How to mark the place of the cut at 45º on the profile pipe

Some “experts” say that with a square cross section, like a profile pipe, you can make a 45º cut with a standard tape measure. HouseChief editors do not advise the reader of such a method, unless you plan to ruin the material. The fact is that when measuring with a tape measure it is very difficult to do such work perfectly. A school ruler in the form of an equilateral triangle is just right.

The perfect tool not only for school, but also for working with metal

To begin with, on one of the edges a straight stripe is outlined, perpendicular to the side of the pipe. Further, the product is turned, and on the next face oblique marking going from the edge of the first strip at an angle of 45º is put. Here it is not necessary to measure anything, everything is already done by the manufacturer of the triangular ruler. After that, the profile tube is rotated again and a perpendicular is drawn. Now the only thing left is to connect the beginning and end of the mowing line on the fourth edge diagonally. All, you can safely work with an angle grinder. such cuts are ideally connected in a right angle of 90º. For the convenience of work, you can glue on the edge of the strip with painter’s tape. It will add clarity and make it easier to cut directly over the mowing line.

For the convenience of marking, if you have time, you can weld such a template

Techniques for cutting pipe at an angle

Techniques for not cutting at an angle depend on the material. Some techniques are appropriate for plastic or thin copper, which are malleable and easy to work with. Thick steel will require a more serious approach.

How to cut a 45 degree angle pipe

Plastic pipes of small diameters can be cut using specialized scissors.

Steel pipes can be cut with an angle grinder, but it is better to use a more accurate tool. a band saw with a rotary table equipped with clamps. Even a table saw with a circular cutoff machine will work just as well.

When using a general purpose tool, you will definitely have to use one or the other tooling.

How to cut a pipe at a 45 degree angle

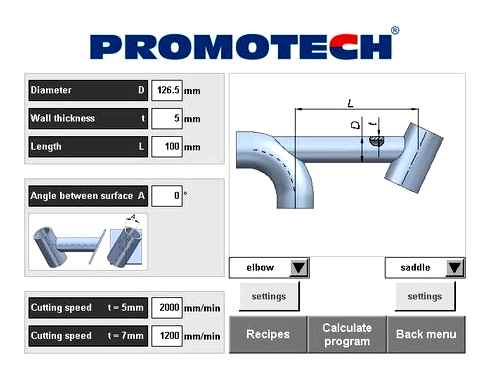

Angle of cut programs

The template for a 45° cut can be obtained by folding a square sheet in half. To form patterns for other bevels you will need to perform more or less complex trigonometric calculations. For those, who have safely left sines and cosines in high school and are not going to remember formulas, there are a lot of programs in the network to calculate patterns for any necessary angle. The program performs a calculation for a user-defined diameter and angle of cut and creates an image of the fishing line to be printed on your printer.

Important: in the print options you must choose the option “life-size” and disable the image scaling.

Paper template for the pipe

To cut exactly at a 45° angle, you can make a paper template yourself. To do this you should:

- Measure or calculate the length of the outer circumference.

- From the corner of an A4 sheet of paper the line must be drawn at an angle of 45°. If there is no protractor, such a line can be obtained by folding together the edges of the sheet adjacent to the corner.

- On it set the length of the circumference.

- This will be the hypotenuse. Finish it with an isosceles right triangle. One side will be the edge of the paper, the second should be dropped perpendicular to the second edge from the point set aside.

- Cut out the resulting triangle. this will be the template for cutting pipes at a 45° angle.

It should be wrapped around the workpiece, aligning the ends of the hypotenuse. By the mowing line of the cathetuses and will pass the segment. the fishing line should be marked with a marker or paper tape. Then along the marked mowing line it will be possible to evenly cut a piece with the required bevel.

The method is suitable for pipes up to 63 millimeters in diameter.

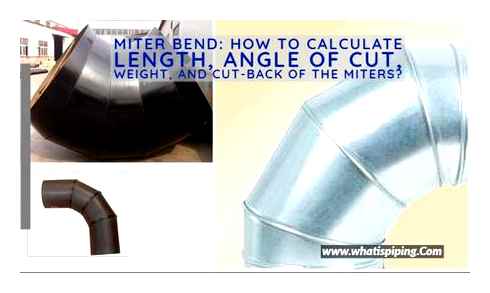

Pipe cutting mitre

Carpenters have long used a simple but very useful device to evenly cut at an angle the ends of bars, rectangular, round and shaped. The carpenter’s chisel is not bad for sawing off plastic or thin metal pipe.

