Working solutions for baguette preparation without miter box

Another option for trimming the plank is to create some kind of structure from thick cardboard and a wooden block. The first step is to bend the cardboard to the angle you measured in the corner of the room. Then, to the wooden block intended for cutting the corner, press the cardboard and draw the line along which you want to cut the block. this will be your template. To cut the fillet, place the wooden template on top of the plank, and cut the required angle along the block.

Current offer in the construction market. Kindecor skirting board made of expanded polystyrene, made by extrusion technology. Therefore, the ceiling slats of the Russian company “Kindecor” do not have the disadvantages of PPU cornices. The cost of cornices is much lower than foam or other analogs.

But in old houses with “floating” corners, such sets are unlikely to come in handy. in the kit you will find only angles at 45 0. 60 0 and 90 0. How to fix the situation? You need to roughly cut the end of the baguette. an angle of approximately 45 0. and then, during several fittings, cut the angle in place to the required value.

When cutting the baguette and shaping the outer corner, use this method:

- Press the plinth to the right side of the corner so that the plank protrudes beyond the corner by at least its own width;

- Use a pencil to mark the line on the ceiling;

- Press the plinth to the left side of the corner so that the plank protrudes beyond the corner by at least its own width;

- With a pencil, mark the line on the ceiling, mark the intersection of these two lines;

- Copy the markings to the plank, connect the dots with a line, cut the baguette along this mowing line;

- Check the evenness of the cuts by applying the prepared baguettes to the outer corner;

- Before gluing the ceiling plinth without a miter box, remove any errors (irregularities, chips, gaps, inconsistencies) on the fillet surfaces.

Cutting and joining techniques for baguettes

In the picture above, you can see the process of cutting off the curtain rod along the slot of the miter box, but how to trim the ceiling plinth without the miter box? We offer you several options with descriptions, as well as making a template for the simplest miter box on your own. Let’s consider all the methods in order:

- Try on the cornice to the ceiling surface, run a marker line along the ceiling surface;

- To the right of the selected corner, press the product against the ceiling, draw another straight line;

- At the intersection of straight lines, mark the plinth itself with a dot, then draw the line from the markings on the baguette to its lower corner. Along it you will cut off the required corner on the fillet;

- The left corner is marked in the same way;

- After cutting both skirting boards, press them into a corner and check for precision. If there are gaps, trim the corners again. Remember. so that the bar does not become shorter than the required length, do not shorten the unmarked part of it until you achieve an exact connection;

- After adjustment, the fillet is glued or screwed on. The ceiling plinth for stretch ceilings cannot be attached to the surface of the ceiling material. it is glued only to the plane of the wall.

Attention: Do not press with great force on the foam or expanded polystyrene cornice when cutting it. it may lose its shape, and after gluing, dents and other irregularities will be visible.

The method is as follows: how to cut a ceiling plinth without a miter box along the outer corner of the ceiling:

- Press the plinth to the right of the corner and draw a line 200-300 mm long with a pencil or marker along the ceiling;

- Press the cornice to the left corner, mark up to the first mowing line so that the markers intersect;

- On the plank, mark the points at the crossroads of the markers and in the corner of the room;

- Connect the marked points on the cornice, cut the plinth along the markings with an angle of inclination towards the inside of the plank;

- Check the accuracy of the joint in place, trim again if necessary.

Classic baguettes are made of wood, but it is difficult to fit them exactly without the use of a factory miter box and appropriate cutting tools. Wooden baguettes are formed with a cross-cut saw, and in its absence. with a carpenter’s hacksaw with a fine tooth, an electric jigsaw or a hacksaw for cutting metal.

Important: A cornice made of polyurethane or aluminum is considered reliable in terms of moisture resistance. But the polyurethane cornice should not be exposed to temperature changes, so it is not recommended to install them in the kitchen or bathroom.

Whatever the plinth, if the angle in the room is not 90 0, then it will be difficult to make an exact cut for joining the planks. In old buildings (stalinka, Khrushchev, and even brezhnevka), the angle in the room can be formed as 88 0 or 93 0 (for a piermer), and it is problematic to cut off such an end according to a template. Then how to properly cut the corner of the skirting board without a miter box, avoiding large discrepancies and without using a complex and expensive tool? Use the presented method.

The figure shows cornices made of materials such as:

- Polyurethane (PPU);

- Polyfoam (PP);

- Polyvinyl chloride (PVC);

- Wood.

To form an exact inner corner from the planks, follow these steps in sequence:

- Try on a baguette to the corner of the room, for example, on the right;

- Draw a fishing line with a pencil along the plinth;

- On the left side, do the same operations with the cornice;

- The point of intersection of the marker lines will be the upper mark, from which it is necessary to cut;

- Place the curtain rod in the corner and transfer the crossing point to the plank;

- Connect the upper and lower marks on the cornice with a pencil;

- Cut the ends according to the markings;

- For the second plank, the points are repeated in the same sequence.

