How to cut a profile pipe evenly

You can cut a profile tube in a similar way, but it will be easier to use the angle piece. The device is applied in turn to each side, for which the element to be cut will need to be rotated, and a marking is made. Then the pipe must be firmly fixed, and you can begin the work. Any suitable tool can be used for sawing. If you have to cut a lot of pipe, then it is advisable to make full templates from scraps. In this case you only have to measure once.

How to cut a pipe at a 45 degree angle

When working on gas or water mains, it is often necessary to change the direction of the mowing line, with the pipe being cut and then welded at the desired angle. Most often, the direction changes to 90 degrees, and the question arises. how to cut the pipe at a 45 degree angle to accurately connect the joints when welding.

To cope with the problem at angles of the cut edge of 45 or 90 degrees is possible with the appropriate knowledge and techniques that will help to save not only time but also materials during the work. At other angles of rotation to solve the problem with a ruler and a sheet of paper is impossible. to help you will have to call a computer technique.

Cutting pipes at an angle: the pros and cons of different methods

Pipes. a widespread building material. They are used in the installation of various systems. A common case in the installation process is a situation where pipes need to be joined at an angle. However, it is not quite usual to see the technology of such works.

To create a similar connection configuration, pipe cutting at an angle is required. Consider how to perform such operations and what are the methods of cutting.

Techniques for cutting pipe at an angle

Considering the methods of work. cutting straight or at an angle. it is necessary to take into account the different material of products to be processed. Thus, hoses made of polypropylene or thin copper are easier and easier to cut than thick-walled steel pipes.

Plastic products of small diameters are cut at the desired angle with special scissors. You can check the angle with a standard protractor.

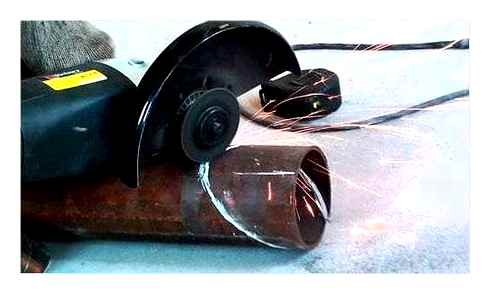

You cut into pipes when working with these mounting elements very often. A popular tool for such cases is the so-called angle grinder. This tool is used for straight and diagonal cutting

Cutting water pipes or other pipes at a 45º angle becomes the most common installation requirement. Let’s find out what tools can be used for cutting at this and other angles.

A paper template for a pipe

To perform a relatively precise cut, you can use a simple technique where an ordinary sheet of paper acts as a kind of template.

For example, A4 size printer paper is good for creating a fishing line. The sheet is preliminarily marked under the square using a ruler.

The size of the diagonal of the square must be equal to the length of the circumference of the pipe to be cut. Excess parts of the sheet are cut off.

The simplest way to get a line of scythe marking on the pipe to make a cut at an angle of 45 degrees. An ordinary sheet of paper is used, which is placed on the body of the pipe in the area of the cut

- Fold the sheet diagonally, aligning the opposite corners.

- Turn the resulting triangle so that the line of the hypotenuse is perpendicular to the axis of the pipe.

- In this position, wrap the paper around the pipe surface, aligning the extreme points of the hypotenuse together.

- Draw a marker with a marker on the cut line of any of the triangle’s cathetuses.

- Trim the tube to the intended mowing line.

This is a good way to mark and cut 45º angles in the diameter range from 32 to 63 mm. For greater convenience of marking it is recommended to take a thick, but soft paper. You can also use paronite and similar materials.

Programs for calculating cutting angles

The technique of cutting according to the templates allows to obtain different cutting angles.

But to form a template for angles other than 45º, you will already need to perform mathematical calculations and according to the calculated data to cut a template from paper or similar materials.

How to Cut Along

Another frequently asked question is how to evenly cut a pipe with an angle grinder along. Here the algorithm will be about the same as for cross cutting. It is important to pay attention to marking.

You can, for example, use painting thread, which is usually used for marking walls. When doing this it is necessary to fix the pipe firmly. The sawing process itself should be performed carefully and slowly, as when sawing long elements there is a high probability of the cutting disc slipping off the scythe line of the marking.

Varieties of pipe cutters are classified according to the objects to be cut and the features of the cutting element. Accordingly, the following types of tools are distinguished:

- Cutter cuts pipes up to 100 mm in diameter. Suitable not only for steel pipes but also for plastic pipes, It has several steel discs.

- The chain cutter differs in that it can cut pipes from dense materials (cast iron, concrete, ceramics), because it has a mechanism for tightly securing the object to be cut, made on the basis of an ordinary chain and rotary levers.

It can be used not only to mechanically cut pipes, but also to carry out work on their facing, chamfering with bluntness, as well as from the outer surface of the pipe.

How to saw with an angle grinder along a round pipe exactly into 2 parts

The first method is not very convenient, but it is quite accurate. Suitable if you are “in the wilderness” and have nothing but a pencil and a tape measure at hand. I had to use it a couple of times. The diameter of the pipe does not matter.

