Blade selection principles

- Type of hand hacksaw for metal, or more precisely, the distance between the fixing holes. It is better if it is changeable, then any size of hacksaw blade is suitable for work.

- Strength of metal being cut. If you intend to use the tool for cutting soft, ductile metals like copper, aluminum, etc., then a variable blade will do., it is advisable to have a hacksaw blade with the lowest hardness. Material can be taken as X6VF steel; imported blades have HCS designation on the side plate. For cutting stronger metals, blades made of high-speed steel are suitable (corresponding imported marking. HSS).

- Thickness of metal to be cut and quality of separation surface. Foreign practice recommends to use PPI parameter as criterion of choice. number of tooth tips that falls on every inch of blade length. So, for thin metals, where you want to get a very smooth cut surface, the correct value is PPI24. If the performance factor is more important to the user than quality, it should be PPI

How to correctly and quickly saw with a metal hacksaw?

To be honest, I do not know any special secrets, but there are some nuances, which should be observed.

Thirty years ago, when nobody ever heard of fortunetools and grinders my father did all his work on metal with an ordinary hacksaw. And with a handheld drill.

First of all, I would advise choosing a hacksaw like the one in the second photo. It’s more convenient to work with. It’s just easier to hold and the handle won’t slip in your hand.

When installing the blade, you should pay attention to the correct positioning of the teeth. As shown in the photo, they should go away from the cut. When cutting, you have to use force with the saw pulling away from you. When bringing the saw back, you have to lift the handle a little and relieve the pressure on the saw itself. That way the teeth stay in working order longer.

You should also pay attention to the tension of the blade when you insert it into the saw. If the saw blade has too little or too much tension, it could break at the slightest vibration of the saw.

And to keep the blade cool, you can put a couple of drops of oil in the area of the cut.

And you should not forget that metal that is cut can be broken. That is, sometimes it is enough to saw off half, for example, a pipe or angle, and simply break the rest, by bending to one side and the other.

I would like to pay your attention to the fact that it is desirable (if possible) to firmly fix the part you want to cut, for example in a vise.

No secrets. You need to remember a few important points and the metal will scatter like butter against the knife.

Choose a saw with a comfortable handle and of good strength. Choose a blade not from the cheap ones, but with a spray on the teeth of a strong composition. Place the blade in the saw so that the teeth of the blade are in the direction away from you.

When chipping, you must actively use force when moving the saw away from yourself and simply move it away from yourself without load. Try to make the cut with the blade positioned over the maximum area of contact of the teeth of the blade with the surface of the object that needs to be sawn or filed. As for splitting the pipe, it is enough to saw the pipe to half or little more, and it can break clearly under your little effort. Much depends on the thickness of the pipe and its age.

As many colleagues have already noted, when working with a hacksaw on metal when cutting (sawing) it is necessary to pay attention to the following points:

- sturdy and with a comfortable handle saw frame;

- quality and appropriate pitch for the particular metal (depending on the toughness and hardness of the metal) hacksaw blades;

- you set the direction of the teeth from yourself;

- arm movements should be smooth and with a wide amplitude.

As for the nuances, I can say that the hacksaw blades.the material is very hard and brittle and is afraid of overheating. So stop working all the time and the saw will last you a long time.

The secret of your acquaintance is probably not in the way you work with the tool, but in the tool itself. Handling with hacksaw on metal is taught at school (many used to make hammers, corners, etc.).д.), that’s why there are no special secrets: set the blade correctly and hold it straight, when you saw. But here in my practice, I met a special metal blade (I do not remember exactly where it came from: either with mech. saws, or from some other machine, but that’s not the point. ), used for lightly cutting pipes in the apartment and other metal objects, which were easier to be cut with a hacksaw than to spin up an angle grinder for the sake of it.

I can offer some recommendations to speed up metal sawing with a hacksaw:

- use a hacksaw with a sturdy frame made of composite materials.

- For work, it is better to buy bimetallic blades with hardened teeth.

- for metals of different hardness select a blade with appropriate number of teeth:

For soft metals the number of teeth should be minimal. 16-18pcs/inch.

for harder metals. maximum (32 teeth per 25mm).

- It is more reasonable to use new blades for cutting softer and tougher metals (aluminum, brass, bronze, copper). ), and b/c. For hard metals (steel, cast iron. )

- If a blade breaks, you need to clean the kerf from any blade fragments and only after that continue working with a new blade.

