- two round pipes of the same diameter;

- marker, measuring tape and compass;

- core and hammer;

- Locksmith’s vise;

- angle grinder;

- hand file;

- piece of cardboard

- scissors, etc.

On the form of one pipe punch the center of the joint with the other pipe. We will work with pipes with an outside diameter of 60 mm. Nothing will change if they are a different size.

Let’s divide the legs of the circular by half the diameter of the pipe, t. е. by 30 mm, which is also its radius. We put the leg of the compasses in the previously planned point on the surface of the pipe and draw a circle on it.

Through the marked point (center of the circle) we draw an imaginary section, perpendicular to the axis of the pipe. From the points of its intersection with the circumference drawn by the compass, we defer in the sides of 5 mm.

Let’s draw a mowing line, passing through the marked points and smoothly conjugate to the circle line.

Cut out the material inside the outer closed mowing line applied to the surface of the pipe with an angle grinder. Remove burrs and smooth out any remaining irregularities with a hand file.

Around a piece of the second pipe, set vertically on a piece of heavy paper or cardboard, draw a circle with a marker and cut out a circle bounded by it with scissors.

We fold the cut out cardboard circle in half by diameter, mark the line of bend, straighten it out again and put it evenly on the end face of the pipe with the mark of the mowing line of the bend outwards.

Mark the points of intersection of the mowing line of the bend (diameter) of the circle with the cylindrical surface of the pipe with a marker.

We divide the fishing line of the cardboard circle into three equal parts of 20 mm each and bend one of the outer parts of the circle along the line (chord), perpendicular to the diameter, and passing through the mark of the extreme point of 20 mm.

We cut the obtained segment along the chord with scissors, attach it to the outer surface of the pipe so that the chord is at the level of the end face of the pipe and its center coincides with the marking that was previously put on the pipe.

Holding the cardboard segment in this position, trace the arc of the segment on the surface of the pipe with a marker. Repeat this procedure with the second point on the pipe on the opposite side.

Round Pipe Cutting idea // 45 Degree Angle Cutting

Remove metal from both sides of the pipe, bounded by the drawn lines, and smooth out sharp edges and corners.

We butt the pipes in the only possible position and weld with a mowing line to the contact.

How to perfectly evenly cut the edge of any pipe

There are several ways to saw the pipe off or cut it into pieces. From available tools an angle grinder works best with this task. But the biggest challenge remains the need to properly mark the mowing line of the cut. They can be different, most often we have to maintain either a right angle relative to the axis of the pipe, or 45 degrees. The techniques vary slightly depending on what products need to be cut:

pipes for plumbing, gas and for heating distribution;

Profile products for the assembly of gates, canopies, and other metal structures;

large-diameter pipes. as a rule, this is rarely needed in the home, where the widest openings are only in the sewer

steel, cast iron, thin-walled non-ferrous and soft alloy pipes.

Both tasks are solved quite simply, even without the use of a special template for the angle of the pipe.

IMPORTANT: stainless steel profile pipe

Using a water tank

Marking in water What to do if we are dealing with a pipe of small diameter, and we need to cut the pipe at an angle somewhere near the edge? A deep reservoir filled with water will help. Before starting work, it is necessary to calculate the angle of inclination and make a mark on the vessel. Next, all we have to do is to carefully lower the edge of the pipe into the water and bend it to the mark on the vessel. We pull out the pipe, mark the line of contact with the water, and boldly cut according to the marking. This method is good for marking a large number of pipes. A pre-made template from a container of water will speed up our work.

- As a first option, we need a sheet of paper. It must be made square and folded diagonally. Next, you need to wrap it around the pipe, so that the long side is parallel to the cuts. The short one, in turn, will become the line on which to make the mark, which will mark the necessary angle.

- The marking of a profile pipe is different from a round pipe. We need a piece of the same profile, which will be the desired mark, made with an angle gauge. This will be the template.