You can use a ready-made, or you can make a crosscut with your own hands. Its advantage is that it can be made to exactly match the size of the pipe. To make it, you will need:

- Cut a plank 40-50 cm long and as wide as the pipe diameter.

- Cut two boards of the same length, but wider by the thickness of the first board.

- Assemble the boards with self-tapping screws, attaching the sides to the base to create a U-shaped gutter.

- In the center, mark and make vertical cuts in the side boards to the base so that the straight line drawn through them will form angles of 90, 60, 45 and 30° with the longitudinal axis of the structure.

- If necessary, make cuts at other angles.

It’s better to make the side walls of stronger wood. it will prolong the lifetime of the rigging.

Such a jigsaw not only defines and helps to maintain the correct sawing line and cut evenly. It also serves as a means of fixing the pipe. It is sufficient to hold the pipe by hand with the jigsaw. For each diameter it is necessary to make a separate tooling.

During operation, the slots in the side walls are also subject to wear. Make sure that the hacksaw blade has as little play as possible in the pipes. In the event of wear, new slots can be cut parallel to the old ones, with at least 3 centimeters of space between them, or the side walls can be replaced.

The advantages of such a wire cutter are as follows:

- inconvenient to work with large diameters and wall thicknesses

- each jigsaw has its own diameter

- Only compatible with the metal saw

Easy tooling for cutting

The universal cut-off saw with the circular circular saw is ideal for evenly cutting large wall thicknesses, whether round or rectangular in cross-section at an angle. These devices work in the blanking sections of small factories and on construction sites where large quantities of rebar need to be cut to size evenly.

The circular saw, together with the electric motor, is fixed to the pendulum lever and can be driven with great accuracy to the working area and further conduct the cut in one plane.

Advanced devices have an articulated lever that allows you to change the direction of the cut. In lower and middle price segment models mowing line orientation is made by means of rotary table equipped with clamps for reliable workpiece fixation. In addition, the table can tilt to the side by up to 45 °. Turning table and lifting mechanism are equipped with protractors allowing you to set the angle accurate to within a degree.

To reliably fix the pipe at a given angle clamp and two steel angle bars with a side close to the pipe diameter are used. A short bend is fixed on the turntable using its standard screw clamps. The process of fastening and cutting in steps:

- Set turntable to desired cutting angle and secure.

- Put the pipe between the angles and tighten them with a hand clamp so that the marked cutting line remains free.

- Start the motor.

- After gaining speed, smoothly drive the blade toward the metal surface and evenly cut the workpiece. At the beginning and end of the cut, when the cross-section of the metal to be cut is at its maximum, do not apply great force to the handle of the pendulum.

- high productivity, even with thick walls

- straight and smooth cut, requiring minimal cleaning and finishing with file

- No need for pattern mapping.

- Applicable for small and medium diameters

- high cost of the machine

- low mobility

- High power and noise consumption

45 degree cutting trick | secret profile cutting trick | pipe cut 90 degree

The nuances of working with rectangular section

To cut a rectangular profile evenly, experts recommend preparing templates in advance. The easiest way. to make templates from a steel angle of sufficient size, marked for the desired bevel. This saves a lot of marking time if a large volume of similar cuts are made.

Angle is placed on the side of the profile tube and on the beveled side mark the line of the cut with a marker or scribe. It is recommended to repeat it with paper tape.

Next, use the available tool to cut the profile evenly along the mowing line.

Using a tank of water

What to do if we are dealing with a pipe of small diameter and you need to cut the pipe at an angle somewhere near the edge? A deep reservoir filled with water will be helpful. Before you start, you need to calculate the angle and make a mark on the container. Then all we need to do is carefully lower the edge of the pipe into the water and bend it towards the mark on the container. We pull the pipe out, mark the line of contact with the water, and then bravely cut along the marking. This method is good for marking a large number of pipes. A ready template from a container of water will speed up the process of our work.

How to cut a profile pipe at an angle

In various situations, craftsmen of the household level often come to the question of the correct marking for the exact cutting of pipe blanks at an angle of 45 degrees. Nowadays there is a great variety of tools for both domestic and industrial cutting of tubes at any angle. The cost of such devices can be quite high.

How to cut a pipe at an angle

We suggest considering methods of marking blanks for cutting at a 45 degree angle at home without the use of expensive professional equipment.

How to properly cut pipes of different metal

Accurate cutting and trimming of pipes depends not only on a properly performed marking. Material is also of great importance. metal of different thickness and hardness is cut with different efforts and side effects. To properly cut a cast iron pipe, you should not saw it all the way through. Cast iron is a fragile metal, so usually a few notches are made, and then a specialist makes a precise blow with a chisel to beat off a piece of.

