Advantages of the Partner 350 chainsaw

- economical engine;

- two-circuit air cleaning system CCS;

- electronic ignition;

- manual fuel pump;

- emergency brake of the saw headset;

- high quality cutting part from the Oregon brand;

- automatic chain lubrication.

Chainsaw Partner 350 S Malfunctions and their elimination. Chainsaw Partner 350: characteristics and features

Chainsaw setting “Partner” 350

According to the operating instructions, before starting the Partner 350 chainsaw, it undergoes special training, which includes:

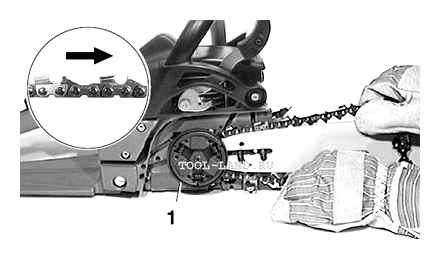

- installing a saw headset or checking its tension for already installed parts;

- checking the serviceability of the brake band;

- putting the brake lever in a ready state as shown in the figure;

- filling the oiler and gas tank with fuels and lubricants. The fuel mixture is prepared in a ratio of 1:50 from oil for 2-stroke engines and unleaded AI-92 gasoline.

The launch is carried out on a flat surface, sharply pulling the throttle cable. With a cold start, open the air damper and allow the chainsaw to warm up. Only after that you can gain momentum and move on to woodworking.

All possible nuances of adjusting the Partner 350 chainsaw with your own hands are detailed in the operating instructions. If they are not observed, the tool is not insured against malfunctions and repairs, the budget of which can be unpredictable.

Chainsaw Partner 350 Malfunctions and their elimination. Chainsaw “Partner” 350: device, characteristics, DIY repair

Chainsaw “Partner” 350. a productive and reliable chainsaw from the “Partner” brand. This manufacturer is part of the group of companies of the Danish concern “Husqvarna”, which significantly influenced the quality and functionality of the equipment it produces.

Easy to operate and convenient, this chainsaw will come in handy for summer residents and gardeners. And the light weight and compactness do not create restrictions for the transportation of the tool.

carburetor adjustment

For installation, it is advisable to have a universal key and a tachometer (crankshaft rotation counter) at hand. Carburetor installation and ignition adjustment are carried out at the Partner plant. Therefore, a completely new saw does not need to be readjusted.

Chainsaw Partner 350 Malfunctions and their elimination of the carburetor. DIY Partner 350 carburetor tuning

Before starting adjustment work, it is necessary to clean the main fuel unit from dust and dirt. To do this, you can use a compressor with compressed air or a carpenter’s broom.

To adjust the carburetor, holes are provided on the left side of the power unit, however, for the convenience of determining their position, experts recommend dismantling the protective plastic casing. First, tighten the screws of the fuel quantity and quality until the stop clockwise, loosening them after 1/5 ¼ turn.

Chainsaw carburetor Partner 350 with adjustment screws

Husqvarna 350 Chainsaw Oiler Step by Step Repair Instructions

When the cover is removed, you need to know that the screw for the quality of the fuel mixture is on the right and, accordingly, the screw for adjusting the amount of gasoline is on the left. For convenience, the carburetor body is marked under the bolts:

- “L”. screw for the amount of fuel (adjustment at low speed);

- “H”. screw for the amount of mixture (setting at maximum speed);

- “T”. idle speed adjustment bolt.

It must be remembered that the adjustment of the carburetor of the Partner 350 chainsaw must be carried out on a warm engine. At high temperatures, the metal expands linearly, as a result of which the throughput of the channels increases.

As soon as the cylinder becomes warm, turn the screw “L” until the internal combustion engine produces the maximum crankshaft speed. Then we twist it a quarter of a turn.

It is worth noting that in this position, the screw for the amount of mixture supply should maintain the engine at idle. If such a setting is not enough, then boldly unscrew the bolt “T” until the engine runs stable.

Using the screw “H” we correct the work of the Partner chainsaw at maximum speed.

Replacing the oil pump on the Partner 351. The pump does not fill the chain with oil.

