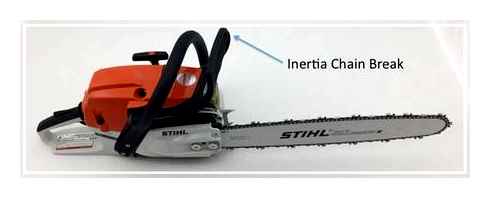

chain saw chain brake device

A chainsaw is one of many types of devices that work with a gasoline engine. The design of a chainsaw is fairly conventional, which ensures its reliability and durability. Instead of a gearbox there is a chain gear with 1 stage, which is driven by a single-cylinder internal combustion engine. These elements form the base of a chainsaw, but apart from them, the structure contains a huge number of devices, without which the functioning of the saw is unreal.

Sketch 1. Adjusting the position of the carburetor float.

Description of chainsaw parts

Two-stroke engines are usually used in chainsaws. They work in combination with the clutch, the flywheel, the ignition system and the bushing to fix the construction. Fuel constantly flushes the crankcase, so lubricant is added specifically to the gasoline, based on the ratio of 1:20. 1:50. In high-end modern models oil drums are used, which join the substances of the automatic. Engine speed can reach 13 thousand rpm, so the oil used in chainsaws must meet stringent requirements. Otherwise, the lubricant will not prevent wear, and contribute to it.

The clutch is centrifugal and engages automatically as soon as the engine reaches the desired speed. Earlier torque elements with friction pads are drawn to the center of the shaft by springs, which prevents the transfer of rotation to the drum. Centrifugal clutches have an important advantage over other clutches: If the chain jams, the saw’s clutch slips. This prevents the accumulation of tension in the motor and the devices that transmit the torque from the motor to the chain.

Ignition system and carburetor

Sketch 2. Chainsaw fuel system.

The contact ignition used in earlier gasoline-powered devices has been replaced by electric ignition. That way, today’s chain saw users don’t have to keep adjusting the contact gap and don’t have to keep cleaning the contacts. The main elements of the ignition system are:

Flywheel generates an electromagnetic field as it rotates, which is converted into electrical signals by means of an electrical circuit. They go to the spark plug and create a spark between the pins, igniting the air-fuel mixture.

High-quality and durable engine operation is impossible without a carburetor. The main purpose of the unit is to prepare the fuel-air mixture for easy start and stable operation of the chainsaw. The design of the chainsaw carburetor is shown in Fig. 1.

Chainsaw brake knob

tormoz-tsepi-sbore.html. Chain brake assembly for Husqvarna 137-142 chain saw. Handle.

Chainsaw brake repair

Chainsaw brake repair. Alpina A 4000 chain saw, chain brake broke, namely, the crimping plate broke.

Where the lower arrow is the air damper drive, the upper arrow is the fuel hose.

Throttle valve is needed to regulate the air content in the mixture. Fine-tune the engine speed by changing the tension of several screws. In order to prevent the carburetor from clogging, it is necessary to clean the air that enters it. An air filter is installed on the top of the machine for this purpose.

Fuel and air systems

The simplest chainsaw has a tank of about 500 ml, a fuel filter (1) and a hose to deliver gasoline to the carburetor

When gasoline is exhausted, the fuel tank is filled with air and a negative pressure zone forms, making it impossible for fuel to flow to the carburetor. To prevent this, a breather valve is installed on the fuel filler cap. If it becomes clogged with dust or dirt, the chain saw stalls.

To make starting the mechanism quick and easy, some models are equipped with a manual pump. In this case the stage of filling the carburetor with fuel takes place beforehand, which helps to speed up the start of the engine and reduce the load on it.

Clean air must be used to create the air-fuel mixture, because harmful impurities can impair engine operation. Fine filter and pre-filter are used to eliminate these impurities.

Pre-filters, usually made up of a mesh diaphragm and a system that prevents snow from getting in. The latter is installed only in sub-zero temperatures, because its installation impairs the flow of air into the carburetor, as a result of which the power of the chainsaw decreases.

Fine dust filters are made of nylon mesh, diffusion foam or similar materials.

