Dignities of homemade and purchased trailers

You can get a trailer for a motor-block in two ways: buy it in a specialized store or make a trailer for a motor-block with your own hands. Both options have a number of their advantages and disadvantages.

Purchased models are made according to ready and tested schemes, you don’t need to spend time and effort to assemble them. These trailers are assembled by professional mechanics who can make strong connections and choose quality materials. But there are some negative aspects. First, it is not always possible to get on a bona fide seller, who will release a quality product, and secondly, a good thing is quite expensive.

For a homemade version will have to spend quite a lot of time and effort. But, it also has a number of advantages:

- If you have the necessary materials, such a trailer does not require a large monetary investment;

- For homemade equipment, you can set the dimensions and parameters that are most suitable for the user;

- the owner of the motoblock himself selects parts for the trailer, which means you can be sure of the quality of components, connections and the unit as a whole.

- The trailer is made clearly for a specific model of equipment, which allows making the work with it as simple and effective as possible.

1.1 Where to Begin?

The first step in creating a trailer for a power tiller with your own hands is to draw a drawing. It will help to choose the right quality materials, determine their dimensions, make a clear plan of action, think through the curiosities in advance.

The process should be approached as seriously as possible. In the drawing the trailer is drawn from different sides, the dimensions of the parts are signed next to each of them. It is desirable that when creating a drawing the proportions were clearly sustained. Individual more complex assemblies, you need to draw individually in close-up and also from different sides.

When working on the drawing, it is important to think through such moments:

- you must foresee in advance what parts and units must be hitched together, and what type of connection will be used for this. Prepare in advance the right amount of rivets, bolts or welding machine;

- Decided to make a tipper trailer (with automatic tipping) or conventional with manual unloading;

- What pattern to use in the swivel units. It could be a bearing, an axle, a bush. These, too, must be prepared in advance.

Once the drawing has been drawn in detail, it should be studied again and key points should be thought through. Then the material can already be purchased. In order to save money, it is better to first carefully review your stock of metal and wood structures. Something may be able to be used in the work. to the menu

How to make a trailer for power tillers with your own hands?

Theoretically, a cart for a power tiller can be divided into the following main units. wheels, body, frame, hitch. Before you begin, you must first think through the design to the smallest detail, calculate the dimensions and create drawings. Also pay attention to such things as the connection of solid assemblies and parts (welding, screwing, riveting), the connection of moving parts (bushings, bearings, joints, axle), seat design (simple or adjustable), the functionality of the body (tipper or static), footrests (platform or footstep), etc. д.

After you have decided on the project of the future trailer and picked up the necessary materials, you need to clean the workpieces from rust and dirt, if necessary trim them and fit to the drawings, fasten. It is desirable to paint the trailer after completing the work.

The step-by-step work on a homemade cart for a single-axle tractor looks like this.

Assembling a frame for a trailer to a power tiller

The easiest way to make a frame is to connect a piece of pipe or metal profile to the wheel axle.

This variant is suitable for a small trailer, to the frame of which a ready-made body will be attached. For a more robust and strong structure it is necessary to weld the frame from round and rectangular tubes and angles.

Installing the axle

The wheel axle can also be made by yourself. Take a steel rod of at least 1.07 cm in length and 30 mm in diameter.

Length should be taken into account and adjusted based on the size of the trailer body. Wheels can be taken from old garden equipment, handcarts, motorcycles, mopeds or cars. it all depends on the size of the future product. Schemes of 2 options for mounting the wheel chassis are shown in the pictures below. The single axle trailer has a significant disadvantage. shifted center of gravity. Because of this, the body, the load in it, or it can lead to a breakdown of the equipment at all. For a large wheelbarrow designed to carry considerable loads, you should design a two-axle structure. Basic fasteners and details remain the same as for the single axle bogie project.

Trailer body

The body is made of wooden boards or metal sheet. For extra strength, the sides and bottom should be stiffened with ribs. In wooden bodies the corners are strengthened with metal corners. It is recommended to make the rear board on hinges in order to open it (tipping board is especially useful for dumping units).

hitch and seat

After the basic work is complete, once all the basic components of the structure are fastened, you can begin to assemble the remaining parts of the trailer. The most important are the hitch and seat.

