How to make a Dolphin potato digger by yourself

Such devices are quite simple. You can make an active Dolphin potato digger with their own hands. To do this, you need to have the following tools: welding machine, angle grinder, drill, bolts and drills on metal.

- Sheets of steel, 3-4 mm thick, for the ploughshare;

- thick steel plate or rectangular profile for holder and bracket;

- rebar. 8-10 mm, not corrugated;

- bolts with a diameter of more than 10 mm.

Dolphin potato harvester with their own hands

The process of making a Dolphin potato harvester is as follows:

- Two holes are drilled in the ploughshare so that it can be attached to the stand.

- Measured parts of steel rod, 47-50 cm long, should be welded to the plough, in its extended part, which should diverge like a fan.

- A rack-holder is attached to the ploughshare by bolts or by welding.

- A bracket is welded on top of the stand. There should already be holes in it so that the single axle tractor and potato digger can be attached together.

- To strengthen the construction, a metal strip is welded to the plough in the lower part.

The potato digger active Dolphin with an active blade is fitted with an additional vibrating nozzle, which is attached between the bars, just in the middle.

All self-made potato diggers should be used on small plots. Experience of many gardeners and vegetable growers clearly demonstrate their practicality and efficiency. For industrial use (processing of large agricultural land) use factory-made devices, according to technical requirements and standards.

Detailed drawings of the fan type potato digger for power tillers photo and video of the device in work.

As is known, there are two types of potato diggers for motor blocks, fan and vibrating, the most simple in the manufacture of fan type digger, and its device we will consider.

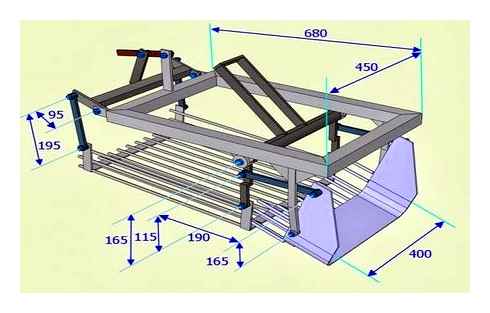

Fan digger is the hinged equipment, in this variant for the power tiller, this is how this device looks like.

The device for digging potatoes is a plough with a fan of rods, while moving power tiller plows into the soil and lifts it on a grid of rods, in turn rods loosen and sift the soil, while potato tubers are thrown already on top of the soil.

The video shows the working principle of a fan potato digger.

To make a potato harvester for your power tiller, you can use the following drawings with dimensions and photos.

The self-made machine consists of several parts:

Variant of making a plough for digging potatoes.

The photo shows the system for adjusting the depth and angle of the plow. Holes in the bipod allow you to adjust the depth of the plow into the ground.

In this video the author shows a potato planting machine made by his own hands.

Fast harvesting is not only important for farmers, but also for homesteaders. Digging potatoes in one or two days is especially important in cold, rainy autumn, when it is difficult to choose a day to go to the fields. Speed up the work will help potato digger, your own hands can make a simple and effective unit, the performance is not inferior to their factory counterparts.

Fan potato harvester. principle of operation and selection rules

Externally, the design of the potato plough resembles a planter that has steel bars instead of wings, forming a fan shape. Mechanism has a simple device and no problems put on mini-tractors and motor blocks.

The unit consists of a curved sheet of metal to which fan-shaped bars are welded, allowing the soil particles to be sifted out. The potato harvester can be up to 33 cm wide and 50 cm high. Weight of the structure about 5.5 kg.

Manufacturing of the potato harvester for the screen-type power tiller

As example for making potato harvester KKM-1 as it is aggregated with power tillers of “Neva”, “Salut”, “Kaskad”, “Favorit”, “MTZ” and power tillers of similar construction.

| Material for making a potato digger on a single-axle tractor | |

| Metal profile | bolts, nuts and washers 2.5 mm. |

| Sheet steel | 3-5 mm. |

| Metal profile | 10 mm. |

| Pneumatic or polyurethane wheels (2 pcs.) | 330 |

| 90 | |

| Belt | А-1180 |

| Pulley | 1 |

| Bolts, nuts, washers | |

Before starting work you need to prepare the following tools:

Digger of screen (or vibrating) type has moving parts, which significantly complicates the design, so the mechanism requires precise manufacturing.

How to make a homemade screen type potato harvester

- Stage. making the frame. To do this, a metal profile with a 2.5 cm square side is sawn into four pieces. Two pieces should be. 1200 mm, and two. 800 mm. Profile size. 4040 mm. The prepared parts are connected by welding into a rectangle

- Step. Fixing the lintels. From the video you can see that they are necessary for the installation of vertical control rods. Fix this element by about a quarter of the base length of the frame. On the other end are mounted two elements for installing the wheels. Such element must be made of two tubes with diameter of 30 mm and length of 150 mm.