An important condition is to have a straight plane near the cut. This can be an edge of the pipe, a socket, a socket welded on or on, a seam, or any other concentric circle.

Mark the place of the cut with a ridge. We measure the distance from the risk to a flat surface. We move the tape measure along it and make marks on the circle, using the specified size. Let’s make a circle out of the marks.

How to cut a pipe evenly with an angle grinder

To make the cut from the angle grinder was flat, it is recommended to use special devices for fixing the metal workpiece. Prepared templates, jigs or vise are suitable for this.

You need to mark the place for the cut very precisely, so that the cut is not to the side. For large volume of work, for industrial purposes, special equipment in the form of lathes or band saws is used for cutting pipes.

On a metal profile you can make vertical and horizontal cuts, to saw it at any angle.

Cutting at a 45 degree angle

Usually in order to turn the pipe at a 45 degree angle fittings, elbows with an angle of 45 degrees, made of the same material as the pipe itself, if the pipe is steel, then the turns are welded from steel. For HDPE pipes there are electric-welded or cast 45 degree bends (note that compression fittings with such angle of rotation in Russia almost impossible to find).

But if it is still necessary to cut a pipe of round section made of steel or different types of plastic, you will need a template for cutting pipes at an angle, the shape is calculated by hand or by machine. The task is greatly simplified if a square-shaped metal profile must be cut at an angle of forty-five degrees.

For cutting quickly you can use an ordinary sheet of paper folded diagonally, with which to mark the surface for the future cut. Using folded paper, proceed as follows:

- Conduct on the straight surface of the profile in the place where the cut is made, strictly perpendicular to the line;

- lay the folded diagonally folded sheet of paper against the side surface with its sharp end against the mowing line, so that the upper edge of the paper triangle is flush with the upper side of the metal profile.

- Hold the line with a pencil along the side of the sheet at an angle of 45 degrees, then the paper corner is attached to the other side and trace it with a pencil (better to use a thin marker).

For sawing, you can use an angle grinder with a disk on metal, first conducting a thin line on the marking, then gradually deepening it to complete separation of the edges.

When working with the angle grinder, the following factor must be taken into account. when fully cutting edges, the disc can be damaged against a sharp corner, which will lead to its failure, and in the absence of protection on the angle grinder even to injury to the employee. Therefore, it is desirable not to cut the corner edges to the end, but to leave a narrow groove and then break up, sanding subsequently the ledge.

Making a template for cutting metal profile

If it is necessary to cut a large number of pipes, you can make a template from metal profile of a larger diameter on a paper sheet by the above method. The angle of inclination is checked with a protractor or a construction angle piece. in this case the two edges of the cut parts of the template are connected.

Tools to use

There are several ways to cut the pipe, for this use construction and industrial metalworking tools. Of all kinds, only the angle grinder allows you to obtain curvilinear surfaces without further processing with the closest arrangement of edges.

For individual use

The following tool is used to cut steel pipes in the household:

Hand pipe cutters. Allow you to cut round parts with an even right angle of cut due to the cutting edges of the rollers. There are several varieties of this type of products, consisting of a single roller or series of rollers fixed to a chain. These devices are quite rare in the home and are more suitable for professional work.

Design and capabilities of the angle grinder

Electric angle grinder is used for grinding, polishing and deburring of surfaces, weld seams and edges. The technique is effective in cutting various materials and the manufacture of products from metals, stones, bricks and concrete. The development of artificial diamond technology made it possible to turn the angle grinder into a universal cutting machine. Now their quality of execution is regulated by GOST R MEK60745-2-3-2011 and checked in laboratories.

In general, the device in the angle grinder is as follows:

- The motor rotor rotation is provided by an electric motor with a control box and a power cable.

- The shaft is fitted with a toothed gear and a fan. The mechanism is meshed with an idler mounted on the drive spindle. The last and rotates the working tool. a disk or stone.

According to the design there are one- and two-handed angle grinders:

- One-handed tools. No main handle, weight up to 2.5 kg, diameter of wheel 100, 115 and 125 mm.

- Two-handed tools. Both main handle and auxiliary handle are present, diameter of wheel ranges from 125 to 230 mm, weight of the machines is 2,5-6 kg.

How to cut a cast iron pipe

If the pipe is made of cast iron, then in order to cut it evenly, you will have to apply certain knowledge. The fact is that this material is characterized by high fragility, which means that before you cut such a pipe, you need to determine the algorithm of action.

- Mark the same way as for steel pipes.

- At the place where the cut is made, a wooden block should be used as a support.

- Next, you need to make a saw cut of a few millimeters around the circumference.

- After that, a chisel is inserted into the groove and a sharp and strong blow with a hammer.

As a result, it will split along the mowing line, forming a fairly even cut that can be further trimmed if necessary.

View the steel pipe cutter on AliExpress →