LAWN MOWER FROM A CHAINSAW

In the spring of this year, this lawn mower was assembled rather quickly. Why quickly? Because I did not have to grind any parts. Inexpensive and accessible materials and parts were also used.

The mower has a number of advantages even before industrial, namely: the big width of grasp. 500 mm, it mulches the green mass of grass (with the basket and the guide sleeve removed, with the upper window closed); it mows the mulched mass, throwing that to the left side; it has a big basket for the mulched grass. And most importantly. its low cost. Often we use the mower to get feed for farm animals, so it rarely stands idle.

Lawnmower engine is used from “Ural-2M” chain saw of 5 liters capacity.с., With a few alterations: we installed an imported scooter carburetor through a textolite adapter, about 15 mm thick. With this carburetor engine runs more smoothly and steadily in all conditions, also consumes less fuel and is easier to start.

Directly to the base of engine gearbox by bolting bracket attached gas tank, also from a gasoline saw Ural, capacity of 1.6 liters (it is more suitable by shape and design to the design of the power plant). To avoid clogging the carburetor, a fuel filter from the same scooter is connected to the fuel line.

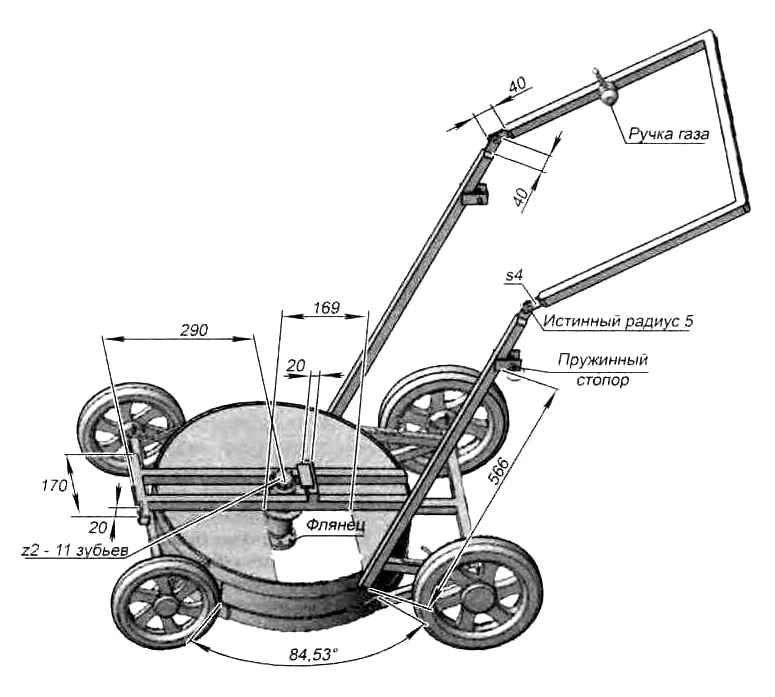

In the transmission of lawnmower has an inertial clutch, allows you to avoid serious damage if you accidentally hit a foreign object under the knife (eg, large branches). Chainsaw gearbox (ratio 1:2) has no changes (it’s only turned 90° with the sprocket down). Chain transmission with 12.7 mm pitch chain has Z1-17 teeth sprocket and Z2-11 teeth sprocket. RPM-increasing chain gear. the price you pay for the lack of modifications in the transmission. Drive sprocket Z1 is welded to the chain sprocket of the chainsaw and the guide pads have been removed.

Main frame dimensions. The mower’s hopper housing is galvanized on the inside and riveted with 4-mm aluminum rivets

The frame just made and painted

The frame of the lawnmower consists of two hoops bent from steel strip with a section of 30 × 4 mm and an inner diameter of 500 mm. These “hoops” are welded together so that the width of the resulting rim is 110 mm. The other parts of the frame, including handles, were made from 20x20x1,5mm square tube, and only on the front axle was a 15x15x1,5mm square tube (came from leftover metal).

