Saw a 45 degree angle

There are special tools for filing, which you can buy in any construction store. The first of these is the jigsaw. This is a frame with special guides, which you can use to saw 90 and 45 degree slats. The convenience consists in the fact that it is possible to saw profiles standing on the edge and lying flat and receive different types of angles for different types of joints. We have sample chairs in our stores, so that you know what to look for if you’re going to buy one. On work with the jigsaw let’s talk more about.

Step One. 1. Take the skirting board 2. Lay it flat, face up 3. Select the marking in the jigsaw at 45 degrees.

Step two. 4. Remove the corner with a 45-degree notch. 5. Take the whole skirting board (you can take a small piece, but make sure it is big enough) and put it face up. 6. We put the sawn off strip perpendicularly on the whole, combining them until a right angle is obtained. 7. Let’s run straight fishing line along the cut of the skirting boards we have installed.

Step Three. 8. Take the whole skirting board with the markings and put it into the mortise with the markings facing upwards. 9. The marks should overlap with the 45 degree notches. Check it. 10. Saw off a corner along the marking 11. Slide the bar with the resulting acute angle to the section of the jigsaw where there are notches for straight 180-degree sawing.

Step Four. 12. Saw a square corner. We want to make an even triangle, this is what we need! 13. Align the triangle and the baseboard in reliefs 14. Glue the parts together and fix the skirting board to the wall. You’ve got a great end piece with a file!

Step one. 1. Take the skirting board 2. Place it with its base on the bottom of the frame. Let’s lean it against the edge with back side (without a covering). Cut a 45 degree notch in the jigsaw. Note the space between the sawed corner and the wall of the jigsaw should be a sharp corner. 3. Sawing off the corner.

Step two. 4. Take the new, straight baseboard skirting board. You can take a short piece. 5. Put it with its base on the bottom of the jig saw. Lean it back against the edge (uncoated). We choose a 45-degree notch on the jigsaw. Attention, it must be on the other edge (not the side)!) from the first notch! Pay attention, the space between the sawed off angle and the wall of the jig saw should be a blunt angle. 6. Sawing off the corner. We need it! 7. Align the skirting board and the corner. You have a great end piece with the sawing! Sawing the outer corner

Step one. 1. Take a skirting board 2. Put it with its base on the bottom of the jig saw. We press the back side of the skirting board against the edge (uncoated). We make a 45 degree notch on the jigsaw. Note the space between the sawed corner and the wall of the ruler should be a sharp angle. 3. Sawing off the corner.

Step two. 4. Repeat the previous steps with the second plank. Take the skirting board. 5. Place it with its base plate on the bottom of the jigsaw. Lean it against the edge with the back side out (uncovered). 4. Place it on the base of the jigsaw at 45 degrees. The only difference from the previous step. it is necessary to lean another notch at 45 degrees on the same side. Note the space between the sawed corner and the side of the jigsaw should make a sharp angle. 6. Sawing off the corner. 7. Aligning the two plinths. We have a perfect outside corner.

Step one. 1. Take the skirting board 2. Put it with its base on the bottom of the jig saw. We lean it against the edge with its back side (without cover). We choose a 45 degree notch on the mitre saw. Note that the space between the sawed corner and the side of the jig saw should be at an obtuse angle. 3. Sawing off the corner.

Step two. 4. With the second skirting board repeat the previous steps. Take the skirting board. 5. We put it with the base on the bottom of the jigsaw. Let’s lean it against the edge with the back side (uncoated). Make a 45 degree notch on the jigsaw. The only difference from the previous step is that you have to lean it against another 45 degree notch on the same side. Note the space between the sawed corner and the side of the jig saw has to be a blunt corner. 6. Sawing off the corner. 7. Align the two skirting boards. You have a perfect inside corner.

One more tool. a crosscut saw. This is a device where the saw blade is combined with the stand. The saw stand has circular markings on it, like a protractor, that measure the degrees by which the saw can be turned. All the work boils down to setting the saw blade to the desired angle, turning on the device and sawing itself. This is the fastest and easiest way to make the cuts. And in order not to buy an expensive tool that you will need once in the next 10 years, you can rent it. Since the speed of the disk is high, it is recommended to cover the sawing area with masking tape to prevent the formation of micro-fractures and the material from crumbling.