Important: Before gluing the strips, check the accuracy of the cut: attach the curtain rods to the corner, and if there are no gaps between the fillets, attach them. If there are irregularities at the ends of the joining surfaces. trim the skirting boards more precisely.

The following solution is how to cut accurately and how to glue the skirting board without a miter box to the inner corner of the ceiling:

- Find out the fillet width;

- On the bottom, mark a point at the distance of the width of the plank;

- Connect with a diagonal line the point of the upper corner with the point of the lower mowing line, cut the product along this mowing line;

- For the second cornice, all points are repeated in the same sequence.

Docking of ceiling fillets without an industrial miter box

Factory miter box. it is an aluminum, plastic or wooden tray with depressions 45 0 or 90 0. Such a device is rarely used at home, so it is not found in everyone. But few also know how to cut a ceiling plinth without a miter box, so we will consider a few simple solutions that will allow you to dock the ceiling plinths in the corners of the room with great accuracy.

When renovating an apartment, installing a new ceiling is often necessary to create a complete design idea. The completed ceiling is decorated with beautiful fillet skirting boards. The baguettes are glued, nailed or screwed along the perimeter of the room, their position is previously marked in the corners at the joints of the walls and ceiling. Ceiling cornices are often rigid and solid strips (although there are elastic silicone ones), so they need to be beautifully docked in the corners of the room with each other, and without a miter box it is difficult to do this, but it is possible.

Fillets for framing the corners of the ceiling are made of polyvinyl chloride (PVC), expanded polystyrene (PPU), polyurethane (PU), polystyrene (PS), polystyrene (PP), wood or metal:

- Foam decorative cornice is fragile, but this does not matter for unloaded ceiling structures. PP skirting boards can have different widths, the standard length is 1 meter, the surface is bas-relief with various patterns;

- Expanded polystyrene. the material is dense, easy to install, the edges of the cornice do not crumble during cutting;

- Aluminum or wood is the most difficult to dock. you need great accuracy, which is difficult to achieve without the use of a miter box. It is recommended to cut the corners of such cornices with a sheet for metal, to calculate the correct cutting angle, use the methods below.

Polyvinyl chloride is easily crushed, after which it is not restored. Requires caution and minimal pressure when machining

Cut with a carpenter’s cutter or a hacksaw for metal

The foam plank is fragile and crumbles easily. It is recommended to cut the PP plinth with a very sharp cutter or a special tool. an electric nichrome cutter

Cut with a carpenter’s cutter or a hacksaw for metal, hot wire clamped in clamps

It is cut with an ordinary hand or special tool (electric side saw, wood saw with fine teeth, metal blade), the cost of products is higher than PPU, PP OR PVC curtain rods

How to make a miter box template yourself

In the absence of a miter box or unwillingness to buy it, it is not necessary to purchase a special tool in order to use it once or twice in the entire history of repairs. You can make a homemade template with the same capabilities. it doesn’t take much time. As a blank for an impromptu miter box, take a board, thick paper or cardboard, and mark the required cuts on them.

Then draw two parallel mowing lines on the template, find the center in the drawing, and use a school protractor to set any corners. This simple technology gives very accurate results, while you can draw and cut any angle greater or less than 90 0.

The technology for working with a homemade miter box is no different from operations with an industrial product. The baguette should be attached to one of the lines, put the hacksaw at the selected angle, and cut off the workpiece. If you do not plan to spend money on miter box pr

Skirting tools

When installing friezes, you need to prepare the necessary tools to perfectly cut the skirting board and fit the ceiling frieze to the corners of the room. To trim the baguette, a miter box and cutting tools are used: knives (carpentry and ordinary), hacksaws, saws. When handling each of them, it is necessary to take into account the features of the device and the subtleties of application.

The miter box is a device that guides the cutting tool blade with the required inclination. It is specially designed for cutting materials that are then mounted at a specific angle. Structurally, it can be conventional and tilt-rotary, or precision. They are visually different, but the principle of operation is the same.

Different types of miter boxes Plastic miter boxes with clamps

An ordinary miter box is a U-shaped tray made most often of plastic. It also comes in metal or wood. There are slots in its walls for guiding the cutting tool at a given angle to the base. This variety has a template type and cannot be adjusted: the material is cut at standard angles (normal or negative), which are structurally embedded in the grooves. When choosing a miter box, you need to look so that it should be wider than the workpiece for cutting. To fix the material in the device, a clamp or special pins can be used. if the structure has perforations for their installation. Usually, the workpieces in it are simply held by the free hand.

Plain plastic miter box Plain wooden miter box

Swivel, or precision miter box. by adjusting to any angle of inclination, it allows you to cut at an angle and get a simultaneous cut in two planes at once. It is a professional tool that is rarely used under normal conditions.