The handle has an articulation that allows it to be adjusted in height and folded backwards for storage in the winter. the handle will take up less space. The wheels were used from baby carriages and have different diameters (it’s easier to find two wheels than four of the same size). And another thing, from experience: in the previous version of the mower used a wheel of small diameter (the side wheels from a children’s bike), they were not very handy to use (always something clung or ran into small obstacles). I didn’t make an adjustment of blades of grass by the height of mowing, because this parameter was defined long ago. It is approximately 50 mm from the ground plane to the blade plane. These 50 mm found by experience: if you cut the grass shorter, it is not very beautiful (denuded root part of the stems. turf, and it’s either white or yellow). as a result, mowed lawn looked unpresentable, in addition, in the basket with a green mass of “pulls” the earth (animals are not very happy about such “seasoning”). When stubble is high, the area looks like mowed land.

Total for the frame took: strip 30×4 mm. 3.5 m; pipe square section 20x20x1,5 mm. 5.1 m; pipe square section 15x15x1,5 mm.0,4 м.

Fuel tank, carburetor and air cleaner

To install the blades, a steel part of the hub, which was taken from an aluminum part of an IZh motorcycle wheel, is welded to the frame. Accordingly, the axle was used from the front wheel of this motorcycle, I had only to replace the bearings on the closed ones, since the “native” ones were worn out. A sprocket with Z2-11 teeth is welded to the top of the axle, as you can see. Between the sprocket and the hub bearing there is an 8 mm thick washer, made of water pipe with an inner diameter of 15 mm. On the other, lower side of the axle is installed a flange from the UAZ-31512 water pump, its inner diameter matches the hub axle. I only had to grind the axle with an angle grinder, to “pick out” the metal for the wedge connection between the flange and the axle.

Later, after assembly a side “window” was cut in left part of the cover for ejection of green mass to the side. left. This arrangement allows to mow (mulch) the green mass of grass with less strain on the mower motor and allows to use the mower even in very overgrown fields.

The mower’s blade was cut out of ordinary nonhardened steel 3,5 mm thick. It is made in such a way that in case of a serious obstacle the mower blade will not break and its part will not fly off but it will just bend and stay in place. The blade has two curved “blades”, cut from stainless steel 1.5 mm thick. The blades are connected with 5 mm steel rivets. The blades “feed” the green mass into the basket. The blade was balanced directly on the mower shaft (until the chain gear was connected). the shaft rotated easily and the blade. mounted on the workplace, turned and sharpened at the “heavy points” until equilibrium was reached.

How to make a mower from a chainsaw with your own hands?

The easiest variant of making. this is a homemade mower on the basis of a chainsaw. The design of the chain garden tool already has almost everything you need to work. The manufacturer only needs to complete the device with the missing parts.

Before you begin assembling a lawn mower from a chainsaw, you will need to study the drawings. During their preparation, it is necessary to specify the dimensions of all the parts used and the order in which they are mounted directly on the mower.

After studying the schemes it is necessary to prepare the materials that will be needed during the work:

- metal angle. needed to assemble a rigid support frame;

- steel plate. required for installing and securing the motor;

- 2 pairs of wheels from a garden cart or children’s stroller;

- A mounting rail or a pair of rotary discs;

- A 5-cm piece of pipe;

- pinion and bearing for connecting to the pipe;

- Blades made of steel blade that can be removed from a utility wood hacksaw;

- bolts, nuts, brackets, and other fasteners.

From the tools, the constructor will need a welder, a drill with a set of drills for metal, as well as an angle grinder with a set of disks of different diameters.

This is interesting to know community. Blog Friday’s home-made chainsaw crafts!

Low weight and solid power combined with compact size allows you to aggregate this “logger’s dream” with an ice drill and a bicycle, a sawmill and a winch.

Interesting homemade chainsaw with their own hands can make anyone who confidently works with a welder, grinder, and, if necessary, can get up and to the lathe.

In this case the knowledge of the basics of construction and drawing will be very useful, because the accuracy of all dimensions and quality of assembly are the main conditions for the normal operation of the unit, powered by a chainsaw.

