Throw away the template from the package, let amateurs use it. Now you will learn how to mark the countertop by the experts in their business. You should consider a few important points:

Then we turn our basin and lay it on the countertop, taking into account the above nuances. Be sure to invite the hostess, show her the limits of maneuvering and ask her to make the final choice.

Otherwise, if she doesn’t like the position of the sink, you’ll have to buy a new countertop. When all wishes of a female half are taken into account, outline dimensions of a sink with a pencil or a thin marker, depending on the color of a tabletop.

Within walking distance of you, there is a service for the calculation of cabinet furniture.

Insetting the sink

We need to get the jigsaw into this circle, to do this we choose from our arsenal a drill bit with a maximum diameter. And make a hole, indenting inside the circle from the line, at least 16 mm.Read on and you will understand why.

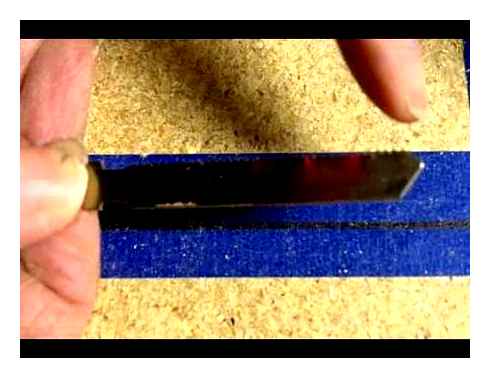

Lead the scribing line not along the jigsaw blade, but along the inner edge of the jigsaw blade. The distance from the saw blade to the edge of the inner sole of the jigsaw is equal to the distance from the edge of the sink to the lock of the sink. Т. е. This is the necessary rim that holds the sink.

By the way, so that the table top will not fall on your feet, it is necessary to screw any length of black self-tapping screws into the kerf. At least three diagonal points. And then you don’t need a third hand and your feet are safe.

To protect against moisture

Having previously checked the cutout for unobstructed entry of the sink and degreased with acetone. apply silicone. Protecting your finger with a glove, we carefully rub silicone into the edge of the sink, without sparing it at that.Along the edge of the file we make a silicone ring to prevent the penetration of moisture.

In walking distance from you, there is a service for the calculation of cabinet furniture.

The assembly of the sink in the kitchen can be made by invoice or sink-in installation method. Giving preference to the first option, in addition to the bowl for washing dishes, you can additionally buy a pedestal or a pedestal, on which it is installed. The sink is placed directly in the kitchen unit countertop. The second method is preferred much more often, even though it is much more difficult to implement, but against the background of the many advantages this disadvantage becomes less significant.

In the first place, overhead sinks is the cause of the constant presence of moisture in the room, which is formed between the cabinets that are located near the unit with it. One of the main positive aspects of inset products is the greater variety of products, from which it is much easier to choose a sink, taking into account all personal preferences and needs. They are made of more different materials and some of them have shapes in which overhead sinks are not made. Inset kitchen sinks come in ceramic, stone, copper, plastic, stoneware, bronze and stainless steel. On the outside, they can have round, rectangular, corner and one of many asymmetric shapes.

The sink can be mounted in three ways: exactly at the level of the countertop, slightly below or above it. It depends not only on personal preferences, but also on the configuration of the purchased set, due to which during its purchase, you should learn how the bowl should be placed and what fasteners should be used during installation. The choice of fasteners also requires special attention, since the strength level of these components directly affects the period of their operation.

The nuances of installation of overhead sinks

The method of how to install the sink of the overhead type in the countertop has a number of features. Mounting is carried out on a separate module so that it overlaps the entire upper part of it.

This work is characterized by simplicity, because L-shaped elements with an oblique slit are used for fixing. A minimum of 4. 5 fasteners. Before you put the sink in the countertop, you need to connect the faucet, which allows later not to have difficulties with installation.

Overhead sinks are fixed in this sequence:

- Apply the fasteners to the inside of the kitchen cabinet and mark them accordingly.

- Screw the 15-millimeter self-tapping screws in the planned locations so that they are at least 5 millimeters above the marks.

- The end of the cabinet is treated with sealant to both protect the furniture and increase the reliability of attachment of the sink.

- The design is placed on the screwed-in self-tapping screws and moved until the maximum fit.

- Next, fix the fasteners and remove excess sealant, after which the sink is connected to the water supply and drainage system.

