Chainsaw ignition

A chainsaw, like any device powered by an internal combustion engine, has an ignition system. It is responsible for igniting the fuel-air mixture in the engine cylinder. This occurs through the delivery of an electrical discharge that breaks through the space between the spark plug electrodes.

It is clear that without fuel ignition, no engine will start and will not work. However, the problem is not only this: the quality of the chainsaw depends on how accurately the ignition is set. In other words, fuel ignites on time or at the wrong time. Therefore, the chainsaw with knocked down settings needs to be repaired. The troubleshooting can be entrusted to an experienced mechanic, but you can repair the ignition of the chainsaw with your own hands.

Important: new chainsaws are supplied with adjusted ignition, there is no need to disassemble and assemble the tool immediately after purchase.

Some Chinese chainsaws come with low-quality spark plugs. it may make sense to have several spark plugs included. In our review, we will introduce you to the device and how the ignition system works, its main problems and how to fix them.

Step-by-step diagnostics of ignition with a multimeter:

- We set the multimeter to the position in which the arrow is at the 200 ohm mark.

- We study the instructions for the chainsaw. We find out the optimal resistance for the coil winding installed on our model (in most modern chainsaws, this indicator fluctuates within 3-5 ohms.);

- We connect the multimeter to the primary winding of the coil and measure the resistance, if it is normal, we continue testing;

- We connect the multimeter to the secondary winding of the coil, compare the readings obtained with those indicated in the instruction manual;

- We connect the multimeter to the coil hole into which the wires are inserted. If the device gives normal readings, we come to the conclusion that the coil is in good working order. If the measurement results are far from optimal, you will have to replace the assembly (coil) with a new one;

Determination of fault location:

First of all, it is necessary to inspect the spark plug, if or a lot of soot has accumulated on it, then the cause of the malfunction is most likely associated with the operation of the carburetor, piston group or fuel quality. If the candle visually looks good, it is not thrown and it is dry. make sure there is a spark.

- Unscrew the plug, put the ignition cable on it;

- Using pliers with insulated handles, press the candle thread to the motor housing;

- Pull the starter handle sharply and check for a spark;

If there is no spark, replace the spark plug with a new one and test again. After making sure that there is a spark, we start the engine. But what if there is no spark even on a working spark plug? We continue to search:

- We test the electrical cable for breakage and insufficient contact with the spark plug. We check the serviceability of the spring in the candlestick cap and the presence of contact with the armored cable;

It is best to use a tester to check the integrity of the wiring.

- We check the gap between the ignition module and the flywheel magnetic circuit. It should be no more than 0.3. 0.4 mm.

How To Check For Spark On A Lawn Mower, Chain Saw or Other Engines. Video

You can set the correct gap using a feeler gauge, they are not in short supply and are available for a small fee.

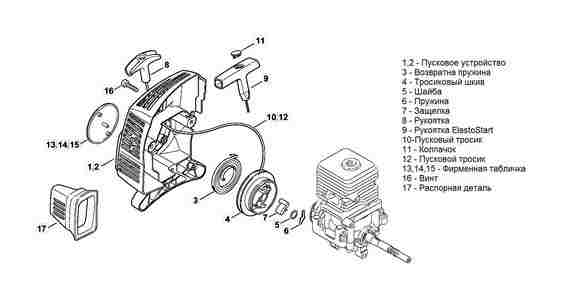

Chainsaw ignition device:

- Magneto: a device that converts mechanical energy into electrical energy, provides a current impulse to the spark plug of the chainsaw;

- Spark plug: designed to ignite the fuel-air mixture, through a discharge that occurs between the electrodes;

- Electric cable;

- Engine shutdown button.

There are spark plugs, arc plugs, incandescent plugs and catalytic plugs. Chainsaw devices use spark plugs for 2-stroke engines. A schematic diagram of the ignition of a chainsaw is shown in the image.

The need for ignition adjustment

If it turns out that the fault is still in the module, then it is necessary to check the gap between the coil (core) and the flywheel (magnets). In the event that the gap does not correspond to the required parameters, then it is knocked down.

It should be understood that the ignition itself, on imported gearless chainsaws, cannot go off by itself. If this happens, then your tool is counterfeit, or you ran into a marriage!

The problem lies in the screw retainers with which the ignition module is fixed. To be more precise. in their absence. What it is?

The ignition module is secured with screws. The chainsaw vibrates during operation, and vibration affects all parts of the structure, all components. The gap between the magneto must be constant and consistent. The screws (seat) for fastening the ignition module must be “sealed” with a special fixator. a viscous substance of different consistency. In the case of the ignition of a chainsaw, the retainer must be of a strong consistency. The retainer, in fact, is a gasket, a seal that excludes the loosening of fasteners. screws.

To eliminate the malfunction, you must:

- unscrew the screws securing the module;

- fill the mounting holes of the screws with the retainer;

- screw the screws back on;

- set the gap;

- firmly tighten the module fixing screws.

Another case when it is necessary to set the ignition is to replace a faulty module with a new one. How the ignition is exposed, we will consider in the next chapter.

Chainsaw ignition module (coil) problems

Husqvarna chainsaw ignition coil

The switch and the ignition module that regulates its operation can often fail. The coil may also be faulty. If all elements of the ignition system are in good working order, but there is no spark, suspect the module and the coil. And the problem of a malfunction of these elements is that it is impossible to repair the module or fix part of the coil. they need to be replaced. Of course, if possible, it is better to put the module from some old saw and see if this is the case. After all, you can elementarily make a mistake at some stage and suspect what actually works.

