How to properly change the disk on the angle grinder

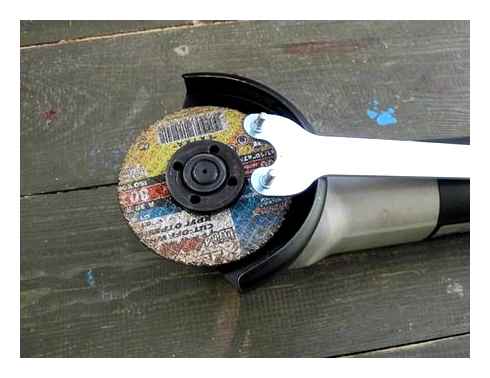

Since the wheels for the angle grinder are consumables, then sooner or later they have to be replaced. They are attached to the spindle angle grinder with a clamping flange (nut) with a thread of M14. To unscrew it, a special horn wrench, which has pins on one side, must go in the package to the angle grinder.

So, to replace the tool on the angle grinder, follow these steps.

- Turn off the power by unplugging the device from the socket.

- Lock the spindle of the angle grinder with the button on the front of the housing. When the key is pressed the stopper enters the hole in the disk mounted in the gearbox and locks the spindle in the stationary position.

- Insert the pins of the wrench into the holes on the clamping flange.

- Hold the retainer with one hand and turn the wrench counterclockwise to the left with the other until the nut is loosened. Then it can be unscrewed without a spanner and removed from the shaft. In this case, the spindle of the angle grinder rotates clockwise. But which way to unscrew the nut if the shaft of your appliance rotates counterclockwise? Remember: always unscrew the clamping flange in the exact opposite direction to the shaft rotation.

- The tool can now be changed by removing the old tool beforehand. If you notice that dirt has accumulated inside the housing, you should remove the bottom flange and use a steel brush to remove dirt from all surfaces.

After you have carried out the above steps, the tool change is considered complete.

Wood disc for angle grinder: varieties

Angle grinder or angle grinder allows the processing of various materials, including wood. If it is necessary to cut metal, resort to the use of an abrasive disc on the angle grinder. If you need to cut a brick or ceramic tile, then diamond discs come to the rescue, due to their high strength and durability. What to do if you need to saw or grind wood? To do this you will need to buy a special disk for angle grinder on wood.

Wood disc for angle grinder

First it is necessary to determine the tool with which you plan to cut the wood. It is known that discs are issued for standard sizes of angle grinders. The smallest diameter is the size of 115 mm, but such a tool is used in extreme cases.

The main advantage of this angle grinder is its compact design, but it is extremely inconvenient to work for long periods of time with such a tool. The optimal option for working on wood is an angle grinder with a 125 mm disc. This is the size of the wheel for wood is the safest, that is why it is widely used.

The wood angle grinder requires a special disc. It is categorically forbidden to cut wood with abrasive or diamond wheels. This will not help to cope with the task, but rather lead to the destruction or overheating of the tool.

Cutting wood with an Makita angle grinder and saw blade

When selecting a wheel for angle grinder on wood, it is important to pay attention to the inside diameter of the shaft, which by standard is 22.2 mm.

Older models of angle grinder may have a different size of shaft diameter, so this point is important to consider when buying the appropriate wheel.

The optimal wheel for woodworking has the following parameters: 125 x 22.5 mm. angle grinder under the disks of 150 mm and above is not recommended for use in wood, as increased risk of serious injury. It is better to use tools for cutting or sanding wood under 125 or 115 diameter circles.

Not only power tools, but also hand tools pose serious hazards if the safety rules are not observed. Wood cutting angle grinder attachment in such a case is no exception.

-

When working with an angle grinder with discs for woodworking, it is important to pay attention to the following points:

Do not perform work without a protective hood, with the exception of sanding, grinding and polishing of wooden surfaces. It is especially dangerous to work with circular saw blades. Never use circular saw blades or other discs on the angle grinder.

