How to cut a round hole in tile with an angle grinder

Making a round hole in the tile with an angle grinder doesn’t seem like a good choice. There are more convenient tools for this.

But there are times when it is only possible with an angle grinder. For example, when:

- You also need a Raimondi machine for these cutters. If you use an angle grinder for this purpose, the bearing on it will not live long. Polish tile and brick cutters used for this purpose have a maximum diameter of 83 mm.

- Polish cutters When you want to make a hole in porcelain tile or floor tile. With a chisel or ballerina, making a hole will be a problem for any diameter.

In such cases, may be useful little-known way to cut large round holes with angle grinder. Such holes need to be cut for sewer pipes and fans in the sanitary unit.

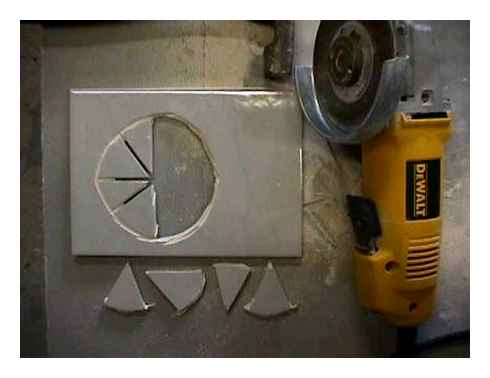

Its essence can only be understood by watching the video. The first step is to mark out the hole (how to make precise markings is a topic for a separate discussion) and the oval drawn with a felt-tip pen. The flomaster gives a thick line and it helps to hold the line as it is machined.

It is important, when cutting an oval, to get as close as possible to the markings with the cutting wheel, but not to touch the scythe line.

Once the through cuts appear on the tile, you need to cut the inner circle into four pieces and hammer out each sector (if they don’t fall out on their own before then).

In the future, bring the cut hole to the mowing line of the felt-tip, you can use a turbine and a narrow piece of sharpening stone on the back side.

I agree that the most handy tool for creating holes is a professional cutter. One of the options for such a Montolit Mondrillo FS08 cutter in the video.

And another video about these cutters from the manufacturer of this tool.

The only thing that stops them is the price:

A selection of videos from Western You Tube. How they cut similar holes in tile and marble with an angle grinder:

Subscribe to updates of this and other playlists, as well as new videos on the channel:

Add comment Cancel reply

This site uses Akismet to fight spam. Find out how your comment data is handled.

Drilling the hole

Consider another way to make a hole in a ceramic tile. The situation is more complicated if the tile is already laid at the time of processing. In that case, you need to use the traditional way and drill the hole with a drill. To work with this type of cladding material, you can use special drill bits of cone shape or the usual spiral.

Cone holes for utilities

How to make a hole with a simple drill bit:

- Since the ceramic tile surface is quite slippery and it is very difficult to hold a drill on it in one position, cover the area to be worked with masking tape. It will protect the tile from scratches, prevent chipping and slipping of the drill bit;

- Mark the point for drilling the hole;

- Slowly start drilling;

- To avoid overheating the drill bit, periodically moisten it with water. You can also spray the tile itself, but only after you go deep enough so that the tool does not slip.

If you want to make a bigger hole, this is what you can do: Start drilling in the same way as above, then change to a bigger one. Increase the diameter of the hole gradually, so you minimize the risk of splintering.

Another way: Drill a few holes along the inner contour of the future hole with a thin drill bit. Then gently tap out the center and sand the serrations along the edge.

Since wall tiles are very soft, you can drill them without a drill bit by screwing in self-tapping screws with an LM tip. On average, 2 to 3 self-tapping screws are needed per hole. Diamond tile crowns. Allow you to make holes of large and small diameters for outlets or pipes, installing a toilet.

For drilling tiles, special diamond drill bits are used, but if, except for the installation of the floor toilet, nothing else is expected, then for the sake of two holes it is not worth spending on an expensive part. It can also be done with a regular drill bit for stone with a pobedite bit.

How to cut a hole in the tile for the socket without a drill bit of the required diameter?

This question often worries people who, due to the infrequent use of tools, prefer to keep at home only a minimal set of equipment. Why buy an expensive core drill bit if you only need to make one cutout?? Usually in such cases, the usual relatively thin drill bit drilled a number of holes on the contour and then, taking advantage of the fragility of the tiles, knock out a fragment inside the “outlined” thus the contour.

This option is also suitable for complex curved shapes in the absence of a small disc angle grinder.

The photo above shows how to make a hole in tile for a three or four socket outlet.

Each round cutout is drilled separately with a diamond or pobedite drill bit, and then the areas between the round holes are cut out with an angle grinder with a small-diameter disc.

How and what to drill ceramic tiles and porcelain tiles?