Swivel miter box with hacksaw Precision (swivel) miter box

Saw. Recommended mainly for hard wood skirting boards. Using the saw on soft materials such as styrofoam and polystyrene is not always a good idea. The cut from the saw turns out to be rough and requires additional grinding with sandpaper or a file.

A hacksaw is a widely used cutting tool for cutting a baguette. It is necessary to carefully approach its choice: the canvas must correspond to the size of the slots of the miter box. be of sufficient thickness and width. When working with a hacksaw, it is necessary to observe the inclination of the tool so as not to damage the miter box and observe the correct direction. At the same time, the saw cut of the part often turns out to be not very smooth and sometimes requires alignment and grinding.

Construction knife. makes it easy to cut soft foam fillet. It is not difficult for them to work, and the cut turns out to be even and smooth. Instead of a construction knife, it is permissible to use an ordinary knife. the main thing is that it is of sufficient sharpness and length.

Cutting tool h2 3.0.0.0.0.-

Materials for ceiling plinths

Ceiling moldings can be of different widths, have a convex pattern on the front side and special recesses for engineering systems on the back side. Fillets are made in specialized production from polystyrene, its varieties. expanded polystyrene, polyurethane and wood.

Polyfoam is the most affordable finishing material. Its positive qualities: light weight, ease of cutting and processing, the possibility of finishing by painting in any color. Negative point. grain size and low strength. even a slight mechanical damage can violate the integrity of the foam surface.

Varieties of foam plinth Foam plinth on the ceiling

Expanded polystyrene is a more durable type of foam. It is also light in weight and in processing, but it has a higher density and a smooth surface, is more resistant to mechanical damage, and lends itself well to staining. These two materials, due to their low weight, have little stress on the load-bearing walls.

Ceiling plinth made of expanded polystyrene Baguette painted to match the wall

Wood is the hardest and most impact-resistant of all fillet materials. Products made from it retain their appearance longer and are able to withstand significant mechanical stress. In the style of some interiors, it is wooden friezes that are most applicable. Wood ennobles the room and fills it with warmth. However, it has a higher price than previous materials.

Как самому поклеить багет (потолочный декоплинтус)

Different types of baguettes made of wood Wooden fillet in the interior

Products made of polystyrene, as well as expanded polystyrene, have an advantage over wood. The softness of the material makes it possible to press the baguette as tightly as possible against the wall, ceiling and each other. therefore, there are no gaps. It is possible to achieve excellent joining of the plinth on not perfectly flat walls if you use not a wide foam or expanded polystyrene fillet.

How to properly cut a corner on a ceiling plinth

Ceiling plinth, also known as fillet, frieze or baguette, is a finishing material that is used at the final stage of renovating a room. At the same time, it not only masks possible irregularities of the upper edge of the wallpaper or peeling of plaster near the ceiling, but also acts as a decorative element, giving completeness and uniqueness to the space.

Ceiling plinth with internal and external corners

Many people install the ceiling frieze in their apartment on their own, without involving masters. This job is not so difficult if you know how to choose the tools and cut the corner correctly on the skirting board. The main thing when working with a ceiling molding:

- take into account the peculiarity of the material from which the fillet is made;

- have the right tools and use them correctly;

- know the intricacies of step-by-step work.

h2 1,0,0,0,0.-

Trim skirting in miter box

The miter box is one of the most important tools when processing a baguette, allowing you to make cuts on the skirting board with the desired slope for an even joint. Consider the features of working with fillets using this device.

To correctly and evenly cut the ceiling plinth using a miter box in the corners, you must follow certain rules.

- Cutting workpieces with a miter box is only suitable for 90 ° right angles.

- When cutting a baguette intended for the ceiling, it is applied and sawn on the inner side of the miter box closest to you.

- The workpiece is installed in such a position as it will be mounted later on the ceiling.

- Cutting is carried out on the front side of the baguette.

- The side that is subsequently glued to the ceiling must press firmly against the bottom of the tray when cutting.

- It is recommended to use a specific cutting tool for each type of material: a hacksaw or knives are good for cutting soft materials such as foam, a saw is preferable for wood.

Ceiling corners can be internal and external, or external, therefore there are differences in the preparation of the baguette, which consist in the methods of joining the planks and different inclination of the cuts. To make it easier to work with the miter box, it is useful to make visual prompts on it in the form of small stickers with inscriptions, as shown below.

Miter box with tips for easier work Angle types

The main attention should be paid to the accuracy of cutting workpieces at the desired angle. It is recommended to start working from the inner corner and then work to the outer corner. Otherwise, it is possible that the length of the baguette will not be enough. Schematically, the cutting steps look like the figures below.

