Parsing the starter lawn mowers

This stage allows the wizard to establish the reasons for the failure of the launch unit, as well as to troubleshoot individual parts. Disassembly work should be carried out in the following sequence:

-

Unscrew the screws securing the pulley to the starter housing;

Removing the trimmer starter

Remove the pulley from the starter

Removing the pulley from the lawn mower body

Spring removed from the starter coil

Many experts note that it is quite difficult to install the spring from the first time, therefore, when repairing the trimmer starter, the owner will need not only basic locksmith skills, but also patience.

Trimmer Starter Assembly Sequence

Although the process of assembling the lawn mowers launch unit is carried out in the reverse order of disassembly, there are several nuances that should be paid special attention to:

-

The coil with the spring installed must be turned over and mounted in the groove of the starter body so that all the protrusions become in their original place.

Installing the trimmer coil in the starter housing

Installing the compression spring

White cup with trimmer coil mustache

When assembling the starter, pay attention to the compression spring, which must be bounded by steel springs on both sides. If this is not done, then after the first season it will wipe the grooves in the pulley housing.

How to repair a trimmer starter

Petrol trimmer starter repair may be required at the most inopportune moment. In this case, the problem can be solved in two ways: replace the broken part or change the entire unit. The latter option is more expensive. To repair the device with your own hands, in most cases, you will only need a screwdriver with an appropriate tip from the tools. Repair work will not take much time and do not require any special knowledge. It is enough to know the device, the principle of operation, the nuances of assembling and disassembling the starter on the trimmer in order to achieve the desired positive result.

How to repair a trimmer starter

Signs and causes of failure of the starter mechanism

There are two malfunctions in the starter mechanism.

- Broken cord. With regular operation of the lawn mowers, this element is frayed and torn, which will be easily noticed by the user when trying to start the trimmer. To remedy the situation, you need to replace the cord.

- Spring wear and subsequent breakage or release of the hook from the groove. The fault can be determined by a cord that does not come back and does not wrap around the pulley after starting the engine. To repair the trimmer in this case, it is enough to install a new spring.

In rare situations, the starter mechanism breaks when the tool is used carelessly. The consequences can be unpleasant: a deformed cord is wound around the flywheel of a running engine, the pulley breaks, and the spring bursts. But these are isolated cases, a complete replacement of the starter is very rarely required.

The device and principle of operation of the starter on the trimmer

The gasoline engine is, in principle, the main part of lawn mowers.Its power is in the range of 0.5-2.5 hp. The movement from it is transmitted to the shaft, which is inside the hollow rod, and then through a gearbox consisting of gears, already a fishing line or knife (working body).

Also, lawn mowers have the following elements:

- protective casing;

- lever;

- belt designed for the convenience of using the device;

- starter used to start a gasoline internal combustion engine.

All parts of the lawn mowers are presented in the photo below.

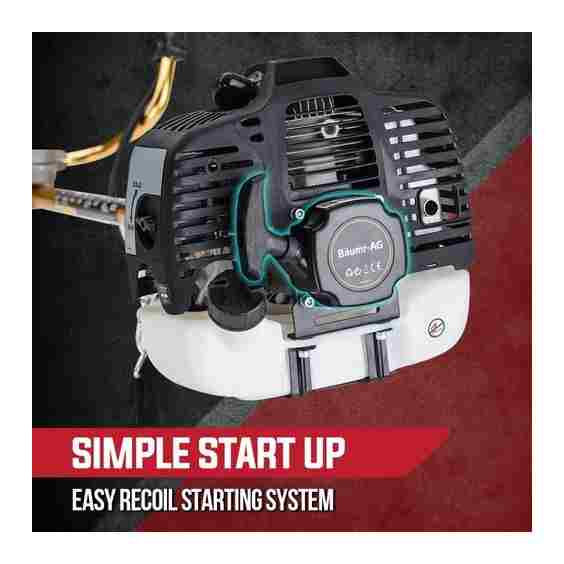

The trimmer starter is an integral part that starts the engine. He is shown separately in the two photos below.