- Stage. installation of vertical props. On the side where the lintels are mounted, at a distance of 5 mm from the edge of the frame, two squares of size 3030 mm and a length of 500 mm are mounted vertically. After that, at a distance of 200 mm long uprights of 40 mm are installed. Then a further 400 mm is required and 300 mm long columns are fastened. Join posts together with a 0.4 mm strip.

- Stage. Making the frame. First, two holes are prepared on the metal sheet 400400mm, which has a thickness of 0.3 mm, and at the bottom of the posts. Workpiece is rigidly attached to the uprights. The same piece is attached to the other side. Another square of 700700 mm sheet metal and 0.4 mm thick is welded butt-welded to the first element, and then bent into the desired cone configuration using a sledgehammer.

Potato harvester for power tiller with your own hands

Fan potato digger for power tiller

Component component:

- The steel required is 8 mm sheet.

- Required bars. 10 mm in cross section, preferably steel or iron.

- The necessary wheels. rubber or, preferably, metal.

- U-shaped metal profile. channel N8.

- Iron angle (rolled metal).

- Required pipe. metal for posts.

- Required chain. roller chain.

- Welding machine.

- Angle grinder (angle grinder).

- Welding and electric drill for metal work.

- Caliper, angle and level.

- Complete set of wrenches.

- From hammers the sledgehammer should be used.

The fan digging design is divided into:

- Making the frame. at an angle of 63×40 mm and a length of 120 cm is welded from the channel N8.

- Welding of two channels, which are necessary as a base for fixing the regulation part. one should be welded on 1/3 part at the beginning of the frame, but the second one should be welded on 1/6 distance from the front edge.

- Welding metal studs to be able to attach the bars. vertically to the ground and at the same distance of about 10 cm. It is necessary to mount props of different lengths about 50/40/30 cm and further.

- The remains of the ploughshare should be welded to the shortest posts so that the ploughshare can be attached. the result should be triangles on both sides.

- Staves are made from materials such as. a piece of pipe (pre-cut along the diameter of 200 mm), an old plow, metal plates.

- it is necessary to make a bend in the manner of a plough followed by a rounding to minimize the possibility of spoiling the potato tubers. Next, it is necessary to securely fasten the elevator shell with nuts.

- It is possible to make rods from reinforcing bars of a suitable length. if one end can be to the metal plate, then the second end should already protrude beyond the frame of the structure. The bars should be welded at a distance of 4-5 cm with the free second end, and to prevent dropping out of the tubers, you can weld 2 sheets of metal on the sides.

- Making a bracket for fixing on the end of the frame (with a hinge). from metal strips or a small cross-section pipe with the subsequent welding of the free ends of the rods by the bracket.

- Elevator can be replaced by a cleaning drum, which is made of armature or metal strips in the shape of a half cylinder.

- Installation and attachment of the slider (on bearings) to the rod of the reducing unit. it can be used to change the angle of ploughshare and elevator.

- Attachment of the connecting axle. using sprockets, followed by welding metal planks and attaching the wheels on both sides.

- Direct attachment to the tiller.

Rumble Potato Digger

Component component:

- Square metal profile. by 2.5 cm on each side.

- 3-5 mm steel plates.

- Use of non-rifled rebar or steel wire. 8 mm in diameter each.

- Measuring tape and eccentric with levers, joints, bolts and other consumables.

- Manufacturing the frame. measuring a metal profile, followed by cutting and welding the frame.

- Making and welding the wheel posts to the bottom of the frame.

- Creating a mount for the screen. welding holders to the hinges inside the frame.

- Welding brackets to the structure. this is necessary for the subsequent attachment of the gearbox and other mechanisms to create vibration.

- The screen (screen box) is welded from prefabricated bars.

- Direct attachment of the screen to the hinges inside the structure.

- After the installation of the screen, the connection of the gearbox and other mechanisms to work with it. the vibration is created through the work of the shaft of the motor with the vibration created by the eccentric.

- Potato harvester’s blade (Bend) is made of steel sheet and then bent to required parameters.

- The blade is attached directly to the screen through the lower part of the design.

- The last procedure is the direct attachment of wheels and structure to the tiller.

Transporter potato harvester

The transport potato harvester is not much different from the vibrating one, except that the construction is replaced by a belt.

Component part:

- Reinforcing bars.

- Use of nuts and bolts necessary for the construction.

- Metal angles.

- Transport belt.

- Iron plate.

- Making the frame. from a square section of metal, cut the necessary piece in shape and length and weld a rectangular structure.

- Manufacturing of the ploughshare, e.g. from sheet steel.

- attaching the rollers to the frame to enable the belt to rotate on them.

- Assemble the belt to be able to work the mechanism.

- In the frame according to the type of a screen design, it is necessary to attach gears and gears.

- Straightforward conveyor belt installation.

- Plowshares and wheels are mounted on the frame.

Drum type potato harvester

The drum design differs from the trommel design in that the drum is fitted with a drum. this is the hard part to produce.

Component Component:

Approximate fabrication procedure:

- In the case of a screen mechanism, a rectangular flat frame is made. a drum mechanism requires a bottomless cubic frame.

