What can be used to cut a tabletop so that there are no chips on it?

Making kitchen furniture requires certain knowledge and skills. One of the tricky things about this area is the intricacies with Laminated particleboard. And while a simple board or particle board can easily be sanded and coated with any material if necessary, laminated particle board already has a coating, and it is unlikely to be possible to replace it.

How and what to saw a tabletop without chipping at home, and what points you should pay attention to?

What tools to use?

If the question of how to saw a countertop has arisen, then first of all it is necessary to decide on the tool for cutting, and most often several tools are used.

For example, using a circular saw, you can get a perfect result, but it is quite an expensive pleasure, because a quality tool costs a lot of money. That is why this machine can be found mainly only at special factories.

Angle grinder. has a similarity with the previous tool, but the result will be far from ideal. In the course of work with the angle grinder can cause a lot of chips.

Usually, to saw a tabletop, the two main professional and interchangeable tools are a jigsaw and an electric jigsaw.

Specialists in the field of construction are divided into two main categories of blades or, as they are also called, saws:

In the case of work with a tabletop you will need the variant that rips on one side.

Before you proceed to the main work, it is necessary to well sharpen the blade of the tool, so that no chips were formed in the process of work. With a sharpened blade, before you begin to directly saw the material, you need to make a groove, the depth of which will be about 2-3 mm. This will allow you to perform the work without injury or splintering.

A cutter with a plastic pad on the sole

One of the reasons for sawing with a jigsaw with chipping is its sole. It does not press the edge of the kerf, so it gives him the opportunity to break during the reciprocal movement of the file. This is solved with a simple plastic overlay.

The sole pad is cut out of the plastic sheet. It is necessary to make a kerf under the file. It is simply clamped to the board and sawn with it. The sawn overlay is glued to the sole with a double-sided adhesive tape.

The jigsaw then makes an even cleaner cut than with masking tape.

Sawing through knife notches

This method is a little more labor-intensive than the previous ones. It implies making two notches under the ruler with a knife. They are made with a millimeter indentation to the sides of the marking line. That is, it is necessary to spend the knife so as to cut through the thin top layer of sheet material. The gap between the two lines must match the width of the kerf made by the jigsaw blade.

After that all that’s left to do is to carefully make the jigsaw cut between the lines. All of the resulting chips will end up on the notches. Eventually they will be missing or inconspicuous.

How to saw chipboard without splitting

In order to saw evenly and without chips chipboard at home, you need to know some tricks. No doubt about it, it’s better to use the jigsaw. Of course, you can also saw with a hacksaw, but the result is unlikely to please you, although it is possible to saw chipboard for various needs, where the quality of the cut does not play any role. And so, we need a smooth and beautiful cut. To do this, we take the jigsaw, ruler, tape measure and a square to right angle (if it is necessary), awl or sharp object with which to trace the trimmer line on the laminate on the chipboard. We measure off a part that we will saw off with 1-2 mm reserve on the subsequent adjustment and we put a ruler, on it we guide with an awl or a sharp object a line for a saw trimmer, try to press harder to cut through a laminate, and we saw along a line not on the line, but exactly along, only catching it the edge of a saw.

Then with coarse sandpaper finish the edges of our saw cut to the right state, and if you are not satisfied with the quality of the sawn end, we take a wax chalk of the desired color t.е. in the color Chipboard and grind up the chips. Let’s talk about saws for a jigsaw, I personally use BOSSNevsky.

If it is necessary to saw off without chips on one side only, it is possible to use saws as a tooth upwards and downwards, I use small saws with a direct tooth they less scalate and cut from both sides rather a decent. It will be more convenient to work the sawed off face with sandpaper, if you stretch it on a flat bar. Furniture wax crayons and markers you can buy in furniture stores, where they sell fittings. If you can’t find a crayon in the color you want. No problem, it can be made from several others, mixing like paint. Simply melt crayons with a candle and drop them on a plate, one color on it another, then roll them into one and rub the chipped edges, remove the excess with a ruler or knife and polish with a rag gently, no need to press much.

How to saw Chipboard without splintering

In order to saw evenly and without chips chipboard at home, you need to know some tricks. No doubt about it, it is better if you saw with an electric jigsaw. Of course, you can also saw with a hacksaw, but the result is unlikely to please you, although it is possible to saw chipboard for various purposes, where the quality of the cut does not play any role. And so, we need a smooth and beautiful cut. For this we take an jigsaw, a ruler, a tape measure and an angle bar for right angles (if it is necessary), an awl or a sharp object with which to trace a fishing line for a trimmer on the laminate on the chipboard. We measure off a part which we will saw off with reserve of 1-2 mm on the subsequent adjustment and we put a ruler, on it we spend with an awl or a sharp object a fishing line for a saw trimmer, try to press more strongly to cut through a laminate, and we saw along a line not on the line, but exactly along, only catching it the edge of a saw.