Only consumables expressly intended for the angle grinder may be used. In conclusion, it should be summed up, and noted that the circles under the angle grinder for woodworking are no less popular than abrasive circles. After all, the use of such consumables greatly facilitates human labor, as well as save time.

Each of these components must be used for its intended purpose.

Wood saw blade for angle grinder

Wood saw blade for angle grinders consists of a metal disc with a chain attached to the edge. The design of special saw tools is similar to those used in chainsaws. But saw blades are made of tungsten carbide.

When the disk for angle grinder wood hits a hard obstacle in the wood. knots, resin, metal, its base rotates without breaking the chain. With a chain sander it is easy enough to remove knots and bark from logs, give them the necessary initial shape.

The wood circular saw blade for angle grinders is suitable for a wide range of applications in the construction, renovation, furniture and home improvement industries.

Wood saw blades for angle grinder, visually practically do not differ from circular saw blades. But they are made from entirely different metal. Until recently, these products were a rarity, but now there are quite a lot of quality tungsten carbide wood circles on the market.

Important: Never try to fit a circular saw blade onto an angle grinder. Theoretically, you can do it with the adapter, but circular saw blades are designed for low RPM and they get warped or just fly apart in most cases with angle grinder.

Rapide circular saw blades are made of high-quality tool steel and are highly wear-resistant. The carbide teeth of this blade are tungsten carbide tipped and precision ground.

Rapide 180 mm wood saw blades have 36 or 60 set toothed teeth that can be sharpened with special equipment after the blade has been in use for a long time.

This design successfully cuts fiberboard, hardboard, laminated panel, hardwood and softwood with a very clean and smooth cut. The Rapide 180 mm saw blade has special thermal breaks to keep the blade cool and to prevent it from overheating.

Use of this blade with any other power tool not specified by the manufacturer or with a different diameter drill is extremely dangerous and could cause serious injury.

One of the important advantages of Rapide saw blades is that they can be used for different types of cutting. both cross-cutting and longitudinal. Manufacturer recommends an allowable RPM of up to 80 meters per second.

Wood disc for angle grinder 180mm is quite popular among professional craftsmen for various carpentry work, sawing of branches, logs and cutting firewood. This circular saw is often used in furniture production, construction of any kind of structure or building with wooden beams.

Wood saw blade characteristics 180 mm:

| Appointment | Saw blade |

| Material processing | Chipboard, Wood, Hardwood, Softwood, Laminated chipboard |

| Diameter exterior | 180.0 (mm) |

| Diameter inside diameter | 22.23 (mm) |

| Number of teeth | 60 / 36 |

| Quantity in package | 1 (pcs.) |

Chain saw blades for wood: advantages of use

In this case the saw blade is made with chainsaw chain. This attachment is the most suitable for woodworking because it has the highest efficiency.

The wood chainsaw for angle grinders is also considered the safest. Using this attachment significantly reduces the chance of injury in the event that the tool jams.

Wood saw blades for angle grinder with chain are used for all kinds of work. They can be used to remove tree limbs and cut through small boards. The functionality of chain products allows you to use them as roughing tools. They are excellent for removing bark.

The circular saw blade can be used to evenly cut parquet, plywood, fiberboard, particle board, as well as regular unedged and edged wood products. It is important to remember that the thickness of the material to be processed by such a nozzle should not be more than 4 cm. Otherwise there is a high risk of overheating the unit.

Wood cutting disc for angle grinder

Various manufacturers also produce and cutting discs for wood especially for angle grinder, for example, cutting disc Bosch. Their design is quite different from that of circular saw blades.

-

They usually have side teeth that keep the bit from jamming. Cutting tools are differentiated by the number and shape of teeth:

The first version of the tooth shape is considered to be universal. It is suitable for any kind of wood for small amounts of work. When sawing soft types of wood, a straight-toothed angle grinder blade can be used. Trapezoidal teeth can cut quite hard types of wood: chipboard, fiberboard, OSB.