Chain and chain feed mechanism

It consists of cutting and driving links as well as connecting elements. All these parts are riveted together. The cutting links are the most technologically advanced and critical links in the chain, because they are subject to heavy wear and abrasion. The hardness of the material on the top face of the tooth must be considerably higher than that of the wood so that the surface of the links does not deteriorate.

Different chainsaw models have different shaped links. The most common are the chipper (a) and the chisel (b)

Chainsaws are usually fitted with cross-cutting chains whose teeth are ground at 30°. Another important chain parameter is its pitch. The greater the number of teeth, the better the cutting performance of the chain. A small pitch requires a large number of teeth, and this has the positive effect of reducing vibration and improving cut finish.

The chain is guided by the chainsaw bar, in the front of which there is a sprocket. Chains are designed differently depending on their intended use, but there are also universal products for domestic use.

Chainsaws use a lubrication system that continuously supplies oil to reduce wear. Every modern chainsaw has an automatic lubrication system which shuts down when the engine is switched off.

How To Replace Chainsaw Chain Guard Clutch Cover On A Husqvarna Chainsaw

Chainsaw chain brake

Even a light touch on an exposed cutting element is enough to cause serious injury. That’s why, for safety reasons, each chain is equipped with a brake to quickly stop the mechanism in the event of a blowback.

How to repair the chain brake

So, how to repair the brake of the driving mechanism. It serves for emergency braking of the saw chain in order to prevent injury to the operator, i.e. the logger. This is one of the safety systems that are designed on the tool. On “horned” analogues of chainsaws this system is unnecessary, which is understandable. In addition to the safety of the operator himself, the chain brake system serves to save the mechanism itself in case of jamming. Brake breakage is a rare occurrence, the causes of failure are infrequent maintenance of the saw, lack of cleaning, wear and tear due to long service life, incompetent use of the tool while sawing.

When this braking system is activated? often than not, the brake is activated automatically on kickback, when the saw operator touches an object (wood) with the toe of the tire, there is, as it were, a sudden obstacle, a bump. in the other hand, the chain brake is released when the guide bar is caught in the cut and the chain saw operator tries to free the saw with jerky movements. Chain stop protection is triggered by the inertia shock. The (operator) can also switch on the chain saw brake himself. manually, using the upper lever (shield), a.k.a. the recoil lever. This is usually needed when the chain keeps turning without throttle, or in the case of a clutch or carburetor malfunction.

How the brake works

Let’s see how the brake works. The construction of the mechanism is simple and unpretentious. This is a purely mechanical process. The starter switch of the brake system is the above mentioned lever (shield), which is a solid element on the upper front surface of the chain saw above the muffler. The screen is located just behind the operator’s hand, almost flush with the cover. But, because we turn the tool while working, the screen may not be behind the hand.

Glide lever without spring in cocked state

The sliding lever without the spring when the trigger is released

The slide lever without spring with the trigger releasedThe slide lever is secured by a return spring at the base of the attachment and by the trigger switch. On impact, rebound of the guide bar, the screen engages-is resting in the sawyer’s hand and then through the chain it engages the trigger, which is interconnected with the screen. In the normal position, the trigger compresses a spring (not to be confused with a return spring), and when triggered, it unclenches it and locks it with a locking latch (detent). The slide lever, which is located inside the spring, in turn tightens the metal strip. A metal band is located around the clutch basket (clutch drum), it tightens (clamps) the drum which stops it turning. Chainsaw chain stops.

Insert screwdriver in the slide lever spring

Press the spring with the palm of your hand so it does not pop out.

Insert the spring with a screwdriver in its seat

Release the brake trigger with the crescent wrench to loosen the metal shackle

But it’s not just the pressure on the screen that sets the brake. In the lower part of the shield (in the place of attachment to the cover) in the body of the lever there is an inertial weight installed which actuates the trigger as a result of the sharp recoil. Braking is automatic due to the centrifugal mass. the saw is in an inclined position (prone) and, in this case, the shield is not behind the arm, but is in the side of the saw. In the case of kickback in the cut, the braking system is also triggered by the mass of inertia.

When and how does the chainsaw brake system malfunction?

