No prerequisites for restoring a worn sprocket

The drive sprocket for a chainsaw of any power category is made of special steel, processed by a special technology, so the repair of the part by cladding with arc welding and subsequent milling is not possible.

The price of the part itself is several times less than the cost of its replacement in the service structures.

- The advantages of repairing a drive unit yourself are lower costs and less time.

- With the proper tools the work can be done in a fairly short period of time.

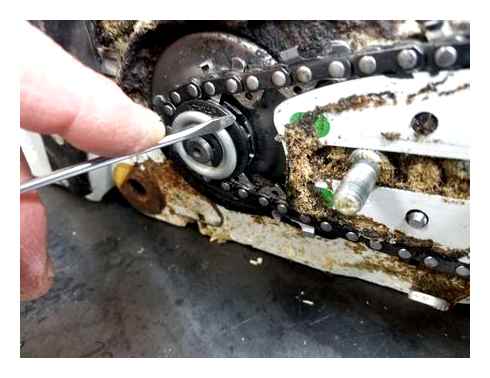

HOW-TO Replace A Chainsaw Chain Sprocket

Yuriy Vladimirovich, 50, Leningrad region

“I’ve been doing this for a long time. Often handymen come in and ask to make a chain saw faster. I will tell you right away. it is very dangerous. There are 7- and 8-tooth sprockets on sale. One tooth more, along with the replacement of the bar and chain is quite acceptable. But if we are talking about more cogs. do not even try to make a replacement. The speed of the chain will increase, so will the vibration, and if it bounces you just can’t hold the chainsaw in your hands. I’m not even talking about the chain breaking, no chain catcher can do it.”

Zhenya Kovalev, 25, Tver region

“I bought a chainsaw a year ago. Hadn’t repaired anything in all that time, and then the chain started coming off, so I replaced it with a new one. It flies off again after a week. A neighbor came and took a look, said the drive sprocket needs to be replaced. Well, okay, started to take it off. The piston was fixed with a plastic stop (specially bought). All unscrewed, replaced, but when trying to unscrew the stop, it fell apart. Plastic got in the cylinder. Told my neighbor to use a rope. What do I do now, how much will it cost to repair it??”

Andrey Krivenko, 34, Altai Territory

“I have a Chinese chainsaw. I have already done three chainwheel changes. There is nothing complicated about the replacement process itself, but it is the quality of the parts that is stressful. Here I think to pick up the European accessories for the chain pitch, replace all the Chinese and see what happens.”

How much is a sprocket and how much does it cost to replace?

The price of a chainsaw sprocket is highly dependent on the manufacturer and is slightly lower than the cost of the saw chain. To avoid regular replacement, the manufacturers recommend operating the saw with multiple chains and periodically swapping them out. The sprocket teeth then wear more evenly.

Tools needed

After we have diagnosed the failure of the clutch system and the drive sprocket, you need to buy replacement parts. It is important to know the chainsaw and the chain parameters. If you decide to put a chain with a different pitch, respectively, the sprocket must be replaced with a new one.

We also do not recommend putting Chinese components on European-made chainsaws. If you do, the reliability of your chainsaw will be severely reduced.

This requirement applies to all models, no matter where they are made or what class they belong to.

The drive sprocket is often sold as a set with a replacement bearing, but it can also be purchased separately. If we talk about the price of the sprocket and the whole repair kit, then you need to consider the brand of chain saw and its model. For a Chinese chainsaw, the drive sprocket will cost about 5-7 dollars. for chainsaw repair kits from European manufacturers start at 20.

Important: Take your chainsaw model and class into account. Domestic and professional tools have different drive gears.

Before going to the store, it’s best to take a picture of the assemblies you’re going to replace and show the photo to the salesman.

Structural problems, differences between different models

Brand-name chainsaws have a special design that makes it impossible to replace a worn-out drive without dismantling the clutch and other parts of the chainsaw. that means you need to disassemble the saw almost completely. modern models of expensive chainsaws are always equipped with a special key.

The chainsaw owner may also encounter the following nuance: on Chinese imported chainsaws or electric saws the sprocket on the clutch mechanism may be located in an unusual way. On older models, if the chain teeth are worn, it is necessary to unscrew and replace the drum, one-piece with the drive. on newer models it is possible to replace the sprocket separately.

A little about the rules of the node

Regardless of the brand manufacturer (Shtil, Husqvarna, Partner, Patriot, Makita) chainsaws are subdivided into home, semi-professional and professional. The difference, however, is not in the quality of assembly or manufacture of components, but in the class of the tasks to be performed, the productivity and the long power of the drive. This determines the choice of drive sprocket material for the chainsaw, its construction and the design of the saw chain.

