How to cut a hole in the countertop for the sink with the jigsaw

The times when the sink in the kitchen was a metal sink, screwed to the wall and equipped with two taps, are long gone. Today, design features allow you to place it directly in the countertop. It can be surface-mounted or recessed. In the latter case, its parts won’t be visible from above on the countertop. Consider today the first option, as it is most suitable for self-installation.

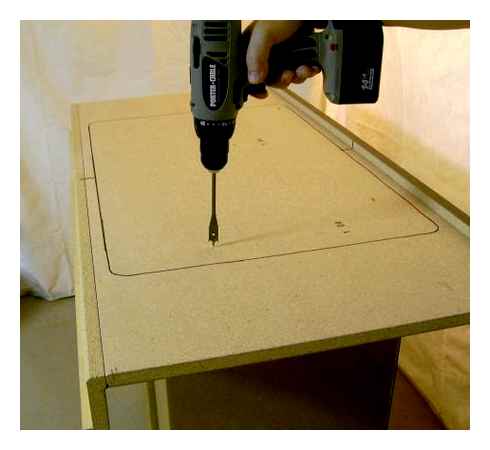

On the photo. installing a rectangular sink into the countertop

The sink should be centered in the middle of the countertop depth, offset to the left and right for the most comfortable position. The distance from the edge of the sink to the countertop edge must be at least 50-70 mm, otherwise the sink must be pushed in deeper. It is not recommended to make an indent from the corner baseboard less than 30-40 mm, otherwise it will be difficult to wipe the surface in this place. When installing the sink in a corner section, it is useful to leave an indentation of 100-140 mm from both walls to get a small space for convenient placement of household chemicals and detergents.

Some manufacturers provide their products with installation templates, some do not. If you have a template, you must glue it to the countertop‘s front side, moisten the surface slightly. This will help to avoid unintentional misalignment and allow you to align the sink without assistance. The template usually indicates the width of the sink rim, otherwise it should be measured and marked to clearly control the fit.

If there is no template, the sink must be turned over and placed on the countertop, carefully observing the indents. The sink should be circled with a water-soluble marker and removed, and then the contour line should be moved inward by the width of the rim. If the bowl does not follow the outer contours, as is the case with sinks with a drying tray, the scythe line of the markings must be displaced by a certain distance on each side. If two sinks or a waste compartment are combined in one unit, a common hole is cut out under them.

Sink types by installation method

The installation of sinks with their own hands can involve different technologies. Consider the main structural types of kitchen sinks.

- Overhead models. This type is considered the most common due to the ease of installation. Even a beginner can cope with the installation of the overhead sink. They are made, as a rule, of stainless steel, are mostly rectangular in shape. Mounted on top of a kitchen cabinet that has no countertop.

- Sinks and washbasins. Install such accessories in a prepared hole in the countertop, which must be cut clearly to the size of the design. The wash basin is dipped into the sealant-finished hole and secured with fixtures.

- countertops. Their method of installation is similar to the previous one: the sink is installed in a hole cut into the countertop. The only difference is that not all countertop materials can provide an integrated type of installation, and the cuts of the hole must be trimmed carefully.

One of the important criteria for choosing a sink is its depth. Too deep sink (20 cm or more) is not convenient to use, as it forces a strong bend. Shallow bowl (up to 15 cm) is bad by the fact that the knocking water on it from the open faucet will splash around the entire work area.

Choosing the height of the mixer in no small part depends on the depth of the bowl. For example, for a deep sink, it is better not to choose a faucet with a high position of the spout, as well as for a shallow sink with a low spout. This all affects the ease of use.

Of all the above types of sinks, today’s users mostly choose the mortise type. Such sinks are available, have a convenient depth and, what is important, have a modern appearance.

How to perform such work independently

As an example, consider the installation of washing equipment in the countertop, made of particle board. Type of installation. above the surface of the table. The entire work process can be broken down into the following steps:

The work should begin with the preparation of the necessary tools. Make sure that the sink comes with all the necessary fasteners. From the tools you will need:

- Construction pencil;

- Level, angle and tape measure;

- Drill and drill bit for woodwork;

- An electric screwdriver;

- The jigsaw is electric;

- Silicone and self-tapping screws.

You can start the work. Make sure that you do not interfere with foreign objects. It is desirable that the countertop is not fixed to the frame. If the table is already assembled. no problem, you can also saw the hole out. Carefully make the marking. Let’s look at how this is done for a rectangular sink:

- Use a pencil to draw two lines perpendicular to each other. In the place of their intersection there will be a drainage hole.

- Turn the sink over, place it on the countertop and draw its contour. Do not forget to take into account the level of the edge of the sink in relation to the table door.

- We measure the width of the sink rim and draw the inner contour. The cutting will be carried out by this scythe line.

- Once again, double-check all parameters and start cutting.

Cut the hole with an electric jigsaw. In order to insert the saw, you must drill technological holes in the worktop. It’s usually done with a drill in the corners of the contour. All drilling work must be carried out on the face of the worktop. This will allow you to do the work without any kind of chipping of the laminated areas of the table. Now you can take the jigsaw and cut the hole along the inner contour. After that you should preliminarily try on your sink to the obtained hole.

Now the edges of the hole must be deburred. This is to ensure that the rough edges do not interfere with the performance of quality sealing joints. Use sandpaper with fine grit size for this work. After scraping perform sealing. There are two ways to do this:

The first method is good, but it should be done with great care so as not to miss areas of the tabletop. It is best if you do not spare the sealant and apply it with a decent margin. The second way is more difficult. PVA glue must dry for almost an hour. But it reliably protects against the penetration of moisture.