Choosing a place

Before sawing the countertop, it is necessary to determine where exactly the sink will be installed. It should not protrude beyond the inner fishing line of the box, otherwise the sides will have to be cut. Arrange the design should be so that you can easily access it, while leaving room to install accessories, detergents and other things. Popular options for location:

Depending on the design features, the instructions on how to cut the sink in the countertop may differ in the number of procedures and their sequence. Nevertheless, in general, the algorithm of actions is about the same.

Inserting the sink into the worktop: 5 basic steps

To make it easier to cut in the sink, the manufacturers supply the product with a template for sawing a hole. It is already exactly matched in size, with the location of the hole for the bowl and the recess area (if necessary) for the shelf connected to it marked on it. The template is located on a box or other element of the package. If it does not exist, the marking will have to be done manually.

All work is divided into 5 main steps for convenience. Each of them must be performed in accordance with the instructions and as carefully as possible. The installation of a ceramic sink is carried out according to the same principles as those indicated for a metal sink.

1: perform the marking

Work with the template is simple: it is cut to the contour and circled on the front side of the countertop. If the manufacturer has not taken care of the customer, then proceed as follows:

- The sink is released from the packaging;

- Lay upside down on the chosen place for installation or a large sheet of paper, cardboard;

- Aligning, outline the contour of the outer edges;

- measure the distance from the edge of the board to the wall of the bowl (if the shape is complex, in the key points on the corners and bends to measure in small increments);

- transfer the results obtained to the drawing.

When marking, it is more convenient to use a piece of cardboard: after transferring dimensions and cutting out a template, it can be fitted to the sanitary product, and then already outline on the countertop.

2: work with the hole

To install the sink in the countertop, you will have to cut a hole in it, into which the bottom of the sink will pass. The more accurate the drawing, the less work you will have to do to finish the edges.

Saw the seating for the bowl can be made using the following procedure:

- After marking, drill a through hole in the worktop on a scythe line for the bowl contour. The size of the drill must be larger than the width of the jigsaw blade (not less than 1 cm). To make the edge of the recess even, the hole is drilled inside the contour, slightly touching the mowing line. If there is no large drill bit, use a smaller diameter, but place several holes next to each other, gradually combining them. On the square recess for the sink, make holes in all corners.

- Insert an electric jigsaw saw into the drilled hole and cut the countertop for the sink. This often results in chipping on the laminated or stone surface. To avoid their appearance, a construction adhesive tape is glued to the table top. If the fishing line becomes little visible, mark it directly on the tape.

- To prevent the fragment from falling out during the completion of the work, it is propped in advance or secured with clamps. If you have an assistant, you can ask him to hold the part to be removed so it does not break the laminate coating. Carefully remove the cut piece.

- Clean the cuts from sawdust and dust.

3: Finish the cut

To protect the wooden countertop from penetration and exposure to moisture, the unprotected cut should be treated with moisture-proof substances. It is best to use silicone-based sealants: they will securely seal the wood or the porous layer of particle board and prevent rotting and swelling Fiberboard around the embedded sink. The cutting process is not as critical for laminated stone, as with resin. к. stone worktops are not affected by moisture.

Before machining, the edge of the cutout must be cleaned of dust, the edges cleaned with emery paper and any burrs removed. After that, a thick layer of any sealant is applied to the cut (the cut will still be hidden under the sink). On laminated countertops it is desirable to cover with paste not only the surface of the cut contour, but also the edges at the transition from the vertical part of the board to the horizontals: in the coating when sawing may be formed microcracks into which the moisture will penetrate. After treatment, the edge should be flat and completely covered with a waterproof layer.

4: Preparing the sink

Inserting the sink begins with the installation of the gasket along the contour of the sanitary product. The rubber part is included in the package. Before installation, it must be treated with any degreasing agent (gasoline, white spirit, etc.).). Then adhesive or silicone sealant is applied to the tape, without making gaps on its entire contour.

Press the prepared sealant with an adhesive layer to the underside of the inset sink rims and fix it until the glue dries. A number of manufacturers produce seals with an adhesive layer. Remove the protective tape from them and glue the rubber band to its original position.

When the sanitary ware is ready, you can immediately install the siphon and supply line on it. After installing the sink in the countertop, these operations will be difficult.