By the way if only one or two teeth are broken the blade can be saved from the further destruction if we make an arc with rounded edges in this place with an emery.

- high tempo does not always mean fast cutting of metal. There is a definite dependence of the number of reciprocating movements on the hardness of the metal.

the harder the metal, the less intensity you have to work with, otherwise the blade will overheat and quickly shrink.

The position of the hacksaw, arms, body, and legs is clearly demonstrated by this figure.

To learn how to cut metal quickly with a hacksaw, you need to understand the following!

First. a hacksaw only cuts in a forward direction.

Second. in order for the hacksaw to cut the metal, it is necessary to apply a uniform force when the hacksaw moves forward and loosen it completely when it pulls back.

Third. arm movements should be as confident, even, and as flat as possible (no rocking to the sides, side to side or forward to back, no twisting or jerking).

Fourth. is the need to lubricate the hacksaw blade with machine oil on both sides, before starting sawing, and in case of significant cuts and application of lubrication to the blade as it is worn out.

Fifth. it is necessary to water the cut periodically, so that it does not overheat the blade of the hacksaw, which can release the hardening and the blade will simply rub off.

Sixth. Of course the metal you are going to saw is important, because not every metal can be easily sawed with a hacksaw, and there are some that can not be cut at all, then it is advisable to use a diamond cutting tool.

So there are such nuances. I hope it is not necessary to stop on a choice and installation of the blade, and in the previous answers it is already more or less described.

Hacksaw blades

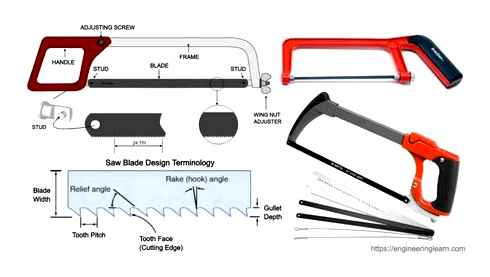

Metal hacksaw is a hand tool that is used for cutting profile metal and pipes. The simplest hacksaw consists of a machine and a hacksaw blade. The machine, in turn, consists of a frame into which on one side is inserted a handle which has a device for fixing the blade, and on the other side, a device for fixation and regulation of the tension of the blade. The tensioning device, on one side, has a groove for inserting and fixing the blade and, on the other side, a screw with a ram which is used for tensioning the blade.

Metal saw blades differ in width, length, thickness, distance between teeth and their height. Use of one or another blade depends on thickness, hardness and shape of material to be cut. The manufacturers of blades have made sure that you can choose a blade exactly for the material you need to cut, be it aluminum, copper, bronze or even plastic. The dimensions of the blade, namely the length, width, tooth size and steel grade can be found on the purchased band saw blade.

How to Install a Blade into a Metal Hacksaw?

As it is shown in the first picture of the article: with the teeth downwards (if the blade is single sided) and the teeth pointing forward from the handle. When you are sawing you apply downward and forward pressure. just like the teeth of a hacksaw should be pointing, down and forward. To install, release the tensioning screw, take the old blade off the pins, put on the new one and tighten it so much that the blade would ring like a string when your finger nail clicks. The main thing here is not to over tighten and tear the sheet. You will find the optimum tension by experimentation.

The tension is adjusted with the turnbuckle on the adjuster, i.e. by turning the turnbuckle you will tighten the sheet. So when tensioning a hacksaw blade, you need to find a happy medium. Also, make sure that the blade is set straight, without twists, because twist will cause an uneven cut during cutting.

How to saw?

Since you were interested in how to set the blade, it doesn’t hurt to get some advice on how to use a metal hacksaw. Hold the handle of the hacksaw with one hand (right hand if you are right-handed, left handed if you are left-handed) and the vertical edge of the arc of the hacksaw opposite to the handle with the other hand. Place the blade on the cut line. Guide the blade strictly in the direction of the cut line. Keep the angle of the hacksaw small. The blade should rest almost on the material, usually at an angle of 30-45 degrees. This way there is less vibration, less noise and the cut line is smoother. Cut laterally across the material. at a 90 degree angle. only in emergencies, e.g. when turning the cut line. The flatter you want the cut line, the smaller the angle.