- If you need to mark a large number of small pipes, a container of water will help. To do this, you need to draw water and make a mark on the vessel, which will determine the angle of inclination of the pipe. Then it is necessary to dip the pipe into the water, exactly at the mark, and mark the place of contact of the pipe with the liquid.

How to cut a profiled tube at an angle

Marking a profiled tube is different from a round tube. Doing it manually could result in a significant inaccuracy. The best way to solve the problem is to create a template for cutting from the same profile, but larger in diameter.

You need a small section of profile pipe. On it, using an angle gauge, mark the angle of 45 degrees. Now using an angle grinder is necessary to cut off a part of the workpiece on the marked line. The edges of the cut should be grinded, to eliminate defects. It remains simply to insert the original product into the template for cutting pipes at an angle. Then you need to make a marking on the mowing line of the cut of the larger profile. And then the tube itself is cut according to it.

The text describes how to cut the pipe at an angle of 45 degrees. When the marking is already completed, it is recommended to use an angle grinder. It can be used to make a straight cut. It can be replaced with a hacksaw for metal. You can also cut the product by welding, but you need experience with the tool, otherwise there will be irregularities. “How to cut a pipe evenly. tools and cutting methods”.

Now in construction stores you can find special tools for cutting pipes. But it is easier and cheaper to make a template yourself.

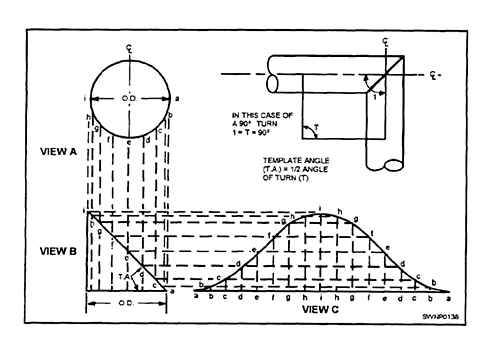

When carrying out work on the installation of gas or water mains, it is often necessary to change the direction of the mowing line, and the pipeline is cut and then welded at the desired angle. Most often the direction is changed to 90 degrees, and the question arises. how to cut the pipe at 45 degrees to accurately connect the joints when welding.

To cope with the problem at angles of 45 or 90 degrees of the cut edge is possible with the appropriate knowledge and techniques that will save not only time but also materials during the work. At other angles of turn to solve the problem with a ruler and a sheet of paper is impossible. you will have to call for help computer technology.

How to cut a pipe at a 45 degree angle: tips from a specialist

Installation of systems often requires laborious preparation. In particular, it is necessary to cut pipes of the required size. Sometimes it is necessary to cut them at an angle. The angle in this case must be accurate, because otherwise it will be impossible to install the system correctly. The welding line will be broken, which will reduce the quality of construction. In this article we will consider how to cut the pipe at a 45 degree angle.

How to cut a pipe at a 45 degree angle

Carrying out installation of the pipeline, it is often necessary to cut the pipe at an angle. And the angle must have exactly the degree that is necessary for the construction. If the wrong angle is made, it is impossible to make exactly the dimensions of the pipeline that were intended. For example, the pipe will rotate 45 degrees during installation, hence the need to know how to cut the pipe at 45 degrees. For this we will need marking tools, an angle grinder or a metal saw.

How to cut a pipe at an angle

Sometimes it is necessary to cut the pipe at a certain angle. In this article, the master plumber will tell you how to perform such operations and what are the methods of cutting.

When we look at cutting straight or square, we must keep in mind the different materials that are being cut. So, hoses made of polypropylene or thin copper, it is easier and easier to cut than thick-walled steel pipes.

Plastic products of small diameters can be cut at right angles with special snips. In doing so, you can control the angle with a standard protractor. Plastic pipes can also be cut with an ordinary fine-toothed hacksaw.

To cut pipes made of metal, in the process of installation, it is necessary very often. A popular tool for such cases is the so-called angle grinder. Use this tool to cut straight and at an angle.