But even if you can’t afford to rent tools, and you doubt your ability to evenly file corners, you can always use ADEFIX F putty. It is a dense, white, thick, acrylic-based micro-ink compound. When applied, the mass fills the voids, and after drying, the joint can be sanded and painted, if necessary. And even if there are no major cracks, chips and irregularities, the seam can still be filled with this putty. then the baseboard will look absolutely solid and monolithic. But acrylic glue, like any other water-based sealant, can not stand direct contact with water and high humidity. Moisture will simply wash acrylic particles out of the cured joint. If the joint is painted together with the skirting, the acrylic composition, of course, insulates from moisture, but in very wet areas, such as bathrooms, to put a skirting glued “ADEFIX F” manufacturer does not recommend.

Yes, on the one hand, to file the corners at 45 degrees, it is necessary to fuss. It is especially offensive when, for example, you take a good, high-quality, expensive polystyrene skirting board, and then to install it you have to put some extra effort. and you’re afraid to damage it, and you want a high price to be all at once, so you have to work yourself as little as possible. But, on the other hand, sawing is a routine construction operation, for which they have come up with both special tools and grout for joints, in case something goes wrong. So the question: “And how to decorate the corners??”. when selecting a baseboard should not stand. You can not pay attention to the technical points, and be guided solely by your preferences and design ideas. Have an uncomplicated repair!

Instructions

Now we cut the side trims to length. To do this, remove the old trim strips and cut the new ones according to them. The method is not original, but practical. Do not touch the upper strip yet. For trimming, remember these rules:

- Cutting is on the front side,

- Use an angle grinder or hacksaw for metal,

- When working, put the slats on two stools. so it is more convenient.

Why do we have to cut along the right side?? Because otherwise you will damage the outer decorative layer. Why you can not use a hacksaw on wood? Because you’re not a lumberjack or carpenter today, but a cabinetmaker and you do fine work.

The laths are cut to length, and now we make the first two 45-degree angles. Don’t try to get the sides of the saw cut wrong. one strip is cut on the right side and the other on the left. If there is a plane in the arsenal, the work is simplified, if not, you will have to use a protractor. Remove the angle from the outside of the casing and cut the strips under the door on different sides. Hold the hacksaw horizontally as much as possible so there is less chance of damaging the lamination.

How to saw correctly?

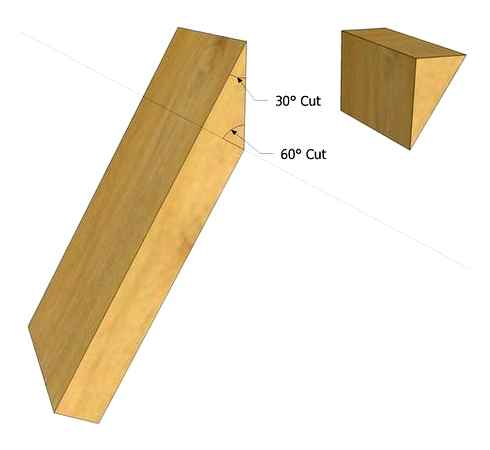

Even when the roof is different. instead of tiles and slate used steel corrugated steel, metal or cellular polycarbonate, the basic work, that is, the arrangement of mauerlat, intermediate bearing supports and rafters, is the same on the stage, technology and execution methods. For sawing the rafters at the right angle the sequence of calculations is determined by the original dimensions of the building.

As an example. the following parameters: let the length of the house is 480 cm, width. 240 cm (external dimensions).

The length of the rafters is calculated according to the Pythagoras theorem: the cathetuses are the attic-ceiling plank to the middle, over which the ridge of the future roof is located, and the height of the ridge supports. The hypotenuse is the length of the rafters without letting the lower end hang over the outer perimeter of the walls.

For a gable roof the length of the structure is divided in two. in this case its half is 240 cm. Use the protractor on the drawing to measure the necessary angle of inclination. For four-slope roofs use separate drawings that take into account the angle of side slopes: it is also measured with the same protractor, and the width of the building is also divided in two. in this case is 120 cm.

In this case 2163 cm are measured from the opposite side. after measuring the required angle. On the other side of the intended gable, the opposite line of the roof slope is drawn.

You measure 2400 cm in the middle. and draw an extra side. A triangle is formed, marking the slopes of the roof.

After calculating the length of the rafters a timber or board is sawn according to the drawing. Before sawing they are stacked face down. Board strips are lifted up. After their preliminary installation, they are secured at the edges with battens. The rafter angle is cut to a specific shape.

Make a triangle with the angle at which the rafters will be filleted. It can be prefabricated from aluminum or stainless steel thin-walled profiles.

Place this triangle on the side of the rafters. and use a construction marker or pencil to draw the corner outline under which the rafters are filmed.

Cut a corner on the mauerte as per the outline cut.