Maximum possible size. 230 mm. But the latter option is not advisable for wood, as it increases the risk of injury. Depending on the size, the depth of cut in wood will be different.

-

If you need cutting discs on the angle grinder on wood, then you should first pay attention to such parameters as the diameter of the circle, the depth of cut and the characteristic of the teeth. Depending on the wood material, you need to use a wood saw blade with the following teeth:

Wood cutting disc for angle grinder 125 mm, is classified not only by diameter and accordingly the depth of cut, but also by shape, frequency and number of teeth.

If you plan to use the wood saw blade for the 125 mm angle grinder from time to time and you do not know what kind of wood you have to cut. The best choice would be a circular saw blade with alternating beveled teeth.

Straight-toothed products can be used for cutting softwood as well as any other softwood.

Trapezoid tooth has a wider range of uses. Wood saw blade for angle grinder 125×22.2 mm with trapezoidal teeth, able to cut medium-density chipboard. Bilaminated chipboard, USB boards, and medium-density fiberboard are also easy to work with.

Wood sanding disc for angle grinders

-

This type of wheel enables the machine to be used for its direct purpose. Different kinds of nozzles can be used for finishing and polishing wooden surfaces:

Rough treatment of wood is done with special cord brushes. The end discs are designed to straighten the edges of parts, which is often required when sawing workpieces obliquely. They are an excellent alternative to the file. The widest range of sanding tips is in petal circles.

Depending on the size of the abrasive grit, different grades of wood can be roughened. A gradual transition from using a coarse-grained bit to finer grit discs achieves a polishing effect.

Using sandpaper or sandpaper on a special nozzle allows you to sand quite large areas of wooden surfaces. The ability to quickly change the sanding pad makes these attachments versatile. When removing old paintwork, scraping tools are often used.

As a rule, it is a wire brush attached to a metal base. It may be parallel to the surface of the wheel or perpendicular to it. There are options for fixing the bristles on the perimeter of the disk.

When working with wood, make sure that it is fairly dry. If there are fungal lesions on the surface of the workpiece to be treated, they need to be cleaned up to healthy wood.

Wood scraping disc for angle grinder: characteristics

With an angle grinder you can not only cut and saw off wooden parts, but also perform roughing work of varying degrees of complexity. Modern market offers a large assortment of such nozzles. They are classified according to several indicators: shape, design and purpose.

Roughing circles are used to remove bark from logs or boards. Thanks to them you can easily remove excess wood from the end surface of the board. They can have special spikes or crumbs.

On sale you can find roughing products consisting of twisted wire. They are commonly referred to as brushes. There are two types of woodworking angle grinder attachments, depending on their construction. The first option involves a base in the form of a cup, to which the wire is attached. The second type is a disc with a wire fixed along the edge.

Paint brushes are used for removing paint from wooden surfaces. It is important to note that such tools are mostly used for removing paint and rust from metal pipes.

Please note! For wooden parts choose a thinner wire that won’t damage the workpiece itself. These products are suitable for different types of wood.

Wood rasping discs with wire coils are also used for brushing. This action allows you to give the wood an unusual appearance, artificially aged.

However, only small amounts of wood can be sanded with an angle grinder fitted with a wire sander. This item is therefore not recommended for industrial-scale roughening.

Wood grinder attachment for angle grinder

Sanding is one of the most popular processes for which the angle grinder is used. With such a tool and a set of nozzles it is possible to conduct rough and gentle processing of metal, stone and wooden surfaces.

As a rule, sanding precedes the polishing of blanks. The bits used in this process may consist of sandpaper or felt.

The use of the petal wheel allows roughing blanks of different materials. You can also use it to perform a finish sanding. Fine grinding wheels are used for finishing.

Today you can meet another variety of grinding discs on the angle grinder. Some abrasives are fixed to the base through a special Velcro. To use such a wheel, you need to screw it onto the spindle of the tool.