The starter mechanisms of different models of lawn mowers work on the same principle: when the engine starts, the protrusions marked with 1 in the photo above engage with the pawls 3. When the engine starts to work, they return to their previous position due to the influence of centrifugal force. A similar role is also played by wires 2.

The process of returning to the initial position of the elements of the mechanism occurs due to the presence of a spring wound around the axis. It unfolds when the rope is pulled. After releasing the cord, it is pulled in and wound up due to the coiling of the spring. During the start of the internal combustion engine lawn mowers, the starting mechanism turns its shaft until it starts to work (starts).

Today, gasoline lawn mowers are equipped with two types of starter mechanisms:

The first option is much more common.

The trimmer starter can operate without breakdowns for a long time. It is impossible to clearly indicate the period of uptime. Everything is determined by the initial quality of the device and adherence to the rules for handling it.

How to start a lawn mower without a starter

At the moment, gasoline lawn mowers are equipped with 2 types of starter mechanisms:

Option 1 is even more common.

The trimmer starter can work for a long time without breakdowns. It is impossible to precisely indicate the period of non-refusal work. It remains for our client to be determined by the initial quality of the device and the observance of the rules of appeal with its help.

It is not difficult to find the cause of the breakdown of the launching device. There are several main options:

Best Lawn Care Setup for Beginners

- break of the cord (rope);

- when the spring breaks or disengages.

The designated parts are shown in the photo below.

It so happens that the starter mechanism is accidentally broken. The consequences will be disastrous if the broken rope is wound around the flywheel of a working internal combustion engine: then the spring will burst, the pulley will break. But such cases, when a complete change of the starter unit is required, do not occur often. As a rule, in order to repair the mechanism, it is enough to put the newest spring as it is also called to change the cord.

To repair the trimmer starter, it will be useful to first disassemble and then assemble it. This process is not particularly difficult. A screwdriver with a tip of a suitable shape is useful at work.

It remains for our client to do it carefully, observing safety precautions, mainly so that the spring does not injure the master in case of an accidental departure.

The launch mechanism is disassembled with the intention of installing new parts instead of broken ones in the following order:

- unscrew the screw fixing the pulley with the starter cover with a screwdriver;

- take out the spring and antennae;

- carefully remove the pulley (it is necessary for all this to turn your head away or work, wearing glasses and gloves for earlier);

- determine why the starting mechanism has broken down;

- if the spring has collapsed by 100 percent, then it is replaced;

- when the spring is ready from the hook, it is installed in its original place, bending the antennae before this (the photo shows the laying process);

DIY trimmer starter repair

The starter is one of the main components of the lawn mower, which greatly facilitates starting the engine of the tool. Its breakdown can happen at the most inopportune time, which will certainly entail significant changes in the daily plans of the site owner. There are two ways to solve the problem: repair the trimmer starter with your own hands, or replace the entire assembly. The easiest way to troubleshoot a starter system is to replace it entirely, but from a financial point of view, buying a new starter can seem far-fetched. For self-repair of breakdowns, it is enough to prepare a screwdriver with an appropriate tip and read the following recommendations.

The device and principle of operation of the starter on the trimmer

The gasoline engine is, in principle, the main part of lawn mowers.Its power is in the range of 0.5-2.5 hp. The movement from it is transmitted to the shaft, which is inside the hollow rod, and then through a gearbox consisting of gears, already a fishing line or knife (working body).

Also, lawn mowers have the following elements:

- protective casing;

- lever;

- belt designed for the convenience of using the device;

- starter used to start a gasoline internal combustion engine.

All parts of the lawn mowers are presented in the photo below.

The trimmer starter is an integral part that starts the engine. He is shown separately in the two photos below.

The starter mechanisms of different models of lawn mowers work on the same principle: when the engine starts, the protrusions marked with 1 in the photo above engage with the pawls 3. When the engine starts to work, they return to their previous position due to the influence of centrifugal force. Wire 2 also plays a similar role.

The process of returning to the initial position of the elements of the mechanism occurs due to the presence of a spring wound around the axis. It unfolds when the rope is pulled. After releasing the cord, it is pulled in and wound up due to the coiling of the spring. During the start of the internal combustion engine lawn mowers, the starting mechanism turns its shaft until it starts to work (starts).