Repeat the last step for all locations where rafters are installed, align them so that they fit into the kerf along the contour. Assemble and secure the rafter system.

Cutting out the planting area

Having made the calculation, it is not enough to be guided only by general advice. The second step after the calculation is the cutting of the landing. Down at the construction site in front of the building itself to quickly make a perfect, high quality rafter sawing at a certain angle is difficult. The reasons. from awkwardly positioning the mauerolat to lack of precision when sawing. In practice, the angle of the rafters can change noticeably. The rafters should be on the same lines. Only a template can be used for making identical cuts. However, when the mauerlite is slightly sideways, each rafter is recalculated individually. The depth of cut should not be too great. the strength of the rafter system will suffer.

When joining rafters, mark the points at which the former adjoin the mauerolat and draw lines perpendicular to the existing line. Determine the angles of the vertical and horizontal guide notches.

And here’s how the template for the rafters is made.

Attach the workpiece to one side of the mauerault without changing the angle of the future roof. In this case, opposite the corner should be the intersection of the just drawn lines.

Mark the location of the scythe line of the resulting triangle, and on it cut a template.

After making the template, check how accurate it is compared to the expected lines of sawn rafters. Make sure the mauerolat fits over the top of the walls along its entire length. If the fit is not perfect, reinforce the fit where possible. deviations of approx. 2.5 mm are permissible.

Place the template against the rafters and mark the points to be scribed with a scythe line. Sawing the rafters at the same distance from the ridge ridge. Make the first notch across the board or bar. Attention of the master is the key to respect the outlined boundaries. If you are completely inexperienced at this stage, it is better to use additional tools that reduce rejection and eliminate the cost of rewiring.

Make a second hack notch with a power saw, or make the notch with an axe. Before notching, check if the axe is sharpened enough. a serrated edge can lead to a more jagged cut and chipping around the edges of the notched channel. The master at this stage has considerable physical strength and a certain dexterity.

Check that the cuts match the template. if there are discrepancies, correct them. The rafter is ready to be installed in its proper place. After installing the rafter, file it down and install the next one, and so on.

Trimming for the straight joint with the mauerlaut

The butt joint is a noticeably easier method than cutting out the planting point. To ensure that the connection master selects the place of undercutting and the angle of incision. In theory, these steps would come down to a knowledge of geometry to calculate the required angle. Here’s what to do:

Divide the distance from the ridge to the edge of the wall by the length of the rafter, the resulting value is the cosine of the angle of inclination;

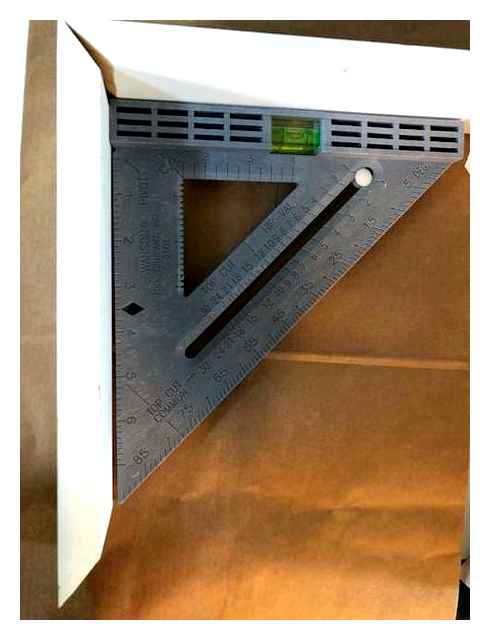

Use a mitre saw or angle piece to transfer the calculated angle to the rafter. In the absence of an angle, use a template. Its production is reduced to the following:

On a sheet of plywood or particle board mark a point at a distance of 50 cm at the bottom edge of the sheet;

Calculate the angle tangent, and calculate the product of the two.

It is advisable to convert all measurements in centimeters to meters. The second side of the right triangle is found. Mark out the scythe line and points on the workpiece, get the angle you want. and cut out the template. Using the template, saw and mount the rafters.

The practical method does not require an abundance of pre-calculations. Measure the rafter when it is attached in raw form to the place where it is fixed. To do this proceed in a number of steps.

Align the timber so that its lower end is aligned with the mowerbar in a certain way.

Draw a horizontal straight line from the corner to the bottom of the rafter. Make sure that this part is strictly parallel to the top edge of the wall. If you put a rafter or a board on its end (vertically), the line will be diagonal.

How to Cut a Board to Length w/ Angles. A Beginner Tutorial

Make a cut along the scythe line, install the rafter. Repeat these steps for the other rafters. After installing the rafters, install the front board on both sides of the house.

