How to tell if a chain needs sharpening?

It is quite simple to determine whether the chain is worn out. if its tension has dropped, it seems to be “stretched”, then it must be returned for repair as soon as possible. Effective and quality sawing is only possible with a sharpened chain. Sometimes it plays a much more important role than even engine power, which means you should not neglect this issue.

There are also a number of other ways that will easily help you understand that it is time to pay attention to sharpening the chainsaw chain:

- sawing becomes slower;

- the tire takes away in different directions;

- after sawing, a lot of dust remains, and the sawdust themselves look like needles from a hand saw. If the chain is still in good condition, then the sawdust will be square in shape, and the chips will be homogeneous.

Chainsaw sharpening in Minsk

Regardless of how high-quality tool you use, sooner or later it will need a fine and professional sharpening. Chainsaw sharpening from pilka.by. guarantee of the highest quality and durability of your tool. After the procedure, its performance will increase, which will have a positive effect on fuel consumption.

What is chain sharpening for??

This procedure significantly extends the service life of an expensive tool.

If we turn to statistics, regular and timely sharpening extends the durability of the chain by 40-50%, and the chainsaw will cut wood more accurately.

It is recommended that such service be performed regularly. Needless to say, repairing and buying a new chain. expensive, so it’s better to spend money on preventive maintenance.

Our advantages

The use of a file by non-professionals promises an uneven sharpening. This is due to the structure of the tool, which does not allow evenly processing each tooth at the required angle. That is why we recommend entrusting the work to our professionals.

How chainsaw chains are sharpened?

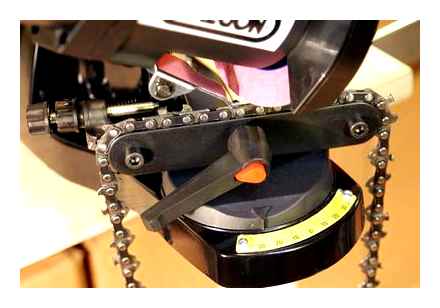

Since chainsaw teeth are made of carbide, diamond wheels are used for sharpening. Professional equipment allows you to sharpen all chain elements evenly, removing the minimum possible metal layer from them. The quality here is determined by the equipment used. Why is it better. the thinner the layer will be removed from the metal with each sharpening. Therefore, in our work we use only the most modern machines.

about the technological process of sharpening:

How you can sharpen your saw chain yourself?

What you need to know to sharpen your chain yourself?

How to sharpen a chainsaw on a machine

A chainsaw sharpener is usually used in such cases:

fast and high-quality sharpening of the chain is required for one or several units;

after hitting a working saw on gravel, stones, sand.

Sharpeners are manual and electric.

Electric machines are equipped with a motor that rotates the abrasive wheel. It is not necessary to exert effort to sharpen the teeth, it is enough to fix the chain on the bed at the desired angle and turn on the machine. This sharpening option is usually used in production, it allows you to quickly and conveniently process several chains. The question of how to properly sharpen a chainsaw chain at a power plant will not cause difficulties, because this procedure does not require special technical knowledge from a person.

Hand tools are placed on a chain attached to a bar or attached to a workbench. A file is located at the bottom of the structure, which can be replaced if necessary (round to flat, for example). The teeth are sharpened in two or three movements. Using a manual machine, you can sharpen and straighten the chain and adjust the teeth to the same length.

The services that we provide have long been loved by our regular customers, they value their time and quality of work. If you are not new to using different types of saws, then you know that they need regular checks and diagnostics, as well as neat storage. With careless use, the quality of work and the life of a recently purchased expensive tool decrease. Watch your tool and avoid defects!

Sharpening chains for chainsaws at the address: Moscow, metro Taganskaya, st. Verkhnyaya Radishchevskaya, 5, building 5. (Call, specify how to get through) works for you seven days a week

Self Sharpening Chainsaw

Working hours: seven days a week from 10:00 to 21:00

A heavy load on the chainsaw quickly dulls the chains, it happens that you have to sharpen the chain more than once in one day. Another factor of rapid blunting is the contact of the chain with the ground, even having hooked the ground with the bus several times, you can immediately send the chain to sharpening, it will simply stop cutting wood with high quality.

