Simple flat crafts

Simple flat plywood figures are easily made with a jigsaw. They are made in the following order:

- A rectangular blank of the desired size is formed from a plywood sheet using a hacksaw.

- The stencil (template) is prepared according to the size of the workpiece. It is made of cardboard or heavy paper (Watman). The figure can be drawn yourself if you have a talent for art, translate it from a picture using tracing paper or print on a printer from the Internet. Then it is cut out along the contour.

- The stencil is imposed on the plywood workpiece and outlined with a pencil or marker (felt-tip pen). Through copy paper are translated onto plywood all the internal details.

- The figure is sawn out according to the markings with a jigsaw.

- Edge dressed and all sawing errors corrected. The surface is ground with a sandpaper.

- The shape is given the necessary shape. All the necessary elements can be applied with the burner. Another option is to paint with acrylic paint using a brush on the markings made with a stencil.

- Finishing. Most often, lacquering.

The basic criteria for the selection of paint material can be found in our article What wood varnish to choose for work inside and outside.

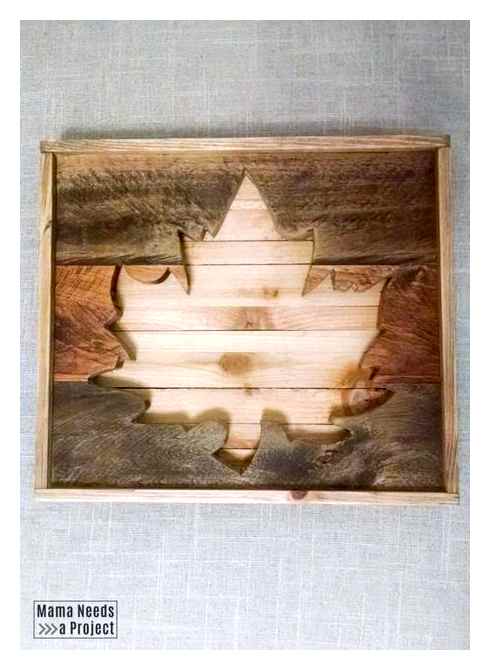

You can make such crafts with this method:

- Figurines of animals, birds, fish. In Fig.Swan figure stencil for making swan figures is shown in picture 1. It can be enlarged to the desired size and printed on the printer.

- Figurines of funny people, cartoon and fairy tale characters.

- Composition crafts. Figure 2 shows a dolphin on a sea wave.

A cute “dog” handicraft can be made using an annealing machine. For this, you can cut the workpiece to the contour of the head or burn the pattern directly on the plywood workpiece. A huge number of different ideas can be offered. One’s fantasy is not limited by any limits.

Sawing with a jigsaw, transferring drawings for the miracle jigsaw to plywood: we consider in detail

After completing the installation work in the pre-bathroom, there is an option to add decorative elements. In this master class, we will make a shaped cut out of plywood for the ceiling. Firms that work on demand, provide expensive services for laser cutting plywood. However, it is possible to develop a sketch and finish it with your own hands, and the result will turn out to be completely unique and author’s.

Master class on making a cutting board

Beginning craftsmen should start working with the jigsaw with simple jobs. A cutting board will be a great option.

- A piece of a wooden saw cut;

- Jigsaw. both manual and mechanical ones will do;

- Sanding machine. You can also use sandpaper.

- mineral oil to impregnate the finished board.

- Begin with the choice of material. Any wooden workpiece will do. the type is not important here. It is important to pay attention to the following aspects:

- The wood must be dry.

- On the workpiece should not be stained from technical fluids.

- Knots and cracks on the surface are not desirable.

- Choosing the design. It is determined by the shape of the future product and decorative patterns. A template or stencil is created according to the chosen design. It is transferred to the plywood.

What Can You Do With a Jigsaw? A Lot! | WOODWORKING BASICS

- Using a jigsaw, accurately, in one continuous cut, along the contour of the template saw the future product. This is necessary to achieve straight, well machinable ends.

- In a predetermined place, a through hole is made so that the board can be hung. For this purpose, using a drill drill a hole is drilled, a saw is inserted into it and a cavity is sawed out along the outlined contour with a jigsaw.

- Using a grinder or emery board carefully process the ends and, if necessary, the entire surface of the board. A file is used for hard-to-reach places.