Then with coarse sandpaper bring the edges of our saw cut to the right condition and if you are not satisfied with the quality of the sawn end, we take a wax chalk of the desired color t.е. in the color of the chipboard and grout chips. Let’s talk about jigsaws, I personally use BOSSNevski.

If you need to saw without chipping only one side, you can use saws as a tooth up and down, I use small saws with a straight tooth they shear less and a cut on both sides is pretty good. It will be more convenient to work on the sawn end with sandpaper, if you stretch it on an even bar. Furniture wax crayons and markers you can buy in furniture stores where they sell fittings. If you can’t find a chalkboard in the color you want. no problem-it can be made from several others, mixing like paints. Simply melt crayons with a candle and drop them on a plate, one color on top of another, then roll them into one and rub the edges with chips, remove the excess with a ruler or knife and polish gently with a rag, do not press too hard.

How to saw laminated chipboard without splintering.

Before we talk about sawing Laminated Particle Board without splinters and deciding what to saw with, let’s define what it means to saw without splinters? Everyone has his own attitude to the number of them after sawing, someone a lot, and someone and a dozen just right. That’s why let’s consider not one, but three types of home cutting Laminated chipboard, from which you can choose the most suitable one. For obvious reasons we will not consider the use of expensive equipment designed for sawing laminated chipboard, this is the destiny of professionals. We are still amateur furniture makers and therefore we will use the appropriate tool.In the photo three parts, the upper was sawn with an electric jigsaw, the middle one with a hand circular saw (parquet), and the bottom was also sawn with a hand circular saw, but then processed with a hand router. Of course, in each case it is possible to achieve different results, it is all about experience and skill. But in general the capabilities of the equipment in question give roughly the same results for chips on Laminated Particle Board.

In this case three things allow to get more or less good results while sawing.

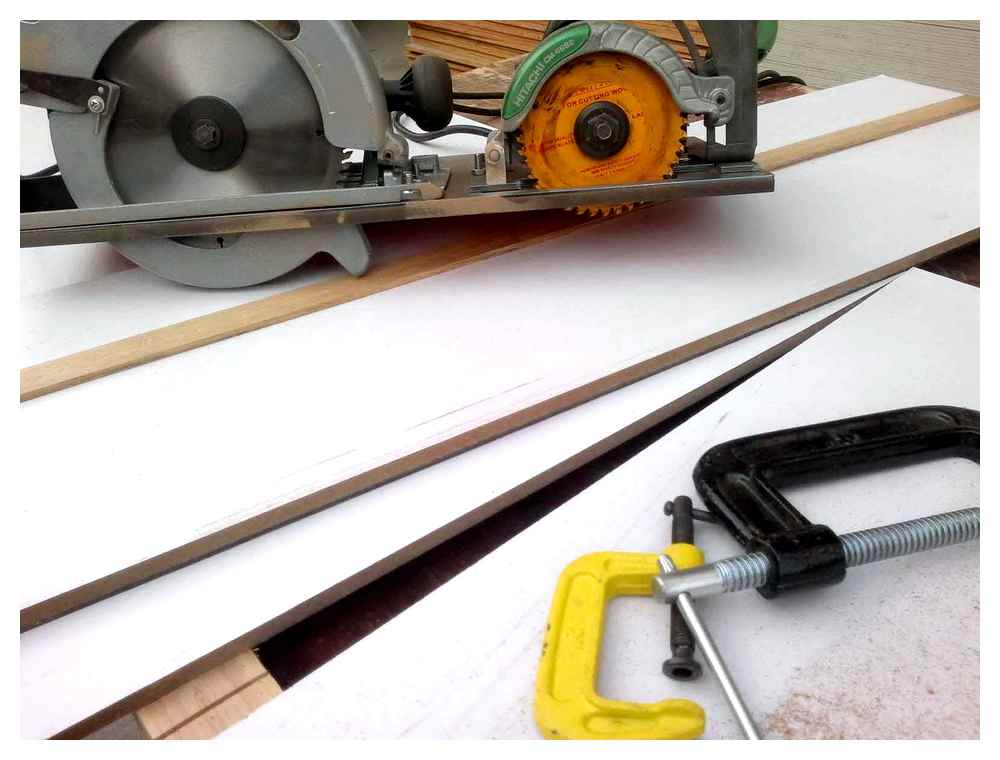

- Guide. It is not a good idea to go too far with the jigsaw blade guide. An ordinary spirit level and two screw clamps would do.