What tools for sharpening are there

To start work, you need to stock up on tools that are divided into two types.

How to sharpen a chainsaw chain

Tool sharpening training

We provide tool sharpening training in our sharpening center.

We teach to sharpen manicure tools, hairdressing tools, knives of various types.

You can also purchase equipment for sharpening from us.

How to Sharpen Chainsaw Chain. Ozito Tool Tips [PXCCSSS-018]

Sharpening cutters and other complex tools

When sharpening tools, we use various professional equipment

Organization of the workplace of the master sharpener

How to sharpen a chainsaw chain

Any chainsaw needs periodic maintenance: this applies to both internal mechanisms and cutting equipment. The saw chain is the main working element of the saw. The frequency with which it is recommended to sharpen it directly depends on the intensity of use. Correct sharpening of the teeth affects the quality of the cut and the life of the chain.

Any chain, even the most expensive one, will need sharpening after a certain period of time. How can you tell if the edges of the teeth are dull:

by the nature of sawdust: if they are very fine, almost dust, then it’s time to start sharpening;

drop in cutting speed and productivity in general;

This procedure can be carried out at home, since it is not difficult to sharpen the chainsaw yourself. Sharpening work should be done on time. This will save tooth material, effort and time required to complete the job.

How to sharpen a chainsaw chain

Over time, the original consumables on the chainsaw wear out and need to be replaced. But in the case of a chain, different sharpening technologies can be used to extend the life of the parts. The chains are sharpened at home using files, as well as on special machines. There are often recommendations for using an angle grinder for this procedure.

If you have no experience in performing these tasks, you should entrust the procedure to specialists. An experienced craftsman knows how to properly sharpen a chainsaw chain on a machine or other methods. The remanufactured part will serve for a long time and will not require replacement in the near future.

Tooth shape

The sharpening process begins with defining the operating principle of the cutting teeth. Directly the cutting part of the tine cuts the wood layer like a plane, and the depth of cut is controlled by a stop located above.

Hand tools (files and templates) are usually used for sharpening, but the chain can also be machined on the machine.

The element should be sharpened only at a certain angle, this directly affects the performance of the chainsaw.

For efficient cutting, the blades are bent at a certain angle. The back of the tine back creates a clearance angle and allows for easy edge cutting into wood.

The back blade is used for lateral cutting of wood fibers. So it is sharpened at an angle back.

The edge of the upper blade should create a 60 to 85 degree rake angle with respect to the bottom of the tooth.

The upper blade can be tilted 50-60 degrees, depending on the type of saw.

The sharpening angle may vary depending on the type of saw operation. For effective cutting of very dense frozen wood species, an acute angle is required (but not less than 25 degrees!); For soft wood, this parameter must be increased. In addition to cutting quickly, this solution reduces vibration during operation and contributes to a smoother chain run.

The distance between the stop and the top edge should be between 0.5 and 0.8 mm. Increasing this distance due to excessive grinding will result in lower cutting speed, excessive vibration and an increased risk of kickback when cutting. Therefore, it is important to know how to sharpen a chainsaw correctly so that sawing is as easy and productive as possible, and the chain serves properly and for a long time.

Features of the structure of the chain

To effectively be able to sharpen a chainsaw chain, you need to know the structure of its teeth. You cannot do without knowing the sharpening angle. Each tooth has a complex structure. Its geometry is represented by the following components:

- basis;

- spatula;

- depth gauge.

In this case, the blade consists of two blades: end and top. over, between them there must be the correct sharpening angle of the chainsaw chain in order to provide it with the necessary performance.

As you can guess now. the chain does not cut the tree, since it serves as the basis for securing the cutting links, moves them at high speed. The links themselves have sharp blades, with the help of which the wood is cut.

Helpful hints

Some helpful tips will help keep your equipment in good working order and also eliminate the risk of injury. Of course, it is necessary to know the correct sharpening angle of the STIHL chainsaw chain. But timely tire care is also important:

- The chain tension must be monitored. Especially if the chainsaw tilts to one side during operation. Poor tension can be dangerous to humans.

- Sharpen in a timely manner, without putting everything on the back burner. It may be expensive, but it is better to give preference to electrical equipment.