- If desired, a groove can be made along the contour of the board. A milling machine is needed for this. After the furrow is made, the product is carefully sanded.

- The non-working surface of the board can be decorated with decorative elements, such as pyrography or painting.

- The final step is the treatment with specialized solutions. Mineral oil is suitable for this. This can be done by immersing the board in mortar. Or by applying oil in several layers. it is applied with a brush, allowed to soak in, then another layer is applied. Repeat until the oil is no longer absorbed.

As you can see, having the necessary tools at hand, it is not difficult to create a cutting board with your own hands.

The secrets of the jigsaw craftsmanship, you will learn from the video.

How to choose?

Apart from that the choice of cutting blade is of course important. Jigsaw blades are made of different materials with different shapes, sizes, and sharpening. If materials with low density will be processed, saws with a length of 75, 85 or 100 millimeters are sufficient. Jigsaw pitch varies from 2.5 to 4 millimeters in the case of wooden materials, and from 1 to 2 millimeters when cutting metal. The abrasive coating on the cutting blades is mainly diamond, which is indispensable for tile, ceramic and glass.

Colored metal can be cut with a wave saw. Buying a cutting blade, you should definitely see if it is suitable for the available jigsaw. And also the choice is often made between professional and amateur jigsaws. The latter have less power, but are still suitable for typical domestic work.

It is believed that such a device is able to make a cut in wood to a depth of 50 millimeters, and on metal. from 2 to 3 millimeters.

Features and types of carving with a jigsaw

Wood carving with a jigsaw. a type of, rather, original art that allows you to create real masterpieces. At the same time, everyone can master such a skill. And what you should know for this and what types of carving exist, is told in the article.

Technology and blueprints for jigsawing plywood

According to historical data, the mass production of plywood dates back to the beginning of the nineteenth century. And as this material at that time was produced exclusively for decoration and furniture manufacturing, almost simultaneously appeared this type of craft such as cutting out of plywood with their own hands.

For more than two centuries, this type of art has not lost its relevance. It is loved for its simplicity and the final product of decent quality.

By and large, anyone, regardless of gender and age can do this kind of art. A huge plus is the absence of serious financial investment.

Apart from a great own desire you need only a sheet of plywood, the jigsaw itself and stencils or as they are also called by masters, the drawings for artistic sawing with the jigsaw from plywood.

How to Saw Patterns?

The most difficult, but beautiful is artistic pattern sawing. To create an ornament it is necessary to transfer the stencil on the plywood. To make a stencil, use Watman, paper or remnants of wallpaper. Large elements of furniture can be placed on a piece of cotton or wallpaper, for small elements is suitable a simple sheet of A4. On the sheet with a pencil to create a drawing or take an existing one, then you need to duplicate it with a brighter pencil or felt tip pen to make it easier to transfer the image on the wooden workpiece. To make a pattern or ornament using a hand and electric jigsaw, you need to:

- draw or find on the Internet the drawing that you will translate and cut out;

- transfer this pattern to the workpiece;

- saw the pattern. large elements can be made with an electric jigsaw, small elements only with a hand jigsaw;

- Remove the remnants of paper, if you glued the stencil to the plywood;

- trim the edges;

- clean the workpiece of dust and shavings;

- Coat with varnish, stain or paint.

There are the following options for transferring a pattern to the workpiece:

- Simple patterns can be transferred with an awl, and then connect with a pencil scythe line;

- You can use tracing paper;

- Glue the pattern to the plywood with glue or double-sided adhesive tape, and after work remove the rest of the paper.