Today, gasoline lawn mowers are equipped with two types of starter mechanisms:

- manual;

- electric.

The first option is much more common.

The trimmer starter can operate without breakdowns for a long time. It is impossible to clearly indicate the period of uptime. Everything is determined by the initial quality of the device and the observance of the rules for handling it.

Spring tension

After installing the spring, tighten it. To do this, perform the following actions:

Honda GCV160 Mower Pull Starter REPAIR How To Fix Recoil Starter BROKEN String Spring Replacement

- remove the handle from the starter cord;

- then the rope is inserted into the reel groove;

- tension the spring by rotating the coil in the opposite direction to the clockwise direction (winding);

- make the required number of revolutions specified in the operating instructions for the used trimmer model and corresponding to the length of the cord used;

- at the very end, the rope is threaded into the hole intended for this, located in the starter cover;

- put the handle in place, fixing it with a knot.

If, after repair, the spring continues to fly off, then you can get rid of it in the following ways:

- squeeze a piece of the plate suitable in size into the groove at the location of the spring hook;

- drill holes on both sides of the groove in the spool, into which to insert the spring hook and fix it with a wire.

How to repair a trimmer starter

Petrol trimmer starter repair may be required at the most inopportune moment. In this case, the problem can be solved in two ways: replace the broken part or change the entire unit. The latter option is more expensive. To repair the device with your own hands, in most cases, you will only need a screwdriver with the appropriate tip from the tools. Repair work does not take much time and does not require special knowledge. It is enough to know the device, the principle of operation, the nuances of assembling and disassembling the starter on the trimmer in order to achieve the desired positive result.

Starter assembly

The assembly of the starter unit is carried out in a number of stages:

- the coil is turned over, setting it so that the spring bend fits exactly into the groove of the body, as in the photo below;

- two washers are laid, between which a spring is placed;

- put in place the cup with the antennae;

- tighten the screw (photos below).

When doing the described manipulations, it is imperative to put two washers. If this is not done, then the spring will eventually damage the plastic cup, and when it is pulled up, wedging will begin. Because of this, there is a feeling as if the spring has flown off. To eliminate this drawback, you need to install this part of a greater length or an additional washer.

When such parts are not available, you can simply unscrew the screw a little, and the starter unit will start working without wedging. But this option is temporary. it is better to repair it with high quality as soon as possible.

Removal and disassembly of the starter, replacement of broken parts

To repair the trimmer starter, you will first need to disassemble it, and then assemble it. This process is not particularly difficult. For work, you need a screwdriver with a tip of the desired shape.

Everything should be done carefully, observing safety precautions, mainly so that the spring does not injure the master in case of an accidental departure.

Disassembly of the starter unit

The launch mechanism is disassembled in order to install new parts instead of broken ones in the following sequence:

- unscrew with a screwdriver the screw fixing the pulley with the starter cover;

- take out the spring and antennae;

- carefully remove the pulley (you need to turn your head away or work, wearing glasses and gloves first);

- determine why the trigger is broken;

- if the spring has collapsed almost completely, then it is replaced;

- when the spring comes out of the hook, it is installed in its original place, bending the antennae in front of this (the photographs show the laying process);

- after the spring plate is installed inside the groove, carefully twist it.

To change the spring, you must work carefully and carefully: it can accidentally burst under the influence of the force caused by installing it in place. Even if you carefully remove the roller, the spring strip very quickly flies off the reel and can injure your hand with its sharp edges.

It is not always possible to immediately put the spring plate in its original place. It often slips, so attempts must be repeated until the desired result is achieved.

The main malfunctions of the trimmer starter

It is not difficult to determine the cause of the breakdown of the triggering device. There are several main options:

- break of the cord (rope);

- when the spring breaks or disengages.

The above details are shown in the photo below.