Make the first few strokes with little effort so that the blade engages the material and does not slide sideways off the cut line. With a smooth, forward motion, apply firm, gradual pressure on the workpiece as you move forward, and release pressure when you return to the starting position. When the blade grips the material you can work with all your strength.

Swinging range. maximum, from blade edge to edge without hitting the workpiece with the arc of the hacksaw. Do not trample on the blade. that way you will quickly wipe the blade in one area and have to throw it away, because you cannot use a damaged blade. Keep the arc of the hacksaw straight, do not let it bow in different directions. The direction of cutting corresponds to the arc plane of the hacksaw, so chattering is contraindicated. In addition, the blade easily breaks when the hacksaw jerks to the side. The material properties of the blade are such that it holds very well under longitudinal tensile force, but is very brittle in bending.

Cutting with a hacksaw on a curved mowing line

A metal hacksaw is also valuable in that it allows you to make a cut in almost any curve of mowing line. In order to cut in an arc without stopping the forward motion of the hacksaw, align it perpendicular to the face of the workpiece material (t.е. 90-degree angle) and gradually turn the arc of the hacksaw smoothly so that the blade follows the intended mowing line. Yes, always be sure to mark the line of the cut with anything pencil, marker, scratch nail. The main thing is to be able to see it when you work. You have to turn the blade as gently and smoothly as possible, or it will break; turns are an extreme for a metal saw blade.

If you have to make a sharp turn of, say, 90 degrees, you’ll practically have to stomp on the spot. continue sawing and smoothly turn the arc of the hacksaw, periodically stepping back so as not to go far from the place of turning, while using the side of the blade that is external to the piece for turning.

To cut an inside corner, you must first drill a straight line with a thin drill bit a little longer than the width of the blade, slide the blade into that groove, and continue cutting with the hacksaw. In general, practice will show you how to do it. There is nothing complicated here.

The illustration below shows another way to use a metal hacksaw. For this method, you need to reset the blade by turning it 90 degrees.

Hacksaw blades for metal

Metal hacksaw blades are one of the most short-lived elements of the entire range of consumables for tools. Of course much depends on the technology of working with metal and the skill to use a hacksaw, but first you need to be able to make the right choice of blade. Today, we will talk about the choice and types, as well as learn how to easily change a hacksaw blade.

Metal hacksaw as a correct choice of blade

Sawing wooden products, metal corners and rods, plastic, plasterboard, foam blocks all this allows to make a hacksaw. The range of this handy and popular tool is quite wide. The pickiest customer will choose the right model for the work to come.

Handheld hacksaws can be divided into several basic types. The most common of them are hacksaws for wood and metal. There are also models that are designed to work on Styrofoam, drywall, cellular concrete, etc. Each may have one or another form of teeth of the cutting blade and handle. In addition, the very materials from which the tools are made, can be different. Familiarized with all the features of the tool, you can correctly choose a hacksaw, which is best suited for you to perform the upcoming construction tasks.

Wood saws are used for sawing logs, chipboard, boards, beams, cutting skirting boards, laminate boards, trimming dry tree branches in the garden. Such a tool is in the arsenal of any handyman.

For the right choice of a wood hacksaw, you should take into account the following points. Teeth on its blade may be small, medium or large. The unit of measure for teeth is TPI, the number of teeth per inch of blade. Thick wood is best cut with a hacksaw with coarse teeth (TPI of 3). 6). These teeth are spaced about 4 to 8 mm apart in the metric system. Medium-sized details are best cut with a hacksaw with a TPI of 7-9, t. е. with an interdental pitch of 3-3,5 mm. And for fine carpentry work a model with TPI 9 15 with spacing of 2 2,5 mm comes in handy.

In order to choose the right saw, you need to consider the geometry of the cutting tooth. Hacksaws designed for cross-cutting have straight cutters. If the tooth is tilted forward, you can also cut longitudinally with this hacksaw.

The most productive in the work is a hacksaw with two- or even three-sided sharpening of the tooth. Its cutting edge cuts through wood as it moves away from and toward you.Wood hacksaw with cutting teeth hardened by high-frequency currents have the longest service life.

This tool differs in appearance from a wood hacksaw. Its working part is a thin toothed blade. Work with a hacksaw for metal, holding it with two hands. Cut bars, tubes, channels and angles only when moving the blade forward, clamping them for convenience in a vise.

saws are sold with heavy-duty frames made of composite materials for work with hard alloys and metals. If it is necessary to saw a detail in a hard-to-reach place, then there are hacksaws with a shortened frame or which have an adjustable angle of inclination of the blade.