As a rule, the metal band that tightens the drum, as it is also called the clamping bracket, breaks. It is either completely torn or rubbed, or one of its strips (in the case of a through tape). It happens because of the wear and tear of the bracket, which, in turn, arises from natural reasons (exhausted resource), as well as from illiterate use of the chain saw by the user.

What it means to use it incorrectly? This is more likely to be due to carelessness on the part of the sawyer. First-time users of imported saws equipped with a brake system and their analogues don’t notice when the brake engages when operating the tool. For example, when trying to pull a jammed tire out of a cut in wood. A sudden movement of the saw causes the braking system to trip, but the inexperienced chain saw user does not notice it. After releasing the saw “from captivity,” the logger is confronted with a surprise. the chain does not rotate when the throttle is applied. Not understanding why the chain doesn’t rotate, he desperately starts turning the chain, kicking and “wiggling” the guide bar against a stump, against a log, against any object. Some “comrades” even remove the cover on the clutch side, pull it out, although the metal band clamps the clutch basket. Then they check it in vain and even somehow manage to put the cover back on. Of course, the bracket already has a defect from this. Apart from that, it is not clear how, but these saw users manage to “excite” the tool and even saw. In that case not only the clamping bracket is damaged, but also the clutch itself. it gets burnt and has a characteristic blue color. Service men often say and show rubbed band and drum with a characteristic groove and a shoulder, saying that the owner of the saw was using the tool with the brake on!

Design and operation of individual assemblies

The individual assemblies of the chainsaw discussed above, in turn, consist of various parts. In order to repair the technique yourself, you should know the construction and operation of the main systems.

The ignition system

Originally, the ignition system of chainsaws was of the contact type. Now it is practically not used. Modern manufacturers equip their equipment with electronic ignition (shown below in disassembled form). Because of this there is no need to regularly clean the contacts and set the necessary distances between them.

The ignition system, thanks to which the formation of a spark during engine starting, consists of such parts:

The following illustration shows the components of the ignition system of a STIHL chain saw.

The magneto is an alternating current electrical generator that supplies voltage to the spark plug. It can be of two types:

Schematics of ignition systems with non-contact and contact magneto types are shown below.

The magneto of any type includes these parts:

The electronic unit usually includes diodes, resistors of different sizes, thyristors, capacitors. The connection diagram depends on the model of the saw.

The ignition works on the following principle:

- rotation of the flywheel with a permanent magnet attached to it induces an electromotive force in the system;

- The current generated in the circuit is converted by the electronic unit into electrical signals;

- these are transmitted to the spark plug;

- a spark is formed between its contacts, which causes ignition of the fuel-air mixture.

the ignition is initially set so that the spark formation occurs when the engine piston does not reach its top dead center by about 3-4 mm. If you look at the crankshaft circumference, it corresponds to an angle of 28 degrees.

The ignition system malfunctions can be visually diagnosed by the condition of the spark plug.

In this way, the presence of the ignition ignites the fuel mixture, which ensures that the motor goes into working order. Periodically, the system needs adjustment, which is not difficult to perform yourself.

Carburetor assembly

The carburetor is required for the continuous operation of the internal combustion engine. It consists of such structural elements:

- One-piece aluminum body;

- jets, which are valves that regulate the amount of fuel;

- diffuser;

- float chamber;

- atomizer.

The body of the carburetor has a choke that regulates the flow of atmospheric air, a pulse channel, a diffuser, an inlet fitting, two screws (idle and main). Very often manufacturers of chainsaws equip their products with a carburetor from the common brands on sale.

Most chainsaw models are equipped with identical (by design) carburetors. Their arrangement is shown schematically in the photo below. Only rare cheap Chinese modifications may differ in the absence of some parts in the carburetor unit.

In order to properly perform the adjustment of the gasoline saw carburetor, you should understand the principle of its operation, which consists of the following:

- When you start the engine, the air damper on the lower part of the housing opens;

- the evacuation of the piston (stroke) creates a vacuum inside the float chamber and also in the air duct;

- this causes the air mass to be sucked in through the diffuser;

- from the petrol tank the fuel mixture enters inside the float chamber, passing through the connector;

- then the gasoline in the diffuser mixes with atmospheric air, and a fuel-air mixture is obtained;

- then it goes into the intake ducts;

- from there the mixture enters the combustion chamber.

the choke can be used to enrich or deplete the fuel, i.e. adjust the rate of its inflow to the operating conditions. the engine revolutions are adjusted with the help of screws. The speed at which the gasoline enters the nozzle from the chamber is adjusted by the nozzle. The incoming air is cleaned by a filter installed over the carburetor.