The coupling can be made from 3 pieces of pipe and a trailing mechanism (in our case it is a tee designed specifically for the coupling node of the motoblock). This hitch is bolted to the frame. details about the hitch device is shown in the diagram below. A normal seat can be welded on, for example, from an old car or a toolbox seat can be added to the front of the trailer. Its dimensions will depend on the overall design of the trailer. The main thing is not to use too thin boards and securely fasten the box.

How to make a trailer for a power tiller with your own hands: drawings and dimensions, video

The structure of the power block is quite simple, but it is enough to effectively cope with many tasks for processing the land. If the area is small, then such a machine can be a productive substitute for manual labor. There is no need to waste a lot of time and effort on tillage. one single-axle tractor equipped with special attachments can do it all.

Returning to the device, it is really simple: engine, transmission, running gear, controls. Part of the transmission is the clutch, which transmits torque from the motor shaft to the gear shaft. The clutch also provides a decoupling between the motor and the gearbox when the gear shifting process takes place. This allows you to start and stop the machine smoothly without shutting off the engine.

A trailer hitch to a power tiller consists of:

The ability of the body to support a particular load depends on the quality of the assembly. The bogie must be made of strong material that can withstand the weight of the load and all weather conditions. Trolleys used on trolleys are equipped with wheels: automobile, motorcycle, etc. It is also desirable for the trolley to have drop sides for easy loading and unloading. The dimensions should be roomy and match the power of the power tiller.

Wheels are used on carts: car wheels, motorcycle wheels, etc. п. The main thing is that the cart for a power tiller can withstand heavy loads.

Wide wheels are preferable, as it increases the passability of the vehicle.

Cars also have fenders. Protect against rocks and dirt from the wheels.

All modern trailers are equipped with seats. Some craftsmen build a drawer underneath them to store the necessary things.

The drawbar is a triangle-shaped attachment that connects the trailer to the tiller.

The brakes will improve the process of transportation.

Trailer equipment for power tillers can be purchased from manufacturers of agricultural machinery, or you can make a self-made trailer for your power tiller. Consider both options.

There are many off-the-shelf models for power tillers on the market. They come in all sizes, weights, capacities and costs. Their advantage is that they are assembled by professional mechanics according to predesigned schemes. You do not spend any time or effort on this. The disadvantages are: firstly, you need to find a bona fide manufacturer that sells quality products, and secondly, a good-quality product is not cheap.

A single-axle tractor acts as a horse harness. It acts as a drive connected by the drawbar to the trailer. For this purpose, such brands of power tillers are suitable as: Patriot, Ural, Caiman 320, Forza, Crosser, Pro Arab, VIKING, Texas.

It is possible to make a trailer for the motor-block Neva, made of durable metal. Load capacity of the body is 500 kg. The dolly has a brake drive, which makes driving easier. On the Internet you can find a lot of drawings of trailers for the motor block Neva. They have a successful design with minimal consumables.

Among the ready-made models you can find a device with the function of a dump truck. The design is basically the same as a standard dolly, but with a modification that allows unloading by tipping the box. Though such model is more expensive, but it is necessary in the economy.

The construction and assembly of the cart is often done by the owners of power tillers themselves. There are a lot of homemade, but they can be assembled on the same principle of running gear on the wheels, sides and axle to connect the trailer to the power harvester.

From the beam VAZ-2109

Trailer from a beam VAZ-2109 will be suitable for power tillers with high capacity. 10 liters.с. The design will be pretty heavy, so you need more traction power. Such trailers have a large carrying capacity.

Make a trailer out of a beam VAZ-2109 with their own hands is simple, just watch the instructional videos, which are available free of charge. You can also find drawings and dimensions of the design, almost any will do, with one or two axles.

The beam will be used as an axle, for the rear axle fits a whole axle with wheels from VAZ-2109. For the front axle will be enough one beam, the wheels can be any. Wide wheels are recommended for large trailers, providing flotation and stability.