It is not difficult to replace the hacksaw blade, you just need to detach its mounts. Blades can be not only in metal, but also in drywall, wood, or plastic.

Special types of hacksaws.

Saws for polypropylene have non-hardened teeth and a blade of small length. They are used to cut various plastic parts from skirting boards to facing boards.

For foam blocks use a blade with anti-corrosive Teflon coating. Every second tooth of such a hacksaw has a tipped surface that gives it additional hardness and wear resistance.

Saws for drywall are similar to large kitchen knives. Their teeth are very sharp, hardened and ground on three sides. They can be used to cut material along a curve and make holes in it.

Saws Manufacturers and Prices

Leading brands among manufacturers of hand hacksaws Banco, Quick, Irvin, G-Man, Stanley, Kraftool, Delta, Izhstal and some others.

To choose the right hacksaw, examine its blade. It should not have any traces of corrosion and small cracks. Bend it into an arc. A quality saw will quickly regain its original appearance. Pay attention to the handle, is it comfortable to hold the hacksaw in your hand. If it doesn’t fit, it will rub on your blisters. The best handles are those with rubber inserts.

Prikhodko Valentin Ivanovich. Copyright © 2010. 2016 E-mail: adm-site-val@rambler.ru. Ukraine. Reprint of materials with obligatory reference to the site. WELCOME.All the materials on this site are provided solely for informational and educational purposes, the administration of this site makes no claim to authorship and bears no responsibility for their

The choice of the tool or what to pay attention to

To choose the best metal hand saw, pay attention to the following parameters:

- Length of tools and blades. Blades have different lengths, but if you choose a device, you should take one that is convenient to work with. If the tool is selected for a specific purpose, then remember that the length of the hacksaw should be 2 times longer than the part to be sawed

- Handle. To choose the best tool, you need to take several models and hold them in your hand. The difference is felt immediately, as some handles are uncomfortable. The tool with hollow handles is better not to take, because they are not reliable. The handle must be comfortable and lie well in your hand

- Blade. The main characteristics of the blades are: the shape of the tooth and the pitch. Depending on what part is to be sawn, appropriate blades with tooth sizes are selected. Since few people pay attention to this in the home, it is better to get several different products

- Cost. The price depends on the quality and functionality

- Manufacturer. If you like to choose tools strictly, then pay attention to models of famous manufacturers. A popular brand specializing in the manufacture of hand tools is the firm IRWIN

Such a reliable tool as a handheld metal saw is a household necessity, so it is worthwhile to choose it responsibly and competently. After using the blade do not throw it away, because it can be used for making auxiliary tools: knives, cutters, circular saws and even chisels (provided that the teeth are not worn out and blunted). It all depends on the imagination of the craftsman, so it’s never too late to start putting your ideas into practice, and don’t forget to share your inventions with others. The video tells about the proper use of hand hacksaws for metal, which will also be useful and interesting to know.

Description

The hacksaw blade itself is a rather thin band made of steel. That is why it is considered the most vulnerable part of the saw. Just one wrong movement can cause the tool to break. Additionally there are small teeth on the edge of the blade with which the work is done. It is very important that they are not only wedge-shaped, but also properly hardened. This will increase the life of the blade in the future.

If we consider the standard dimensions of blades, then, according to GOST, they must be 24 to 30 centimeters in length. As for such a parameter as tooth pitch, this parameter should range from 8 to 12 millimeters. The thickness of the blade ranges from 0.64 to 0.80 millimeters.

Classification of products

Hacksaw blades are narrow strips with two holes at the ends for attaching to the tool. There are three main criteria for classifying them:

- purpose (for hand/electric hacksaws);

- material of manufacture;

- tooth parameters.

Division into groups according to the first feature occurs as with hacksaws. there are blades for manual (mechanical) and electric (sometimes called machine) tools. The dimensions of the working elements vary. So, for manual saw blades with length of 250-300 mm, width of 12-25 mm, thickness of 0,63-1,25 mm are used. Example. a domestic-made blade made of steel X6VF with the parameters of 1,25x12x300, which will cost the buyer in 30 rubles apiece.