Serviceability of the carburetor unit determines the performance of the chainsaw and the performance of its motor.

The clutch mechanism

Centrifugal clutch on chainsaws. It engages automatically when the motor speed reaches the required number of revolutions.

The function of the centrifugal clutch is shown schematically in the photo below, where the numbers correspond to the following design elements:

At low engine speeds, the linings, which can move radially, are forced up against the shaft by springs. At this time they do not rotate the drum connected to the chain sprocket. When the internal combustion engine reaches a speed at which the spring force becomes lower than the centrifugal force, the friction plates in the clutch drum cause the drum to rotate by pressing against the inner surface of the drum. The sprocket that moves the chain starts to rotate. The chainsaw can be in front of or behind the clutch on various gasoline-powered saw models.

The design and operation of the individual assemblies

The individual gasoline saw assemblies discussed above are in turn made up of various parts. In order to repair the equipment yourself, you should know the construction and operation of the main systems.

The ignition system

Originally the ignition system on chain saws was of the contact type. Nowadays it is practically not used. Modern manufacturers equip their equipment with electronic ignition (pictured below in disassembled form). That is why it is not necessary to regularly clean the contacts and set the necessary distance between them.

The ignition system that gives the spark when the engine is started is made up of the following components:

The following illustration shows the appearance of the ignition system on a STIHL chainsaw.

The magneto is the alternator that energizes the spark plug. It can be of two types:

Schematically ignition systems with contactless and contact types of magneto are shown below.

A magneto of any type includes these parts:

The electronic unit usually includes diodes, resistors of various sizes, thyristors, capacitors. Wiring diagram depends on the saw model.

The ignition works according to the following principle:

- When the flywheel with a permanent magnet attached to it rotates, an electromotive force is induced in the system;

- The electronic unit converts the current arising in the circuit into electric signals;

- These are transmitted to the spark plug;

- a spark is formed between its contacts, which causes the fuel-air mixture to ignite.

The ignition is initially set so that spark formation occurs when the engine piston does not reach its top dead center by about 3-4 mm. If you are guided by the circumference of the crankshaft, this corresponds to an angle of 28 degrees.

You can visually diagnose ignition system malfunctions by the condition of the spark plug.

Thus, thanks to the presence of the ignition, the fuel mixture is ignited, which ensures the engine’s transition to the working state. Periodically, the system needs adjustment, which is not difficult to do yourself.

Carburetor assembly

A carburetor is required for continuous operation of an internal combustion engine. It consists of the following structural elements

- One-piece aluminum body;

- jets, which are valves that regulate the amount of fuel;

- Diffuser;

- float chamber;

- atomizer.

The body of the carburetor has a choke that regulates the flow of atmospheric air, a pulse channel, a diffuser, an inlet fitting, two screws (idle and main). Very often, chainsaw manufacturers equip their products with a carburetor from common brands on the market.

Most chainsaw models have identical (by design) carburetors. Schematically their arrangement is demonstrated in the photo below. Only rare cheap Chinese-made modifications may differ in the absence of a number of parts in the carburetor unit.

To properly perform the adjustment of the carburetor of the gasoline saw, you should understand the principle of its operation, which is as follows:

- When you start the engine, the air damper on the lower part of the housing opens;

- Due to the movement of the piston (stroke), a vacuum is created inside the float chamber, as well as in the air duct;

- it causes the air mass to be drawn in through the diffuser;

- from the petrol tank the fuel mixture enters inside the float chamber by passing through a nozzle;

- then the gasoline in the diffuser mixes with atmospheric air, resulting in a fuel-air mixture;

- then it enters the intake ducts;

- from there, the mixture enters the combustion chamber.

