What is a baler for power tiller

The baler for a power tiller compresses hay into bales that can be conveniently transported and stored afterwards. Cattle farmers and farmers with small farms prefer to use a mini-press on a single–axle tractor, which gives an opportunity to save financial resources.

This mechanism has compact dimensions, which allows it to be attached to a power tiller. But at the same time you can not count on a large working width and the size of the unit.

Presspickers come in two varieties:

Consider the design and method of operation of each of them separately.

The bale baler rolls up the hay, which is permanently pressed by the screen. This method of operation controls the density of the crop and leaves the looser hay and stalks inside the bale.

Before the bale is removed from the mechanism, it is wrapped with a rope.

This design is most often used in agriculture because it has certain advantages:

- Bale mowers are more compact than bale mowers.

- Have a lower price.

- Do not require constant and close monitoring by the operator.

- Due to the fact that the middle of the roll is more loose, more favorable air circulation is provided.

- All rolls have the same density and size.

The square bale baler compresses hay and stalks into square bales. These mechanisms are less used on the farm, but they have an important advantage: rectangular blocks are easier to transport and store, and they are more convenient for feeding livestock. During baling this design of the mechanism allows you to adjust the density of the block, thereby changing the weight and size of the bale, which creates additional convenience in transportation.

Consider the design of these devices. Roll motocultivators consist of the following elements:

- drum

- straw belt for baling

- tensioning device;

- a knitting device;

- moving roller;

- conveyor.

Electrical circuitry is uncomplicated and consists of a buzzer and turn signal devices with lights. The power comes through the shaft from the power harvester.

The bale press for the power tiller consists of the following elements:

The power is also supplied by the bale shaft from the power harvester.

Let’s understand the working principle of the cultivator. The bale press picks up a mass of straw with its tines, which is then fed into the chamber and wrapped with the press mechanism. When the density is as high as it should be, a horn sounds and the operator has to use a rope. A bale is wrapped with string and then the rear wall of the chamber is opened to release the pressed bale.

The bale picker collects the straw in a similar way, then uses an auger to feed the collected hay into the baling chamber. The mass of straw pressed against the walls of the chamber triggers the binder. Using two strings, the bale is wrapped and pushed to the ground.

On the market of light agricultural equipment are sold mini balers, which work without the help of power tillers. Their design is more complicated than usual and they cost more, but the speed of operation, build quality and set of customizable features are higher than usual. If you put speed and assembly quality first, the mini-press is an excellent choice. On the market such equipment is represented by various brands, the choice between which depends entirely on your goals and desires. You can find cheap models in the area of 150 000, and expensive equipment which price exceeds the mark in 500 000

Construction of a hay baler

Here it is worth noting that the more powerful a single-axle tractor, the more likely it is to achieve the desired speed of rotation of the rollers, the higher the performance of the assembled machine.

Rake

Rake for a power tiller is an attachment that is attached to the unit with a special adapter, it is possible to meet models that are aggregated with a hitch.

Hunterwood FC10000. Export Hay Press

In addition, this equipment has several modifications:

Let’s consider each modification in more detail:

Transverse hay rake

This attachment is used for quality raking of hay or grass in swaths.

It is used with an adapter that transforms a single-axle tractor into a mini-tractor. The rake is raised with a lever and lowered with the same lever. The work is carried out with the lowered rake.

Installation of this awning is possible both in front of the power tiller (there is a special pivot mechanism), and in its rear part. The rake is made of durable steel, protected by a special anti-corrosion coating and has a long service life.

If desired, the owners of garden equipment can make a rake for a motor-block with their own hands, for this purpose there are many descriptions, detailed drawings and videos on the Internet.

Rake “Solnyshko”

Rake rakes for power tillers “Solnyshko” consist of a tubular frame, which can be attached to two to four independently rotating discs. Such tedders are ideal for uneven ground.

The discs are equipped with high-quality bearings, and are attached to the frame with special holders. Working width can be more than 2 m. This equipment is fixed at the back of the power tiller and is suitable for both Russian and Chinese machines. If desired, the Solnyshko rake can also be used with a small tractor.

How to make a rake for a single axle tractor with your own hands will tell you about how to work this tedder rake

Belt Rake

Belt rakes also belong to the category of tedders. They can be purchased in stores, or you can make them yourself from whatever materials are at hand. How to make a rake on a single-axle tractor with your own hands tells and shows

This equipment allows you to quickly form a stack by grabbing and throwing grass clippings, hay and even dried-up forage crops.