It may happen that the starter mechanism is accidentally broken. The consequences will be disastrous if the broken rope is wound around the flywheel of a working internal combustion engine: then the spring will burst, the pulley will break. But such cases, when a complete replacement of the starter unit is required, are extremely rare. In most cases, to fix the mechanism, it is enough to install a new spring or replace the cord.

How to repair a trimmer starter

One of the key components of the lawn mower is the starter, which is designed to make it easier to start the engine of the device. Like other parts, it breaks down periodically. In this case, there are two solutions to the problem: repair the trimmer starter or replace it completely. The second option is simpler but more expensive. In addition, the required part must first be found on the market, since different types of lawn mowers are used with different starters. If you have free time and a screwdriver with a suitable tip, you can restore the operation of this unit yourself if you know how it works, what malfunctions are typical for it, and how to fix them correctly. All this is in this material.

Removing and disassembling the node

The procedure for disassembling the starter consists in performing a certain sequence of actions:

- first you need to find the screw that connects the starter cover to the pulley and unscrew it;

- then you need to remove the spring, antennae and washers;

- then you should carefully remove the pulley, keeping the structure away from your face so that the accidentally bouncing spring does not injure the user;

- then you need to inspect the spring: if it is damaged, then you need to put a new one (the cost of such a part is low), and if it jumped out of the hook, you need to return it to its original place, having previously made bends, if they broke off.

Other malfunctions

Sometimes, after the repair, the spring still flies. There are two solutions to fix this problem:

- To prevent the spring bend from jumping out of the groove, you need to insert a small fragment of a metal plate between the bend and the wall of the seat. This will provide a tighter fit for the spring.

- A self-made fastening also helps to keep the spring in the groove. It is necessary to drill holes in the coil on each side of the groove, place a spring bend in them and fix it with a piece of wire. These steps should be performed so that the wire does not touch the starter cover and does not slow down the movement of the pulley.

Trimmer starter. device and principle of operation

In order to repair the lawn mowers starter on your own, you need to understand the principle of its operation and know its structure. Today, manual and automatic starters are installed on trimmers, with the former being the most common.

The part is a plastic case that houses a pulley with a cord wound around it to start the engine. In order for the cord to twist independently after winding the tool, a ribbon spring made of alloy steel is located on the inner side of the pulley. A ratchet is installed on the front of the pulley, creating engagement of the starter with the drive shaft of the tool motor.

On a note! Depending on the model and brand of the trimmer (Huter, Husqvarna and others), the ratchet pulley can be one piece or two separate parts.

The principle of operation of the recoil starter is the same on lawn mowers of Chinese, European and domestic production, be it Hitachi, Patriot or another manufacturer. To start the engine, the owner of the device pulls the cord sharply. From this movement, the pulley turns, and the protrusions on it engage with the pawls located on the flywheel. Further, the flywheel and crankshaft begin to rotate with the pulley. After starting the engine, under the influence of centrifugal force, the projections and pawls diverge in different directions. And the starter cord, after the user releases it, is wound around the pulley using a return spring.

Important! With heavy use, the drive cord will break over time and the ribbon spring will wear out. These parts are easy to replace with your own hands.

Diagnostics and elimination of breakdowns

To diagnose the starter mechanism for the purpose of its subsequent repair, the unit must be disassembled. This is not difficult to do; you only need a screwdriver. But during this operation, you need to be careful. with careless movements, the spring can fly out and cause injury to the user.

Problem prevention

Sooner or later, problems with the starter arise on any trimmer. Stihl FS 55, MTD 790 or another brand. You can delay the appearance of such a malfunction, but for this you need to handle the instrument with care. In particular, you should not make too sharp jerks, this will lead to a break in the cord or to a spring out. It is not recommended to subject the lawnmower to shocks or other physical influences. If the starter housing breaks and the cord breaks, it could wind up around the engine flywheel. This will result in a ripped pulley and a bursting spring.

So, having discovered that the starter mechanism has broken on the lawn mower, you should not rush to the specialists for help right away. Knowing how the malfunction is eliminated and / or the part is replaced, the repair work can be done independently. This does not require any specific tool. At first, the procedure may seem complicated and tedious, but numerous videos on the Internet dedicated to repairing a starter will help solve the problem as quickly and simply as possible.