Scheme for trimming adjacent skirting boards for inner corners Scheme for trimming adjacent skirting boards for outer corners h3 1,0,0,0,0.-

Fillet cutting for inner corner

Internal corners are always present in rooms. so you will definitely have to deal with them when installing skirting boards on the ceiling. In this case, when cutting a baguette, we follow the algorithm:

- we measure the required length of the workpiece by attaching it to the ceiling at the place of future installation;

- we place the bar in the miter box along the near wall so that its location coincides with how it will be mounted on the ceiling;

- holding the plinth, we put the cutting tool in the groove with an inclination of 45 ° and cut the workpiece without unnecessary pressure;

- we do the same actions in a mirror image for the second, adjacent bar. For the convenience of cutting, you can turn the miter box with the bar installed in it to the desired hand.

Knowing how to properly cut out the inner corner on the ceiling plinth with a miter box, you can easily arrange more complex ones. outer corners.

Position of the left bar for the inner corner with the direction of pressure when cutting Right bar position for the inner corner with rotation for easy cutting Cutting the left inner bar Cutting the right inner bar h3 2,0,0,0,0.-

Fillet cutting for outer corner

Outside corners in a room are not so common, but they require particularly careful cutting of fillets and precise joining of their sides. Unlike the internal ones, small gaps in the external ones are more noticeable and difficult to hide. You also need to take into account some peculiarities when working with external corners. It’s easy to do, following certain rules:

- parts of the frieze should protrude slightly from the edge of the wall, forming a small margin;

- we measure the bar by attaching it to the ceiling as it will be glued in the future;

- we place the frieze in the miter box, pressing it against the wall closest to you;

- insert a hacksaw or other suitable cutting tool into a groove with an angle of 45 °, and cut off the workpiece without unnecessary pressure;

The location of the left outer strap in the miter box

- we put the adjacent bar to the nearest wall of the miter box and, holding it, insert a hacksaw or other tool into the groove at an angle of 45 °. For the convenience of work, we unfold the miter box with the workpiece “under the arm”;

- we do the same as in the previous case. carefully and evenly cut the fillet.

Position of the right outer plank in the miter box with rotation for easy cutting Cutting the left outer plank Cutting the right outer plank

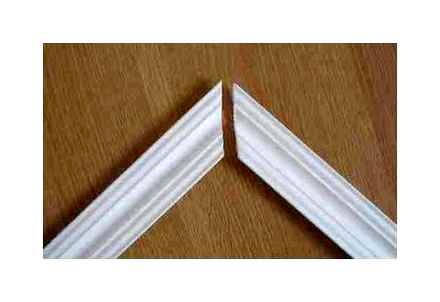

It remains to join the cut baguette strips and check the cutting accuracy. Taking the cut pieces of the baguette in pairs, we join them, forming an inner or outer corner. If the cutting of the planks was carried out accurately and accurately, then the edges of the adjacent planks will ideally coincide with each other.

Fitting the skirting board for the inner corner Fitting the skirting board for the outer corner

In the presence of small irregularities and roughness, it is allowed to work on them with a sharp knife, clean them with a file or emery paper fixed on a bar.

Precise baguette fit

The layout shows how a properly cut and mounted fillet will look in finished form on the inner and outer corners.

Inner skirting board on the layout Outer skirting board on the layout

Following all the rules and principles of working with special tools when preparing fillets, you can easily independently install any ceiling skirting boards.

The need to trim skirting boards

Installation of ceiling plinths (also called fillets) must be carried out using the correct technology. However, there are no difficulties in it. the vast majority of fillets are mounted with glue. It is enough just to properly coat the product and hold it in the right place for a while.

But with how to properly cut the ceiling plinth in the corners, questions arise. When arranging a ceiling, there is always a need to process corners. but their value can have both a standard value (for example, a right angle) or a certain deviation. The latter case is possible if the room has a complex shape, or if during the repair it was not possible to align it.

The fillets should fit perfectly evenly, regardless of the corners of the room. In addition, skirting boards often have to be cut at the outer corners. To carry out such work correctly, you need to stock up on the right tools and figure out how to cut the corners of the ceiling plinth at home.

Styrofoam

Styrofoam fillets are one of the cheapest options. However, the advantage in the form of low cost is offset by a large number of disadvantages. In particular, the foam itself is a rather brittle and soft material that is very easy to break. Even if you just squeeze such a product in your hand, it can deform.

Due to the low strength, it is very difficult to handle foam skirting boards. If there is little experience in cutting such parts, then most of them in the process of work will become unusable, so all the benefits from the cheapness of the skirting boards will be leveled. A hacksaw or a well-sharpened knife is usually used to cut foam fillets.

Cutting skirting boards for ceilings without miter box

You also need to figure out how to glue a ceiling plinth without a miter box. this tool is far from always available. One of these methods involves marking the skirting boards on the ceiling. Perhaps the only drawback of this method is the fact that it is not very convenient to keep the plank motionless while applying the markings. Otherwise, the method is quite reliable. the measurement accuracy is higher, since when the plinth is applied to the place, all errors become noticeable.