- Choice of jigsaws for laminated chipboard. The saw cuts the laminate and the particle board itself with its teeth, and the finer the tooth, the finer the splintering. And the cutting speed is just right. The direction of the tooth up or down tells only about which side of the workpiece will have more chips, the first from the top and the second from the bottom.

- Control over sawing speed. If you feed the jigsaw too much, the saw will bend and remove the kerf in the side, and the kerf will not be perpendicular to the plane of the workpiece. After such sawing, you can’t dream of gluing the edge.

Now let’s consider whether it is worth “scratching” the laminate layer. Perhaps this can help, but only if the following conditions are met. As the saw forms chips not only on these layers, but also on the outermost layers of the Particleboard, accordingly it is necessary to “scratch” them too. The width of the “scratched” line should correspond precisely to the thickness of the saw (if you make it narrower, it will stab, if you make it wider, it will leave a trace on the workpiece). The lines should be strictly on top of each other and you have to saw strictly along the line. Think about how realistic it is to do at home with their own hands, and the answer about “scratching” will be obvious.

Sawing the laminated chipboard with a parquet.

Chipping is caused here by the cutting teeth, but not only in the direction of the kerf, but also on the opposite side. (The vibration of the power tool does not make it possible to drive the parquet perfectly straight and as a result the saw blade tilts in relation to the kerf). In this case the guide not only allows the chipboard to be sawed evenly, but also prevents chipping on the side opposite to the sawing direction. When choosing a saw blade for sawing laminated chipboard pay attention to the number of teeth. the more you have, the cleaner the kerf is.

Before processing furniture parts with a router, it is necessary to saw them with a reserve of 3-5 millimeters from each side to be processed. Manual routers leave a perfect surface, unlike previous methods of sawing. splintering is extremely rare and it is possible to keep the cut perpendicular. up till now we have considered only straight sawing, but when it comes to sawing circles and curves of all kinds, there is no alternative to the jigsaw and router. The disadvantages of using a router can include the need for skills to work with it. We will talk about them in other articles.

Cutting a chipboard Particleboard

With the right tools and proper marking, cutting chipboard is no problem. The most important thing is to move very slowly. Even when using a fine-toothed saw, chipping can occur when making sharp moves. Cut the chipboard all the way through without trying to partially cut through it. To break the material so that it does not have cracks, then it will be impossible.

How to Saw Particleboard Without Chips at Home

How do I cut chipboard without splitting??

board. is the well-known particleboard that is finely ground and coated with a paper-polymer film. Laminating is carried out at a pressure of 25-28 MPa at 140-210 ° C. The coating is strong, beautiful, resistant to mechanical damage and thermal shock, which makes particleboard very attractive for the production of furniture and interior decoration ,

Many home craftsmen prefer to make their own furniture and buy high-quality particleboard from construction stores or manufacturers. Fortunately, the shorter color range of laminate coatings makes it easy to choose the most suitable material. The surface texture also varies: it can be smooth, imitating wood or natural stone, embossed under a shagreen or wooden pore.

But to make your own hands a unique furniture or an exclusive interior, it is not enough just to buy particle board and cut it according to the patterns. The thin laminated coating has a fragile structure. If you make a rough illiterate actions the cut is torn, and on the edges of the coating appear deep shells. To cut chipboard without chips and cracks, you need to know some tricks for working with it.

Rules of sawing laminated chipboard

Cutting chipboard at home can be a hand saw with small teeth, a circular saw, an electric jigsaw. To work smoothly, you need:

Tape the saw trimmer fishing line tightly through it to keep the teeth from damaging the front of the coating. Using a sharp knife, cut through the trimmer line to cut through the laminate and the wood underneath. Thus, the saw cuts through the inner layers of the Chipboard, affecting the coating only tangentially. The hand saw must be at a very sharp angle to the surface of the board. Cutting with electrical tools to work with minimal power. On the resulting piece, with a sharp knife, cut a thin layer of coating edge at an angle of 45.6. Chop the saw cut with a small file, machining the cut in the direction from the edges to the center.

To ensure that the edge of the sawn chipboard does not form chips and cracks during further work, it must be protected with special spacers. This can be self adhesive melamine tape, C-patch, T-edge.

Cutting panels of particle board and other materials

Any homemaker sooner or later is faced with the need to cut Particleboard. This could be making furniture by hand or paneling walls with fiberboard or particleboard. As you know, sawing particle board is very simple to make the saw cut smooth and chip-free. is not an easy task.

With your own hands or by order?

Individual sawing will be smoother

Quality sawing Chipboard is difficult to produce by hand due to the large size of the sheets. The dimensions of a standard board are 2440 × 1200, and this is not the limit. However, if you often work with particleboard or fiberboard, it makes sense to buy an expensive tool and work for your own pleasure. If you need to cut multiple sheets, you can go two ways:

- Cut the boards yourself using the hand tools available

- Order the sawing of particle board from a specialty shop.