- Lubricate the entire chain regularly, otherwise it may fly off (its speed is about 100 km / h). Everyone will draw conclusions himself.

- Do not use used automotive oil or any product of questionable quality. It is worth choosing only specialized lubricants. As the best remedy. autol.

Before starting to work with the chainsaw, the chain should be run in. Let it run at minimum speed for 40-50 seconds. The lubricant will reach every part, and the chains with a sprocket will heat up a little, rub against each other.

All these expert advice should not be ignored if you want to remain safe and sound.!

Features of the chainsaw

Sawing a tree is like working with a plane. In this case, the size of the cut depends on the thickness of the limiter. When the saw chain is used at high speed, the teeth become dull more quickly. This is clearly manifested when the ground surface appears in the path of the chain. To completely blunt the teeth, it is enough to “catch” on the ground for a couple of seconds.

If you sharpen as often as possible, the chain will last much longer, since very little metal will be removed. In addition to the question of what angle of sharpening the chainsaw chain should be, this should also be known!

Working with a blunt tool is undesirable for a number of reasons. First of all, this is reflected in the quality of the cut, and not for the better. Also, fatigue quickly sets in, which is felt not only in the hands, but also in the body.

Another reason. unjustified excessive consumption of fuel. All parts will work in an enhanced mode, which inevitably leads to their rapid wear. Performance drops dramatically, which also happens when using a defective chain.

What is the correct angle for sharpening chainsaws?

Chainsaw. a necessary tool for household needs, He will find a worthy application in the country. Chainsaw makes it easy to cut wood for a stove or fireplace. She also shows herself well when felling wood. Every owner of such an assistant should know the correct sharpening angle for chainsaw chains. It costs a lot of money to call a specialist at home, and even more so, to the dacha. Therefore, you have to make do on your own.

While it is best to outsource sharpening to a professional, some lumberjacks have learned the craft on their own. If specialists in forestry have to sharpen the chain 3-4 times a day, then the ordinary gardener does not have such a need due to the fact that he rarely uses the tool. How can you master the craft yourself? There are some guidelines for this.

Correct grinding angle values

The angle of sharpening of chainsaws is not a constant value, it does not depend on the manufacturer or model of equipment. It is selected taking into account what kind of tree you have to deal with. You can choose an average value, but the efficiency of the cut may be ineffective. For this reason, it is necessary to choose the correct value, taking into account the specific wood species.

When it comes to hard wood, including those trees that have been “frozen” for a long time, it has a high resistivity. In this regard, the sharpening angle should be reduced. This will virtually eliminate the occurrence of vibrations, and the chain will run more smoothly. The minimum value is 25 °.

For soft types of wood, the sharpening angle can be increased, but not more than 35 °. This will significantly increase productivity. The sharpening angle of the rip saw chain is 10 °. In this case, the cut will be as smooth as possible, and the vibration of the equipment is minimized. Knowing such features, you can proceed to consider different ways of sharpening.

angle grinder is a good alternative

Professional lumberjacks consider this method to be primitive and labor intensive. It is used as a last resort, since the angle grinder cannot be fixed to the template. For this reason, it is very difficult to achieve control over the observance of a constant angle and depth of sharpening.

The tire is securely fixed in a vice to prevent its movement during operation. It is not necessary to attach a new cutting disc to an angle grinder, it is better to use an old disc 1.5-2 mm thick.

It is better for beginners not to use this method at all. they will be more whole. There is a risk of serious injury to yourself. In addition, there is no way to do without the skills of working with such equipment.

How to know when sharpening is needed?

It is possible to determine whether the teeth of the chain are sharpened or not by some characteristic features. Of course, it all depends on how intensively the chainsaw is used. It is worth taking a closer look at what kind of shavings it leaves. Its uniformity and square shape indicate sharp teeth. If the chain is worn off, then it usually leaves behind wood dust, and the sawdust themselves look like needles, which are “produced” by a hand hacksaw.

If the cutting speed is reduced, then this is also considered a sign of a dull chain. An increase in the load on the instrument itself and the appearance of vibration are felt. Beginners may not always be able to notice some of these signs. Therefore, they should pay more attention to the quality of the chips. Sometimes it is brown, which is already guaranteed to indicate that it is time to sharpen the chain.