Tooth harrow. advantages and applications

Tooth harrow design includes trough and rectangular bars with teeth at the intersection. The latter are set in such a way that when working each of them leads a different groove. Depending on the harrow used, the distance between the furrows can vary between 220 and 490 mm.

In order to prevent the harrow from being blocked by weeds and soil, a distance of 15 cm is kept between the adjacent tines. The working depth of the harrow depends on the force the tines exert on the ground and the length of the connecting harrow wires.

Depending on their design, the tines of the harrow can be straight, curved with a special spring-loaded strut or chiseled. All tines of the harrow are mounted on an articulated or rigid frame. Hinged harrows are preferred in areas where there are a lot of irregularities. A rigid frame design should be used on more or less flat surfaces.

Tooth harrows for power tillers are used for the following tasks

- cutting and crumbling turf;

- The mole crushing and spreading over pastures and meadows;

- Effectively combing through turf;. Scraping the mattock;. Scraping the grass effectively.

The design of tooth harrows allows them to be used not only as an independent attachment, but also to work together with cultivators, seed drills, and plows.

The disc harrow with their own hands

The disc harrow is a more advanced model, which performs more functions for processing the land. The design is more complex, so it is better to buy a ready-made device at the industrial market. But for those who are not afraid of work, you can make a disc harrow yourself.

The work on the manufacture comes down to the following:

- For the manufacture you need discs and 2 pipes with the obligatory reliable fixation on the shaft of the power tiller. The total length of the pipes should not exceed 1 m. Choose discs with a diameter of up to 20 cm.

- On the discs with an angle grinder make cuts at a distance of 10 cm from each other around the circumference, in the center. the landing holes for further installation on the shaft.

- Ready-made discs are installed on the shaft every 5-8 cm with an inclination to the axis of the shaft: on the left side. to one side, on the right. to the other side.

Make a harrow for your own hands is not difficult, but it requires correctly constructed in size drawings, diagrams, tools and materials. The choice of device depends on the capabilities of the master and the purpose of using the mechanism.

Disc harrows for power tillers are available in lightweight and heavyweight versions. The first version is used for works with power harrows weighing up to 100 kg, while the heavy version is suitable for works with machines weighing up to 200 kg.

Disc harrows are used for the following tasks:

- breaking up crusts formed as a result of frosts

- stubble grinding;

- effective loosening of turf layers;

- The distance between the discs has a spool spacing to keep the discs spaced apart for the purpose of tilling pasture and grassland;

- removal of large weeds.

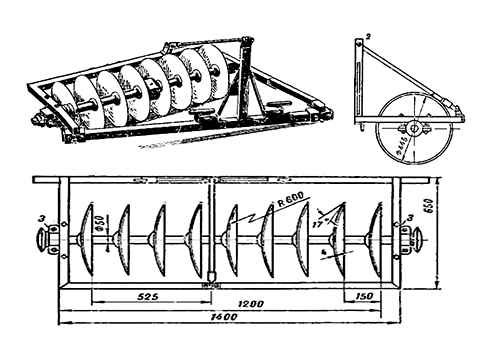

The working body of the disc harrow is a sharp steel spherical disc, which can have a diameter of 45 to 51 cm. The entire design of the disc harrow for power tillers resembles a battery of several discs mounted on one axis. There is a distance between the discs, in which spacer bobbins are placed. All cutting blades are mounted on the axis at a certain angle and always in 2 rows. When cultivating the soil, the front discs work in an upward direction and the rear discs always fall back.

To loosen soil more effectively the rear discs are offset on the power harrow. When the harrow is in use, its discs rotate, making them grip the soil. The cutting edges of the discs cut through the hard packed soil by lifting and turning it upside down. the soil layer falls from a certain height, and as a result it overturns and crumbles.

An important advantage of the compact disc harrows for tillers is that they are less likely to get clogged with soil and weeds. Thus, they can be used much longer without regular cleaning, which saves the farmer time and effort.

For power tiller tools: mulcher, mulcher and counterweight with your own hands, wheels for cultivator dimensions and drawings

Previously, it was necessary to harrow and plow by hand, using a minimum number of auxiliary tools, but now it can be done with the help of special equipment. In this case, we are talking about power tillers. units that are complete helpers in the garden and vegetable garden. However, the cost of all these equipment is quite high, given the cost of the power tiller itself, so many masters have adapted to make new self-made this or that technical means.

Not surprisingly, the growth of such interest in this technique was associated with the use of various additional equipment of trailed and mounted type (KUHN), which significantly expand the functionality of a power tiller.

On the Farm Episode 172: The 3 Point Hitch Harrow Bar.

Harrowing Features

Harrowing is considered the most important stage of soil processing, which affects the condition of crops and crop yields. This agro-technical action simultaneously solves several problems, the main of which are the destruction of weeds and loosening the soil. In addition, harrowing effectively levels the ground and helps significantly reduce moisture loss. The ripping effect is achieved through the action on the ground of the working elements mounted on a common frame and shaped like discs, teeth or hoes.