Without going into technical details, let’s consider variants of the most interesting constructions with its use.

The first thing that comes to mind when you think about what can be done with a chainsaw is its use as a sawmill. Many builders have had to use this tool to split logs into logs.

The log in this case lies motionless and is accurately sawed along the entire length without wiggling or slanting joints. If this mobile sawmill is equipped with four lifting screws, you can accurately set the thickness of the sawed log.

Lightweight homemade snowmobile from a chainsaw is more complex by design than a saw, because here you need to put the gas, the clutch, as well as take care of shock-absorbing suspension of the carrier frame.

To increase traction on the drive shaft of the track put “traction” gear, the diameter of which is larger than the size of the drive sprocket of a chain saw.

There is usually no problem with the steering mechanism, because it is taken from a normal bicycle or scooter and modified so that the central axis moves the rods that turn the ski. Power of the snowmobile engine should be at least 5 horsepower, so for this purpose it is better to use a chain saw Ural.

The winter range of self-made vehicles will be supplemented with aerosleds

From a chainsaw, which is structurally simpler than a snowmobile. The driving power is provided by a large diameter propeller, which directly rotates the gasoline engine.

The same should be known to those home inventors who would like to turn a chainsaw into a backpack-type helicopter. Such a machine requires not one but at least two engines, working in concerted mode.

This vehicle is most often made for principle rather than practical use. The main driving force in its creator is the desire to test their strength as a mechanic and prove to others the option of the original use of this cutting tool.

Basis for the design is usually an old grandfather’s chain saw Druzhba and no less ancient bike with which you can conduct any experiments on remaking the frame for the installation drive.

The power transmission here is carried out through a toothed pair by means of a bicycle chain, and the start of such a self-made machine resembles the preparation for cutting firewood.

Less common are more advanced models, the base for which becomes a mountain bike, equipped with reliable brakes and shock absorbers. Such a moped from a chainsaw is equipped with a reducer with a gear ratio of 18:1 and variator gear, which allows you to comfortably ride it at the speed of an ordinary bicycle.

Lawnmower from a chainsaw with their own hands

Lawn mower. this is one of the things that seriously ease the lives of owners of their own garden plots in the summer, especially if those have a significant area. All mowers that can be purchased on the market differ mainly in their protection against breakage, and the type of blade.

But before you buy a new lawn mower, you can think about the possibility of creating a lawn mower from a chainsaw with their own hands. The experience of thousands of people suggests that this option is quite serviceable, and can be compared to most factory-made mowers

The main element, which will provide a chainsaw, will be its engine, which has more power than most other equipment used on the farm, so will be the best option. In addition, the lawnmower from a chainsaw with their own hands will turn out much faster than variants using, say, the engine from a vacuum cleaner. The mower is able to work for a long time without interruption, and easily copes with the frequent stones and small bushes on the site.

Mounting a homemade rotary mower from a chainsaw

The first thing to do is to make a small cart on which the chainsaw will later be mounted. This can be done by welding several metal pipes, or strips, to which the wheels are attached, the diameter of which should allow the cart to move without problems on any soil.

The “hand wheel” and the guide bar are unscrewed from the chainsaw, and the saw itself is attached to the cart in such a way that the engine shaft is at the bottom of the structure. Having welded pipes, which will be used as cart handles, let’s bring the “hand wheel” of the saw to them, and lengthen the “gas” cable and the fuel hose. This will allow you to start the homemade rotary mower from a chainsaw without leaning over the engine.

A version of the mower with two solid saw blades:

After the basis of the home-made mower from a chainsaw is ready, it remains to deal with the part of it that is directly responsible for cutting the grass, namely, the blades and mounts for them. We cannot weld the disc with the blades to the shaft of the engine, unlike the vacuum cleaner mower. Instead, we make a kind of attachment to the rotor, which is represented as two pipes of different diameters. One of them will be welded to the “star” of the saw, and has a length of about 8 cm with a diameter of 50 mm. The second one is 8mm bigger in diameter. i.e. it has to be put on top of the first pipe, leaving a small gap between them. The pipe is not welded together, but secured with M 6 bolts with locknuts. The purpose of this device is to be able to adjust the length of the tube, i.e.е. it is telescopic. You can pre-drill a few more rows of holes along the length of the body, and if necessary, change the height to which the grass needs to be cut.