The advantage of the trailer for power tillers on the basis of a beam from the VAZ 2109 is that there is no need to spend time on making additional components, especially if you take the whole rear axle.

Making a cart

In order to understand how to make a cart to the power tiller with your own hands, you need to perform this algorithm of operations:

- For the manufacture of supporting welded rigid frame take 5 blanks of pipes, trim the ends with an angle grinder.

- Clamp the Woodchip sheet to the chipboard and weld the joints of the 3 longitudinal pieces and the 2 perpendicular ones so that they form a lattice frame.

- Check the geometry of the structure with an ordinary angle grinder. The angles of the joined ribs must be 90°.

- Install spacers between the tacked billets in the corners of the bottom and in the center, tack weld.

- To the longitudinal pipes of the bottom make tack welding electrode 4 vertical struts in the corners.

- Check the perpendicularity of the angles and verify that the dimensions of the sides are the same as in the drawing for the power tiller carriage.

- Finely weld all the workpieces to each other, grind the welds, clean them of laps and formations.

- body can be made of plywood or wooden boards and fastened at the corners with steel brackets.

- Boards are mounted on the frame and bolted together.

- Stronger boards are made of steel sheets. The sides can be hinged and fixed. Flip-flap sides are seen as more rational because they are made of plywood and metal.к. Large-volume loads can be unloaded more easily. The boards are also made of square or rectangular metal tubes. They are made in the same way as the frame, welded, checked geometry for strength and to avoid slopes and deviations, finally welded, rigidly attached to the frame. The rear tailgate is fastened with ordinary door hinges and equipped with bolts.

- Take a metal bar with a diameter of 30 mm and a length of about 1050 mm to make the axis for the wheels, connect to the longitudinal hinge and angular supports. Length must be chosen so that the axle does not extend beyond the wheels. Grind it to the necessary diameters for the bearings in the hubs.

- As a chassis you can take the wheelbase from a scooter, baby carriage, wheelbarrow or other farm equipment. Heavy wheels from car trailer with hubs are not recommended.

- To make the drawbar take 2 profile pipes with a diameter of 25×50 mm length about 1.85 m, weld them to the beam frame so that you get a triangular design. For reinforcing in the corners fix metal braces 4mm thick by welding, in front of the cart attach 8mm thick plate.

- Dumping technology involves the installation of door hinges, attached to the bottom of the beam and to the bottom braces.

- Frame the made construction to cover with wooden boards, plastic or metal.

- The driver’s seat on a single-axle tractor with dolly is installed ready-made or in the form of homemade boxes from a piece of particle board and foam rubber, lined with dermantin. Such boxes are necessary for hiding inventory and materials.

- You can use the parking brake drive of the machine as a brake. The brake pedal, made from a 6 mm thick plate, mount on the footrest under the seat, weld 2 angles. In the front to install a pedal, in the back plate with 2 holes for attaching the brake cables, the ends of which are connected to the T-shaped plate with a rod.

This is how to make a cart for a motor-block with your own hands.

The self-assembly of a motor-block trailer. it couldn’t be simpler

How to make a trailer for a power tiller with your own hands? The main thing you need to save effort and avoid unwanted mistakes is the correct drawings of the trailer for the power tiller and the schematics.

After selecting the exact drawings with your own hands and the size of the planned trailer, you need to calculate all the nuances of manufacturing.

- Decide what you want the cart to carry: Will it be a small, light load or probably a heavy load? On this basis, choose the strength material for the frame and cladding of the trailer.

- If the trailer will be a tipper, two-axle, heavy-duty trailer, then there is a need to equip it with a hydraulic drive. This is needed for easy tipping.

- For a model with one axle (single axle) a manual tipping device is enough.

- For safety, the cart, which will have a load capacity of more than 350 kg, should be equipped with a mechanical homemade brake. When a single-axle tractor with a dolly will be sufficiently loaded, it will be impossible to stop it when going down a hill. But since it is quite difficult to make brakes on the trailer to the tiller by yourself, so the best option would be the help of a qualified person.