To work with thin-walled pipes you will have to very accurately align the position of the angle grinder. In doing so, the master must correctly select [discs for cutting metal with an angle grinder]. In industrial environments, special pipe cutters, gas cutters and welding machines can be used for the same tasks.

Safety when cutting a gas pipe

When working with mains-connected gas pipes, it is important to observe safety precautions. First shut off the gas supply tap, then make sure that there is nothing in the pipe. To do this, just open the burners of the stove and light the gas. when it runs out, the flame goes out.

How to cut a pipe at an angle. marking options for round and profiled pipe

When installing piping, it is often necessary to cut the pipe at a certain angle. When performing this task, precision plays a major role. There are a few simple ways to cut a pipe at an angle.

Incorrect cut of the pipe will lead to the impossibility of assembling the construction of the shape that was originally conceived. For example, if it is planned to turn the system to 45 degrees, it is necessary to make a cut of the pipe under 45 degrees. You will need marking tools and an angle grinder (you can replace it with a metal saw).

Marking the corner with a paper sheet

The paper sheet marking is one of the easiest ways to accomplish the task. A square sheet of paper is necessary. It is folded exactly diagonally. The resulting template for cutting pipes must be wrapped around the product so that the long side runs parallel to its cross-section.

Then a 45 degree angle is formed on the smaller side. It remains to mark the line of the cut with a construction pencil or marker on the sheet of paper.

It is recommended to wrap the marking area with a narrow adhesive tape so as not to accidentally erase it. This method is great for long, large pipes with the cut approximately in the middle of the piece.

Method of marking with a container of water instead of a template

This method of marking is suitable for small-diameter pipes, which are planned to be cut at a certain angle close to the edge. To begin with it is necessary to prepare a deep container with water. On it the planned angle of inclination is marked. Now you need to gently dip the end of the product into the liquid, tilt it toward the mark, and then pull it out.

Precision cutting machines

Band saws are characterized by high stability of the plane of motion of the blade and the accuracy of the cut. They are also widely used in the blanking sections of small and medium-sized productions. They are characterized by their versatility, reliability and high performance.

For private applications MASS from Italy offers a compact band saw unit. It is equipped with manual clamping device and can evenly cut pipes up to 65 mm in diameter, as well as rolled sections of the same thickness.

The swivel mechanism allows you to set an arbitrary cutting direction from 0° to 45°. Cutting blade speed is up to 45 strokes per minute. Economical motor of 370 watts allows the use of conventional household single-phase electricity 220 V.

Cutting at 90 degrees

To cut a round pipeline or metal profile with a rectangular cross-section evenly, use a sheet of ordinary paper. It is wrapped around the workpiece so that the edges of the paper sheet overlap, and then it is secured to the workpiece with tape or glue. Use an angle grinder to guide a thin line near the edge of the paper sheet, and then gradually deepen it until it is completely cut out.

Metal profile or round pipe can be cut using a template, putting on them evenly cut element with a large inside diameter.

Collar Tapping

To get the branching of metal pipe lines in the form of tees, a collar cut-in is used, for which it is necessary to cut the edge of a circular tube, adjacent to the walls of the other at right angles. To implement the method, proceed as follows:

- trim the edges of the workpiece at right angles with the previously mentioned method.

- Mark four equidistant points at angles of 90 and 180 degrees to each other on the circular end surface with a marker.

- Measuring the circumference, divide the obtained diameter by 3. From two diametrically located points, the resulting distance is set aside, and then these points are connected to the other two by a smooth arc, drawing a fishing line with a marker.

- According to the markings make a cut with an angle grinder and separate semicircular segments, after which the part is ready for welding. With small inaccuracies in the mating, it can be sealed with a sledgehammer against the round surface of the other element.

Angle cutting methods for metal pipe

There are several ways to saw or cut the pipe into pieces. From available tools an angle grinder works best with this task. But the biggest problem remains the need to properly mark the mowing line of the cut. They can be different, most often you have to maintain either a right angle relative to the axis of the pipe, or 45 degrees. Techniques vary slightly depending on what products need to be cut:

Water, gas and heating pipes;

Profile products for the assembly of gates, canopies, and other metal structures;

Large-diameter pipes. as a rule, it is rarely needed in the home, where the widest gap only in the sewer;

Pipes made of steel, cast iron, thin-walled non-ferrous metals and soft alloys.

Both tasks can be solved quite easily even without using a special template for the angle of the pipe.