A disc of metal, 4 mm thick, is welded to the wider of the pipes. Sufficiently powerful motor of the electric saw makes it possible to work at once with a large volume of grass, leaving behind an even path of trimmed lawn. On this 18-centimeter disc is attached three blades made from the blade of an ordinary saw or hacksaw. They are 12 centimeters long and 3 centimeters. in width. They are fastened with the same bolts M6, which are not tightened to the full power, so that the accidentally hit by a rock or other object did not break the blade. Once the obstacle has been passed, it will move out on its own to the “starting position” thanks to the centrifugal force.

On this example, we saw how to make a mower from a chainsaw, but it is also possible to assemble the engine back to the working saw. It will only have to replace the “sprocket”, which we welded to the bottom of the telescopic tubes. You can also make a lawn mower with your own hands from a vacuum cleaner.

Advantages of the construction

Engage in the manufacture of homemade electric mower encourage several reasons:

- Low cost of the device compared to factory-made counterparts.

- Eco-friendliness of the electric motor. An “electric lawn mower” does not produce harmful emissions like a gasoline mower.

- Low noise level.

- Ease of operation: no need to store and periodically refuel.

- Compact dimensions.

But you should be prepared for some peculiarities:

- Electric mower is not autonomous: its range is limited by the length of the mains cable. But if the size of the lawn is up to 12 acres, this disadvantage does not particularly matter.

- Limited power. Gasoline lawnmowers are usually more powerful, and the power of the electric version is also limited by the wiring capabilities.

- Danger of electric shock when working on a wet lawn.

The homemade version is inferior to factory-made models in the following ways:

Lawn mower mechanical

Mechanical lawnmower, made by your own hands, is characterized by less noise, lack of power consumption, the ability to work in the rain, but more labor-intensive manufacturing. The problem is the difficulty of correct selection of knives, sizes of wheels and gears.

The mower consists of two kinds of blades: one rotates and collects the grass, while the other, stationary, clips the elongated grass. For the mechanism of lawnmower requires a good speed of rotation of the blades, which is created by the transmission movement from the gears and wheels. Knives must be very sharp, protected by a shroud from the outside environment.Important! The creation of this version requires more patience, correcting flaws identified by experience.

General arrangement of the lawnmower

The simplest design of the unit has various structural components. The main structural units and parts of the machine are:

- engine;

- framework for fixing all the nodes and parts of the mower;

- knives;

- protection cover;

- wheels;

- Machine control handles.

Construction of a four-wheel mower.

The frame of the simplest design is a sheet of metal, which has a thickness of 2-3 mm with a hole in the center for the shaft of the propulsion system. Base plate is secured by means of angles welded to form a frame. The motor unit is attached from above to the sheet. Protective cover is fastened at the bottom of the base plate. On the sides of the base, the axles for attaching the wheels are installed. The control handles are attached to the base plate, where the control levers are located.

If an electric motor with a flange is used in the construction of the device, it is fastened using this flange. In order to secure the motor, it is necessary to drill holes in the base, which must coincide with the holes in the flange. When using a standard motor, two angles are welded to the base plate to which the motor is attached by means of the feet on the drive body. To attach it, holes can be made in the corners in an oblong shape in a vertical direction. This type of attachment lets you change the distance between the blades and the ground in the future. This design feature is indispensable when optimum cutting height needs to be selected.

One of the main units is the cutting unit, which consists of a mandrel with several short blades attached to it.

You may be interested in: All about air conditioning units.

Mounting a mower from a chainsaw

Cutting attachment diagram for a lawn mower.