Assembling a homemade trailer for a power tiller

When getting down to implementing the project, the master self-made carriage needs to:

- Create a working design or drawing (drawing);

- prepare the material for the frame and other main assemblies;

- Prepare the workplace;

- make a marking of the main elements of the trailer’s design;

- to conduct the lay-out and alignment of the corners of the alignment;

- assemble template parts;

- Fitting purchased assemblies to the structural elements.

Necessary tools and materials

To carry out the work it is necessary to prepare all the necessary tools:

- welding machine;

- angle grinder with a set of cutting and abrasive disks;

- measuring tool. tape measure, metal ruler, protractor, angle, marker and chalk, metal draftsman;

- hammer, chisel, pliers;

- Locksmith’s vise, a set of clamps, welding clamps;

- drill, a set of drills on metal;

- rivet.

As the necessary materials you will need:

- Steel square or rectangular pipe 60×60 or 60×30 mm;

- steel square tube 30×30 or 25×25 mm;

- angle 25×25 mm;

- channel;

- springs of the Moskvich car;

- 2 mm thick steel plate;

- Galvanized sheet metal 1 or 0,8 mm thick;

- fasteners, bolts, nuts, rivets.

For models with a rigid body, instead of a spring-loaded structure of the wheel set on springs, you will need an ordinary beam.

BIG BRAKES FOR MOTORIZED BICYCLES (part 1)

For the wheels of the trailer fit ready-made car wheels from passenger cars “Tavria”, “Moskvich” or “Zhiguli.

Wheels must be chosen immediately with hubs, it will facilitate the further assembly of the self-made device.

The frame of the trailer is a fully welded construction in the form of a frame grid made of square tube. Crossbars made of 25×25 mm square form frame crossbars, and longitudinal members are made of 60×60 or 60×30 mm pipe. All structural elements after marking are cut and laid out on a flat surface, the joints are welded with small seams, each joint of the elements is checked with an angle piece. After assembling the structure is carried out the final welding of all parts along the perimeter of all planes. The frame is painted after the surface has been treated with a metal primer.

Undercarriage

The undercarriage is the most complex element of a homemade trailer for a power tiller.

The undercarriage is based on a beam with hubs at the ends. Studs are docked together so that they form a square. butt joints are welded with a continuous seam. wheel hubs are installed and welded on the axle ends.

Check that the axle is properly assembled by checking that the wheel flats are parallel. Connecting of frame and strut is made with the help of leaf springs, the ends of leaf springs are placed into the welded brackets on the frame, and the strut is pressed to the central part of the leaf springs with the help of a suspension eye.

The undercarriage mounted on the frame is additionally checked for stability against tipping. As in the car, the axle spring group must have rubber bushings in the frame mounting bracket.

Body, skinning of the frame

the platform is measured in relation to the grid, leaving enough space for fastening the bulwarks. The front and side boards are set permanently, and the rear board is made detachable on door hinges.

Trailer sides have frame construction from 25×25 mm angles. Corners are welded butt-welded, seams on the inside are deburred to the level of the metal plane.

The detachable sides are assembled in the following sequence:

- side frame;

- galvanized iron sheet is adjusted to the size of the frame;

- the bead blades are cut out and fastened with rivets through the corner.

The bottom of the body is made of a sheet of 2mm sheet metal, put on the frame and welded with a small seam around the perimeter every 3-5 cm.

The installation of the walls begins with the front wall, then the lateral walls are installed and welded together.

The tailgate is attached last. first the hinges are marked and welded, and then the ratchet clamps.

Other construction details

After assembly of the frame and the body, a folding seat is installed. a wooden bench placed over the front wall with support on the sides of the.

As the brake system of the trailer it is recommended to use elements of car brake system, hub and wheels of which are used in the construction. To secure the braking system an additional lever lock is recommended.

You may also be interested in self-made carts for a power tiller.

Read about the attachments for the Neva unit in this article.

Self-made brakes

To make homemade brakes on the trailer of the motoblock will be very easy, if the master in advance makes sure that all the necessary materials, as well as tools are available. It is highly recommended to install brakes on each wheel for effective braking. It allows you to stop quickly, even at high speeds, and avoid turning the trailer.

