How and what to cut the tile under 45 degrees. Tile trimming

In order to beautifully cover with ceramic tiles (porcelain, mosaic) any right external corner, the end of the tile is cut at an angle of 45 degrees, and a neat right angle is formed from the two tiles.

Plastic angle. it’s not fashionable, not interesting and not beautiful.

The more so it will not be beautiful if you just attach one tile to the end of another. But this is also very common.

How to cut (sharpen) the tile at an angle of 45 degrees?

Everyone has different names for this action: file, sharpening, trimming, boring, Kremlin angle. the meaning is the same.

For quality trimming the face of tiles at 45 degrees you will need an electric tile cutter (tile cutting machine) or, in a pinch, an angle grinder (angle grinder) with a tile disk.

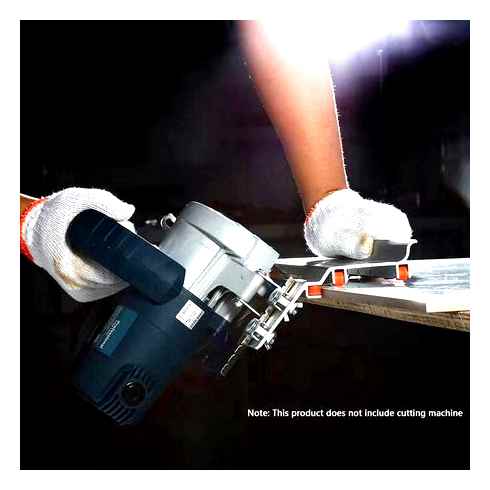

The easiest way. angle grinder

It is more difficult to achieve a good result with an angle grinder, but in principle, it is also possible. This is the easiest way to grind a tile corner at 45 degrees with your own hands at home.

The process of boring and grinding of porcelain tiles in the video below.

First of all you must have a good diamond tile disc.

You put the tile on a rib (prpendicular to the one that is being trimmed) and grind at a 45 degree angle to the back of it (the clay).

If you get a little rough, then large rough irregularities can be passed again with a disk, and in order to get a cleaner and smoother edge you can use this (pictured below) sanding pad with sandpaper or diamond “turtles”.

The sanding discs are Velcro-covered, you remove them and attach a new one. The base itself with Velcro is screwed onto the threads of the angle grinder. Diamond nozzles have a much longer life, but they cost many times more. If you do tile-laying all the time, then it makes sense to take a diamond turtle. If this is the first and last repair job you will do in your life, you can do with sandpaper wheels.

When working with such a thing you need an angle grinder with adjustable speed (speed to a minimum)!) Otherwise the edge of the tile will melt and burn rather than grind.

Electric tile cutter

An electric tile cutter, or as it is also called by tile-layers. a wet cutter. It has a water-cooled blade, and the same water quenches all possible dust. The tile cutter cuts along one clear, fixed path and minimizes such human factors as hand shake, etc.п.

The tile cutter has two positions to work. a flat cut and a cut at an angle of 45 ° (actually you can set any angle from 0 to 45 °, but most often it makes no sense).

A straight cut of a ceramic tile with an angle grinder

This type of work is the easiest to perform. It is carried out as follows:

- The first thing to do on the outside of the ceramic tile is to mark the line for the trimmer saw by means of a spirit marker.

- After that, it is necessary to securely fix the tile on the plane, eliminating the possibility of its movement during the cutting. To do this, place the tile on a flat surface of wood and secure it with a clamp over a sheet of rubber or by gently pressing it with the sole of your foot, which should be wearing special shoes.

- Next, you need to turn on the angle grinder and wait a few seconds for the tool to gain the desired speed.

Note! The cut edge of the tile must remain overhanging in the place of the strip of necessary notch.

- Hold the angle grinder should be so that the produced line for the cutting trimmer was clearly visible during the sawing.

- Then it is necessary to hold the tool firmly and evenly in your hands, and not to let it move from side to side, because otherwise it will not only make a torn cut, but also damage the nozzle, parts of which can fly out in any direction.

Important! Ceramic tile is a rather fragile material, so you should not put too much pressure on it when making the cut. During the first cut, you only need to remove the top layer of glaze. If you immediately make a through cut from the edge, the product may end up cracking. Because of this, the cut must always be made evenly from beginning to end in several stages.

- Now you should hold the moving wheel on the marked line on the ceramic tile in the direction of yourself, making the cut to a depth of 1-5 mm, depending on the material and thickness of the workpiece. Start cutting the tile from the side slowly, then move the tool faster to obtain a straight cut.

Please note! The circle on the angle grinder must be fixed correctly using a special key and taking into account the direction of rotation marked on it.

Optimal rotation speed of the cutting disc with diameter of 100-125 mm during cutting ceramics reaches 6-8 thousand. rpm.

Cutting a round hole with an angle grinder

With this tool it is possible to make an exceptionally large diameter hole in the tile. The process itself is carried out as follows:

- The first thing to do is to use an alcohol marker to draw the required hole on the glossy surface of the tile and on the back side in the same place.

- After inside the resulting outline on the front surface should be carried out straight strips crosswise to determine the middle of the circle made, putting at its detection mark.

- Next, you need to use a carbide drill bit exactly on the intended point to drill a through hole with a diameter of 3-4 mm.

- In the next step, you can begin to make 1-2 mm deep notches with the wheel of the angle grinder along the contour of the hole depicted with the marker on both sides of the tile.

Please note! The tool needs to be rotated carefully so that it gradually fits into the planned circle.