Parameters of blades for power tools vary from 150 mm length, to 55 mm width, from 1,25 to 2,5 mm thickness. Example. a blade for saber saw HAMMER RS BL 001, the parameters of which are 150x19x1,25 mm, and per piece.

Another difference between saws for manual and saber saws is the number of holes for fasteners. The first has two, the second. one.

- Carbon (less strong, suitable for non-ferrous or soft metal; marked as HCS); e.g. Bosch HCS TF 350 M 408 mm GFZ for 1400;

- HSS (have the most resistant to wear teeth, but are brittle and high in price; marking HSS); Gross HSS 18TPI 300 mm. 160 for pair;

- Bimetal blades (innovation on the market, replacing the analogues; the base is carbon steel, over which a strip of high-speed steel is welded that serves as a base for the teeth; marked as BIM); Gross Variozahn 300 mm BIM from 300 per pair.

There are also alloy steel blades (designation HM), but more often they are used for cutting bricks, concrete or stone.

Tooth size for metal hacksaws is 2-2,5 mm. This parameter is considered “fine” because there are products with a larger tooth (for example, saws for wood have 4-6 mm).

International standardization has a different principle of division of blades. For example, the number of teeth per 1 inch of blade is taken into account. This number appears in the marking before the letters PPI (points per inch) or TPI (formula “PPI. 1”). The larger the number, the finer the tooth is represented on a given blade.

When choosing products for a hacksaw the user will not have to guess for a long time. most of the well-known saws have a tooth pitch of 18 or 24. This is a designation of brand products for construction (e.g. Standart 24 TPI 300 mm, Kraft-Flex 18 TPI blades from the manufacturer Kraftool).

The basic classification of metal saw blades is made on the basis of the following criteria. It is important to know the presence of the teeth are welcomed, if the user expects comfortable work without pauses and breakage of the tool. Now about how to properly install a hacksaw blade in a manual or electric tool.

Characteristics and selection of hacksaw blades for metal

The hacksaw is used to create through cuts in dense materials made of metal, cutting slots, trimming contoured products. A locksmith tool is made of a hacksaw blade and a base machine. One end of the frame is equipped with a static clamping head, a handle to hold the tool, a shank. The counterpart consists of a movable head and a screw that tightens the cutting plate. The heads of metal hacksaws are fitted with slots into which the working blade is inserted and secured with pins.

Frames come in two forms: sliding, which enables mounting of the blade in any length, and solid.

Selection tips

The tool in question, like any other, you need to know how to select. You should take into account not only the reviews and recommendations of sellers, but also your own feelings when you pick up a tool.

It is better to avoid buying budget versions and overpriced solutions when there is no way to understand why the price is so high.

The tool should be practical, so that while making a move in any direction and at different angles it is possible to carry out the necessary work easily. For example, so that it is possible to saw metal not only with normal movements, but backwards as well.

When buying, you should first look at the frame. It can be different, for example, usual or made of some solid composite materials. These solutions have a longer service life and can cut even very hard metals and alloys. It will not be superfluous to pay special attention to the handle of the category of tools under consideration. The fact is that it will constantly need to be held during the work.

When it comes to the handle, it should be as comfortable as possible and fit well in your hand. It should also have special supports for the hands.

Also, the tool should not seem flimsy, and no parts should wobble, but should sit firmly. This will significantly affect the integrity of the hacksaw and its ability to hold a blade in a certain position.

You can even use a 150 mm metal saw as an example to see what you should be interested in. Let’s start with the shape of the teeth. Everything will depend on the slope of the edge, which performs cutting. It usually varies from 0 to 10 degrees.

The next point is the tooth pitch. This point will affect the thickness and hardness of the material with which a particular hacksaw can work. When analyzing this indicator it is necessary to evaluate the category of the material and the size of the product with which it will have to work. Please note that the workpiece must be treated with not more than three teeth at a time. But that’s assuming that cutting is done at an acute angle.

How to use a hacksaw

The next important indicator is the length of the blade. Here the attention should be paid to the size of the workpiece and its volume. On average a hacksaw blade can have a length of 30 to 70 centimeters. It is important to have flat teeth and the same surface.

When bending, the blade must immediately return to its original shape. There must not be any mechanical damage such as cracks or corrosion.

A small set of hacksaws is not a bad option, each with its own purpose, to cut some particular type of metal.