Tedders, whether “Solnyshko” or belt type, are much more productive than their transverse counterparts, their design is more complex, the requirements for operation are higher. It can also be used to toss hay from one side (drying) to the other for faster drying.

The bale press for power tillers. making briquettes and bales from hay

A press for a motor-block, which is installed for directly on the device, allows farmers to quickly and easily collect hay on the plot. The machine not only helps to collect already dry grass, it compresses it into briquettes or bales of various shapes. So, the machine can give out rectangular or cylindrical, which will already depend on the variety of balers.

The machine can also transport quickly and store hay compactly.

For large-scale operations there are large hay balers on the market. Such “helpers” are of two kinds:

The second type is mainly used, which can be explained by its compactness. bale equipment is suitable for large agricultural activities.

And for farms of farmers, which are not characterized by a large area, fit a mini baler, suitable for power tiller and tractor. Therefore, it is popular in private farms. Small machines also come in bales and bales. Their advantage is the created briquette, the maximum weight of which is 20 kg.

How to make briquettes of straw at the factory?

Many homeowners and farmers are interested in making such fuel. After all, burning straw in its original form makes no sense, only gunpowder burns faster. As an option, you can consider burning it directly in bales, this is often done in large farms. However, in this case you need a boiler with a large furnace volume, where the bales are loaded mechanically. It is clear that for heating a private house, this method is not suitable, but the fuel briquettes from straw are quite suitable.

According to the production technology and the characteristics of calorific value of straw biofuel is very close to briquettes made of wood waste. The caloric value of straw, compressed according to all the rules, is approximately 4 kW / kg, this is slightly less than the same product of sawdust. The question is how to properly compact it in order to obtain a quality “brick” or “sausage.

The industry uses the following equipment for the production of straw briquettes:

For reference. The line for the production of straw briquettes includes a special stalk chopper, while the raw material from wood goes through a crusher.

Now let’s move directly to the stages of the technological process, according to which the processing of straw into fuel briquettes takes place:

- since during the mowing of grain and harvesting of straw in the raw material enters the soil and dust, then the first stage it is cleaned in a centrifuge or other similar machine;

- Although the moisture content of freshly mowed straw is lower than that of wood, it still needs to be brought to normal. The moisture content limit is 16%;

- the next step is to chop the stalks to a size of no more than 10 mm;

- the last stage. the production of briquettes from straw on the stamping or screw press (extruder) at a pressure of more than 30 MPa;

- at the end of the process, the finished product is weighed, packed and sent to the warehouse.

The raw material is pressed in the stamp press by crushing, no binding agents are added. We get a rectangular-shaped product, the binding agent is a natural substance contained in biomass. This substance is lignin and is extracted from the raw material under high pressure. In the extruder the production of briquettes from straw is made by compacting and pushing the biomass through round holes with a screw. At the output we get firm “sausages” of cylindrical shape.

Pick-up press for a mini-tractor with his hands

Homemade hay baler for power tiller with your own hands: instructions, photos, videos, drawings Roll baler, which can work as a hitch to power tiller, greatly facilitates the work of the farmer. It can mechanize the long and time-consuming process of gathering ready-made hay from the field, simultaneously rolling it into tight bales for easy transportation and further use. Commercially available balers are usually designed to work with a tractor. regular or mini. However, for smallholders with only a single–axle tractor in their arsenal, this is not always convenient. a power tiller system is often not able to pull a cumbersome device and provide it with enough power to work properly.

INTERESTING! Such a unit is quite possible to create yourself, picking up the right size and using a minimum of improvised means. A homemade baler will not only be able to handle a homemade power tiller, but will also collect mini bales that are easy to load onto a transport cart and carry on the farm by hand.

Purpose

Straw baler is used to perform the full cycle of collecting and packing of hay or straw, providing a fairly high quality of results:

The baling of dried hay from windrows in the field; The baling of a selection of dry crop; The simultaneous winding of the baled web into a bale. Photo of self-made round baler

Advantages and disadvantages

The baling press and baling press are the most popular baling machines amongst balers. Choosing exactly this type of baler to make with your own hands will provide:

Initially. the convenience of adjustment, provided by the simplicity of the machine device. Gentle baling without distorting or crumbling the crop. The ability to produce hay bales of minimal dimensions, which can be easily handled and stored by one person. The subsequent convenience of storage and use of the hay bales formed.