Use the inner diameter of the template

A filler can be used instead of sealant

Fitting under the worktop

This method implies that the countertop will be higher than the edges of the sink. The mounting method is used for furniture made of expensive materials. This allows you to achieve an attractive, refined and austere look.

To perform such installation, you need to buy a special sink, designed for under table installation. The wash basin can be mounted to screws or brackets.

For the more expensive products, special self-tapping screws are included.

To saw a hole in the countertop usually a special tool is used, but you can also use an ordinary jigsaw with diamond blades. The edges are necessarily sanded and impregnated with moisture-repellent agents or covered with a special film.

It is quite difficult to install a pedestal sink without the skills to perform such work. It is desirable to call a professional.

When installing it is necessary to take into account the following:

- You must buy an undermount sink and the tools to install it.

- If you make a mistake when cutting the hole, the countertop is likely to be ruined. After that, you will only be able to install an overhead sink.

The easiest way to install such a model implies that the hole will be cut from the inside. The main thing is not to make a mistake in measurements. The sides of the kitchen sink must be exactly in the hole. It is unacceptable that they protrude or recede.

How to cut a hole for the sink in the countertop yourself

The furniture industry offers a wide range of products to choose from, including kitchen sets. Their variety is impressive and you can choose any, based on preferences and financial capabilities. But in most cases, the sink is sold separately and installed by the purchaser himself. Therefore, it is necessary to know certain rules and tricks for carrying out such a procedure, as well as to have a certain set of tools.

How to quickly and accurately cut a hole under the sink

We should immediately note that with a household tool, you can cut a hole only in a tabletop of chipboard or solid wood, regardless of the type of coating. Stronger materials, such as silicon agglomerate, require special cutting tools and attachments.

First you need to drill a few holes in the countertop with a diameter of 1012 mm at the mowing line of the marking, but without crossing it. Usually 4 holes are drilled at diametrically opposite points of the contour or at the corners of the rectangle. Drilling must always begin on the front side so as not to tear out a large section when the drill comes out.

To cut the hole for the sink, you will need an electric jigsaw, which has a saw with a width of at least 8 mm and a tooth length of about 1.42 mm. The direction of the tooth is better to choose the opposite, so that when sawing does not form chips on the face surface. Although the edge of the sink covers a band 1220 mm from the edge, some coatings on worktops behave unpredictably and give quite a long crack.

First, the hole is cut on two opposite sides, then a small slat of particle board or wood is laid across the cutting lines. It is drawn with self-tapping screws to the part of the tabletop to be sawed out and keeps it from falling over when the cut is complete. After installing the bar, it is necessary to complete the cutting of the fragment and remove it. Open cut, all chips and unprotected edges generously treated with transparent silicone, leaving a layer of not less than 0.5 mm, and let it dry.

How to Cut a Wood Counter for a Top Mounted Sink

The router

The router allows you to get the cleanest edge of the workpiece, and the quality will not be so easy to distinguish from the formatting machine, and sometimes it will be even better.

To begin with, you need to saw the workpiece with a jigsaw, making an indentation of 2-3 mm from the marking line, and then make the alignment of the mowing line on the template. Usually a second piece of laminated chipboard is used for this, which is sawn on the formatter, so that it is the right size.

It is necessary to use a copying cutter, that is, one that has a bearing. You can get a very clean cut this way. Among the disadvantages of working with a milling machine is a lot of fuss, as there is a need for accurate marking, pre-sawing workpieces and in the alignment of templates for the milling machine.

To make the right choice, you need to have information, which countertops for the kitchen produce. There are a lot of options: for every taste and wallet. There are just functional, but there are also those that become a decoration of the kitchen. The main criteria for selection are:

- aesthetic and appearance;

- Waterproof and moisture resistance;

- resistance to mechanical damage;

- compliance with the requirements of hygiene;

- environmental friendliness;

- durability of coating;

- resistance to external factors.

The main and most common materials for countertops are:

| Material name | Pros | Minuses |

| Plastic | Reasonable price, resistance to temperature fluctuations, easy care, variety of types | Looks cheap, if moisture penetrates it, it stratifies or swells, toxicity is possible |

| Wood | Good appearance; ecological cleanliness; possibility to give the tabletop any shape; easy to renovate | High cost, the need for careful attitude, periodic restoration of the original appearance |

| Tile | Budget option, good appearance, temperature resistance, long service life, easy care, environmentally friendly | It is difficult to take care of the seams, it is afraid of heavy objects |

| Quartz | easy to care for, not afraid of mechanical damage, resistance to temperature changes, hygienic and environmentally friendly, the use of abrasive and detergents for its cleaning, design appeal | Difficult to install |

| Granite | Beauty, resistance to high temperatures, not afraid of mechanical damage | Imperfect moisture resistance, so there is a need to treat with water repellents, high weight, difficulty in transportation and installation, high cost |

| Marble | Hypoallergenic, unique, durable | High cost, immunity to temperature changes, ability to absorb liquid compositions (tea, coffee, juices, etc.).д.), which subsequently leaves stains on the surface, afraid of acidic environment |

| Glass | Does not fear the temperature differences, no need for special care, hygienic, variety of colors and textures | Expensive, afraid of mechanical damage |

| Concrete | Uniqueness, durability, strength, the possibility of creating a variety of forms and configurations, a variety of colors, | Requires regular maintenance and restoration |

| Fibreboard | Low cost, variety of colors and patterns, can be exclusive | Afraid of temperature drops and mechanical effects, the presence of moisture can serve bloat at the joints |

| Particle board | Not expensive, hygienic, easy to clean | The joints are subject to swelling with excessive moisture, can pose a threat to human health |

| Stainless steel | Sturdy, hygienic, restorable, resistant to moisture, long life, resistant to temperature changes, looks great in a modern design, matt or glossy surface, the presence of textured decoration | Considerable cost |