- Tools and materials

- How to cut chipboard without chip?

- Cutting shapes

- What you can’t see Chipboard

?? We cut chipboard without chips

In this video, I offer the option of chipless sawing

, Without resorting to plunge-cutting molding machines.

How to saw an electric saw without trimming

Sawing without chip on one side and on both sides and what nail files need to be sawn What. If you have at least once tried to make a chipboard at home, you know for sure that this work is not easy at all and requires not only skill, but also a good tool. Particularly difficult to handle laminated chipboard, when cutting often forms a lot of chips. That’s why many craftsmen, faced with this problem, came to the conclusion that it is better to buy chipboard when buying, especially since many trade organizations provide similar services, and the price for them is quite acceptable. Sawing particle board is done using precision molding machines, which will help you get blanks of a given size and shape.

READ Why the saw heats up when you saw with it

Modern models allow you to cut flat materials not only horizontally and vertically, but also at an angle.

In addition to cutting sheets you can calculate and provide in the form of a video file several options for competent and economical cutting of sheet material (using special computer programs) and, if necessary, to make the cut. However, if for some reason you prefer to do the job yourself, before you see the EAF, you will have to do some preparatory work.

Tools and materials

If possible, it is best to cut Chipboard with a hand router, using homemade guides. This method is not very convenient when cutting large sheets, because a table is required when working with this tool. In addition, this method should often change the cutter. But you will end up with cleanly machined “jammed” edges.

Electric jigsaw. The most popular tool for sawing Chipboard

Some craftsmen use a jigsaw in their work, but in the absence of skill, it is difficult to cut accurately and chips may be formed.

You can try to mount a bimetal canvas jigsaw with the teeth sharpened inward for laminate. To make a saw cut with an electric jigsaw, increase the speed with a small amount of feed, so that no rips are formed.

If these methods do not suit you, then to prepare the sawing at home, we will prepare for the work:

How to saw chipboard at home?

The easiest way to cut chipboard at home. Use a joiner’s saw with fine teeth. This will allow you to perform an even cut and get a quality material with the right dimensions. Move smoothly, avoid sudden movements, directly on the board should be pressed gently.

An ordinary hacksaw will do the job of cutting the countertop. However, when working, you need to take into account that you need to leave a margin of at least 100 mm. The tool should have fine teeth. Better if it is a hacksaw for metal.

How to saw smoothly Laminated chipboard?

Saw a chipboard at home If you do decide to saw the chipboard yourself, prepare a hacksaw with very fine teeth or, even better, prepare an electric jigsaw. The fine-toothed blade gives you a very precise and even cut on the chipboard.

How the machine works

The principle of operation of the chipboard machine is not complicated:

- The panel to be cut rests against the left table leg.

- Marks out a cutting line.

- Starting the engine.

- After the working speed has been reached, the table is moved along the guide rails to the disk and the cut is made along the planned line.

The basic settings and adjustments of the unit are as follows:

Additional equipment is used in furniture factories along with a sawing machine for finishing and auxiliary operations. It is a router for edge trimming, laminating unit and drilling machine

How to cut chipboard without splintering?

Before you start sawing Particle board, especially laminated board, cut through with a sharp tool the trimmer line along which you will be sawing and glue a paper tape with a sticky layer along it. This will help to minimize damage to the decorative layer Particleboard.

To chipping was as little as possible, to direct the movement of the hacksaw should be at an acute angle to the surface (no more than 30 °). The movements should be smooth, without excessive pressure on the plate and sharp jerks.

If, however, chips still can not be avoided, treat sawing file first, working in the direction from the edges to the center, and then finely sanding sandpaper. You can also mask all the defects, using, where possible, a flexible profile.

To sum up

If you are faced with the question of sawing worktops, then do not be afraid, because it is quite possible to do it yourself. If there is a possibility, then it is better, of course, to use the services of specialists and take the material for processing to the workshop, where all work will be carried out on special equipment and in a particularly high quality.

In the case of sawing the tabletop at home, so that there are no chips, use a suitable tool. a jigsaw, adhering to the maximum accuracy and precision when working with the workpiece.

What’s important to know

The most important rule in this case. the less thickness of your tabletop, the more convenient it will be to cut it at home. Therefore, the ideal worktop has a thickness of 28 mm. When ordering a countertop, be sure to take into account a small margin in size. After all, at least 5-10 cm can “go away” in the course of your experimental sawing.

However, if you have never yet encountered the sawing of countertops, and you have absolutely no experience in this matter, you are better to turn to the services of specialized firms.