- Now it is necessary to make through cuts inside the contour, and then using the cutters you should begin to remove small pieces of ceramic from it. As an alternative, you can instead make the deepest possible cut along the previously marked out lines crosswise, and then carefully remove the four parts of the circle you have made.

- The last step is to perform processing of the inner surface of the cut along the entire length of the hole with coarse sandpaper or a file, which will remove any chips and roughness that appeared during cutting.

The nozzles used

Tile cutting with an angle grinder is done with a diamond grinding wheel. This attachment can be made in several variations. A fine diamond wheel is mainly used for this type of work and is designed for dry cutting. Of course there will be a lot of dust, but this way you can make a clean cut.

If you plan to work for a long time, in order to prevent overheating of the tool you can use a wet cutting wheel. In this case it will be necessary to additionally arrange the water supply. You can also do it manually, using a sprayer, or just dip the disk in water.

To protect against the possible disruption of the nozzle before you start work, you need to carefully inspect the tool and secure all its parts. To protect against dust and a sharp disc, in addition to the protective cap for the angle grinder, use goggles, mask and gloves.

Diamond wheel for angle grinder can be used in both dry and wet cutting

How to cut tiles

Now let’s move on to the process itself and look at how to work the tool to make the cut without chipping and with a minimum of dust. With regard to this nuance, we can distinguish three directions:

- Straight cut. This type of work is the easiest. In order to cut a ceramic tile with an angle grinder in a straight line, first of all, you need to fix it on a flat surface so that the edge remains on the weight of the line of the cut. Hold the tool so that you can see the direction of cutting, that is, the wheel will move “on itself”. In this case it is important to observe the safety rules.

- At a 45-degree angle. Cutting tile at an angle is somewhat more difficult. In order to perform an angle grinder oblique cut, you must first saw the tile at a right angle. The diamond wheel is then guided so that the excess material can be removed at an angle. Bring the edges to perfection with sandpaper.

- The hole in the tile. This type of work is only suitable for making holes of large diameter. In order to saw it with an angle grinder, you must first draw the contours of the circle with a marker on the front side. Then mark the center point with straight lines, positioned crosswise at right angles to each other. After that, proceed to sawing. Angle grinder should be directed at an angle so that the circle made a small depression around the circumference of the hole on the inside from the line of marking. Gradually move over, evenly sawing the tile. When you have gone deep enough, create straight lines. Carefully remove the 4 sectors of the wheel, one after the other.

Tile cutting options with an angle grinder

Mandatory condition to prevent chipping: Work only on the front side of the tile. This way you will damage the top layer less, and defects on the back side will be hidden by the mortar when laying. After making a notch, the edges of the tile are processed by sandpaper, which is printed on a bar, so you should consider the possibility of milling some of the tile material in advance.

How and what to make a 45 degree cut on the end of the tile?

The best option is to get a cut on the tile with a cutting machine, where there is an opportunity to turn the cutting wheel at an angle to the cut tile. The machine can be with or without water in the cut zone. This does not affect the quality of the cut. Wet cut provides more comfortable conditions for work. less dust. With either option, the quality of the bevel is acceptable and large quantities of tiles can be cut quickly.

Sawing a tile under 45 degrees on a machine.

The only difficulty arises when cutting concave tiles. It’s not a defect. the tile has that shape. The machine cannot repeat the deflection when not sawing:

Therefore, the cut part should not reach the front edge of the tile. where the enamel begins. Chips appear. Especially on porcelain stoneware. It is better to finish this area by hand. You can do it with a grinding wheel on a turbine. It’s faster and easier. But not always better quality. The grinding wheel can choose in some places stronger or weaker.

A more even plane is obtained manually, from longitudinal movements along the tile with a bar covered with sandpaper. The longitudinal movement scrapes off the projections, making the bevel in one plane. Another trick. Bevel on the tile is necessary to do at a sharper angle (less than 45 degrees). Visually, nothing changes, and the convenience when tiling is essential. This method is not suitable for ceramic baseboard, where you can see from above the junction of the ends of the two tiles.

Joining a ceramic baseboard at 45 degrees.

It is better to make a cut, on the painted end of the tile (many tiles have one end of 4 half or completely covered with enamel). In this case, you can not bring the bevel at 45 degrees to the edge, and leave a strip of one millimeter on the end. The end of the tile on the corner is obtained without chips and is less vulnerable to impact. This is especially important for dark colored tiles with dark grout. When you sharpen their face, you get light streaks and you can’t hide them with grout. This occurs, often from. That the tile has a slightly convex surface in the middle, and when cut at an angle, the circle clings to the ends of the tile face enamel.

The white stripes appeared when cutting the end of the tile at a 45 degree angle.

In the case of light grout, the unpainted tip of the tile is less noticeable.

The disadvantages of the angle on the tile being sharpened at 45 degrees :

The corner becomes more vulnerable to impact. Especially if it’s on a pass. It’s enough to hit the slope with an empty metal bucket so that a piece of the worn corner on the tile falls off. The labor-intensive work increases, and thus the price.

To catch such a corner can be anything, even a harmless belt buckle of a trouser belt:

Opinion of masters about the sawing of tiles at an angle of 45 degrees.

It is also possible to prepare a 45 angle on the tile with an angle grinder. Lots of dust. Wrong quality. But realistically. The main thing is cheap and always possible.

It is especially important to mark the correct angle when laying decorative stone. Often the corner elements for such products are not provided or are not available. Cutting stone at a 45-degree angle is the only way out of this situation.

Angle on a decorative stone at 45 degrees.