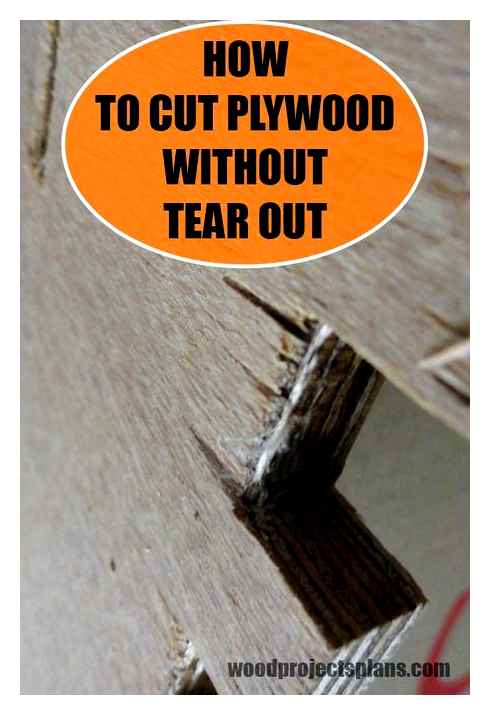

Artistic carving with a jigsaw requires preparation and skills that require patience and diligence in learning. Start with simple patterns, gradually increasing the complexity of the patterns. Openwork is very graceful and beautiful, and is also an inexhaustible space for creativity and imagination. Shaped cutting will require more work with a hand jigsaw than with an electric jigsaw, as mentioned above. A hand jigsaw allows you to make small elements in the drawing. Particular attention should be paid to the corners, which can provoke cracks or splintering corners.

A large number of elements and parts makes the workpiece more fragile, so do not make sharp turns, cut slowly, gently move the workpiece, work smoothly.

How to choose plywood

Plywood is a multilayer construction material of high strength, one of the most convenient and easy-to-work materials. In its manufacture thin sheets of wood (veneer) are glued under pressure; different glue compositions are used for different grades. Common varieties of plywood include:

- FK veneer. Material with low moisture resistance, designed for interiors. Veneer sheets are glued with urea glue.

- FKM plywood. Characterized by high water resistance, used in interior finishing work. Weakly toxic melamine and melamine-formaldehyde resins are used in production.

- FSF plywood. The popular variety, has high water resistance and mechanical strength, is used in exterior finishing and roofing work. Resin phenol-formaldehyde glue is used for gluing of veneer sheets. An important characteristic of the material is its emission class; plywood of E1 class can be used in living rooms.

For garden crafts, the best choice in terms of price/quality ratio will be FSF plywood, despite the formaldehyde, it is not dangerous to health outdoors. Other varieties more strongly absorb moisture, and the figures made of them are deformed. Plywood is mainly made from birch and softwood (pine, spruce, larch); the composition can be combined or homogeneous.

The type of plywood by material is chosen depending on what the finished product will be. If you like the natural wooden texture and want to leave the figurine unpainted and varnished, choose birch plywood with its denser and harder surface. If you want to decorate the garden with a bright craft, choose a pine sheet. the paint will lay on it better. To choose a quality material, it is important to pay attention to the other characteristics:

- Thickness. Plywood can consist of three, five or more veneer sheets (always an odd number); the thickness varies from 3 to 30 mm.

- Flexibility. Depends on thickness.

- Sanding. The following types of plates are produced: not sanded (NC, rough treatment), sanded on one side (SH1) and on both sides (SH2). The choice depends on the way of displaying the figure. If it will be attached to the surface of the wall or fence, it is logical (and more economical) to stock the material with one sanded surface. If the decor will be visible from all sides, you will need a fully sanded material.

- Grade. Plywood comes in four grades, depending on the number of knots per unit area. Examine each sheet when purchasing: knots and spots may be evident on the finished work, as well as resin filled cavities.

- Quality. Choosing material, pay attention not only to the defects of the grade. the number of knots and their color. Side cuts must also be inspected. If you notice even the slightest peeling of the veneer on the end-parts (where you can see the veneer layers), it is worth refraining from such a purchase, despite its attractive price.

Plywood is subdivided depending on the appearance of the veneer, the number of defects, knots, into 5 grades. Classes are identified by Latin letters and numbers. Elite grade, marked E, has the greatest number of requirements. Class 1 is marked with the letter B. Further labelling is defined as BB (2), CP (3), C(4). For each grade, the standard specifies the limit value of possible defects.

According to the degree of processing the material is either sanded or untreated. The first option involves changes on one side, both sides. Another variant of processing lamination.

Knowing the purpose of the product, choose the level of moisture resistance. Brand FSB is suitable for outdoor use, FC. for placement indoors with low levels of humidity. If the requirements are not met, the product burns out, swells from water.

Plywood is made from hardwood and softwood veneers. The former include birch, beech, maple, aspen and poplar. The second category includes spruce, cedar, larch, fir and pine. A sheet of material can be made of one type of wood or a combination of hardwood and softwood.

If it is assumed that the work will have a natural color, it is better to choose a birch base. When the surface is planned to be painted pine plywood is used. Acrylic or oil paint is used for the craft.