Using the flap, it is possible to enrich or deplete the fuel with air, i.e. adjust its intensity to the working conditions. the engine rpm is adjusted with the help of screws. The speed at which the gasoline enters the diffuser from the chamber is adjusted by the nozzle. The filter that is installed over the carburetor cleans the intake air.

The functionality of the carburetor unit determines the chainsaw’s performance and the efficiency of its motor.

The clutch mechanism

Centrifugal clutch on chainsaws. It engages automatically when the engine reaches a desired speed.

Schematically the work of the centrifugal clutch is shown further in the photo, where the numbers correspond to the following elements of construction:

At low engine speeds, the linings, which can move radially, are pulled up against the shaft by the springs. At this time they do not rotate the drum connected to the chain sprocket. When the internal combustion engine reaches a speed at which the spring force is lower than the centrifugal force acting, the friction plates set the drum in motion by pressing against the inner surface of the drum. The sprocket, which moves the chain, is in rotation. Depending on the petrol saw model, there may be a handle in front of or behind the clutch.

Working with a chainsaw: first start, safety precautions, video instructions

Before you buy a good chainsaw, you should find as much information about the tool as possible and learn how to operate it carefully. If you choose a chainsaw which is the right one for you and learn to use it properly, it will be a pleasure to use, but also completely safe.

If you have never used a chainsaw before and have not had any experience with it, it is important that you understand the basic principles of how to use it:

- Hold the saw with both hands and wrap all your fingers around the handle. The left thumb should be under the front handle;

- Do not stand directly behind the saw while working, but stand slightly to the side of the tool;

- You can use either the bottom or the top end of the tool for cutting. If you saw with the lower edge the chain will guide the saw away from you and if you saw with the upper edge the chain will guide the saw toward you;

- avoid arching your back when using the chainsaw, but bend your knees instead. When you work with the saw in a standing position, it is recommended that you spread your legs wide to maintain your balance;

- Activate the saw brake or turn off the tool’s motor before moving to another position. Do not move with a tool that has a rotating chain;

- start cutting with the part of the bar closest to the body of the tool;

- in case you are going to work with a chainsaw often, it is necessary to buy a set of protective clothes: a helmet with a mask, a bright protective jacket that does not let air in, special pants with protection against cuts, strong gloves and strong boots, which should be protected by steel plates if possible.

How the brake works

Let’s see how the brake works. The design of the mechanism is simple and unpretentious. It’s a purely mechanical process. the starter, the switch of brake system is the lever (screen), mentioned already by us, which is a solid element on the upper front surface of a chainsaw above the muffler. The screen is located just behind the operator’s hand, almost flush with the cover. But since we turn the tool while working, the screen may not be behind the hand.

The sliding lever without the spring when the brake is applied

Glide lever without spring when the trigger is released

Glide lever without spring with trigger releasedThe screen is locked in place by a return spring at the base of the mount and the trigger switch. When you hit it, the tire bounces, the screen touches the saw’s hand and then by the chain it engages the trigger, which is connected to the screen. In the normal position the trigger compresses the spring (not to be confused with a return spring), and when it is actuated it opens and locks with a retaining clip (latch). The sliding lever inside the spring tightens the metal band. The metal band is located around the clutch basket (clutch drum), it tightens (clamps) the drum, which stops rotating. The chain saw chain stops.

Inserting the screwdriver into the spring with the sliding lever

Press the spring with the palm of your hand so it does not pop out.

Insert spring with screwdriver into seat

Release the brake trigger with the cantilever wrench to loosen the metal bracket

But the brake can be activated by more than merely pressing on the screen. In the lower part of the shield (in the place of attachment to the cover), in the body of the lever, an inertial weight is “embedded”, which actuates the trigger due to the sharp recoil. The centrifugal weight is responsible for the automatic braking process. A logger, for example, when felling a tree, holds the saw in a tilted (prone) position and, in this case, the screen is not behind his hand but to the side. In the case of kickback in the cut, thanks to the inertia weight, the braking system is also activated.

Do-it-yourself chainsaw repair. save money on servicing. Gasoline chain saw ignition device

HomeAgnitionChainsaw ignition device

Gasoline-powered saws are used in log construction, logging, clearing brushwood, restocking firewood. They allow you to effectively perform work with wood. Its relatively simple construction makes this chain saw a durable and reliable tool for both home and professional use.