Replacing the cord

To replace an element, you need to find a hole in the coil for it, through which you pass the cord, and then tie a knot. Next, you need to cock the coil with the spring by performing a few turns.

On a note! The exact number of turns can be found by looking at the instructions for using the trimmer, or by hand. To do this, you need to measure the length of the rope and count how many times it can be wrapped around the coil.

For example, if the cord is wrapped around the circle six times, then to tighten the spring, you need to turn the coil counterclockwise six times. After that, it remains only to thread the rope through the hole and fix the handle on the cord.

Truck

Manufacture of a hand-held mower from a vacuum cleaner

It is quite possible to make a trimmer from an old vacuum cleaner. In this case, the engine will have to be removed from the housing and, as such, secured to the holder in one of two possible ways. The first option is described in the previous paragraph. fasteners are welded from metal to the size of the motor. The protective cover can again be made from a plastic bottle.

But there is also a second way to mount the motor. Since the engine is larger and heavier, it is convenient to place it on a structure with wheels, for example, from an old sidecar. As practice shows, it is extremely tiring and inconvenient to hold a trimmer made of a vacuum cleaner on weight due to muscle strength. A home-made head for attaching a knife is not needed in this case. The motor in the vacuum cleaner is equipped with a fan, removing which frees up space for installing the cutting element. The latter is done by analogy with the description for a trimmer from a drill.

How to make a grass trimmer with your own hands

Reinforced construction with two knives

To increase the width of the work area in one pass, you can make a structure with two knives. In this case, a pulley or sprocket is attached to the crankshaft. Using a backpack strap or bicycle chain, torque is transmitted to the knife shaft. In this case, the cutting parts are carried from the front to the sides. And the frame in this case is made so that the cutting elements do not reach the front wheels. They are mounted with bearings and also have a pulley or sprocket.

The sprocket and pulley are selected in such a way that the rotation of the knives is carried out at a speed of 500 rpm. this ensures an even cut. It is optimal to make a sharpening angle of the knife 60 degrees, otherwise it will often need to be sharpened again. The length of the knives is selected based on the width of the supporting structure, so that during rotation there is a minimum gap between them. The part opposite to the tip is bent at a slight angle, which makes it a kind of blade. This gives airflow. the grass will not stick. The knife should not be fixed tightly so that when stones hit it, it changes its position, since it is easier to put it back in place than to repair the engine or shaft.

Advice! In order to properly assemble a mower from a chainsaw, it is recommended to watch thematic videos, since the design is more complicated here than in previous models.

Trimmer from angle grinder

Another easy and convenient option is to make an electric garden trimmer from an angle grinder. In general, the assembly scheme is similar to the previous method, but with the difference that it is even easier to attach the power tool to the holder. If you remove the included protective cover from the angle grinder, you can screw the U-shaped fastener, welded by yourself, into this thread. You can fix it to the holder by means of bolts or welding, if you do not plan to disassemble the homemade trimmer in the future. Some craftsmen immediately weld a protective casing to the fasteners.

On a note! Convenience of using an angle grinder as a basis for a trimmer is that the knife is attached to it very easily on an existing mechanism. The cutting element itself can be made from an old circular knife from a circular saw. In the absence of such, you can use a fishing line or wire.

Chainsaw-based lawn mower

The chainsaw is a popular tool. A huge number of removable units were created for her. from a cultivator attachment to a drill. There are other options for using it. One of them may be a trimmer, or rather, a lawn mower on wheels, since the large weight will not allow you to hold such an assembly in your hands.

How to make a trimmer from an angle grinder and other electrical appliances with your own hands

Any home plot needs mowing of grass. An electric or gasoline trimmer is expensive, and not every owner can afford to buy one. Therefore, some craftsmen have learned how to independently make a trimmer from an angle grinder.

Of angle grinder

- First, a brace is prepared. It is designed to grip the body of an angle grinder. The metal plate is applied to the body and bent.

- On both sides of the body there are threaded holes in which the rocker handle is attached. Attach a trimmer bracket to them.

