensively used in jewelry: it can be mixed with gold to produce what is known as “white gold. Palladium is also used to mint rare coins to commemorate historic dates. The metal is also in demand in medicine, because it is used to make parts for pacemakers and dentures. Palladium is needed in cars to turn harmful substances into harmless chemical compounds.

.

The value of platinum

Many nations did not know of the existence of platinum until the 16th century, but there are nations that have been using this metal from time immemorial. Platinum is found only as an alloy with other metals, but in its pure form it is colored silvery white. It has gained great popularity because of its beautiful appearance and malleability. South Africa, Russia, the United States and Canada are considered the largest suppliers of platinum. It is noteworthy that in the 1800’s Russia had huge reserves of platinum. sources, for example, were found near Ekaterinburg.

Previously Russia was the top producer of platinum

Platinum is used in jewelry industry, and coins are minted from it. It is also widely used in engineering. for example, mirrors for laser equipment are made of it. Demand for platinum is also high, so it is very expensive.

.

Applications and production

The use of rare earth metals is highly specialized, but varied. These elements were used in cell phones, superstrong magnets and therefore motors and generators, some oil refinery catalysts, lasers and in fluorescent bulbs or flat screens, some batteries and in superconductors and other technologies important in modern life. Some rare earth metals are especially useful in energy applications.

Scientists warn that a shortage of rare earth metals, or China’s near monopoly on them, could stifle the transition to renewable energy and other clean technologies.

In the mid-1990s, China consolidated its control over most of the world’s market and production of rare earths in the world. And the last U.S. mine and mill that once dominated the world closed in 2002 because it wasn’t profitable. China began imposing export quotas in 2006 and limited exports to Japan (a major consumer for high-tech miniaturized motors) so world soared. U.S. government agencies issued urgent reports on the rare earth crisis and its threat to national security.

Could China’s control of these critical elements (about 97 percent) block Washington’s ability to produce Tomahawk missiles, F-35 jets, and night vision goggles, as some scientists have warned, not to mention electric vehicles and wind turbines?

Neodymium

Used to create powerful magnets used in loudspeakers and computer hard drives to make them smaller and more efficient. Magnets containing neodymium are also used in environmentally friendly technologies, such as wind turbine manufacturing and hybrid cars.

Lanthanum

This element is used in cameras and telescope lenses. Compounds containing lanthanum are widely used in carbon lighting applications such as studio lighting and film projection.

Cerium

Used in catalytic converters in cars, allowing them to operate at high temperatures and playing a crucial role in chemical reactions in the converter. Lanthanum and cerium are also used in crude oil refining.

Yttrium

Yttrium is used in the process of creating color displays on devices such as television screens.

Praseodymium

Used to create strong metals for use in aircraft engines. Praseodymium is also a component of a special grade of glass used to make canopies to protect welders and glass fabricators.

Gadolinium

Used in X-ray and MRI scanning systems, as well as in television screens. Research is also being conducted into its possible use in developing more efficient refrigeration systems.

Yttrium, terbium, europium

Used in television screens, computers, and other devices that have visual displays because it is used to make materials that emit different colors. Europium is also used to make test rods in nuclear reactors.

Rare Earth Market

The rare earth market is currently in decline, and China plans to limit annual production to 140,000 metric tons starting in 2020 to try to raise again.

Reasons for the drop in rare earth prices

Neodymium is a rare earth element, about as concentrated in the earth’s crust as lead and chromium, but concentrated in high-grade ores. In 1982, General Motors and Sumitomo of Japan discovered that mixing one-fourth of neodymium by weight with three-quarters of iron and boron could make the most powerful family of supermagnets then known, Nd2Fe14B, and that the properties of these magnets could be further improved by adding traces of other rare earth metals. praseodymium plus dysprosium or more expensive terbium.

China, with plenty of all these elements and a preference for added value over exporting raw materials, created a supermagnet industry whose low captured much of the world market and shut out competitors. China is also vigorously pursuing research and development to find further uses for its rare-earth bounty.

Even in 2015, China accounted for more than 80 percent of global rare earth production, now about 70 percent is an unreasonable balance.

Technological solutions to reduce demand

Since 2010, industrialists have warned that the rare earth market with China’s monopoly on super magnet elements could make the growing global shift to electric cars and wind turbines impossible. because their motors and generators supposedly required super magnets and, therefore, those elements. Some such reports were even in 2017. But this is all being questioned. Anything that makes such rotating machines with permanent magnets can also be made or better by two other types of motors that do not have magnets.

Now engines use modern control software and power electronics made of silicon, the most common solid element on Earth.

The first kind is the asynchronous motor, invented by Nikola Tesla 130 years ago and used in every Prius and Tesla electric car today. Magnetless motors are made not only in electric cars, but also in wind turbines, which frees up tons of neodymium. Just because some wind turbines and manufacturers use permanent magnet generators doesn’t mean others should make them as well.

Similarly, the red phosphors in compact fluorescent bulbs have traditionally used europium. But these bulbs are now largely superseded by white LEDs, which use about 96 percent less europium. In addition, the new red phosphors do not use rare-earth metals, while the latest green phosphor reduces terbium use by more than 90 percent.

Erbium in fiber optic repeaters is another rare-earth element. Erbium is needed to increase fiber capacity. Bandwidth is now increased by multiview transmission and wireless rationalizations.

Some hybrid cars, such as the 2001 Honda Insight, used nickel-metal hydride batteries containing lanthanum, but these have now been largely replaced by lighter lithium batteries, which generally do not use lanthanum. In addition, electric cars with lithium batteries require two to three times fewer batteries in terms of mass and dimensions.

The market-leading electric car lithium batteries in the world, like their motors, do not use rare metals at all. The number of electric cars in the world is growing. New technologies are emerging in the form of powerful potential battery substitutes (notably graphene supercapacitors).