Structurally, the product belongs to the category of machines with an internal combustion engine (ICE). In many cases, it is a two-stroke single-cylinder motor.

Knowledge of the device of the tool and peculiarities of functioning of its individual components is necessary for the user. it will help to perform correct maintenance and, if necessary, to make repairs by oneself.

On the market there are many models of gasoline saws from different brands. The products of different manufacturers differ in design and technical characteristics that determine the ergonomics and functionality of the equipment, but the tool has the same structure.

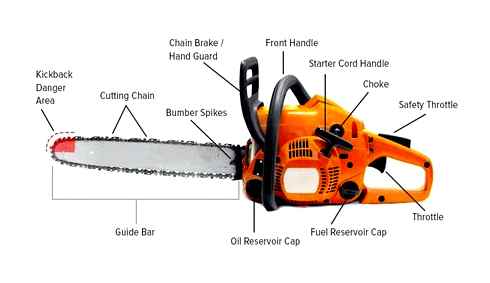

The chainsaw consists of the following structural elements:

- The internal combustion engine;

- carburetor;

- the bar;

- circuit;

- handles;

- clutch;

- starter;

- ignition, fuel supply, air filtration and chain lubrication systems;

- muffler;

- Chain brake and chain tensioning mechanism.

Chainsaw schematic diagram is shown in the photo below.

The carburetor engine runs on a mixture of oil and gasoline. The scheme of its working process is shown in the photo below.

The fuel mixture components are mixed proportionally. Their ratios are given in the instruction manual (oil to petrol from 1:20 to 1:50 respectively). The quality of fuel affects how long a tool can be used without repair.

Modern petrol saws in the expensive category often have an oil tank. It mixes with petrol in these versions automatically.

The two-stroke motor is capable of speeds up to 13,500 rpm. It can be mounted vertically or horizontally on the tool. The first option of the internal combustion engine placement is characteristic of many professional models of large chainsaws. Their muffler is on the front of the engine.

If the motor is positioned horizontally, gasoline-powered saws are compact in size. And they don’t have much weight, either. These features make products with a horizontal motor popular with farmers, loggers, and other workers who use hand-held saws.

The chainsaw is designed with two handles: front and rear. They have a switch, throttle and safety levers on the last one.

The tool is implemented protection against the effects of vibration and backfire. The former is due to the rubber pads between the handle and the saw. Some models also have springs to dampen vibrations.

A special brake or a guard can protect against kickback.

Design and function of the individual components

Individual nodes of the gasoline saw, discussed above, in turn consist of various parts. In order to repair the technique yourself, it is necessary to know the construction and operation of the main systems.

Ignition system

Originally, the ignition system in chainsaws was of the contact type. It is practically not used at present. Modern manufacturers equip their equipment with electronic ignition (in the photo below in a disassembled form). For this reason, there is no need to regularly clean the contacts and set the necessary distance between them.

The ignition system, thanks to which the spark is formed during engine starting, consists of such parts:

The following photo shows the appearance of the ignition system components for a STIHL chainsaw.

A magneto is an alternating current electrical generator that supplies voltage to the candle. It can be of two types

The ignition systems with non-contact and contact magneto types are shown schematically below.

All types of magneto include these parts:

The electronic unit usually includes diodes, resistors of different sizes, thyristors, capacitors. Wiring scheme varies with the model of the chainsaw.

The ignition works according to the following principle:

- The rotation of the flywheel with a permanent magnet attached to it induces an electromotive force in the system;

- the current generated in the circuit, the electronic unit converts it into electrical signals;

- they are transmitted to the spark plug;

- A spark is formed between its contacts, which causes the fuel-air mixture to ignite.

The ignition was originally set so that spark formation occurs when the engine piston does not reach its top dead center by about 3-4 mm. If you are guided by the circumference of the crankshaft, this corresponds to an angle of 28 degrees.

The condition of the spark plug can be used to visually diagnose ignition system malfunctions.

Thus, due to the presence of ignition, the fuel mixture is ignited, which ensures the transition of the motor to a working state. Periodically, the system needs adjustment, which is not difficult to carry out yourself.