Another method is associated with corner trimming of the plinth. The edges of the two joining workpieces are cut at right angles. One of the planks is applied directly to the corner, after which a fishing line is applied to the ceiling along the contour of the plinth. The same operation is repeated with the opposite skirting board.

The point at which the two separate mowing lines intersect is the mark at which the skirting board will need to be cut. The workpieces are in turn applied to their places again, the cut mowing line is marked on them. A straight line is drawn from the mark to the opposite edge of the part. The skirting boards are cut in accordance with the markings applied to them and are joined in place. This method is an excellent answer to the question of how to connect the corners of the ceiling plinth without a miter box, especially when it comes to internal corners.

Polyurethane

Polyurethane skirting boards are the most expensive products. The high cost is due to a large number of advantages, among which are excellent resistance to moisture, high mechanical strength, reliability and elasticity. For most situations, this option will be optimal.

However, there are exceptions. polyurethane does not withstand temperature extremes. If you place such skirting boards in the kitchen near the stove, then over time, the polyurethane will deform and crack. Cutting of such fillets is carried out with a special knife, and no complications arise during work.

Wood

Wooden ceiling skirting boards differ from analogues. Wood has a fairly large weight, which affects the mass of products made from it. As a result, the skirting boards turn out to be quite dense, very resistant to mechanical damage and hard, which allows you not to be afraid of accidental deformation during installation or cutting.

To trim the fillet out of wood, it is best to use a fine-toothed hacksaw designed specifically for fine work with this material. However, a good option would be a high-quality sheet for metal.

How to properly cut the ceiling plinth in the corners. options and methods for plinths made of different materials

Ceiling skirting boards are special parts designed to visually separate walls from the ceiling, as well as to mask the joint between them. Such skirting boards are used almost everywhere and well complement the interior of the room. Installation of skirting boards is quite simple, but it has a number of nuances. for example, to connect individual parts, you need to cut them off correctly. How to properly cut the ceiling plinth will be discussed in this article.

Pruning with a miter box

To give the plinth the required angle, a special tool is used. a miter box. Structurally, this tool is a tray made of wood, metal or plastic. In certain areas of the miter box, there are vertical slots that allow you to cut various parts at an angle of 45 or 90 degrees.

complex devices can be found on sale, in which, in addition to the angles already described, there is a possibility of a 60-degree cut. There is also a professional miter box equipped with a swivel mechanism. This tool differs from the simplified one in that it has the ability to fix the cutting blade at any angle. You need to know how to properly glue the ceiling plinth in the corners so that everything looks beautiful.

Skirting materials and cutting methods

First of all, let’s try to determine what fillet can be made of, and what specific material is better to cut.

On sale today you can find products made of foamed polymer (PVC), wood, expanded polystyrene and polyurethane.

Perhaps one of the very inexpensive skirtings is made of foamed polymer, which is a fragile, soft and brittle material.

Even fingers can dent them, and they easily get creases and imperfections. It is very difficult to cut an aesthetically pleasing and even corner of a PVC-based skirting board.

From an inexperienced craftsman, a huge amount of purchased material can go to waste for this particular reason. Also, this polymer material has high electrostatic properties, which explains its ability to collect dust.

It is best to cut such a plinth with a hacksaw or a sharp construction knife.

Products made from expanded polystyrene are also inexpensive, although this material is considered a very durable similarity to the classic expanded polymer.

It can also be finished with a sharp tool.

Skirting boards made of expanded polystyrene extrusion are slightly more expensive, they are somewhat denser and more difficult to cut. But they crumble much less and can break.

This makes cutting them more convenient and easier. For this purpose, it is good to use a hacksaw or a sharp knife.

Polyurethane ceiling skirting boards are now considered, probably, one of the much more very expensive.

However, they justify their own cost: moisture resistant, as strong and dense as possible, very flexible.

Placed above the stove in the kitchen, the skirting board can change its shape and even crackle slightly.

They are perfectly cut with a special knife, without forming a crumb. But these products are very susceptible to temperature extremes.

Wooden ceiling plinths are rather weighty and dense products, solid and reliable.

They lend themselves well to finishing with a specialized fine-toothed hacksaw. Also use a good metal cloth. So how to cut the plinth for the ceiling correctly?

How to properly cut the corners of the skirting board. Ceiling plinth. fillet

To do this according to the rules, it is important to strictly follow the existing recommendations and rules for finishing work. And then you will like the result.

There are no problems in fixing the plinth (this is the name of such an element): almost all types of products are fixed with good glue.