- Holes are drilled in the bracket on both sides so that they correspond to the openings on the tool body. For accuracy, make notes on the part with a marker, clamp it with a vice and drill.

- Then a guide is attached to the bracket. Its size should correspond to the length of the body or be slightly shorter. The guide is attached with a welding machine, the remaining scale is knocked down. The part is grinded with a metal brush.

- A handle (rod) is made from a metal pipe. To fix the handle at a slope, the end of the pipe is cut off under the bevel. The finished handle is welded to the structure, the scale is knocked down and the part is cleaned with a brush.

- To attach the tool, you need to unscrew the protective disc of the angle grinder.

- Then the homemade product is installed on the wheels. To do this, you can borrow wheels from a trolley or stroller with brackets.

- First, the angle grinder is mounted, then the wheel with the bracket. All are secured with a bolt. On the other hand, they make the same fasteners.

- The cutting unit is made of a steel cable. A nylon wire designed for trimmers will do. It is threaded through the clamping nut and keyhole using a criss-cross method. Then the nut is tightened together with the cables.

- The wire is fixed with electrical tape.

For safety reasons, it is recommended to make a protective device for the device. The casing for the angle grinder is made of aluminum sheet or thin sheet metal.

How to remove the spool and replace the line

Trimmer owners, mostly beginners, find themselves in confusion, bordering on panic, when they need to change the cutting tool or line in the reel. Very often, when trying to unscrew the mowing head, users simply render it unusable, not suspecting that it is unscrewing in the opposite direction. To prevent this from happening, if you need to replace the tool, it is recommended that you read the step-by-step instructions below.

- Stop the mowers engine or power off the trimmer before placing the line into the spool to avoid injury from accidental starting rotation of the cutting tool.

- Unscrew the attachment attached to the gearbox shaft. To do this, the shaft must be fixed by aligning the holes on the washer and on the axle, and inserting a metal rod or screwdriver into them.

- Unscrew the nozzle. You should be aware that the thread on the shaft is left-handed. Therefore, turn the trimmer coil to the right, that is, clockwise.

- Disassemble the mowing head. Most often, the head cover is attached to the clips. To remove it, you will need to sink these latches into the case, squeezing the edges of the cover. If your trimmer has a semi-automatic mowing head with a button on the bottom, then the disassembly of the attachment should be done carefully, since you can lose the spring, which sometimes flies out when the cover is removed.

- Cut off the required amount of line. Usually its length is 5 meters. Use a cord of the same diameter as indicated in the instructions for the tool. It is not recommended to exceed the maximum line diameter as this will result in increased engine load and higher gas mileage.

- Find the midpoint of the line by folding it in half. You will have a loop.

- Special grooves are cut inside the coil (there may be holes). Insert a loop of line into this groove.

- Wind the line around the spool by turning it counterclockwise. It is necessary to fill in the cord as evenly as possible, the turns should lie down without overlap and with good tension. When the winding is finished, leave free ends of the line about 20 cm long and fix them in the grooves on the sides of the reel.

- Assemble the mowing head. Be sure to insert the spring and washer (if equipped) before final assembly of the accessory. Place the spool in the body and thread the ends of the cord through the holes or lugs.

- Put on the cover and secure it with the latches.

- Screw the adapter back onto the gearbox shaft, also securing it with a screwdriver. You will need to twist the trimmer coil to the left (counter-clockwise).

The cord lengthens spontaneously

There are times when the trimmer user notices a very fast line flow. However, he never hit the ground with a button to lengthen the line. The reason for the fact that the line spontaneously lengthens, being cut on a special knife on the casing of the device, may be the absence of a spring in the mowing head. Often novice users of mowers, trying to load the line into the reel, forget to install the pressure spring in the head, or even lose it when opening the lid, and in the future, do not even suspect of its existence.

Also, the line can be lengthened without using the button if the spring is loose. If checking the spring has confirmed this fact, then several washers must be placed under it in order to enhance its clamping properties.

Major coil faults

Trimmer users and lawn mowers often face a problem with the semi-automatic mowing head. Coil malfunctions can be as follows:

- the line does not lengthen automatically;

- the cord spontaneously comes out of the reel.