Oil supply system malfunctions

The situation when chain lubricant spontaneously flows out of the chainsaw body and does not reach the cutting parts indicates that it is not necessary to repair the oil pump, clean the oil supply pipes or replace them with serviceable spare parts. In addition, grease drips can indicate a depressurization of the connection between the pipes and the oil sump. If these breakdowns are not eliminated in time, the chain will begin to overheat, stretch out and prematurely fail.

Do-it-yourself repair of the Partner 350 chainsaw should be performed only by people who understand its structure and operating principle. Only in this case can one hope that the replacement of the drive sprocket or crankshaft will be performed correctly and safely for further work.

Repair of the Partner 340 chainsaw. Repair and maintenance of the Partner P340S chainsaw

I decided to work with a Partner 340 s chainsaw. About 20 days, 7-8 hours a day. The frosts were severe. There are no complaints about the cranking and the engine, but the chain lubrication has disappeared. What to do It is very likely that if the oil was thick, the oil pump drive was ripped off. It should be, as it were, a weak point in the drive, just in case. or a worm, or a gear on the plunger, but to such an extent weak is not good to do. It is necessary to remove the clutch, remove the pump and watch. Or to the service. On the 3rd day of operation, the gear mechanism failed, that is, the motor is running, and the chain does not spin as at idle. What’s the problem? Some kind of gear flew? Saw Partner P340S, sawed wood. He took off the box, there is a drum, under which an asterisk, dangles. Maybe a marriage? I twist the chain by hand, the sprocket rotates, it is not movable inside, the drum itself is also not movable. When assembled and wound up and the brake is raised, the chain does not rotate either at low throttle or at full throttle, there is no clutch, which means that the sprocket is sealed off from the drum. Surely a factory defect, only the leading sprocket is attributed by manufacturers to a consumption, many even clearly indicate this in the saw’s passport. This is a problem with the P340S model. I press the gas and it happens that the failure goes, as if the mixture is not enough, but the tank is full. The mixture was made 40: 1, oil 2t, turn active Partner, rosy, gasoline 92y. The saw is new. I saw the board at low revs and it may stall. And the oil flows from the chain when it just stands idle. The carburetor is most likely not adjusted. Tell me about the Partner 340 S saw. It stopped starting at all. In operation a little more than 2 years. At first it began to start up intermittently, but every time it started up. Now you can’t start it at all. as much as possible, pull the handle, start the engine for a couple of seconds and immediately stall, after which it will not start. I changed the candle. there was almost no difference (the old spark was noticeably worse), except that she began to grasp at least for the first time. After pulling the handle of the plant several times, the candle becomes damp, after drying it is possible to start it only for 1-2 seconds, after which it fills the candle again. I tried to blow through the carburetor. no change. What else can you see? Start by removing the muffler. It’s simple enough there. At the outlet, inspect the condition of the piston. If you see longitudinal grooves, that’s it. replacement piston.

First warnings during repair

A chainsaw has many parts. Let’s highlight the main ones, such as:

- engine;

- fuel tank;

- ignition cable.

Since this is only a small part in a not very detailed description, it should be borne in mind that chainsaws are almost identical in structure, which greatly simplifies their diagnosis and repair. Repair can be greatly complicated by the fact that you do not contact the master in time and continue to operate the broken equipment further. And it is absolutely true that in order to repair the chainsaw, it is best to contact the master, because the future “life” of your “irreplaceable partner” at work depends on the repair.

So, when carrying out repairs, the master must check all the parts of the chainsaw, for which it is disassembled into parts. Most often, breakdowns appear from improper and careless operation of the device, therefore the fuel filter or breather is often clogged with sawdust. To diagnose the blockage, the master disconnects the hose and checks how the fuel is flowing.

There may also be insufficient fuel supplies. This is due to the clogging of the air filter, so it should be changed every three months.

One of the important elements of a chainsaw is the spark plug, which must also be checked. Interesting causes of the malfunction are possible here:

- dry candle;

- candle in oil;

- the candle can be shrouded in black carbon.

If the spark plug is dry, it means that no fuel enters the cylinder, and this, in turn, means that everything is in order with the ignition and the repairmen are looking for another problem. If the candle, on the contrary, is in oil, it means that there is an excess of fuel. In this case, it is necessary to unscrew the candle and wipe it well, and then put it back again. The black carbon on the candle means that the owner of the chainsaw mixed gasoline and oil in the wrong proportions during its use. Be sure to check for a spark.