As well as on the tool market you can find circles, the working part of which consists of a dense fabric. Angle grinder bits for polishing are very popular when working with wood, because their use allows you to bring the surface of the material to the smoothest state.

If you decipher the abbreviation angle grinder, it is clear that the main purpose of the “angle grinder.

Are used mainly for primary (coarse) sanding of wood, when you want to smooth out the irregularities of the sample.

The name says it all. Such tips are used for finishing the final parts of wooden workpieces (cuts). Especially effective if you have to deal with angular (oblique) cuts.

The most commonly used sanding accessories for angle grinders.

The attachment on the angle grinder for wood brushing

Many craftsmen believe that the metal brushes are used to clean only steel products from rust, oxides. Contrary to this fact, products made of brass wire are popular in wood processing. Relatively low price, high service life, make the brush a direct competitor to abrasive nozzles.

The main purpose is to remove the paint coating from the material surface. It should be understood that the top layer of paint can be removed by applying temperature, the brush is used when working in hard-to-reach places.

It is also possible to perform wood brushing with an angle grinder with a brush. The process involves artificial aging of surfaces in the manufacture of unique interior products. Treated surface with soft wood particles, irregularities and temporary rings stand out.

The nuances of working with an angle grinder on wood

Professionals rarely use the angle grinder specifically to work with wood, for this there are special devices and tools. belt sander, electric saw, electric jigsaw. But in everyday life, if there is a need to perform woodworking works, buying a whole set of expensive tools is not reasonable, then the help comes to an angle grinder with wood sanding attachment.

Sawing

angle grinder is not the most popular tool for sawing wood, as it is a material with a fibrous structure. With insufficient fixation and the slightest fluctuations and changes in the angle of cutting, the fibers are swelled, delaminated, formed chips, defects and dispersion of sawdust and chips.

The cutting attachment is justified only if the angle grinder is fixed as firmly as possible on the cutting table. With the angle grinder you can make only a rough, not precise cut, as it is impossible to organize all the conditions for precise work. rigidly fix the material, the tools and see the place of the cut.

Sanding and polishing

The angle grinder is excellent for sanding. The works are performed according to the following algorithm:

- Preparation works. Initially a coarse grinding using the roughing head. It is in the form of a bowl with a twisted wire, located all around the perimeter (similar in appearance to a brush with metal bristles). At this stage, old layers of paint are removed from the board.

- Preliminary (rough) sanding. Remove coating residues, protruding fibers and other defects from the surface of the material. Work is done using grinding wheels for angle grinder on wood. At this stage, the material is prepared for painting.

- Final (fine) sanding. It is used for wood that will not be painted. For work, an angle grinder attachment is used for sanding wood with an abrasive of minimum grit. nulivki.

- Polishing. Produced at low engine speeds, fabric wheels are used as an abrasive.

In order to maximize the convenience and quality of all processes, it is necessary to choose the right nozzle from the entire variety of their modifications.

Why it is difficult to process wood with the angle grinder

First of all, it should be noted that the high speed of the disk distinguishes the angle grinder from the circular saw. And even the presence of the compensatory ring, which comes complete with a disc, does not completely solve the problem. But if your angle grinder has adjustable speed, it partially makes it easier.

You can adjust the tool so that its speed corresponds to the speed of the circular saw, this will also reduce the injury hazard of the process

But the main difficulty is not that, but in the structure of the wood itself, which is often heterogeneous and knotted. In addition to multi-directional fibers, there is resin in the wood, possibly the presence of pellets or ingrown wire, which you immediately and did not notice. In general, wood is an unpredictable material. While working you may encounter an unexpected obstacle, and, as a consequence, a jerk that can knock the tool out of your hands and direct it along a dangerous vector.