The performance of the tool will be determined by how the sprocket chain works. In most cases, users use one of two options:

- The chain works until the teeth are completely worn, and then both the saw blade and the sprocket are replaced at the same time;

- Changing the chain periodically, which has a different pitch, and each will require its own sprocket.

The choice of option is often determined by the owner’s attitude toward their tool. If it’s anything like sawing (wood or steel staples, screws, etc. stuck in it. Д.), then you can go with the first option. However, the chain will need to be periodically adjusted, thereby reducing your chainsaw’s performance.

It is strictly advisable not to leave the old chain with the new sprocket and vice versa. When the saw is worn, there is almost a 100% chance that the tooth pitch is off. Both components in the chain train will therefore be subjected to considerable dynamic stress at the initial start-up. As a result, either the chain stretches prematurely, “adjusting” to the sprocket, or if one of the teeth on the drive sprocket breaks.

You should also pay attention to the functioning of the sprocket shaft bearing. When the saw is running at operating speed, only the crankshaft rotates. But all chainsaws periodically run and idle when the bearing rotates. If there is no lubrication, the seat is worn and, as a result, additional tooth beating is still a workable chain drive.

Why the drive sprocket needs to be replaced

Chainsaws have some parts that are subject to natural wear, including the chain, the bar, and the drive sprocket. This is not considered a tool breakage, because the wear and tear is the result of use. Unsuitable chain or mechanical shocks can also be the cause. For example, after the chain meets a metal object, it is recommended to inspect the sprocket.

If a part is not replaced in time, the tool can become unstable. Worn parts cause excessive vibrations, which in turn have a negative effect on the crankshaft bearings.

It is normal to have teeth up to 0.5 mm worn out. Often, however, users wear parts down to as little as 1 mm, not realizing that the chainsaw’s operation causes damage to other parts. It goes without saying that bearings break down and need to be replaced.

How to Remove a Sprocket from a Partner 350 Gasoline Chainsaw

Gasoline chain saws, like most other tools, require periodic diagnosis of failures and replacement of worn parts. A large part of them are related to the chainsaw drive sprocket or clutch disc. one of the important elements of all chainsaws without exception. Despite the relative simplicity of its design and the hints of the instruction manual, every year thousands of inexperienced masters are stumped in this matter and spend money on service centers or make it wrong, thus aggravating the problem even more.

That’s why we’ll concentrate on this topic and look at the construction, functionality and repair of the chain saw.

Replace Worn Parts

If the gear has a replaceable ring gear, you should carefully check the condition of the base. If you notice chips, cracks, deep scratches, changes in geometry or corrosion, not only the capscrews but the whole part should be replaced. Worn and new parts working together in one unit will shorten the life of the entire unit. The risk of jamming or chain breakage increases significantly.

In addition, the vibration load on the clutch, transmission and engine will increase. The same factors arise in the case of prolonged use of one chain.

Folk “craftsmen” sometimes reanimate the stretched chain blade, simply by throwing out one or for a link and re-pressing the axle. The chainsaw then needs to have the sprocket replaced.

It is also not necessary to change the diameter of gears (and, accordingly, the number of teeth). When working with a larger or smaller sprocket in the transmission and engine forces arise for which the designers of the device did not expect. It will shorten tool life and not increase productivity.

Despite the presence in the chainsaw design of safety systems that instantly stop the movement of the blade if it breaks or the bar breaks and protects from flying torn links, it is better not to lead to such situations. The need for gear replacement is only reinforced by safety requirements.

The feasibility of replacing worn chain drive components in a timely manner

The design of the chain ring determines the chain pitch selection.

- Installation of a new part on a worn sprocket reduces smoothness of its motion, accelerates its wear, initiates risk of its breakage and creation of injury situation.

- The operating loads on the motor and kinematic elements of the tool will also increase.

- A similar process is used when putting old sprained chains on a bar, the diameter of which is adjusted to the size of the bar by removing some of the links.

Specialists also advise against arbitrarily changing sprocket dimensions. The experimentation can have a negative effect on motor life and tool kinematics in general.

Safe sawing operations of varying degrees of difficulty are ensured by an effective emergency stop brake and devices to prevent the chain ends from flying off in case of an accidental breakage. In any variant. the most reliable prevention of emergency situations, maintenance of the chainsaw in serviceable technical condition.