Such a device is called a harrow and has been known to mankind since ancient times. To pull the harrow was formerly the privilege of the workhorse, but today, thanks to mechanization, this role is assigned to agricultural machinery.

Large farms more often use mini-tractors as a harrow tractor, while dacha owners and owners of small plots more and more often give preference to power tillers.

The harrowing process is carried out twice a year. The first time. in early spring, immediately after thawing of the soil, and the second time. after removal of the last crop, just before the first frosts.

There are several types of harrow for a power harrow: tooth, needle, disk and rotary (rotary).

Tooth model

is the simplest type of equipment and is a reduced copy of a classical harrow, which is equipped with tractors. Structurally, it is made in the form of a wedge-shaped or rectangular frame, with metal teeth placed on it in lengths from 25 to 40 mm. The arrangement of tines on the frame may be different, but the most common is zigzag, and the tines themselves may have both circular and rectangular cross-sections.

The tine harrow is able to loosen the soil by 10-14 cm, which helps to normalize air exchange and regulate the water balance.

To attach the harrow to the power harrow a chain or rigid hitch is used, and to get a higher harrowing effect the rigid tines are sometimes replaced by spring ones.

The advantage of the species is the simplicity of design, the lack of complex knots and the ability to make the device with their own hands.

The main working characteristics of the tooth model can be considered on the example of the common two-track harrow BN-1, which is designed specifically for the motor-block “Neva“. This model loosens and crushes the coarse lumps of soil resulting from ploughing and levels the topsoil.

Working depth varies from 3 to 10 cm, and productivity is 0,2-0,5 ha/h. Working width is set with a special crank, available in working widths from 60 to 100 cm. Model dimensions are 72x67x51 cm, weight 17 kg, and the optimal harrowing speed is 4 km/h.

Coupling to the tiller is carried out by a screw mechanism with a universal coupling.

Needle model

The design is somewhat similar to the Pinion harrow, but differs from the latter in that instead of teeth welded to the frame it has interchangeable arch-shaped pins. This harrow allows to cultivate stubble and is used for leveling the soil, which prevents it from drying out.

The devices are designed for powerful water-cooled power tillers weighing from 200 kg.

As an example of a needle model we can consider a harrow for “Zubr” power tiller. The working width of this device is 1 m, and the depth of loosening is up to 14 cm.

The tool is attached to the power tiller with a rigid hitch that has an adjustment mechanism. Weight of the harrow is 30 kg.

Disc model

Available with spherical discs of smooth or perforated design. The harrow with peorized discs gives the best results, but requires constant cleaning of the working area during the harrowing process.

The discs are attached to the frame at different angles, which in each case is set by the operator of the power tiller and depends on the type of soil and its condition. The principle of action of the disc models is quite simple and is as follows: during the movement of the tiller the discs of the harrow cut the top layer of soil and crush it. This causes eversion and cutting of the weed roots.

The disk harrow can be attached to the front or rear of the power tiller depending on the model of the power tiller and the attachment.

The range of disk devices is quite wide, so it would be unfair to take just one model as a reference. Most of disc machines in the range of disc harrows are quite powerful devices. The largest of them have a working width of up to 140 cm, can go deep into the ground up to 20 cm and weigh up to 70 kg.

Such devices are mounted on medium and heavy power tillers and attached to them by rigid adjustable coupling.

Rotary or rotary models

They belong to the active class of attachments. Their difference from the previous three passive models is that they are not hitched to the tiller by means of a hitch, but are installed on the machine instead of the wheels. The working part of such devices is represented in the form of sharpened plates located on the discs, which are set at a certain angle. Exactly the plates are working mechanism and carry out tillage.

The penetration depth of the rotary models is quite small, only 7 cm, which is enough to cultivate the land immediately after the harvesting of crops. The highest efficiency is achieved when the rotary models are installed on power tillers with transmissions.

Range of application of rotary devices is somewhat wider than of other types and, along with loosening and leveling the ground includes the possibility of seeding and effective covering of seeds. This method leads to a significant reduction of seed loss and significantly increases yields.

In addition to applying seed, the rotary harrow is used to throw mineral fertilizers at the desired depth.

As an example, one can consider a Russian-made rotary harrow for a “Neva” power tiller. The device is able to effectively level the soil after plowing and make mineral additives at a depth of 5 to 7 cm.

Greater tillage efficiency can be achieved when the tiller is moving at a speed of 4 km/h.

With a working width of 1.4 m and a section length of 70 cm and a diameter of 35 cm, the harrow is just as wide as a conventional harrow. Ripping depth is somewhat greater than other models of this type and reaches 10 cm. Weight of one section. 9 kg.

