These parameters should be known to owners of professional models, who sharpen the chains by hand at home. Cutting depth is adjusted by reducing the height of each cutting link stop.

The parameters of the low profile and high profile chain are 0.025 and 0.03 inches respectively. Knowing your profile types is important for selecting the right height.

Chainsaw chain size chart

In those moments when there is no instruction manual for a chainsaw at hand, and the marking of its cutting attachments cannot be determined independently, information tables can help, designed not only to make life easier for owners of chainsaws, but also to save them from possible mistakes that can be made by choosing the wrong dimensions of the bar or the chain blade itself.

Professionals’ tips for saw chain operation and maintenance

Experienced professionals have formulated several factors that prevent saw chains from reaching their full design life and lead to increased wear:

- Insufficient lubrication causes increased friction and overheating of the parts;

- wear of the drive pinion;

- Too much chain tension;

- use of low-quality lubricants not recommended by the manufacturer.

it is recommended to have several interchangeable chains for each saw. This way you don’t have to interrupt your sawing process while you’re sharpening blunt tools in the repair shop. It is also possible to choose the most suitable chain for different cutting conditions.

Many users do not know how to correctly count the number of links in the chain, although it is quite simple. It is better to count by shank. In order not to confuse when counting, the shank from which you start counting should be marked. You can do it with a marker or by sticking a piece of paper on it.

The second option is to count the number of connecting links. It is faster to count in pairs, to do this, the chain must be unwound, folded in half and placed on a flat surface, for example, on the table.

Important! It is not critical to make one link more than the other in this calculation. If you are missing a single link, it is possible to make a mistake when choosing and buying a spare chain and buy a short chain which you will not be able to install on your chainsaw.

What’s the best chain for your chainsaw?

The chain is the key element of any chainsaw. The type of cutting tool installed on the machine depends on the quality and speed of work when sawing wood. Choosing a chain saw chain seems to be a complicated process for first-time chainsaw users, because they need to know what kinds of this part there are, its characteristics, etc.д. This article will discuss the main factors to consider in order to choose a good chain for a chainsaw.

Number of Links in a Chainsaw

Knowing these three factors, it’s easy to find a chain for your saw, pole pruner or harvester head.

Chain pitch

The chain pitch is usually expressed in inches and is calculated this way: measure the distance between the nearest drive links in the chain, or the distance between the three nearest chain rivets (from the center of the rivet), divide by 2 and converted to inches (1 inch = 25.4 mm).

Chain pitch must always be the same as the drive sprocket of the saw and the driven sprocket of the bar.

- A chain with a pitch of 0.25″ aka 1/4″. the distance between the three rivets (drive links) 12,7 mm ÷ 2 = 6,35 mm converted to inches (÷ 25,4) in inches is 0,25″ (often referred to as 1/4″).

- 0.325″ pitch chain. The distance between the three rivets (drive links) 16.5 mm ÷ 2 = 8.25 mm converted to inches (÷ 25.4) in inches is 0.325″.

- Chain with 0.375″ pitch aka 3/8″. The distance between the three rivets 19 mm ÷ 2 = 9.5 mm translate to inches (÷ 25.4) in inches is 0.375″ (commonly referred to as 3/8″, not to be confused with 0.325″).

- Chain with pitch 0.404″. The distance between three rivets 20.5 mm ÷ 2 = 10.25 mm converted to inches (÷ 25.4) in inches is 0.404″.

- Chain with 3/4″ pitch. The distance between three rivets is 38.1 mm ÷ 2 = 19.05 mm converted to inches (÷ 25.4) in inches is 0.75″ (commonly referred to as 3/4″).

Thickness

The chain thickness is the thickness of the drive link (can be measured with a caliper). This dimension must always coincide with the thickness of the groove of the guide bar.

There are a total of 6 sizes for electric and gasoline-powered saws and harvesters that determine drive link thickness:

The third main parameter when selecting a chain: Length of chain (Number of drive links).

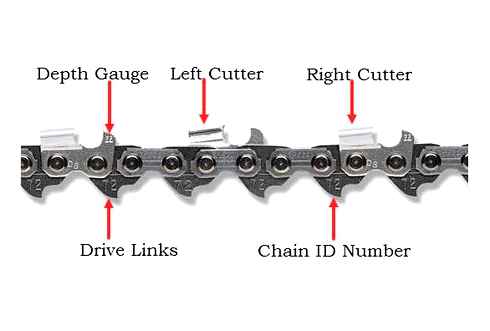

The chain length is determined by counting the number of drive (inner) chain links. Important:

Figure out what size chain you need without stampings on the bar. Chainsaw Chains 101

- cutting links do not determine chain length (do not count them).

- The length of the guide bar does not determine the exact length of the chain (for example, a saw with a 16″ (40 cm) bar may have a chain of 55, or 56, or 57 links, depending on the chain tensioning mechanism of the particular saw model).

- You cannot use a chain of approximately 55-57 links but only a certain length as recommended by the saw manufacturer.

What is the bar length of my chainsaw?