Trimmer coil device

Trimmer mowing heads come in a variety of designs, both simple and complex. The picture below shows an exploded view of the semi-automatic trimmer head from a Husqvarna (Husqvarna) lawn mower.

This type of head is found on most lawn mowers and trimmers such as Stihl (Stihl), Patriot (Patriot), Champion (Champion), Bosch (Bosch), Huter (Huter) and others. The device of the mowing head is quite simple. It includes the following details:

- mowing head base;

- button for semi-automatic cord feed;

- bobbin (spool) into which the fishing line is tucked;

- spring;

- eyes. through them the line comes out;

- trimmer head cover;

- line (cord).

There are also simpler trim heads shown in the following photo.

All these attachments do not allow you to change the length of the line in a semi-automatic mode (after pressing a button). If the cord breaks, you have to stop the mower and change it manually.

Line does not extend automatically

If the line does not lengthen when you lightly hit the trimmer button on the ground, then the reasons for this may be the following.

Option 1. a bite has occurred, i.e. clamping the cord between turns. This problem usually occurs if the user has been winding the line on the reel unevenly, with intersecting turns, or winding it with insufficient tension. In the latter case, when the mowing head rotates at high speeds under the influence of centrifugal force, the cord begins to tighten, as a result of which inter-turn clamping of the fishing line is possible. To fix the problem, you will have to disassemble the coil on the trimmer and rewind the cord correctly, that is, in even turns with good tension.

Option 2. too short ends protrude from the head. The line may not come out when hitting the ground if the ends sticking out of the head are not long enough (short). In this case, the centrifugal force is not enough to stretch the line. Therefore, it is required to stop the unit (turn off the engine or disconnect the trimmer from the mains) and pull out the line manually, after pressing the button.

Option 3. the line is brazed inside the mowing head. This causes the coil to lock and not spin when the button is pressed. Basically, this happens for several reasons: poor cord quality, coil overheating during prolonged operation of the unit, line hitting hard objects.

- In the first case, third-party cord can be made of low-quality and low-melting materials that cannot withstand mechanical and thermal stress. Therefore, you should give preference to “branded” lines.

- But, if you nevertheless purchased a fishing line of unknown quality, and it is often soldered during operation, then you can follow the example of some users who, after filling the cord into the reel, wet it with either silicone grease (from a can) or mineral oil. This procedure greatly reduces the likelihood of the coils of the fishing line being soldered together.

- Also, the line can be soldered if it hits a hard object (stone, fence, dry branch, etc.) during mowing. As a result, it stretches slightly and is pulled back into the head at high speed. From friction, the cord heats up, and its turns stick together. The only thing that can be done to eliminate this malfunction is to open the trimmer spool and rewind the line.

DIY trimmer coil repair

The trimmer, whether petrol or electric, is the only solution for cutting grass in hard-to-reach places that a wheeled lawnmower cannot handle. As a cutting tool in trimmers, metal knives or special fishing line are used, which is tucked into the trimmer coil. But, unfortunately, trimmer heads become unusable over time during operation. Some malfunctions can be eliminated by hand, and some require a complete replacement of the mowing head.

Is it possible to make a coil for a trimmer with your own hands

- Take a piece of plywood or PCB and draw a circle about 14 cm in diameter on it.

- Cut the disc with a jigsaw or metal hacksaw.

- Drill a hole in the center of the disc that matches the diameter of the gearbox shaft. Do not forget to put a washer on it before installing the disc on the shaft.

- Small corners can be screwed along the edges of the disc or 1-2 holes can be made on opposite sides. They will serve for refueling the fishing line in them.

- Several screws can be screwed into the plywood to fix the line.

This homemade mowing head is secured to the shaft with a nut. It will not work to tighten or unscrew the nut without fixing the shaft. To replace the cord, it will be enough to loosen the screws, insert a piece of line of the required length and press it again.

Also, the mowing attachment for attaching the fishing line to it can be made of metal sheet. How to do this can be understood from the following video.