In order to hang the skirting board. even inexperienced repairmen do not have difficulties. They are worried about something completely different: how to cut the ceiling plinth correctly? Almost almost any room, no matter how complex its shape, is equipped with corners.

And in these inner corners, some parts of the plinth should be aesthetically pleasing and evenly joined. And in rooms with a particularly difficult shape, you will have to be smart about the outer corners. Let’s try to figure out how to be in any of these circumstances, and how to cut the necessary part using the available tools.

How to cut the corner of a baguette correctly. Using a laser level

In modern conditions, many home craftsmen already have in their instrumental “arsenal”, which are excellent for checking the straightness of the angle, and marking the baguette when forming both internal and external corners.

How this is done is described step by step in the following instruction table.

| To begin with, it is necessary to accurately position the laser level itself by placing the same distance from the corner along the lines of the floor and walls, for example, 500 mm each. The marked points are connected by a diagonal line. After that, they find and mark its middle. The laser level is installed on the floor, turned on, and then placed so that the vertical plane specified by it (its projection in the form of a line) passes through the middle marked on the diagonal and coincides with corner of the room. The beam should pass vertically along the mowing line of the corner. this at the same time shows how evenly the corner of the room is formed. In fact, a plane is set that cuts the corner of the room exactly in the center. It is in this plane that the joint of the skirting boards should be located. | |

| In this case, the level should be located so that the projection of this plane is also displayed on the ceiling. You can fix the resulting line-bisector with pencil marks. But even better. do not remove the device, as it will help to more accurately display the desired cutting line on the plinth attached to the place of future attachment. Probably, it is clear that the next step is to install one baguette at the installation site. The plank must be resting with the end side against the wall. The beam from the laser builder, passing along the surface of the plinth, and even along all of its embossed protrusions, will accurately show the cut line. | |

| After that, along the mowing line of the beam, with the help of a pencil or a thin marker, the cutting line is outlined. | |

| Using a knife, a corner is cut along the intended mowing line. it is impossible to make a mistake in this case. Then the mowing line of the cut is marked in the same way and the second plinth is cut. | |

| Now that both parts for forming the corner are ready, they need to be connected together at the place of future fixing. If the joint is neat, then you can mount the baguette on glue. If a small gap has formed between the strips, then the ends of the skirting board must be corrected with a knife. | |

| When installing the ceiling plinth, the strips that form the corner are first glued, and the flat trims are fixed last. | |

| If, when carrying out the approximate alignment of the corner side of the baguette, its other end will find on the already fixed segment of the skirting board, you should immediately mark the required length in order to cut off its excess. In this case, the even edge is trimmed just at right angles. | |

| To correctly cut the baguette for the outer corner, it is also necessary to start marking from the floor using a laser level. There is a slight difference in the initial construction. At the beginning, the mowing lines are simply drawn along the ruler, which are a continuation of the walls. Then an equal distance is laid on them from the corner, these points are connected by a diagonal on which the center is determined. The beam is directed through this mark to the protruding corner, also with the projection of this plane on the surface of the ceiling. | |

| Further, segments of the baguette are alternately applied to the wall and the protruding corner so that the beam passes through them. Marking is made along the mowing line of the projection, and then the end part of the skirting board is cut. After that, it is necessary to try on both segments at the installation site, aligning the cuts. If necessary, the ends of the strips are adjusted. If everything is normal, proceed to fixing the fillets on the surface. |

Cutting Crown Moulding-Made EASY!

How to cut the corners of a skirting board with a miter box. How to properly cut the corners of ceiling plinths: both with and without a miter box

When planning the premises of their apartment, many people think about how difficult the work can be. However, everything is not so scary: the ceiling plinth can be installed with your own hands. the main thing is to know about some of the features of the materials from which this finishing element is made.

Different materials and their features

- . The most durable material in comparison with the other two below, the advantages of which are in hardness, impact resistance and the ability to withstand certain mechanical loads. Nevertheless, wooden skirting boards (another name. fillets), glued to the ceiling, are also relatively easy to process. they can be cut (a hacksaw is used for this), varnished. Wood will add warmth to the interior. Of the minuses, the cost can be called higher than that of polystyrene. However, wooden fillets also retain their appearance longer than foam fillets.

Styrofoam. Perhaps this material is the most fragile. it is unstable to mechanical damage, scratches and even minor impacts. Of the advantages. light weight, the ability to paint in various colors and ease of processing (it can be cut with a clerical knife. however, very carefully).

Expanded polystyrene. This material can be considered a type of foam, however, its strength characteristics are slightly higher (extruded polystyrene foam is denser than foam). As for the processing. expanded polystyrene is just as easy to cut with an ordinary sharp knife, and also has a low weight, and this is an important factor when taking into account the load on the walls.

How to cut?