The cutting length of the bar is different from the total length of the bar. The bar length is commonly understood as the length of the cut (working part), which is the distance from the front of the saw to the rounded tip of the bar nose. This dimension is rounded up to the nearest one in inches or centimeters. An inch is ” equals 2.54 cm.

For example, the cutting length of a STIHL MS180 chain saw guide bar is 40 cm. 40 cm ÷ 2.54 = 15.7 inches. That’s 16″ (inches) when rounded up.

For the STIHL MS180 chain saw a 16-inch (40 cm) Oregon model 160SDEA074.

Chainsaw chain graph

Chains, and therefore tires, have three basic characteristics:1. Length (number of links for a chain);2. Pitch (1/4, 0.325, 3/8.404);3. Shank thickness (for chain)/groove width (for bar).

Chain pitch of a chainsaw. Table

On the basis of the pitch, chains are currently divided into several subtypes:

| № | Rivet spacing | Chain pitch (width in inches) |

| 1 | 6.35mm | 1/4 |

| 2 | 8,25mm | 0,325 |

| 3 | 9.3mm | 3/8 (0,375) |

| 4 | 10.26mm | 0,404 |

| 5 | 19.05mm | 3/4 |

As can be seen in the table, the chain pitch is indicated as a regular number (3/4) and decimal number. “0.375”. This division was caused by the similarity of the decimal values, “0.325” and “0.375,” because the difference of one digit created confusion when selecting the saw. For this reason, it was decided at one time to establish two different designations: decimal and regular fractions.

The spacing is stamped in the area of the special sawing depth stop on each tooth.

The pluses of chains with a larger pitch include:

But you have to remember that a wide kerf requires a more powerful motor, which in turn increases the resistance.

The advantages of small pitch chains are:

Advantages are gained by the large number of teeth and the small spacing between them.

All known chain classifications are based on the particularity of their marking according to their pitch, which is designed for specific needs and produced for a specific power of the electrical equipment. For a better understanding of each pitch type, they should be considered individually.

The greater the pitch, the greater the material entry (depth) and the higher the cutting speed

Thickness

Chain thickness is the thickness of the drive link (can be measured with a caliper). This dimension should always be the same as the thickness of the guide bar groove.

For electric and gasoline-powered saws and harvesters, there are a total of 6 dimensions that determine drive link thickness:

- Chain with a pitch of 0.25 or 1/4. The distance between the three rivets (leading links) 12.7 mm ÷ 2 = 6.35 mm converted to inches (÷ 25.4) in inches is 0.25 (often designated as 1/4).

- Chain in 0.325 pitch. The distance between the three rivets (driving links) 16.5 mm ÷ 2 = 8.25 mm converted to inches (÷ 25.4) in inches is 0.325.

- Chain with a pitch of 0.375 aka 3/8. The distance between three rivets 19 mm ÷ 2 = 9.5 mm converted to inches (÷ 25.4) in inches is 0.375 (usually designated as 3/8, not to be confused with 0.325).

- Chain with pitch 0,404. The distance between three rivets 20.5 mm ÷ 2 = 10.25 mm converted to inches (÷ 25.4) in inches is 0.404.

- 3/4 chain pitch. The distance between three rivets 38.1 mm ÷ 2 = 19.05 mm converted to inches (÷ 25.4) is 0.75 in inches (commonly referred to as 3/4).

Shank thickness. width of drive links

Tail part is the part of the chain that is located in the inner part of the bar. the tail comes in different thicknesses, so it should be chosen according to the size of the tire groove. The less power a chainsaw has, the less chain tail thickness is needed. There are the following chain shank thicknesses:

Household chainsaws are suitable for appliances with a shank size of 1.1-1.3 mm, while professional chainsaws use materials with a shank thickness of 1.6 mm. 1.5 mm thickness applies to semi-professional and professional machines. the size of the tail end of the link is 2 mm, which means that these devices are designed for special professional chainsaws, which are operated in harsh conditions. For electric saws you have to buy chains with 1.1 mm shank size.

What are the dangers of buying cheap Chinese bars?

It has been stated in the materials that the bar is one of the most important parts of the tool. If this part fails, it is extremely dangerous to use the tool. at any moment the chain can slip off the guide bar and cause serious consequences. It’s another matter when you just bought a new bar and installed it on the tool. The disadvantage is that it was not purchased at a brand name store, but at the marketplace under an unknown brand name and a very low price. It’s not hard to find a cheap chain saw guide today, but is it worth it?? Of course not, and that’s what it can lead to.

- The first thing is that non-original products wear out very quickly, necessitating frequent replacement

- At the same time as the guide bar, the chain wears out and must also be replaced

- In the process of using a counterfeit guide often such a phenomenon is observed as the wear of one side part, which eventually leads to the inability to make a straight or straight cut

- Breaking the integrity of the part is the most difficult and dangerous case, because when the tire breaks, it will break the chain rotating at over 10,000 rpm

That’s why the manufacturers recommend not to save money when buying chain saw equipment and to buy only branded and high-quality bars and chains from trusted dealers. Because a person’s life depends on the quality of these parts.