Necessary tools and materials

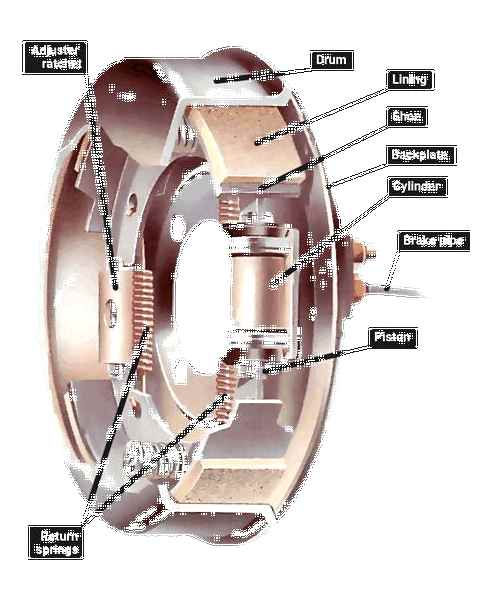

When planning to make homemade brakes for a motor-block cart, it is necessary to prepare materials and tools. As the basis for future brakes, it is best to use the following parts of the motorcycle:

During the assembly, the master will need to use a standard set of tools, as well as a welding machine, which will make all the connections of the structure strong and reliable.

For the correct work of the brakes it will be necessary to perform turning of the discs. Such manipulations are best entrusted to professionals, as they have the necessary qualifications and equipment for such work.

To successfully perform the work, it is strongly recommended to use the drawings of the braking system of the chosen model, which is used as the basis for the self-made construction. Since the system includes many parts, you should be extremely careful and install the unit in full accordance with the diagram, otherwise there is a high probability of their incorrect operation or a quick breakdown.

Order of brake assembly

After all the parts have been properly prepared, it is advisable to proceed directly to the assembly of home-made brakes. To do this, it is necessary to dismantle rods and cables from the discs, turn them and follow the following algorithm:

- Put the turned drums on the hubs, fasten them.

- The resulting gap between the discs must be closed using a sturdy metal wire.

- Install the disc on the axle, securing it with the bushing. Be sure that the disc is securely fastened so that it is not liable to become dislodged in the course of operation.

- Weld an angle or a piece of pipe to the axle for a better fixation of the disc.

- Attach cables to the drums, and then pull them to the control system.

Brakes are controlled by means of a special mechanism, which can be taken from a car handbrake. You can make it yourself from improvised materials.

It should be noted that as the operation, some elements of the design of such brakes may wear out significantly and require replacement. For example, it may be cables, so it is recommended to use elements with a minimum degree of wear and tear during assembly.

Figuring out how to make the brakes on the cart for a power tiller with your own hands, you can finalize the design for greater ease of use. The most obvious improvement is the installation of a spring, which returns the lever to the reverse state, which will allow you to switch the brakes without much effort. Such element can be placed not only on the brake mechanism, but also on the cable, as well as on other components of the design that allows everyone to choose the best option.

If automobile brakes are used for the assembly, you should consider the presence in their design element that switches off the control lamp. Although it is important in the machine, it is absolutely useless for the trailer, so it is recommended to dismantle it to simplify the design.

Some aspects of preparation

Many people can’t work without diagrams or drawings. However, in this situation, they, in principle, are not needed. This is due to the fact that to create a brake system for power tillers with their own hands are already used ready-made braking devices, the dimensions, weight and design of which are known.

In addition, it is easy enough to find drawings for specific brakes. However, it is recommended to first draw a diagram of the future braking system.

In the scheme should specify important additional data such as the dimensions of the axle, the size of the pedal or lever, the location of the return spring, the location of shock absorbers (usually rubber seals are used), brackets to connect the brake cylinders. Such a diagram greatly simplifies the installation process, which allows you to correctly assemble the braking system without errors.

Otherwise, you can make mistakes that will lead to the fact that the braking mechanism will not work, which can lead to injuries. Therefore, it is extremely important to approach the implementation of this system with maximum responsibility and care, paying attention to even the smallest details.

This will allow you to create a device that will be highly reliable and ensure the safe operation of the trailer. This is especially relevant, since in this case the mechanism is made by yourself.