- Directly making the frame. cut off 4 pipes measured for the vertical bar, and in addition cut off 4 more, 2 of which must be cut to the width and 2 to the length of the frame.

- Direct fabrication of the drum from prefabricated thick wire.

- Two metal crossbars must be used to attach the two metal wheel posts to the rear uprights.

- Direct installation of the metal drum inside the frame, followed by mounting of the frame frame rails (in the front).

- Installation of the vibrating elements (gears and other).

Drawings and dimensions of fan potato harvester for power tiller

Fan potato harvester is designed as a plough with tips made of metal rods. This kind of device is designed not only to dig out and sift tubers, but also to loosen soil in the process of work.

Homemade potato digger for the fan-type power tiller is made according to the drawing, on which the proportions of the device are indicated. Its size varies depending on the desired area of the plot to be treated in a single pass.

Planting Potatoes with Tiller / Walk behind Tractor

Another important parameter when making a potato tiller is the depth of tillage

To make a potato digger yourself, you will need an angle grinder, a welding machine and a drill. Also in advance you should stock up on the following materials:

There are no rotating or turning mechanisms in the design of the potato harvester, and the device can serve for many years

Among the disadvantages of potato diggers for power tillers is a fairly high loss of root crops. The sharp tines of the machine can damage the crop. It is generally estimated that about 20% of all harvested fruit can be ruined by the machine.

How to make a conveyor belt spudder for a power tiller with your own hands

The conveyor potato harvester can also often be called a belt harvester. This is due to the design of the device. Ribbon potato digger for power tiller with their own hands is made according to the following plan:

- First of all the gearbox has to be assembled. It consists of the body, two shafts and gears. The device can be borrowed from any unwanted or used machinery.

- Next, you need to make the belt conveyor which transports the fruit on the belt. It can be assembled from metal rods and a chain made of links. With its help, the construction will be set in motion.

- A shaft is attached to the front of the design, and there are three hubs on it. two on the edges and one in the middle.

- Install a second shaft in the rear. On it also attach the sprockets, in the number of two pieces. The total length of the conveyor belt should be 50-70 cm.

- Mount the parts on a frame made of sheet metal and uprights. Fix wheels to the structure.

- Use leaf springs to construct a pruning blade that will bring the earth with the fruit to the transporter.

- The design is chain-driven from a bicycle, so depending on the size of the sprockets you can adjust the speed of the conveyor.

Transporter

Transporter (conveyor) potato diggers are made both large and quite miniature. Potatoes and subsoil are loosened with a plough knife. The cut material is fed onto the conveyor belt and separated.

The belt is a lattice made of metal rods or pipes, arranged in parallel to each other. They are fixed in the moving rim of the conveyor (chain). Conveyor belts are also made of steel mesh and rubber on a fabric base. Soil is poured down through the grating or openings, and the potatoes are moved into the arable or receiving hopper.

There are many designs of conveyor potato diggers, each master introduces new elements and improvements to the products. The process of making a conveyor digger includes the following steps.

- Welding frame (carcass) made of square steel sections and angles.

- Making a plough blade out of sheet steel.

- Installation of conveyor belt rollers or wheels into the frame.

- Assembling a conveyor belt from chain, steel bars, other material.

- Mounting brackets and fasteners for gearbox and pinion.

- Installation of conveyor belt and mechanisms in the frame.

- Installation on the frame of the blade (plowshares) and the wheels.

Potato digger application

A device for digging potatoes. a type of attachment. It is attached to a power tiller or fixed with a trailed device. Purpose. to speed up harvesting. With the potato puller it is possible to pick up tubers on an area of 0.1-0.2 ha in 1 hour.

On small and medium-sized areas it is easy to dig potatoes with a power tiller

Drawings, diagrams, dimensions of potato harvesters for power tillers Neva, Mole, Kaskad, MTZ-09H, Salut, Agat

The most popular among farmers and landowners is considered to be the single-axle tractor “Neva”. It has a user-friendly design and powerful technical features. The most suitable homemade potato harvester for the “Neva” power tiller is a screen-type device.

Due to the specificity of its work, the screen potato digger for the “Neva” power tiller is called the vibrating one

Universal option for all types of power tillers. “Poltavchanka” model potato harvester. The parameters of such a device are 950×790×800 mm, the processing depth. 25 cm. These characteristics allow the unit to be used in any conditions, regardless of soil and type of crops. “Poltavchanka” is valued for high productivity in a relatively small size.

“Poltavchanka” is popular with owners of power tillers “Mole” and “Agat”

The “Salut” and “MTZ-09H” power tillers are similar in their construction, that’s why the identical drawings are often used for the production of potato harvesters for this equipment. Digging tools for these devices have the same mounting system, which allows to use the same tool for both models.

“Salut” and “MTZ-09H” have an original design, so the drawing of the potato digger for these devices has different features

A vibratory potato digger is also recommended for the Cascade power tiller, but because of the more massive wheels, the harvesting device may have different parameters from similar equipment.

Often, when making a vibratory digger for a Cascade power tiller, changes are made in the plowshare arrangement and wheel size