Conventional harrow

The Classic or mounted harrow creates a smooth and friable surface. Also this type of mounted equipment allows quality covering of soil moisture and thus prevents its drying. The harrow breaks up large clods of earth to the required size, eradicates weeds and removes residual vegetation. The equipment is fairly light, so it is used for shallow tillage, crumbling the clods of earth and shallow loosening before the sowing campaign.

Factory-made tooth harrow for power tillers is made of special construction steel that can withstand considerable loads. Also this equipment is good for leveling the soil after milling.

This type of harrowing equipment is a straight or zigzag frame, which can be made with your own hands from steel strip, square tube or angle, a rack for coupling to the tiller and tines. To fix the tines on the frame you can weld them, or thread them, and fix them with nuts. Working tools on the frame are located at a uniform distance from each other, and their length can be 25-45 mm. As for the width of the equipment, then, for example, 500-600 mm is quite enough for the “Neva” power tiller. The video below shows a tooth harrow in action.

You can also make a power tiller with your own hands, following the drawing below. It will take half a day to make such an attachment, but it will be worth it.

In order to make this equipment for a power tiller we will need the following:

- Metal pipe with a square cross-section to weld iron strips, to which, in fact, by means of nuts will be attached to the teeth with a thread cut on one side;

- The drawbar of our attachment ends with a welded sleeve, through which a metal pin will be connected to the used power tiller;

- make a stand with an adjusting screw to adjust the lifting height of the harrow to ensure the uniform penetration of tools into the soil.

Either purchase factory equipment, or Homemade harrow for the tiller on a “Neva” power harrow, there is a feature of damp soil accumulation with vegetation residues on the working tools, which can make land treatment ineffective. In order to easily and smoothly clean the tines with a scraper or any metal object, we will use the lifting lever of the machine.

The video shows the simplest tooth harrow for power tiller with indication of dimensions.

Varieties and their structure

There are several variants of implements for loosening the soil, which differ in design and have a number of characteristic properties.

Harrows are divided into such types:

Rotary agricultural tool

If we talk about the rotary harrow for the power tiller, its main advantage is the optimal removal of the top layer of soil. Ripping the ground is also no problem. Loosening depths of 4 to 8 centimetres can be set, depending on the job site.

Very important and the size of the harrow in width, here is taken into account not only the resource motoblock, but also the cultivated area. As a rule, this value is equal to 800-1400 millimeters. Such parameters are explained by the ability to work comfortably, maneuvering in areas with a small area.

The industrial rotary harrows are made of a quality metal alloy, which means that they can be used for decades (with the right care and maintenance).

On quality farm implements, the blade has an oblique configuration and the tines are at an angle to the ground, having an ideal intrusion angle for quality cutting of the soil, its leveling and elimination of weed plants.

Disc device

The disc harrow is used on dry soils, it performs the same function as the rotary harrow, but has a completely different structure. Here the key ripping components are the discs, which are similar in configuration to the stars. They stand on the same shaft at a specific inclination, guaranteeing maximum penetration into the soil.

Tooth harrow

Cultivation with a power tiller with such a device is practiced if it is necessary to obtain an even and scattered layer of soil. The teeth are set in regular intervals and are available in different shapes and sizes: square, knife, round and so on. The tine height is directly related to the weight of the implement: the heavier the weight, the higher the tines. Basically, their parameters range from 25 to 45 millimeters.

This equipment can have several ways of aggregation with the chassis. In one variant by means of a spring strut, and in the other. articulated.

The toothed harrow is subdivided into:

Needed equipment

Let’s take a closer look at just crop production, the choice of crops that can be grown in the Russian expanse due to the vast territories with different climatic conditions. Take forage crops.

- an extensive area for sowing;

- seeds of future crops;

- technical support:

- machinery for plowing and tillage

- plows:

For more on plow operation, see

- a harvester and a roller;

- seeding units:

- various kinds of seed drills;

- planting equipment;

- tractors and trucks for harvesting;

- mowers and combines.

We should not forget about crop irrigation, irrigation against various pests, and fertilization.

Making a trailer

One of the most popular homemade trailers is the. It can be considered the most basic unit for working with a power tiller. As already mentioned, the first step is the preparation of drawings and calculations. The design may vary depending on desire, imagination and available material.

Preparing the frame is the first step. A rectangular frame is made, with the obligatory insertion of the stiffeners. Envisage a place to which to connect the elements of the undercarriage and attachments to the tiller. The undercarriage is most often mounted on a homemade hub (a fitting welded to the frame is edged).

Next, the direct attachment of the undercarriage. A bearing system or axle can be used here, depending on the design of the trailer. In the second case, it is better to make a removable mount rather than a welded one. You may need it when repairing (replacing) the axle.

It is easier to buy a ready-made hitch. Simply attach it to the trailer. Usually it is attached to a piece of metal pipe that is welded to the cart frame.

Next, the body is assembled. Steel, stainless steel or galvanized steel are used for this. It is important to make stiffeners on the bottom and sides. There is a place for the driver.