If the disk encounters a piece of metal, the tooth can fly out of it, which, like a bullet, can also rush in an unpredictable direction. You will be lucky if there is a safety guard in the way

If you intend to saw with an angle grinder wood on the site, you will have to keep it in a horizontal position. This will make the grip uncomfortable and increase the risk of injury.

Important! It is categorically not recommended to saw wood with a tool that does not have adjustable speed and attachments not designed for this purpose.

Angle grinder a very wide range of tools in one class, called angle grinder (angle grinder). The device can have a huge power and work with a disc of 230 or more millimeters. Or distinguished by its compact size and modest abrasives of 115 mm.

The disadvantages of large and heavy tools are obvious: it is difficult to work for a long time. In addition, you need serious skills and experience to process wood accurately. It is elementary difficult for a beginner to control a massive and powerful angle grinder. However, when a large area of processing or the need to remove a significant amount of material such an angle grinder is very good.

Small angle grinder also has disadvantages. The ratio of its disc diameter to the size of the body does not allow you to process hard-to-reach places. In addition, it is difficult to select a large volume of material with such a tool because of low power and overheating.

Many masters for working with wood prefer an angle grinder with a disc diameter of 125 mm. This is explained quite simply:

- in this class are represented angle grinders in a wide range of working powers;

- it is easy to choose a tool with comfortable dimensions and weight;

- There are many aids and appliances on the market that are designed for a standard 125 mm blade bore.

In addition, the average power angle grinder provides relative safety for beginners. It will not make you get tired quickly, allow you to more accurately control its movement, reduce the likelihood of rejects on valuable parts.

Angle grinder applications for cutting various materials, cutting and sanding wood

If you are trying to understand whether you can angle grinder to saw wood, then the answer to this question is unequivocal: you can. But many people will not do it, because they don’t want to.к. Too many injuries people receive precisely from the use of angle grinder as a saw on wood, which is properly referred to as angle grinder.

First of all, this is caused by its rather high rotation speed, for which most saw blades are simply not designed. But who pays attention to it, when it is necessary to do a job, and there is seemingly a suitable tool at hand, and there is also a compensator ring of the right size attached to the wood saw blade. Yes, and even remove the protective cover for the convenience of work, which you can not do.

But we are not going to tell about injuries, but to talk about what and how it is possible to work (including the cutting of the saw blade).ч. saw) wood with an angle grinder, but first. about the complexities of working with angle grinder is wood.

What to look for when selecting a wood saw blade?

The key features to focus on when choosing a saw blade for an angle grinder are as follows:

- Outer diameter of accessories.The size of the wheel largely depends on the power of the angle grinder and the type of work performed. The 12.5 cm blade is best suited for wood. Larger diameter increases productivity, but requires professionalism and increased safety precautions.

- Inside diameter (bore).For angle grinders it is standard. 22 mm. Otherwise, discs can be mounted through special adapter rings. Some models can be equipped with this accessory.

- Type of disc.Monolithic tooling is characterized by low cost, but requires periodical re-training of teeth and sharpening. The more reliable carbide saw blades do not need frequent maintenance and produce a clean cut at any speed.

- Number of teeth.A cross-cutting cut requires discs with a high number of cutters. 60-90. Accordingly, a longitudinal cut is of higher quality when using models with a small number of teeth.

- Rotation speed.High-speed discs are suitable for work with hard or dense wood. Low speed tooling ideal for soft and tough wood.

Wood angle grinder disc: types and selection rules

The angle grinder (angle grinder), popularly known as the “angle grinder”, is a professional universal device that is used for a variety of purposes. It can be used for many applications: cutting, sanding, polishing, sawing and machining of various materials. When choosing the right model, you should understand its design features, assess your financial capabilities, as well as consult with a specialist.

Because of the large variety of models available, choosing the ideal solution can be a real disaster. In any case, you need to bet on the purpose of the proposed equipment. Wooden structures need appropriate grinding wheels for the angle grinder on wood. The same goes for metal. only work it with the right tools.