For the villager is the actual use of various mowers to facilitate haymaking, but the cost of such devices is high. Therefore, many craftsmen construct haymowers using a power block or chainsaw engine. These motors are characterized by great power and high speed.

A rotary mower made with a chainsaw can work long hours without interruption.

The rotary mower is a small cart on which all of the device’s components are mounted. Such a dolly is made by welding together several metal pipes or strips. The wheels are attached to the cart, the size of which should be such that the machine can move without difficulty on any surface of the soil.

The number of wheels on each handmade mower can vary, there are different modifications equipped with two, three or four wheels. These different models differ in their characteristics. Two-wheeled versions of mowers are more maneuverable, but with the use of four-wheeled design can clearly observe the height of cutting the grass. The two-wheeled versions are also the most popular because it’s easier to find one pair of wheels than all four. If you plan to make a two-wheeled version of the construction, it is necessary to take care of a special casing, which prevents the machine from contact with the ground.

Diagram of a two-wheeled lawnmower.

If you choose a three-wheeled version, two wheels must be placed on the side of the handles.

This is to make it easier to control the structure and move it more easily.

Before using the chainsaw, the handwheel and bar are removed, and the engine is mounted so that its shaft is at the bottom of the structure.

Tubes to be used as handles are attached to the cart.

On the handles, the chainsaw hand wheel is fastened and the throttle control cable of the carburetor is extended.

Making the mowing assembly

After the base of the mower is made, you can move on to making the mowing assembly. The mowing unit consists of blades, which ensure mowing, and the fastening element of these working blades of the design.

In order to make the node it is necessary to attach a special nozzle to the rotor. This attachment consists of two tubes of different diameters. One of the pipes is welded to the motor sprocket and measures around 80 cm long and 50 mm in diameter.

The second pipe must be 8 mm more in diameter than the first one. Connect the pipes with M6 bolts and lock nuts. The purpose of this construction is to adjust the height of the cut of the grass.

The schematic diagram of a chainsaw mower.

Using a welder, a disc of metal with a thickness of 4 mm is attached to the wide pipe. The chainsaw engine power allows to work with large quantity of the grass at the same time. The disc diameter must be 180 cm.

The blades are attached to the fixed disc. The blade blades can be made using an old wood hacksaw. The length of the blades should be 120 mm and their width 30 mm. The blades can be fixed to the disc with M6 bolts.

The bolts should not be tightened to their full force so that the blades will not break when stones hit them. After an obstacle is overcome, the blades return to their original working position due to the action of the centrifugal force and the free attachment of the cutting elements.

General arrangement of the lawnmower

The simplest design of the device includes various structural elements. The main structural components and parts of the unit are:

- engine;

- framework for fixing all the mower‘s components and assemblies;

- blades;

- guard;

- wheels;

- control knobs of the machine.

Four-wheel mower design.

The frame of the simplest design is a sheet of metal, which has a thickness of 2-3 mm with a hole in the center for the shaft of the propulsion system. Strengthening of the base plate is carried out by means of angles welded as a frame. The motor unit is attached to the top of the leaf. At the bottom of the base plate is attached a protective casing. On the sides of the base there are axles for fixing the wheels. To the base, the control handles are attached, on which the control levers are placed.

If an electric motor with a flange is used in the device design, it is mounted by means of this flange. To fix the motor, it is necessary to drill holes in the base, which must coincide with the holes in the flange. If a standard motor is used, two angles are welded to the base frame to which the motor is attached by means of the feet on the drive body. For fixing, holes can be made in the corners in an oblong shape in a vertical direction. This type of mounting later on allows to change the distance from blades to the ground. This design feature is indispensable when optimum cutting heights are required.

One of the main components is the cutting unit, which consists of a mandrel with several short blades attached to it.

You may be interested in: All about air conditioning units.

Mounting a chainsaw mower

Scheme of fixing the cutting tools on the lawnmower.

For the villager, it is relevant to use various mowers to facilitate haymaking, but the cost of such devices is high. Therefore, many craftsmen design mowers using a power tiller or chainsaw engine. These motors are notable for their high power and speed.