There are two main questions facing the installation of a ceiling plinth. How to properly cut a skirting board without gaps and with perfect fit in the corners, and what tools should you use to get a beautifully positioned ceiling element in the end? In order to understand these issues, it is necessary to study all the methods and tools used in trimming the skirting board. Almost all methods and tools can be used to adjust the skirting board in both internal and external corners.

Required tools

Installing a skirting board means trimming the excess length and adjusting it in the corners. In order to do a pruning, you need tools. The choice of this or that type of tool depends on the material from which the plinth is made.

When working with wood and plastic, use an electric miter saw. Cutting with this tool is accurate, fast and effortless, you just need to set the required parameters and correctly lay the skirting board. It will not be difficult to choose the appropriate tool, since manufacturers produce this tool in a wide price range.

But, with wood and plastic, you can cope with another well-known carpentry tool. a miter box paired with a hacksaw. This tool is in the shape of a tray, made either from wood, or from plastic, or from metal. In the two parallel sidewalls of the miter box, there are saw slots for easy cutting of the plinth at the desired angle. In a simple tool modification, the ceiling element can be cut at an angle of 45 or 90 degrees, and in a more complex version, the plinth can be cut at an angle of 60 degrees.

A miter box and a hacksaw are cheaper than a miter saw, but they also have their drawback. this is the risk of damage to the material, especially if the quality of the purchased material is poor. In addition, the miter box is more suitable for rooms with smooth walls and corners.

For a smoother cut without the risk of damage to the material and without delamination of the structure, a jigsaw is suitable. It is easy to operate this tool, with its help you can set any direction and make the most accurate cuts. For materials lighter in weight and with a less strong structure, you can use an ordinary construction knife, the main thing is to pick up a specimen with a sharp blade.

Features of the

Previously, the ceiling plinth had a different name. fillet. Translated from German means “notch” or “groove”. The material for the manufacture of this decorative element was gypsum, which was poured into a prepared mold. The cured gypsum element was fixed to the ceiling surface with mortar. Today, gypsum ceiling plinth is very rare, its cost is high, and it is much more difficult to install it in comparison with modern counterparts.

Ceiling elements are now available in several types of materials in numerous configurations. They are cheaper than gypsum ones, but they look no worse. The cheapest copies are made from polyvinyl chloride (PVC). This material is subject to deformation with insignificant mechanical stress, the formation of irreparable dents or creases leads to a complete replacement of the element. In addition, all PVC skirting boards are electrostatic, dust accumulates very quickly.

Ceiling skirting boards made of polyurethane and polystyrene are among the most demanded products. They gained their popularity due to their reasonable price, a wide range of profile patterns, a variety of sizes (their width varies within 5–250 mm), as well as resistance to moisture. Polyurethane ceiling elements can be found in the design of many rooms, they look great in any interior. But, there are also disadvantages, the material does not tolerate temperature changes, is prone to cracking, especially if installed above a stove.

The classic version of the ceiling plinth is a wood product. Wooden elements, unlike the listed types, are not installed on glue; self-tapping screws are used to fix them. Plinths made of this material are used to decorate wooden houses or rooms, whose style is dictated by the use of wooden elements.

Outside corner

For the outer corner, the skirting board is trimmed at an angle of 45 degrees. First you need to check the evenness of the outer corner. If the wall surfaces are in contact with each other at exactly 90 degrees, you can use a miter box to trim the skirting board. In order to properly cut the outer corner planks, it is necessary to correctly position both parts of the skirting board.

First you need to outline the length of both halves, and only then trim them at an angle of 45 degrees. In order not to change the position of the saw and not to get confused with the location of the halves of the plinth, it is necessary to correctly position them in the miter box. The left half is laid face up, with the part adjacent to the ceiling closer to the center, and the second side adjacent to the wall should be pressed against the slotted sidewall. With the right half, everything is different: it must be laid face down in the miter box, and the location of the adjacent parts to the ceiling and wall here will be the same.

The bar placed in the miter box for a smooth cut must be pressed against the sidewall, placing it as close as possible to the slot. Holding the workpiece with your left hand, you need to carefully make a cut and set it aside. The second half of the skirting board should be cut in the same way, remembering to turn it face down.

In the absence of a miter box, you can make a draft of it on paper or cardboard. First, draw a rectangle, inside which, on the longer sides, draw two more parallel mowing lines. On each side, inside the lines, using a protractor, set the desired angle in different directions. Preparation and subsequent cutting of workpieces is exactly the same as using the tool itself.

How easy it is to cut off the CORRECT EXTERNAL ANGLE at the plinth or baguette without the can

This method is good in that you can postpone the angle not strictly 45 or 90 degrees, but a little more or less, because the surfaces of the walls in the corners are not always directed towards each other at an angle of 90 degrees, there are errors. Therefore, for a more accurate cut on the miter box depicted on paper, you can draw any angle using a protractor. The degree of the angle is first checked using a protractor, the resulting value is divided by 2. The resulting number will be the exact degree for the correct undercut.