Do not trust all kinds of testers. they often show false information about the health of the ignition system. Only diagnostics with a different module or coil will be valid.

If the electronic module is bad, there is such a symptom: as soon as the chainsaw heats up, a very weak spark is emitted. Also, after refueling, the unit may not start. This is due to the fact that the coil or module gets very hot, their resistance increases, so the spark weakens.

If there are breakdowns in the ignition system, and there is no experience in repairing them, you should not try to repair everything yourself. Elementary things, such as checking the integrity of a candle or wires, can be carried out at home, but more complex diagnostics, and even more so, the replacement of units should be carried out by professionals. And then you can be sure of the quality of the work performed.

How to properly check a candle

It is not worth excluding the malfunction of the glow plug itself. Nowadays, there is a lot of counterfeit fuel for chainsaws. A poor-quality mixture directly affects the “lifespan” of the glow plug.

We unscrew the glow plug from the engine and inspect it carefully. if it is damp, then it is flooded with a fuel mixture and, indeed, the cause of the malfunction may be the carburetor. If the spark plug is dry, check for a spark. The defective spark plug should be removed immediately and replaced with a known good spark plug.

Visually, a candle defect can be guessed by the following signs:

- layering or deposits (slag, varnish) on the electrodes;

- non-uniform color and shape of electrodes;

- soot bloom, oil bloom;

- molten center electrode;

First, make sure that the ignition key is turned on when checking. Exactly. It happens that the operator, having muffled the intermittently working saw, begins to check the spark plug with the ignition off.

The unscrewed (serviceable) glow plug, without removing it from the cap, must be attached with a thread (“skirt”) or a side electrode directly to the cylinder. The contact must be reliable! Holding the candle by the cap with one hand, jerk the starter with the other hand and observe the presence of a spark on the candle between the electrodes.

Method 1

The first way to check the ignition coil involves the use of special equipment (stand). It is not available at home. you can find it only in service centers.

Method 3

If there is no multimeter, you can check the coil in another way.

Important! The check must be done carefully so that the magneto does not burn out. For this, it is important not to touch the cylinder with the electrode.

To diagnose, you need to take the following steps:

- open the cover that covers the cylinder;

- remove the cap of the high-voltage wire from the candle without unscrewing the part itself to maintain compression;

- tightly place a nail without a cap in the cap, it will simulate the central electrode of the candle;

- use a dielectric material to tie the cap with a nail to the cylinder so that the gap between the simulator of the candle electrode and the mass ranges from 5.5 to 7 mm (the exact distance for a particular model is recommended to be found in the user manual), but the part does not come into contact with the mass;

- using the starter to reproduce the engine start several times, holding the ignition button in the on position;

- if a spark appears, you need to consider what color it is.

A strong white or bluish spark is normal, and a faint gleam of orange or yellow indicates a broken coil.

Often, a cold magneto creates a powerful spark, but when heated, due to a defect in internal components, it does not conduct current. After the mower has cooled down, the mower starts up again and mows the grass with a line or knife until the magneto is heated. This is abnormal behavior and the coil must be changed.

On a note! In a similar way, the problem can manifest itself when the candle heats up and cools down, so it is recommended to check the performance of both parts.

Replacing breaker contacts

After disassembling the magneto, it is necessary to remove the old breaker contacts and install the new ones correctly. To accomplish this, you must:

- move the latch, remove the cover from the breaker;

- unscrew the screw holding the connecting wire;

- remove the screw securing the breaker plate to the magneto cover and remove it;

- get the screw securing the breaker spring;

- remove the lock washer from the axle, and then the lever with the cushion assembly, which it holds;

- unscrew the screw securing the contact post, remove the part from the axle.

On a note! Despite the ease of operation, most often trimmer owners prefer to simply replace the magneto with a new one.

Do-it-yourself troubleshooting

In order to repair the magneto with your own hands without the involvement of specialists, you need to know how to disassemble it, and how to change the breaker contacts to new ones.

Insufficient sparking

The weak spark on the magneto is caused by a damaged capacitor. To eliminate the breakdown, it is necessary to replace the failed part.

Trimmer ignition coil. faults and repairs

lawn mowers are a popular seasonal tool designed to remove unwanted vegetation from your home. Like any other technique, these devices break down periodically. Repairing the trimmer ignition coil is one of the most common problems with gasoline braids. The ignition system itself is designed in the same way for two- and four-stroke internal combustion engines, therefore, the elimination of breakdowns is performed almost the same for tools from different manufacturers, be it Lux, Huter, Husqvarna or another brand. Ways to restore the performance of the ignition coil or replace it with a new one. in the material below.

Unstable sparking

If the magneto sparks intermittently, the contacts must be checked first. They could be burnt or oily. The carbon deposits found are cleaned with a file, and the oil is wiped off with suede, previously soaked in gasoline. The second possible cause of the problem is the adjustment of the gap between the contacts. To eliminate it, you need to set the correct distance.

If the spark appears intermittently, it could also mean that the breaker arm pad is worn out. To eliminate the malfunction, you must change the lever to a new one. In addition, the clearance should be adjusted, as with another possible cause of breakdown. misalignment of the outline.

Capacitor breakdown can also be the culprit for interruptions in spark formation. In such a situation, replacement of the damaged part is required, since it cannot be repaired and recharged.