As we can see, the repair is still not so simple and we still have a lot ahead of us. The process of restoring the working capacity of the chainsaw also includes some cleaning processes for the elements of this device, such as a muffler. Let’s analyze this operation step by step. To begin with, as in any repair, we need to find this part of our device, remove it and disassemble it. If there is a lot of carbon on it, then we need to clean it, and for this we need:

- an ordinary rag;

- detergent;

- water.

These items can be found in any home. We clean our muffler from carbon deposits, after which it is important to dry it well, so that the repair does not go in vain and, of course, put it back in place.

Dry cleaning the muffler is too dangerous for health, the soot contains a lot of carcinogen, which can be accidentally inhaled!

Troubleshooting on the example of the “Partner 350” chainsaw

In the modern world, one cannot very often imagine working without a chainsaw. This wonderful tool, achieved by the development of civilization in many different fields, is applied. She serves as a good helper for the gardener, carpenter, builder.

Chainsaw not oiling, check this first. Easy fix.

Chainsaw type classification

Chainsaws are divided into several categories. The very first one is household chainsaws, they are needed for not particularly difficult work, since they are low-powered, but they are compact and convenient. Almost every manufacturer has household saws, because they are in demand. Semi-professional saws have a more serious gauge. With their help, you can safely cut logs and carry out construction. Professional saws are the most powerful machines, they have tremendous power and can work with them for up to eight hours in a row.!

Recommendations in case of breakdown

Unfortunately, nowadays nothing is eternal, and therefore our “good helper”. the chainsaw is no exception. In this short article, we would like to consider an example of a breakdown on a Partner 350 chainsaw. This type of gasoline-powered tool is very easy to operate, has good quality and can suit many for the price. This wonderful chainsaw has a 1.8 horsepower engine. It perfectly helps with housework, has a low noise level and is not particularly large in size. But even such a saw sometimes needs repair.

So, what to do if suddenly your chainsaw breaks down. Most often, people try to find information on the Internet. To do this, it is enough to drive into the search line “repair of chainsaw“ Partner 350 ”. And you probably already did so.

First, let’s try to determine what is wrong with our saw. It may not start, or it may start and immediately stall, and the chainsaw may simply lose its power. Yes, without skills and experience it will definitely be difficult for you to do something here, but if you read this article, then with due diligence you will succeed.

The chain is an important piece of equipment of this type.

The chain plays a very important role in a chainsaw, because it is she who cuts wood. It is made of special steel. Chains come in different sizes and pitches. Although the chain is made of special metal alloys, sooner or later it becomes dull. How can we understand when the chain is dull? Most often, the user of the chainsaw notices that the chain is dull at the wrong time. This leads to poor performance and shortens the life of the chainsaw. The first signs of dullness are excessive vibration. Next, you can pay attention to too slow cutting. In fact, you can even elementarily just look at the saw teeth and from them you can easily determine that it is dull.

For our chain to work again, it needs to be sharpened. Sharpening can be done with a file; there are also special machines that make sharpening better and easier. After the sharpening process, blow the chain with air and put it in oil. This is not a very straightforward process as sharpening must be done at the correct angle. The biggest mistake inexperienced exploiters make is sharpening their chainsaw too deeply. This sharpening too deep is the root cause of the deterioration of the link strength.

It is important when carrying out repairs to check how well the chain lubrication and brake are working. The very first sign of improper operation of the lubrication system is oil leaks, they can appear due to the fact that the connection of the pipes along which the lubricant moves is not tight or damaged. This is corrected by the banal elimination of the crack or by replacing the channel. If not enough oil is supplied, then this means that the pipes are clogged.

Price range and guarantee of repair in workshops

If you have a chainsaw, it is always worth carrying spare parts with you so that you can carry out repairs on site if necessary. Amateurs should never try to repair the chainsaw themselves. Improper repairs can lead to more complex damage. There are many services for repairs. try to contact them. The repair is carried out within a certain time frame. In good firms, minor repairs are carried out in just two to three days, and if the breakdown is serious, you will have to wait about a week. When choosing such a service, always pay attention to the warranty. It should be both for the parts themselves and for work!

(or around this).