Self-made hay baler blueprint

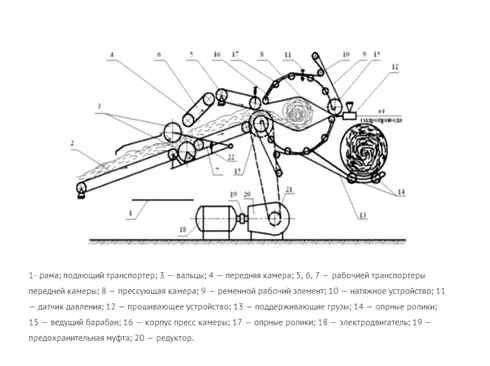

frame;. feeding conveyor; 3. rollers; 4. front chamber; 5, 6, 7. working conveyors of the front chamber; 8. press chamber; 9. belt working element; 10. tensioning device; 11. pressure sensor; 12. piercing device; 13. supporting weights; 14. pin rollers; 15. leading drum; 16. press chamber body; 17. pin rollers; 18. electric motor; 19. safety coupling; 20. gearbox.

In self-made work it is practically impossible to repeat 100% of the complicated structure of factory pickups, which, even if reduced in size, require at least 16-20 hp.с. This is why a tying bar is generally not fitted and the bale may not be as dense.

Materials

The round baler consists of the following main parts:

Headstock, which is the basis for mounting all components and an element of attachment to the tractor unit. Undercarriage with a base for the press chamber on 2 wheels, on which the device moves across the field. Hay or straw pickup with a conveyor belt. Cylindrical bale chamber with bale chamber press. PTO shaft with speed increasing mini-box. IMPORTANT! The most important component of the baler for hay made with their own hands is the press apparatus, which consists of rollers, pressure grid and a spring-loaded molding plate that replaces the factory device in the self-made hydraulic.

The video shows how to make a bale baler with your own hands:

It is desirable that the tractor itself. the basic single-axle tractor. should still be as powerful as possible to ensure the required speed of rotation of the rollers and the productivity of the baler.

The consecutive assembly of the homemade hay baler to the tiller will facilitate the installation work and do it in the best way possible. To independently create a convenient baler to the home motoblock will need to perform several stages of work:

You need to start with the assembly of the undercarriage. the base on a pair of pneumatic wheels. The headstock and the pickup with a conveyor belt are mounted on it.

A separate press chamber is installed, in the lower part of which the rollers and the pressure grid are installed, and in the upper part. a plate on the spring, which will press the pressed layers for a more tight coiling. Next, collect the drive, which gives the movement of the working parts of the machine. connect the cardan with a 2-speed gearbox, from which will go chain drive to the rollers and the pick-up conveyor.

On the mechanism of the hay pick-up we mount gears of a larger diameter than on the windrows, to increase the speed of pick-up and the power of simultaneous baling. If you want to get better results from haymaking with a power tool you can use a simpler and more long-term, but effective option. to divide the work on the collection of grass mass by power rake and pressing it by a separate manual or electric device.

Materials

The round baler consists of the following main parts:

- The front headstock is the basis for mounting all the components and is connected to the tractor unit.

- The running gear with the base for the press chamber on 2 wheels to move the machine in the field.

- Collecting mass of hay or straw from a field with a conveyor belt.

- Cylindrical chamber-casing with baling mechanism.

- Cardanic gear with speed increasing mini-box.

The video shows how to make a bale press with their own hands:

It is desirable that the tractor itself. a basic single-axle tractor. was still as powerful as possible to provide the necessary speed of rotation of the rollers and the productivity of the baling device.

The specifics of using self-made equipment

Constructive complexity of bale balers significantly limits the ability of farmers to make their own devices.

In most cases, self-made balers work on the same principle:

- The grass mass is manually placed in the baler;

- Finished bales are tied by hand;

- Often, the bale chamber has a horizontal method of loading.

The self-made baler has a large mass, finished hay blocks often disintegrate during loading or transportation. Therefore, it is first necessary to assess the profitability of such equipment.

You might also be interested in the article about minitractor Faither.