Let’s find out what devices can be used for cutting at different angles.

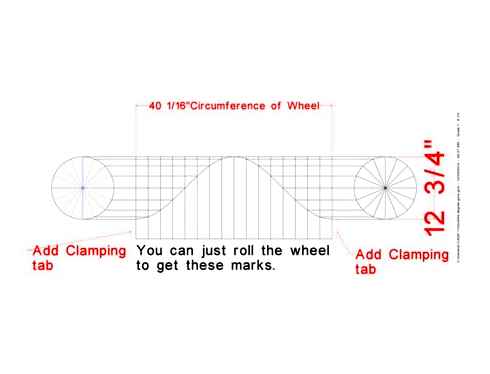

To perform a relatively precise cut, you can use a simple technique where an ordinary sheet of paper acts as a kind of template. For example, successfully suited to create a template printer paper format A4.

The sheet is preliminarily marked as a square with a ruler. The size of the diagonal of the square must be equal to the length of the circumference of the pipe to be cut. The excess portions of the sheet are cut off.

- Fold the sheet diagonally, aligning the opposite corners;

- Turn the resulting triangle so that the line of the hypotenuse is perpendicular to the axis of the pipe;

- In this position, wrap the paper around the tube surface, aligning together the extreme points of the hypotenuse;

- Draw a marker with a marker on the cutting line of any of the cathetuses of the triangle;

- Cut the pipe according to the intended mowing line.

This method is very convenient for marking and cutting pipes at an angle of 45º in the diameter range from 32 to 63 mm. For greater convenience of marking, it is recommended to take thick, but soft paper. You can also use paronite and similar materials.

Well made templates for shaped cutting of pipes allow making cuts with utmost accuracy. At the same time the gap between the prepared blanks is still not excluded. In the connection of metal pipes it is “closed” by a welded seam, in the connection of plastic parts a specialized cord for soldering is used.

Cutting technology by templates allows to obtain different cutting angles. But in order to form a template for angles other than 45º, you will already need to perform mathematical calculations and according to the calculated data to cut the template from paper or similar materials.

True, there are computer programs designed to save the master from making calculations. Such programs print out patterns for pipe cutting.

A simple calculation program, based on MS Excel application, allows you to calculate and create a template for almost any value of the diameter of the pipe and the required cutting angles.

All the user has to do is to enter the corresponding values in the “Outer diameter” and “Cut angle” boxes. These parameters will form a template which can be printed.

There is a simple tool, often used in everyday life, mainly for work with wood. It’s called a jigsaw. So, the same device is suitable for cutting pipes, and at different angles.

The chisel is available for sale, but if you want you can always make it yourself and adjust the design to the desired diameter of the pipe:

- Take a wooden board with a width equal to the diameter of the pipe, length 400-500 mm;

- Take two more boards of the same dimensions, but increased in width by the thickness of the first board;

- From the three boards to assemble a structure in the form of an inverted letter “U”, with the first board installed as the base;

- In the central part of the construction, mark out a rectangle, two sides of which run along the inner boundaries of the side boards;

- Divide a rectangle by diagonals and, along the lines obtained on the upper faces of the side boards, make cuts down to the base.

In this way make a template for cutting at an angle of 45º. But using a protractor, you can mark out almost any angle and make cuts under the pipe cut for a particular angle.

The advantage of the crosscut is that the tool can be used repeatedly. It is allowed to work with the tool as long as the walls of the cuts are worn out and can ensure a high accuracy of cut. It is recommended to make the walls of the tool from a material of higher strength than wood.

The advantages of the method are obvious. simplicity, ease of making a tool (chisel), economy, versatility. Disadvantages of working with this type of tooling. the need to adjust the size of the chisel to the pipe diameter if you make an accurate cut. That is, for each pipe one needs to make a separate tool.

You can also use the pipe cutter to cut the pipe only with a metal hacksaw or secateurs (for plastic products). To work with thick-walled metal pipes under the cut angle grinder this tool is not suitable.