Carburetor assembly

The carburetor is required for continuous operation of the internal combustion engine. It consists of such structural elements:

- one-piece aluminum housing;

- the jets, which are the valves that regulate the amount of fuel;

- diffuser;

- the float chamber;

- atomizer.

The carburetor housing contains a choke, which regulates the atmospheric air supply, an impulse channel, a diffuser, an inlet fitting, two screws (idle and main). Very often chainsaw manufacturers equip their products with a carburetor from common brands on the market.

Most chainsaw models have identical (by design) carburetors. Their mechanism is shown schematically in the photo below. Only rare cheap modifications of Chinese make can be distinguished by absence of a number of details in the carburetor unit.

Chain saws with chain brake

Portable hand tools with closed (circular) working body are widely used in many industries and households. Chain saws with a chain brake are intended for use

- In the logging and woodworking industry.

- In construction, including concrete cutting.

- For rescue and emergency services when clearing debris.

- For work in the home.

- When making ice sculptures and structures and making ice-holes.

Chain saws can be driven by electric or gasoline engines. A comparative analysis of the technical characteristics, advantages and disadvantages of three popular models is presented to the reader’s attention:

Partner P340S chainsaw

The Partner P340S is a semi-professional chainsaw. The customer is supplied with the following equipment:

- universal screwdriver

- saw chain;

- user’s manual;

- box packing;

- plastic cover for guide bar

The tool is notable for the high quality of its components and good matching parts. Advantages of the chain saw of the described model:

- Patented CCS technology pre-cleans the air before it enters the air filter, multiplying the engine life.

- The chainsaw is equipped with a pre-start priming pump, which makes starting the engine very easy, especially in cold weather.

- Automatic chain oil supply during operation relieves the operator from constant checking. Does not distract from the operation, thereby increasing safety in use.

- Steel-spring-based anti-vibration system reduces hand fatigue and fatigue, significantly increasing cutting time.

- Easy to operate: quick protective cover provides easy access to the chain for cleaning and maintenance.

- The saw’s low weight allows for the removal of dry branches in trees and on construction sites.

- Saws equally well in dry and green wood.

- Relatively low fuel and oil consumption for the saw chain, ensuring savings in fuel and lubricants.

- Can be used in the woods or in uncrowded areas, unlike electric saws, without plugging in.

- Detailed instruction is included in Russian with a description of how to use the saw and the necessary safety precautions.

- The low weight of the device allows you to start the engine by weight, which is convenient when working at height.

- Dual chain brake activation by releasing the front or rear handle or control button, rules out the possibility of injury.

- Automatic tool stop in case of tool jam or rebound.

- Comfortable, rubber coated handles for a secure grip and the ability to work in any position.

- The chainsaw is unpretentious and easy to operate. Maintenance operations are easily mastered by anyone, even inexperienced users.

- Low price and low operating costs make the saw accessible to the general public and profitable to use.

- The chainsaw is remarkably durable if the instructions for use are followed. Use of special oil for two-stroke engines greatly extends engine life.

The Partner P340S electric chainsaw has some drawbacks as well: It requires a lot of fuel and oil. During operation, spontaneous unscrewing of the inlet manifold fasteners is possible, non-standard bar fastening nuts in case of loss are difficult to find on sale. There are cases of breakdowns of clutch and engine starting mechanisms due to spring looseness and breakage.

The Partner P340S gasoline chain saw has been produced for a long time, and a considerable amount of feedback has been accumulated over this period. In general, users note such advantages of the saw as compactness, low weight and reasonable price. At the same time pointed out the inconvenience of adjusting the tension of the chain, as well as the rapid clogging of the air pre-cleaner chips or sawdust.

Video review of the Partner P340S:

Electric chainsaw Bosch AKE 40 S

Products of German company are notable for high quality and reliability. The Bosch AKE 40 S electric chainsaw retails in a original cardboard box. The product comes complete:

Among the advantages of the model experts and users include:

- Powerful drive for its class, allowing you to cut through wood, even hardwood.

- Soft, non-slip coated handles for maximum operator comfort in every position.