In this article you will learn how to properly drill a tile wall, what drill bits to use for small and large holes. We’ll tell you a few simple ways to protect tiles from chips and cracks. You will learn how to use painter’s tape for more precise drilling and what a tile ballerina is.

Ceramic tile is a hard and brittle material that is difficult to drill but easy to crack. One mistake or awkward movement can lead to its damage, and you will already have to read another instruction on how to replace a cracked tile. So before you start drilling, make sure you know how to drill into the tile. Fortunately, we have many tips to help you do everything neatly and accurately.

How to drill holes in tiles for dowels?

Depending on the required size, it is recommended to drill the holes with different tools. In some cases you will have to use a drill bit, while in other cases a drill bit of 8-16 mm is sufficient. But there may also be a situation where it will be difficult to do without an angle grinder.

To drill through the tile for dowels, you need a tile drill bit 1-2 mm larger than the plastic insertion for the screw. With it you first have to carefully drill through the glaze layer without excessive pressure. And then slowly pass all the remaining ceramic to the wall.

Directly the wall surface, especially if it is concrete, should be drilled with another drill a little smaller. It is not worth wasting specialized and expensive tools, designed for tiles, and it’s simply pointless.

What drill bits to use for different surfaces

Tools for work

To properly make a hole in a wall without deforming it, you need to choose the right tools. You must have the right tools at hand:

If you need to make a hole in the tile on the wall of large diameter, often a drill-ballerina is used.

Also use round drills with cutters, which with the help of a hexagon set at an equal distance from the center. Cutters, on the other hand, move at different distances, so you can easily make a hole of the right size. Mark the required parameters and, firmly holding the tile, drill at low speeds. The price for such a tool is not high, you can buy it at any construction store.

Important! It is necessary to work with a ballerina drill at low speed, holding the tile tightly, so that possible splinters from under the drill do not hurt you. At the moment of drilling, try not to jerk the working tool, you can use a special tripod to reinforce the position.

- with the electric jigsaw. it is necessary to have a special tooling. a saw with a dusting of diamond crumbs, the tool is placed only on the face surface, along the mowing line of the cut the required piece is glued by the masking tape, which prevents damage to the glaze from crumbs penetrating under the sole of the electric tool;

- angle grinder. a diamond disc is installed in the angle grinder, the remaining half of the tile is sacrificed by making parallel cuts on it from the edge to the mowing line in 1-2 cm, then the same tool trims and falls off the pieces, but already along the mowing line of the cut;

- pliers or pliers. the method is very long, small pieces are bitten off the tile, then the cutting line is ground with an abrasive wheel or bar.

- Angle grinder. the tile must be firmly fixed in a vice or clamps through gaskets to the surface of a table or stool, the underside is ground at an angle of 45-60 °;

- with an abrasive disc or stone. it takes much longer to sharpen, but the chance of chipping the enamel is next to nil.

Note: If a peorized polymer corner is used, the productivity of the finish is markedly increased. Porcelain stoneware with a defective edge can be hidden underneath its strip.

How to Cut a Round Hole in Tile for Pipes and Shower Heads

The basic principles of ceramic tile drilling

In the practice of ceramic tile drilling, there are general principles of operation:

- Drilling must be carried out with a sharply sharpened drill bit. If it is not properly sharpened, no tricks with a tool, masking tape, shearing off the glaze will not help. A dull drill bit gets hot faster in the process, starts to fail to cope with the material. If it is not sharpened in time, overheating will only increase, which in turn will quickly lead to complete wear and tear of the tool. The tool will run slower and harder with each passing second, and it may break the material.

- You should therefore either use a new drill bit or have its sharpening checked and resharpened if necessary. Professional craftsmen usually sharpen their drill bits every day. You need a machine tool and emery wheel for twist drill bits, a diamond wheel and coolant for hammer drill bits.

The harder the material, the lower the speed.

- Before the drilling operation, switch off the impact mode in the drill and set it to the lowest rpm. Drilling itself should be carried out at low speeds, usually from 200 to 800 rpm./minute. The optimum speed is determined by experience and depends on the drill bit type, diameter, thickness and type of material to be drilled.

- Do not apply too much pressure to the drill, but even light pressure can cause slow drilling. The optimum force application to the tool will come with experience.

It makes sense for beginners to try the process on tile scraps to get a feel for the right drill position and the right application of effort during the operation.

- The drill bit and tile should not be allowed to overheat, which can cause damage to the tile. Use water to cool the drilling site. The drill bit is dipped into cold water and then wiped dry. The cooling effect can significantly extend the tool’s service life.

- It is unacceptable to change the direction of rotation of the drill bit during drilling.

- The place of drilling must not be close to the edge of the tile.

- When working with tiles small splinters of material can fly around. Therefore, do not forget about safety precautions: tile drilling work is carried out in safety glasses and gloves.