A rotary mower made with a chainsaw can work continuously for a long time.

A rotary mower is a small cart on which all the construction elements of the device are mounted. Such cart is made by welding together several metal pipes or strips. The cart should be equipped with wheels, the size of which should be such that it is easy to move the unit on any ground surface.

The number of wheels on each self-made mower can vary, there are different modifications equipped with two, three or four wheels. These different models differ in their characteristics. Two-wheeled variants of mowers are more maneuverable, but with the use of a four-wheeled design can clearly observe the height of cutting the grass. The two-wheeled versions are also the most popular because it is easier to find one pair of wheels than all four. If you plan to make a two-wheeled version of the design, you should take care of a special protection cover, preventing contact with the ground of the working machine.

Diagram of a two-wheeled mower.

If a three-wheeled version is chosen, two wheels should be placed on the handlebar side.

This is needed to facilitate the management of the design and more easily move it.

Before using the chainsaw, the hand wheel and guide bar are removed and the engine is fastened so that its shaft is at the bottom of the structure.

Tubes are attached to the cart to be used as handles.

On the handles the chainsaw hand wheel is fastened and the throttle cable of the carburettor is extended.

Making the mowing assembly

After the base of the mower is made, you can proceed to create the unit responsible for mowing the grass. The mowing unit consists of the blades that provide the mowing and the attachment element of these working blades of the design.

In order to make the assembly, a special attachment needs to be put on the rotor. This attachment consists of two pipes of different diameters. One of the tubes is welded to the engine sprocket and measures about 80 cm in length and 50 mm in diameter.

The second tube must be 8 mm larger in diameter than the first tube. Join the pipes together using M6 bolts with lock nuts. The task of such a construction is to adjust the height of the grass cut.

The chainsaw mower component diagram.

A disc of metal with a thickness of 4 mm is attached to the wide tube using a welding machine. The power of the chainsaw engine allows you to work with a large volume of grass at the same time. The disc diameter should be 180 cm.

The blades are mounted on the disc. The blades can be made using an old hacksaw. The length of the blades should be 120 mm, and their width. 30 mm. The blades can be attached to the disc with M6 bolts.

Do not tighten the bolts to their rated capacity so that the blades do not break when stones are encountered. Once the obstacle is overcome, the blades return to their initial working position by virtue of the centrifugal force and the free attachment of the cutting elements.

Lawnmower from a washing machine

Obviously, not only a chainsaw engine can be used as the lawnmower’s power plant, but also any other engine.

In particular, a motor from a washing machine will do.

It is convenient that it is already equipped with a pulley, and the second pulley and drive belt are here in the washing machine.

If you compare a gasoline engine with an electric one, you can note such advantages:

- The absence of unpleasant odor;

- low noise level;

- compact size: the engine itself is not so massive, and there is no need for a fuel tank.

The same disadvantage is that the electric lawnmower is not autonomous: you need access to the mains and a long wire.

Most often, washing machines are equipped with asynchronous electric motors. In the case of loss of the regular control unit, such a motor is run as a normal single-phase: connect the starting capacitor windings.

The motor from the washing machine is not designed for long-term continuous operation, so the mower equipped with it should be periodically turned off for a while. It is also desirable to equip the electric motor with a protective tin cover with holes made for cooling.

Step by step instructions for making

Proceed to the construction of a makeshift machine only if you have on hand a quality scheme-drawing, which will be optimized for the necessary requirements.

- Initially the frame is made, for which pipes and angles are welded. The base made should be as strong and heavy as possible. Such a heavy properly made frame will eliminate the vibration of the sawmill when sawing logs, which improves the quality of the received edges of the boards.

- The skids can be made from wooden board or metal profile. The heavier the load on the sawmill, the sturdier the skids need to be. It is best to choose small rails or strong stainless steel to make movable elements.

- It is necessary to consider the mechanism used to adjust the thickness of the resulting boards. The hoisting mechanism can be made in two variants. The tire saws can lift the log by moving the base, while the cutting part remains stationary. The second variant is a construction with stationary logs and a lifting or lowering cutting tool.