Use the remainder of the joist as a template. its cut location must be straight.

Necessary tools

Beginning to finish the room with ceiling skirting boards, you need to prepare the appropriate tools:

- office knife for foam skirting boards;

- A metal hacksaw;

- tape measure;

- carpenter’s square or a simple school square;

- A wire cutter;

- a pencil;

- a stable and sufficiently high stepladder.

On the floor it is necessary to free up space so that it is convenient to cut the skirting boards. It is on the floor is best to place a crosscut, the length of a table or portable workbench may not be enough for secure placement of the sawn skirting boards.

Outer corners

It happens that a room has not only internal, but also external corners, which also need to be covered with a baseboard (see “The method is exactly the same as in the case of the skirting boards). photo). How to do it? There are also several ways to. The easiest way, as in the case of internal corners, to cut them with a wire cutter. Outside joints should be cut so that the side that will be glued to the ceiling, was on the surface of the chair, and the side pressed against the wall, was facing the wall of the device.

As with inside corners, you can also use markings in place, that is, drawing a scythe line on the ceiling. Here the technique is exactly the same as that used for inside corners.

You can use a marking on the wall by placing the workpiece and drawing a fishing line along its lower edge (see. photo).

If the outer corner turns out to be too rounded, you can refine the joint with a knife.

Trimming a ceiling plinth. Exterior and interior corners

To the point where they converge, a fishing line is drawn directly to the future part of the connection. From the point that is on the ceiling to the second. The resulting marking will be the line along which to saw or cut off the connecting parts. Using these techniques, you can no longer wonder how to cut the corners of the ceiling plinth.

How to cut a cast iron pipe

As a result, it will split along the mowing line, forming a fairly even cut, which, if necessary, can be further trimmed.

Any home workshop should have at least three or four different types of saws.

- Wide-blade hacksaw for rough cutting of large parts and workpieces. The longer the blade, the faster the work goes. However, for the same reason, the mobility of the blade itself increases, which causes the saw, as they say, drifts to the side. Therefore, it is important to carefully follow the line of sawing, not allowing it to deviate from the marking. A novelty in recent years is the Teflon coating of the hacksaw blades that makes it much easier to cut fresh wood and also protects the saw from rust.

- Saw blades with backs not only differ from conventional saws in that they have a rigid sleeve that dampens blade vibration, but also that their teeth are finer and closer together. This saw makes it possible to make a clean and thin cut.

- Fine-cutting saws produce a clean cut.

- Saws with narrow blades for cutting out rounded details and large holes. The basic rule for every circular saw is as follows: Always keep the blade dry and clean. Teeth of the saw should be sharpened regularly, even when hardened.

Circular saw. high productivity and ease of operation

A circular saw is best for the job. It has excellent productivity and allows you to cut a considerable number of workpieces in a relatively short time, and with high quality. In addition, such a saw allows you to make a longitudinal cut of the material, but you need to know how to saw a board lengthwise evenly.

One of the most important criteria when choosing a circular saw is the maximum cutting depth. There are devices on the market that are used for sawing materials 30 to 130 mm thick. It means that it is possible to choose a machine both for cutting thin boards and for sawing bars.

You should also pay attention to the cutting tool itself. disks with a large number of teeth ensure accurate qualitative cutting, but the cutting speed is not high. But discs with a small number of teeth will ensure a high productivity of works, but the quality of the cut will be worse.

Now about how to saw evenly with a circular saw. Reliable fixation of a material is one of the conditions for quality performance. If the material is loosely clamped, the board can “move” when sawing, and the cut will be uneven.

If the circular saw is manual, then all work should be done on a workbench, equipped with stops and guides for the workpieces. Such a device can be made independently, using any table as a base.

Before you start sawing it is important to determine correct cutting depth. Some handheld saws have an adjustable side rail that can be used to cut longitudinally through the material. If you do not have such a device, use the same workbench.

convenient in terms of work is a table circular saw, which is already equipped with everything necessary. guides, locks. It often happens that such equipment also makes it possible to angle cut workpieces.

When sawing it is important not to exceed the force on the tool, otherwise the quality of the cut will be low, the increased load on the saw will lead to rapid blunting of the cutting disc.

How to make a straight cut with an electric jigsaw

A jigsaw is a tool used for sawing workpieces. It can be used to make curved cuts in sheets of plywood, wooden/metal objects, and plastic. Using the tool, the craftsman can cut out products in the form of stars, triangles, circles, etc. д. Read on below how to use the power tool, understand how to make splinter-free cuts on different materials, and find out how to saw straight with a jigsaw.