5: Fixing the sink to the countertop

Attach the holders supplied in the set to the positions provided for this purpose on the sides of the basin. They are not tightened all the way, to be able to adjust the position of the bowl when attaching the sink to the countertop.

Fill the gap between the rubber seal and the edge of the product with transparent sealant. Insert and fix the sink by tightening the fasteners, starting from the far side where the faucet is installed. During fixing, some of the sealant may squeeze out, the leakage immediately remove with a rag.

Connect the sink to the utilities, check the functionality and the absence of leaks. Eliminate any detected defects.

How to cut a hole for the sink in the countertop

Before you start carving, you need to choose the right place in the tabletop. It is selected, taking into account the distance for water drainage through the sewer pipe and the location of water connection.

The most simple tool is needed to make the hole correctly.

It is better to cut at some distance from the location of the refrigerator and stove, since the sink will work with water. It can have a negative effect on the appliances. It should sort of divide the kitchen into several zones.

The question of how to cut the countertop under the sink is not very complicated.

If you place the sink below the countertop, that is, slightly lower it, it will look very nice and interesting. To do this, the hole is cut a little larger than the size of the structure to be installed. But you will have to use additional tools for such a peculiar installation. This can be special mounts from below under the countertop.

Such an arrangement looks very spectacular, but in addition will require the use of special tools.

Location at the same level as the surface. the standard option. The difficulty lies in the fact that you need to cut a correct recess, which will clearly coincide with the size of the sink. The thickness of the edge must be “right in line” with the hole in the countertop.

In this position it is very important to make the right recess, equal to the thickness of the edge.

Another non-standard way to cut a hole for the sink is when it is located slightly above the level of the countertop. The hole is simply cut out to half the size of the sink. This is the simplest option, which does not require much effort or ability.

Drawing

To make a marking, a template is made of paper, which will fit the size and shape of the sink. To do this, the measurements are taken and transferred to paper.

The next step is a simple work step with the template in place. It is carefully cut along the contour. The main thing is not to exceed it, otherwise you will have to make another template. Then it is attached to the surface of the countertop and outlined on the front side.

From the obtained contour it is necessary to step back 10-12 mm and draw a contour of a smaller diameter.

If the sink is non-standard shape, you can use another scheme, how to cut a countertop for a round sink in the drawing stage. This is done in the following way:

- The structure is freed from the film packaging.

- The sink must be placed with the bottom upward on a material that will serve as a template.

Important! The material must be hard and large, so that it is convenient to cut and later use it.

Turn the sink over and trace its contour with a simple pencil.

Necessary tools and materials

In the process of work you will need quite a few tools and devices. It is important to prepare everything beforehand, in order not to distract from the work and to do it qualitatively. List of materials and tools that will be needed in the process of cutting out a place for the sink and its installation:

- Jigsaw.

- Drill with various attachments.

- One elbow.

- A quality ruler.

- A simple pencil.

- Furniture corner.

- Fastening system for sinks (you don’t need to buy it if it comes with the sink).

- Transparent silicone sealant.

- Sealer for sinks.

- If necessary, materials and parts that are not included in the sink set can be purchased.

- Siphon.

- Connecting pipe for the sewer.

- Various fittings (mixer and diverter).

Cut the hole

Work on cutting the hole for the sink is carried out with extreme care. The bottom of the basin will be inserted into this hole later on. The quality of the work done will depend on the diagram correctly constructed. If initially the stage was performed according to all the rules, then there should be no problems. The process will go smoothly, and the result will please you.

On this contour we will make the cut.

You can cut a hole in the countertop for the sink according to the following plan of action:

- According to the marking, one through hole is drilled in the surface of the countertop. It must be placed directly on the contour line of the bowl. A drill for this take no less than 1 centimeter. In the hole that has just been drilled is inserted saw jigsaw and only after that you can go over the entire contour, accurately cutting it out.

- To get an even cut of the edge of the notch it is carried out closer to the inner side of the contour. It is important not to practically touch the mowing line, and walk next to it, but without a strong indentation. If the sink will be square, it is necessary to make holes in the corners of the drawing beforehand. It’s much more comfortable to cut. You can glue the tabletop with construction adhesive tape to prevent it from chipping. If the fishing line is no longer visible, then it is drawn directly on the scotch.

- As the material will fall off while you saw it, it is better to prop it up with something. This will secure the process, and make the cut much neater. If you work alone, you can ask your partner to hold the tabletop while you cut. Afterwards, the cut part is removed with a slight movement. Everything is cleaned of any dust that may have formed.