- The electric saw is fixed with a bolted connection, ensuring maximum strength and reliability of the attachment.

- Sawing advance mechanism can be made of string or clothesline.

- Start-up work and, if necessary, adjustment of the cutting unit feed mechanism is carried out.

In each case, the technology of making a sawmill from gasoline and electric saws can vary significantly, depending on the chosen scheme of the machine.

Making a sawmill with their own hands is not particularly difficult. You need to find a quality scheme on the Internet, pick up all the materials used and, in full accordance with the available documentation, perform a universal woodworking equipment in use. The cost of making a homemade sawmill will not be too high, while in terms of functionality and ease of use, it will not lose the factory options.

Lifelong trimmer line for brushcutter made of bicycle chain

Everlasting line for a trimmer for brushcutter from the chain

to the bike with their own hands is very simple.

A boat motor from a chainsaw. a great alternative to buying an expensive engine. To ensure the movement of 20 km / h enough to set the boat homemade boat motor with a gearbox (gear ratio 2:1) and a 3-blade propeller, diameter 210 mm. The fuel consumption is only 1 liter per hour of operation.

A chainsaw motor cultivator can be assembled by almost everyone. It requires a transmission system (2 gears). What can be made of a chainsaw trimmer for grass, as well as with a gasoline saw remove the chain and. With its help, the motor energy is transmitted to the drive wheel, through which the working mechanism is set in motion. Of course, such a cultivator is not suitable for processing a huge field, but for the household plot its power is quite enough.

Moped from a chainsaw. How to make a haymower from a chainsaw with previously removed blade and chain. For such a vehicle, you will need a base, for example, an old bicycle. A chainsaw motor is attached to its frame. As a rule, a cogged gear is used on this vehicle. If you use a mountain bike, you need a gearbox to control the speed.

In order to manufacture the following devices, the craftsman needs some technical knowledge and experience in working with various mechanisms and materials. From a chainsaw with the help of various components, it is possible to create such homemade devices:

Sawmill from a chainsaw, which can be made with a metal frame. A chain saw is rigidly attached to this frame. Workpieces can be guided on a guide rail. There are also other variants of saws. How to sharpen a chainsaw chain chainsaw consists of how to choose a trimmer for grass. So for a device designed for longitudinal sawing, you need an adapter that attaches to the bar at its base and a guide that sets the direction of movement of the adapter. The guide is installed on a board attached to the log to be sawed. With this sawmill, logs can be split into 2 or 4 parts.

Technical characteristics of the Druzhba chainsaw

Druzhba 4 chain saw has excellent technical characteristics, which distinguishes it among modern professional models. Among the design parameters of the Soviet tool should be highlighted:

- Engine power. 3,5 l. с./2600 Watts;

- The size of the recommended guide bar is 45 cm;

- Saw chain pitch. 0,325 “;

- Tank for fuel filling. 550 ml;

- Lubricant reservoir 260 ml;

- Weight 7 kg.

The 4th generation Druzhba chain saw has the highest technical characteristics of all chain saws of this brand. By the way, their predecessor. Druzhba 2 chainsaw has a capacity of 2.8 liters. с., which considerably reduces the capabilities of the tool in practical use.

Safety precautions

Lawn mower is an injury-prone device, and a homemade one in particular. For safety reasons, mowing should be carried out with the observance of such rules:

- Closed shoes are worn, pants are long.

- Eyes protected by goggles.

- Ensure that children and animals keep a safe distance from the machine when mowing. It is 30 m (a stone or branch can be thrown by the knife).

- Work must only be carried out in sufficient lighting.

- Electric lawnmowers should not be used on wet lawns.

- You can not move away from the device without turning it off.

- Maintenance, cleaning and repair work should only be carried out with the engine switched off.

- Mowing lawns on uneven terrain is crosswise to the ground instead of up and down the slope.

Move the mower on paved surfaces only with the engine off.