If desired, you can build a miter box with your own hands. The easiest way is to make a tool out of wood, you just need to take three planks and put them together in the shape of the letter P. Then make marks on the side parts at different degrees, using a hacksaw to make slots. You can also make a miter box from two planks, having previously made slots in them, or use a drawing with the desired angles on paper to accurately determine the slope.

Even a table can be used as an improvised tool. The main thing is that he has angles along which he could navigate.

In order to properly cut the outer corners, you can do without any auxiliary tools and drawings on paper at all, you just need to design the future corner in place.

The skirting board of the outer corner always protrudes into the room by an amount equal to its width, therefore, to determine the exact cut, it is necessary to make marks on the right and left halves of the skirting board. You need to set aside the width from the side adjacent to the wall. Then, from the obtained point, lead the line to the upper corner of the half. The resulting triangle needs to be cut, and the halves must be joined in place for a preview.

Ceiling skirting boards: how to cut corners?

Any renovation work is always completed with finishing. In rare cases, the interior of the room does without a ceiling plinth, its presence helps to hide the joints of the finishing materials used for wall and ceiling surfaces, in addition, do not forget about the decorative function that this element carries. It is not difficult to arrange the perimeter of the room by simply fixing it in a straight line. It is much more difficult to cut it correctly in the corners without spoiling the material and spending a minimum of time and money.

Interior

The same methods and tools can be used to join the halves of the skirting board in the inner corner. The location of the halves in the miter box when cutting for the inner corner is identical to the location of the parts used for joining the outer corner. But, you do not need to turn the right half of the plinth for a cut, but only change the slope of the cut (use a different cut). In any case, on the left side of the plinth, the line will be angled to the left of the corner point located on the side adjacent to the wall, and on the right side of the plinth, the line will be angled to the right of the similarly located point.

For perfectly flat corner surfaces, you can use a regular square instead of a miter box. To do this, you need to press half of the plinth to the inner corner of the ruler and cut off the unnecessary part at an angle of 45 degrees. It is not difficult to do this, since the side of the ruler and part of the plinth form a total of 90 degrees, the notch line divides this angle in half, which means that part of the plinth will be cut at an angle of 45 degrees.

For wooden and plastic skirting boards, making an incision in place will not work, you can only apply a markup to the surface of the skirting board, and then cut the cut along the mark using a hacksaw or saw.

In order to properly cut and then join the halves of the baseboard for the inner corner, you need to measure in place with a simple pencil. The right workpiece must be applied to the corner from the corresponding side until it stops. On the ceiling surface, draw a line along the half and remove the workpiece to the side. We do the same with the other half.

At the intersection of the two lines, a point has formed, with which you need to make marks on each half of the skirting board. To put a point, you need to attach a half to the docking place. From the resulting point, you need to draw the line to the bottom corner of the half, as a result, you get a small triangle, which you need to cut off.

The halves cut in this way must be adjusted to each other, with inaccurately cut edges, the cuts can be leveled with a knife if the material of manufacture is foam.

To eliminate minor blemishes on the cut of wooden or polyurethane skirting boards, you will have to use a file. Only after complete coincidence of the cuts can you start fixing the halves.

Sometimes you don’t get the perfect fit, but there is always a way out. To eliminate cracks, you can use a putty. The choice of filler depends on the material of the skirting board. In order to eliminate inaccuracies in trimming the skirting boards, you need to practice using small pieces of the skirting board or cut the planks slightly longer than the intended size. Such a margin will make it possible to make a new undercut in case it was made with the wrong slope or the material at the cut point was deformed.

Advice

For a good fit of the ceiling plinth, it is not enough to properly cut and join the halves, you also need to glue them correctly. In order not to later cover up the cracks in the corners or alter the work altogether, you need to adhere to certain recommendations.

- Before the final installation of the skirting board, it is necessary to properly prepare the surfaces that will come into contact with it. Priming or simply treating parts of the ceiling and wall surfaces will help improve the adhesion between the skirting board and the surfaces.

- The corners of the room in which the skirting boards are installed should be decorated first. The remaining sections of the perimeter are mounted only after the complete installation of the corner elements.

If there are not only internal, but also external corners in the room, the priority is in the design at the internal corners, since there is a risk of making a mistake with the length of the plinth.

- In order to fix the ceiling element without gaps, it is necessary to press the plinth rather tightly to both surfaces. It is worth remembering that excessive pressure on some materials can lead to deformation of the element.

- To avoid the ingress of glue residues on the front surface of the element, you should immediately remove the excess adhesive before it has time to dry.

- Sealing joints and cracks with a sealant should be carried out only after the glue has completely dried. Compositions with acrylic are most suitable as a sealant.

For information on how to cut the ceiling plinth, see the next video.