We work the ends with emery paper.

Important! Cutting the hole is the most responsible moment. The operation of the sink will depend on it in the future.

sink installation

Check everything for quality and alignment before installation. If there are any irregularities in the cut, they are immediately eliminated. Once again you try everything on and check its strength. After that, the installation of the sinker takes place. It is carried out with the help of liquid silicone.

On the back side of the sink we apply the sealant and glue on the sealing strip which is included in the set.

It is necessary to step back a few millimeters from the edge of the hole with a scythe line and start applying silicone. It is made in the form of a flagellum, the thickness of silicone should be a little higher than the sink rim. After that step back from the first blotting for another 1 centimeter. The action repeats in the same way.

Insert the sink into the countertop and seal it.

Within half an hour, the silicone has to harden a little. You can check this carefully with your hands. It must not stick. Then you can try the sink on. It’s inserted into the hole and pressed tightly to the edges. The silicone strips should take its shape and bond a little. In this position the construction is left for 10-15 minutes.

How To Cut a Hole For A Sink In A Laminate Countertop

After the sink is dismantled to check the silicone for stability. It must remain intact and not violate the shape. If so, it’s time to proceed to the next no less responsible step.

After installation, tighten the fasteners. It is necessary to tighten the bolts diagonally.

How to independently install the sink

Everyone will be able to install the sink themselves. It is very easy to do this if you prepare in advance and study the instructions. Installation begins with the preparation of the plan and markings. Then the work of cutting out the main hole and mounting the construction. During the work it is important to observe safety precautions, because the work will be carried out with sharp tools.

How to properly embed the sink in the countertop with your own hands: step by step with photos

Hello, dear friends! Today we will talk to you about how to embed the sink in the countertop, what you need to work at home and how to implement the idea with your own hands.

We do sinks in the kitchen, but in the bathroom we may need to mount a sink. In this case, there is no fundamental difference in exactly where this action takes place.

But there is a difference in whether you cut in a round, oval or rectangular sink, and it also matters the material of manufacture of the countertop and the element to be cut in itself. In particular in kitchens and bathrooms can be used stone and metal worktop, ceramic and is made of fiberboard, there are products of artificial stone. I think I do not need to remind you that in the kitchen and in the bathroom you need a moisture-resistant countertop. Especially under the sink. I will try to touch upon all of these points to one extent or another today.

If you will have something to complement, or have any questions, leave your Комментарии и мнения владельцев and feedback.

How I sawed my kitchen countertop. The first experience of installing a countertop

It all started when we waited for the keys to our apartment and moved in. We took the kitchen with us because.к. the kitchen has moved with us for the 3rd time, and the kitchen is not expensive enough, this is clearly her last move. In past apartments, the kitchen layout was different and every time a new countertop, but there hired a wizard, here I decided to find out where my hands grow out and do everything myself.

I bought two boards countertop 3-pack of laminate (on the apron), sealant 3 and a tube of glue, edging (soft strip for the cut corner and for the end and the junction. hard), skirting boards for countertops. For all it took about 14 000.The first thing I did was when ordering asked to cut off at 210 cm (t.к. Elevator it would not fit, and to drag it all to the 12th floor is not very much wanted), both sides I got 190, but I decided to leave the reserve.

measured wood joint (measured it is so, because the angle of the wall is not flat, and the kitchen itself is at right angles, and otherwise would be on the left (the refrigerator would not be bad gap)

05 it is necessary to saw with an electric jigsaw from the “rough side” and to wrap the sawing place with masking tape from the “white side” in order to minimize chipping of the lamination

06 stock up on blades, I had for all this work took a pack and a half (9 blades), the smaller the teeth, the less likely chipping lamination

Next time take the normal Bosch saws for laminated materials such as Bosch Special for Laminate T 101 BIF will save both saws and nerves.

This is only for thin materials, 38 countertop does not take well, you need more tooth and it must be inclined. The saw blade is naturally from a normal manufacturer so it does not break like the one I have, and let the saw cool down, t.к. heats up too much.

Regarding silicone, forget about this material as an adhesive and sealing joints in wet areas, t.к. it rots over time. Use Ms-polymer, it is not much more expensive than sealant, it can be used as glue.