- The electric motor runs on the domestic mains, to which it is connected by means of an ordinary extension cord. Cord is equipped with a bracket that secures the cord when using the saw.

- The control knob is large enough to allow the operator to use gloves while working. Safety button on the left side of the handle, eliminating the possibility of accidental start-up.

Technical features

When selecting a chain saw for cottage or construction work, it is imperative that you become familiar with its main technical characteristics. Read about them below.

The engine is the heart and soul of every tool. And chainsaws are no exception. Electric and cordless models use electric motors; gasoline models use air-cooled, two-stroke carburetor units.

A special wear-resistant chromium or nickel-silicone coating on the cylinder walls of gasoline engines helps retain a lubricating oil film on the piston. This solution significantly extends the life of the motor, as well as making it function as efficiently as possible.

Often low-cost chain saw models are equipped with primitive engines that have no coating on the cylinder walls. This attempt to save money usually does not end well. durability of such machines is not very long at all.

Power has a direct influence on the performance of a chainsaw. The more powerful the tool, the more work it can do in a shorter amount of time. In addition, the powerful models are equipped with long bars and are therefore able to cut harder wood.

When choosing a chainsaw, you should consider recommended wattages for different jobs. For example, a 2 wattage motor is good enough for your daily chores.5-3.5 л.с. (for electric saws. 1.8-2.5 kW). At the same time, professional chainsaws are more powerful. with motors from 5.5 л.с. (from 4 kW in the case of electric saws).

Usually the wattage is directly proportional to the weight of the chain saw. less powerful models are quite light, but the high-powered tools for professionals are quite heavy.

So, if you want to buy a saw for household needs, you should not chase too high power. Remember. even the basic level models can meet the needs of the average homeowner. It is very tiring to work with high-powered tools, especially if you don’t have special skills and training.

The bar is literally the key component of any chainsaw. The length of this element determines working capacity of your tool. the longer the bar, the bigger diameter trunk your saw can “fell”.

The important point here is that the bar length must not exceed the recommended length indicated in the specific model data sheet. If you install a guide bar that is too long, you risk shortening the life of your saw headset considerably. The thing is, that a longer guide bar needs a corresponding motor power, and if there is not enough power, the motor shaft has to make additional efforts. Such unauthorized processes lead to early wear of the harness, and the machine’s crankshaft.

Most often tires of 30-45 cm length are used in chain saws of the base level, in professional models. up to 75 cm.

The saw chain is also a very important part of both electric chainsaws and gasoline-powered saws. Different types of chains are used to maximize tool performance for certain types of work.

There are two basic parameters that reflect the characteristics of a particular type of saw chain:. Chain pitch is the distance between the connecting rivets of the links. There are chains in 0 pitch.325, 3/8 (0.375) и 0.404 in The thickness of the drive link is the thickness that allows the drive link to slide freely in the guide groove of the bar. Today’s chain saw models feature links with a thickness of 1.3 mm, 1.5 mm or 1.6 mm.

The smaller the link thickness and pitch of a particular model, the less vibration you will experience when working. However, such a tool will exhibit very mediocre performance. Usually chains with a pitch of 0.325″ and a link thickness of 1.3 mm are installed in saws belonging to the household category.

HOW-To STIHL Chainsaw Chain Hand Brake Guard Replacement On MS260

Of course, the pitch and thickness of the drive link are higher in the heavy-duty models. 0.375-0.404 inches and 1.5-1.6 mm respectively. Despite their higher level of vibration, these tools are very effective for a wide range of tasks.

A chain brake is a kind of safety system for the operator. A chainsaw is a notoriously tricky tool to operate. Running saw blade can cause severe injury even with a light touch. In addition there are the occasional situations of so called “blowback”. a sharp bounce of the saw at the moment when the end of the bar touches the surface of the tree.

To protect the operator from harm there is a chain brake. a system that stops the chain quickly. The brake is actuated by the blade guard in front of the operator’s left hand. The following types of brake activation mechanisms are introduced in modern models of chain saws:. Inertial. when the lever moves by its own inertia and not in contact with the hand Contact. when the operator’s hand rests on the guard, which is connected directly to the brake. A special spring is actuated, the brake is activated and the chain is stopped immediately.