It is convenient to cut round and rectangular metal pieces with rather thick walls at an angle with the help of an angle grinder attached to the base.

- The rotary mechanism sets the required angle of cut (for example, using a ruler and protractor);

- The found position is fixed with clamping screws;

- Between the short and long angles laid tube and clamped by the screw of the clamp;

- Applying voltage to the electric motor;

- Applying slight pressure on the cutter disk, the pipe is cut in the right place.

Advantages of this technique are quick work, accurate cut, and the possibility of processing a large number of pipes in a short period of time.

Disadvantages: restrictions on use in domestic conditions, higher noise, work with only small and medium-diameter pipes. In addition, the process of cutting tool is carried out stationary at a distance from the place of installation, which is not always acceptable.

Nuances of work with rectangular section

To perform cutting of pipes with rectangular cross section it is recommended to prepare template pieces of angles in advance. They are easy to make from metal angle, pre-marked with the same protractor.

Among the branded machines that could be used in the household to perform cutting at an angle, you can pay attention to the technique of Italian production.

Mini Cut band saw machine by “MASS” is a small-sized device with a manual clamping device to work not only with pipes but also with angles, rods, profile elements.

The machine supports a cutting angle setting from 0 to 45º. The procedure is carried out with the tape blade at a speed of 45 reciprocating movements per minute. The machine is equipped with an electric motor power of 370 W, which is powered from the domestic network. The maximum allowable diameter of round pipe is 65 mm.

On an industrial scale, numerous units with electromechanical and electric drive are developed for cutting pipe. Technically sophisticated machines allow high precision thermal, oxyfuel and plasma cutting.

In the story. Cutting pipe with diameter of 35 mm and wall thickness of 2 mm at 90° and 45° angle

There are special industrial machines for precise cutting operations at an angle. Good example: Machines manufactured under “BSM” brand. German company Rexinger is a manufacturer of such machines.

Although BSM series machines are designed exclusively for work with polypropylene pipes of rather large diameters. Processing of PP, PVC, PE, PVDF types is supported.

The cutting tool of the machine is the band saw, thanks to which the cut is made at angles from 0 to 67.5º. Laser cutting detector provides precise process.

Despite the configuration of the device for large diameter products, it is possible to use a special table, by means of which pipes of small diameters (50. 200 mm), which are easier to cut with the pipe cutter, are also successfully cut. There is a wide range of “BSM” devices.

In the story. Bandsaw for large diameter pipes GR-BSM series

In addition to mechanical methods, thermal methods are often used, where welding or cutting equipment is used as a tool. For example, an autogenous cutting torch or a conventional welding machine (DC/AC).

Thick-walled metal pipes can be cut with such devices. However, it is extremely difficult to obtain a perfectly even quality cut with electric welding or a gas autogenous generator.

Usually after a thermal cutting operation the workpieces undergo additional processing. The cutting line is aligned, the required angle is adjusted. This approach is economically unprofitable, as it is accompanied by additional costs for machining.As a rule, the thermal cutting technique is used in the industrial sector. It is true that utilities often use this method, too.

Thermal cutting is also used when working with plastic material. There are devices. thermal guillotines. Their sharp and thin blades are heated to a high temperature and then the cut is performed.Thermal guillotines support angled cutting, and that is an advantage. However, these devices cannot be used for tougher materials, such as PVC, wood and chipboard.

The most convenient and least expensive cutting method can be selected for each individual installation situation. The concrete choice depends on the pipe material, its diameter, wall thickness.

Cutting pipes at right angles

The technology of cutting at right angles is quite simple. You just need to fix the metal part, mark the cut on the mowing line, and directly cut the workpiece. The end of the cut part of the pipe must be over the support.

A wide or narrow scotch tape, marker or a simple pencil will work for the marking for the cut. Simply wrap it around the piece, mark the cut line, and make a clean cut. When winding, both ends of the tape should accurately dock with each other