07 countertops are fitted, I’ll tell you right away that I attached them to the kitchen at the very end, t.к. had to move them all the time to work

08 all the cuts were thickly smeared with silicone

09 further marked the place of saws under the hob, drilled the corners (do not put pressure on the drill, otherwise it will splinter off a lot of excess) to turn the jigsaw and it is important to saw that saw last, which is closer to the larger area of the countertop leaf, otherwise the thin edges can not withstand the weight and break.

10 the edge fits well and relatively even, all smeared with silicone

12 thought the hardest part. Saw holes for the sink and hob, but no, the hardest part was ahead

16 and here is the most interesting, unfortunately the process of gluing the edges did not make, but there is simply put the iron on medium heat (synthetics), put on a glove (the side where there is no rubber pads) warm the edge and smooth the hand in the glove. I spent almost all of my edging on this process, t.к. at processing the corners (removing the excess) got splinters.

I used a file to remove the surplus, holding it nearly parallel to the table top, with its sharp side, you cut off the surplus sharply at an acute angle. then the processing of the corners of the edges with the same. Edge rounding on a micron (almost) is cut off with a mounting knife (it is very important that the blade was new) on this I screwed up and then the penultimate strip.

22 wax chalk for laminate, a few times smear the corners and wipe with the same glove

23 laminate on the apron in the case, start from the corner and it is important to understand that unlike the floor, it is mounted on the adhesive and the seams are blotted silicone

24 solves the problem of bouncing the end joints on the glued laminate with a cut “lock”, t.к. The problem of bouncing the butt joints of glued laminate with a “lock” cut is solved, since no one will walk on it anyway, but it is practically impossible to bounce the glued laminate flooring on two boards

25 total. On the edge of the laminate will be put a decorative corner (not yet bought) All

З.Ы.I had to deal with the same kitchen. Feet. Shit Careful when repositioning Very brittle plastic, the legs break off easily and effortlessly.

| Quote (Califusa @ 31.08.2015. 13:29) |

| Plus for the effort. |

so i’m not arguing, the jigsaw is fine, but the saws may well be shit, but that’s what it was. But for me the milling machine for one-time work the toad has forbidden to buy

I haven’t seen an aluminum bend profile anywhere. And in general, yes, this is my first experience and a lot I just did not know.

It’s L-shaped as it can be bent without consequences, so it did not go in waves?

The first time I see that the edge file handled, usually a sharp knife, then if necessary to load a fine sandpaper on a bar.Laminate on the work surface, isn’t it afraid of moisture?

IMHO the countertop for such a color should be lighterA for the kitchen greenZ.Ы.This is my

color deliberately chose, t.к. it’s fully compatible with the “angle”

skirting board is attached on the principle of the plastic box, you can base and glue and self-tapping

Half induction, half not, we’ve had it for two years and nothing has happened, it works fine

It’s just such a fan, until the condo is not put such a thing) Comfortable in terms of space does not take almost.

I bookmarked it. green for the instructions.

I always saw them with a regular circular saw. the sink closes the edges and the accuracy of the cut is the same. Well, and sometimes with a jigsaw, too, when you need rounding. With that BOSHEVA saw you wrote about above.

| Quote |

| Dak as far as I remember in the instructions to the laminate flooring is written to wash only a damp rag wipe |

I’d hesitate to use cheap laminate on the apron. There is a normal one, you can even pour water on it and nothing will happen to it

Always something fun to write, I look sometimes, like)

Listen, bro, for the fact that he did himself unequivocally good job, I always respect those people who do themselves and well. But to saw the countertop from the back side, and even a jigsaw with 9 saws? This is some kind of opening. First, there are saws for clean sawing of chipboard (somewhere have posted the photo above), they do not need 9 you enough one for a month of slow work. Secondly, it is necessary to saw from the front side, the edge that is adjacent to the bearing surface of the jigsaw turns out exactly straight with good accuracy, the bottom edge will have deviations from the straight plane in both directions, the dumber saw and the higher the feed rate, the more crooked the edge will be, the saw will always bend in the direction of the sharpest teeth.For cutting straight edges it’s best to use a circular saw. The edges will be perfect. The jigsaw I generally use only where the surface is crooked or where there is no difference in accuracy. But only a circular saw and a router.

And laminate on the apron is fine.Panel. Skynalli seems to have invented a name for it, in essence and technology the same laminar.